- Joined

- Aug 29, 2019

- Messages

- 37

- Points

- 78

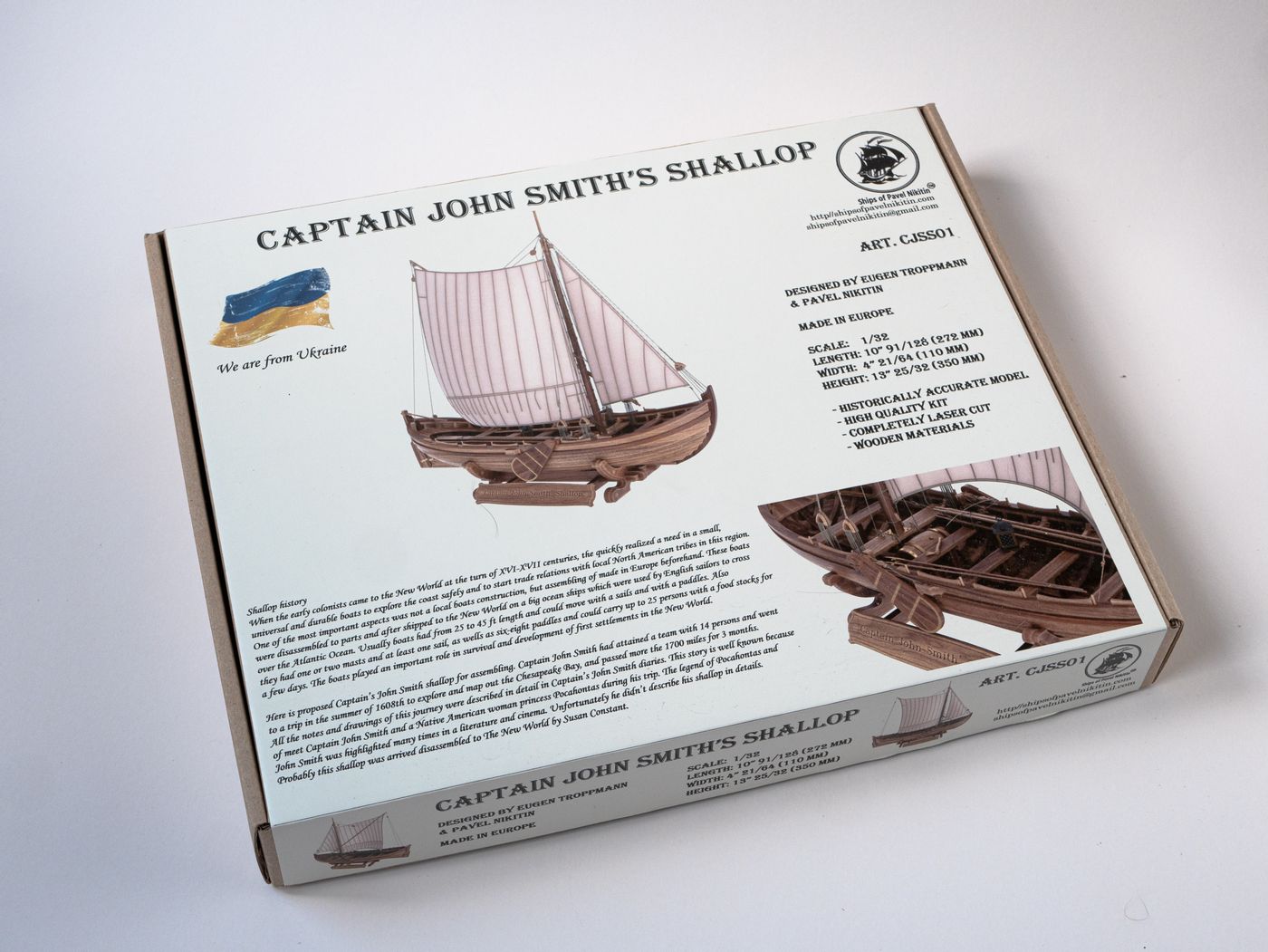

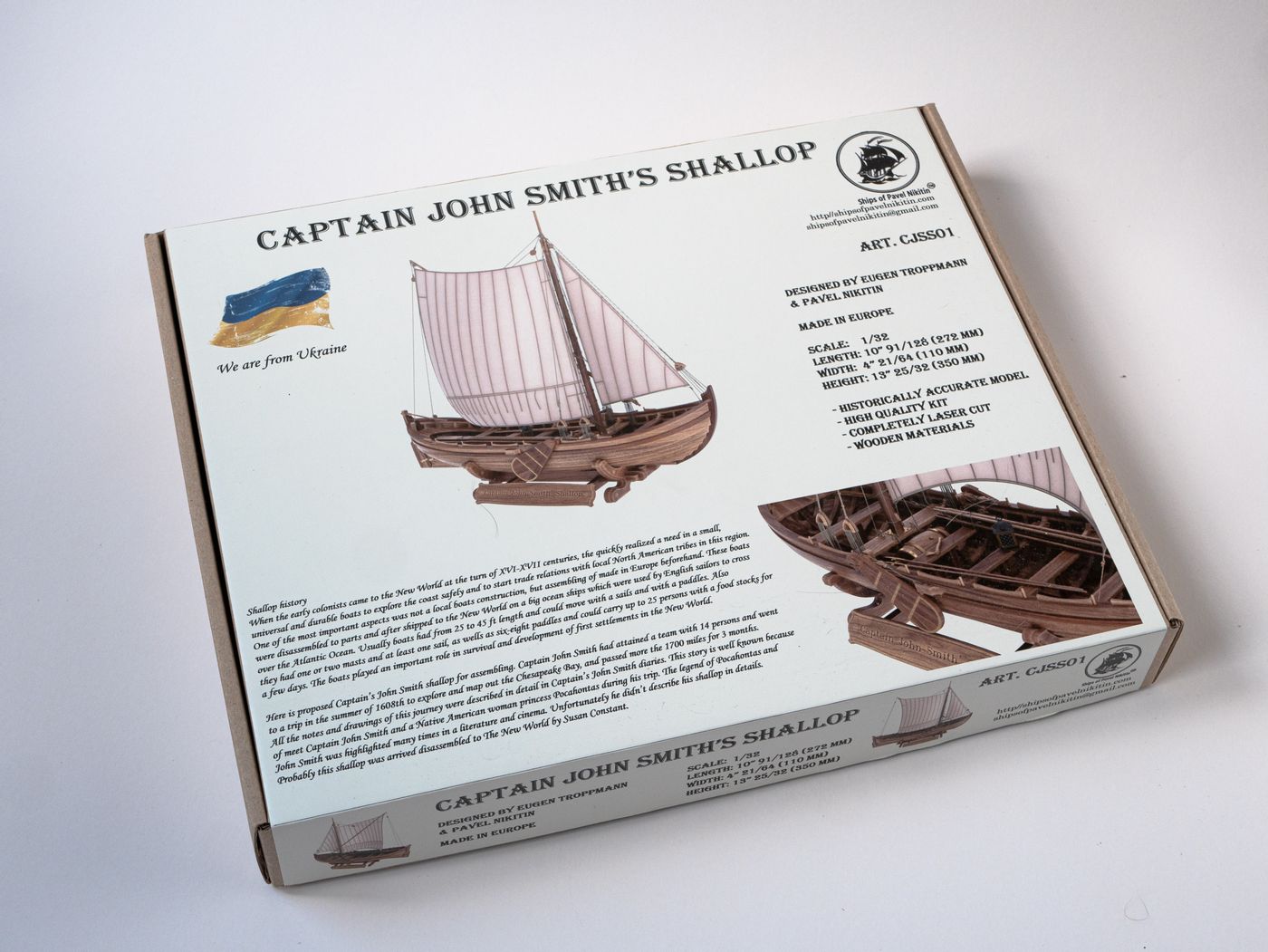

I started this kit in Nov. 2022, and have been keeping a log with comments and pictures. It is a Word document, attached below. I can convert it to pdf if anyone wishes. This is my first log here in SOS so learning as I go. I can attach updated logs as I make progress, or post pictures, questions, and comments one at a time here in this thread.