lol, I use that saying all the time  .

.

.

. .

.Yup. Lots of hidden (and not so hidden) costs wrapped up in this hobby. A happy spouse: PRICELESS!@dockattner ,

Thanks for the compliments.

There are a few other build logs that I've read also filled with entertaining posting.

I try not to make mine to dry, as these build logs get quite long.

Want so more laughs ... currently I'm waiting on the wife to sew the sails for the Enterprise.

She said her sewing machine doesn't work right, it's probably 25 years old, and she could not get the sails done

I suggested it's time for a new sewing machine, and she happily agreed.

To shorten this story, she did get a new sewing machine a few weeks ago. Cost $expensive.00

I still have no sails.

The Admiral says our new sewing machine is a lot cheaper than my ships are.@dockattner ,

Thanks for the compliments.

There are a few other build logs that I've read also filled with entertaining posting.

I try not to make mine to dry, as these build logs get quite long.

Want so more laughs ... currently I'm waiting on the wife to sew the sails for the Enterprise.

She said her sewing machine doesn't work right, it's probably 25 years old, and she could not get the sails done

I suggested it's time for a new sewing machine, and she happily agreed.

To shorten this story, she did get a new sewing machine a few weeks ago. Cost $expensive.00

I still have no sails.

The Admiral says our new sewing machine is a lot cheaper than my ships are.

, how true that statement is.

, how true that statement is.Good plan!Redoing it, no way. Leaving the main fore sail like that.

My intention is (and has been) to bunch that sail up so one can see more of the rigging and ship work.

I might bunch up the topfore sail as well.

Hopefully it will still look good.

Only us sailor types' will even notice.

Redoing it, no way. Leaving the main fore sail like that.

My intention is (and has been) to bunch that sail up so one can see more of the rigging and ship work.

I might bunch up the topfore sail as well.

Hopefully it will still look good.

Only us sailor types' will even notice.

I have no idea what you just said, but it was funny and I loved it. My only experience with rigging with blocks is with the yard lifts on my Connie. I’m getting close to a baptism of fire on my Black Pearl. I hope it turns out as beautiful as your mistakes.Bending the sails to the yards and running the rigging lines continues at a slow pace .

Now that I think about it, everything I do is at a slow pace .

For one, I'm finding that I put the wrong blocks on the yards, when initially built.

The blocks need and eyebolt attached at the bottom, this is where the haylard is tied to when rigging.

