- Joined

- Dec 30, 2021

- Messages

- 278

- Points

- 278

Well how lucky was I. I was offered a partially built model of the EURYALUS in 1:48 scale and the HobbyMill Cherry framing stock package that came with it as the owner is no longer in a position to complete the model.

I didn't fully appreciate the size of the model but when I put in in the modelling room. Well you can see what I mean.

The work completed to date is a full set of frames mounted on the keel, keelson and stems and sterns knees installed and a start made on the internal planking (ceiling). The lowest deck clamps have also been installed.

I could not wait to make a start so while still planking BOUNTY and awaiting planking stock for GREYHOUND, I made the bow pieces and assembled it for a trial fit to the stem.

Well things didn't quite go to plan and although my bow piece is correct to the drawing it did not fit the stem. As can be seen in Image 2 there is a sizeable gap but on measuring the frame to stem (and rabbit)I realised the shape of the stem is not quite right so I will shim it then shape to fit the bow pieces.

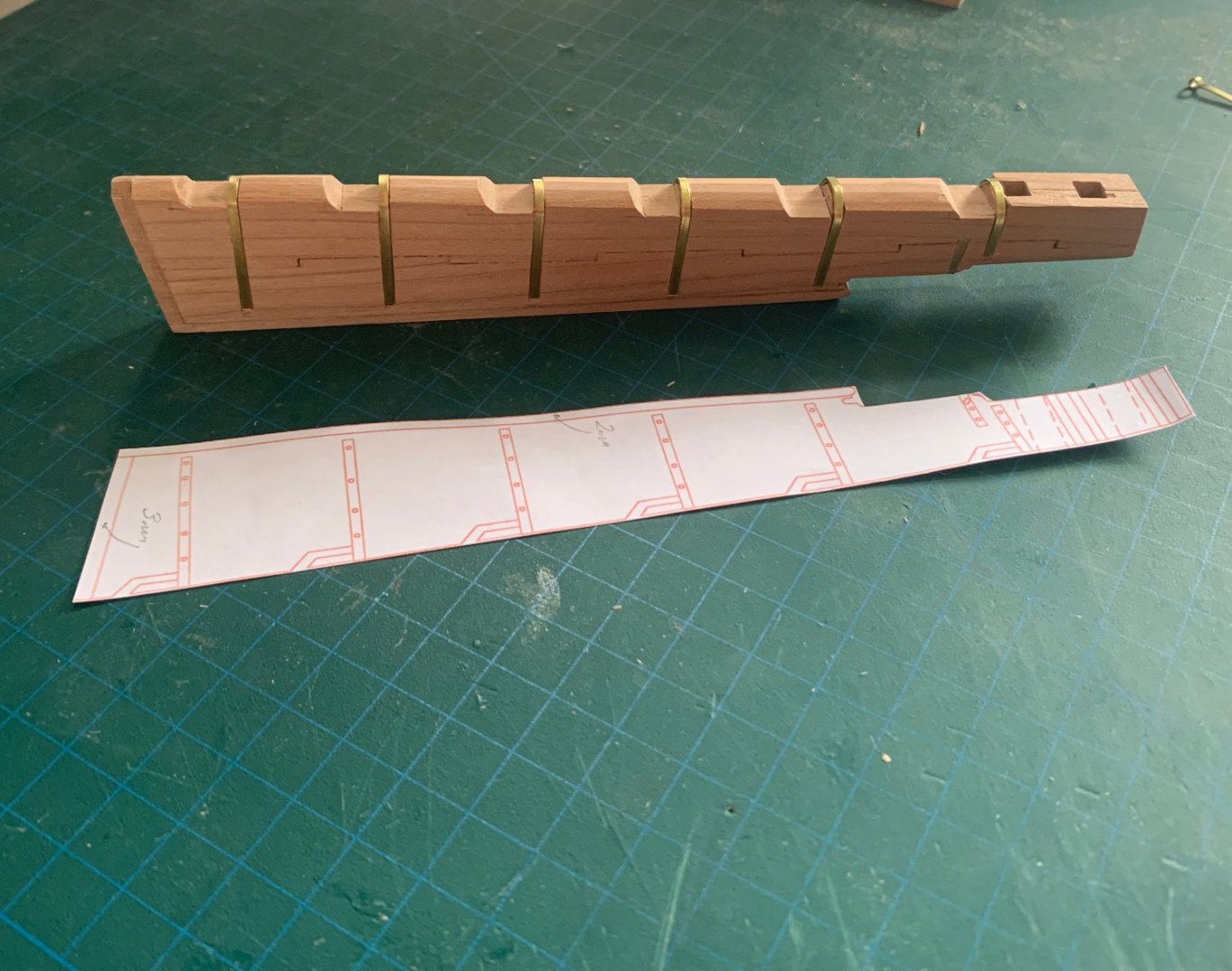

At this time I then noticed that not all the frames sit vertically in the hull. I also noticed that the gunport seemed to be different shapes and not running nicely along the sheer line. While I was going to adjust the gun ports first I realised that I would first need to remedy the verticality of the frames so that is what I am in the process of doing now. To assist, I have milled up some 4x4mm Tasmanian Oak to use as internal and external battens running the full length of the ship. These replaced the short lengths that were there when she arrived.

I have just about finished realigning the middle half of the Starboard side so I will work forward and back to the bow and stern respectively. All the frames are checked off against the framing plan that sits under the ship on the building board.

I didn't fully appreciate the size of the model but when I