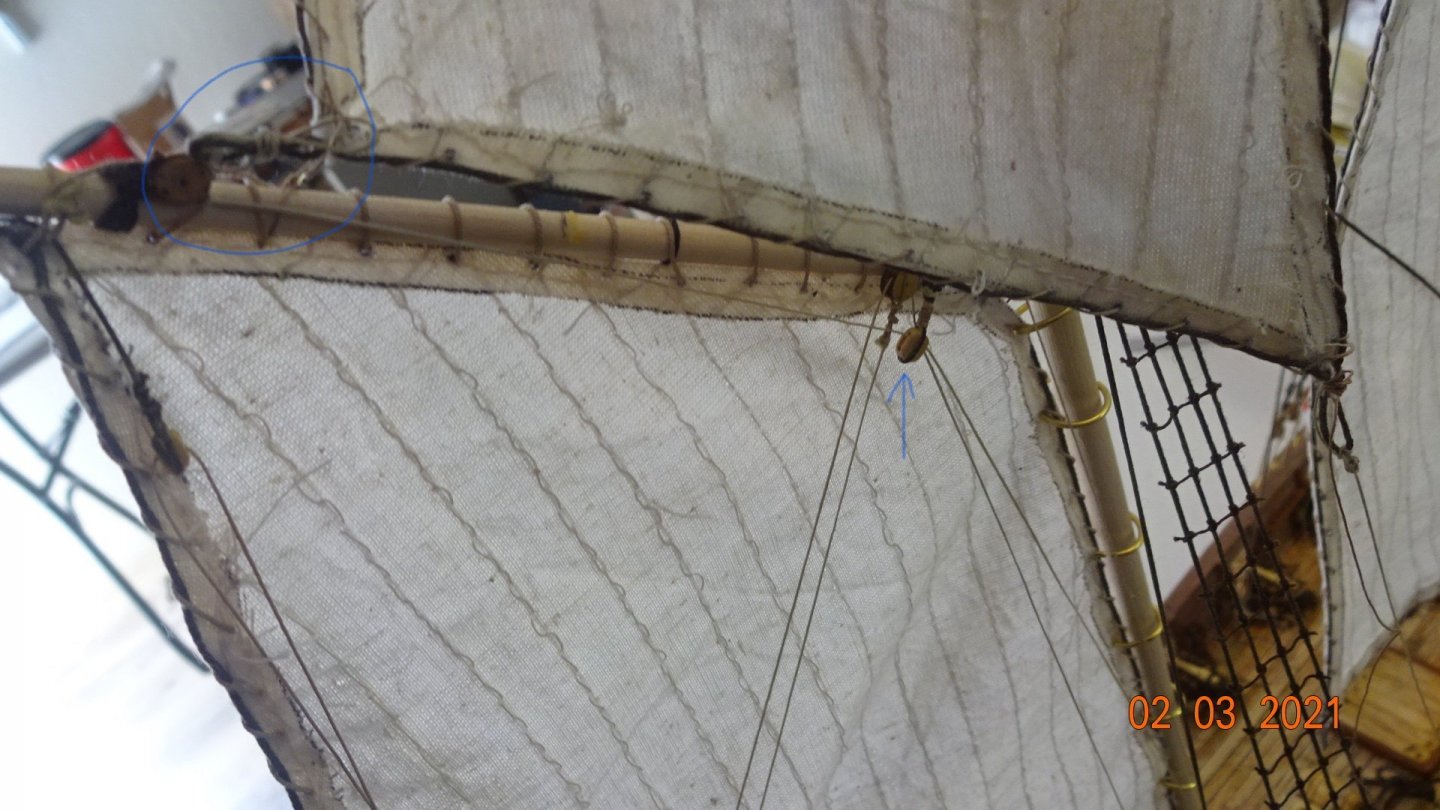

Here's a blurry picture showing (barely) the eyebolt.

You may ask " why a blurry picture", because it's better than no picture.

In the manual it was difficult, sometimes impossible, to tell when a block needed the eyebolt.

Only upon fitting the yard did I find out.

So, fixed the one for the main top gaff.

Then I attached the sail.

No applause please, "we ain't done".

Clearly the right side did not align with the main mast, who's fault is that!

I post another picture of my mistake,,,,,

Sooooo, take everything off and redo the bending of the sail, because doing it right the first time isn't fun .

I'm not looking forward to the sails. That's a very intricate process, isn't it?Back again after fixing my issue with the bending of the sail to the main mast.

Not to much to say, so just post pics of the work.

Only the sails attached to the main mast are complete and tied off.

Not sure if I tied off the main mast top sail correctly or not.

I have one rigging line that runs up from a main mast belaying pin , passes through two blocks and ties off on corner of the top sail.

That was my best guess of where that rigging tied off.

The other side of the sail has the running line tied to a loop on the corner of the sail and is tied directly to a belaying pin on the starboard side of the ship.

This is how I understood the directions.

But I'm not sure if I did this right as the sail angle seems odd.

If anyone can validate this I would appreciate it.

Next I added the gaff boom to the foremast.

This time corrected all the mistakes of my first attempt on the main mast so things went smoother.

The rings I had previously put on the mast made attaching the sail easier since I had pre-punched the holes.

Here is the current state of the ship.

That's about it for now.

Still have 5 sails to wrap, maybe that's a good thing "only 5 sails to wrap" .

.

They get easier as you go.I'm not looking forward to the sails. That's a very intricate process, isn't it?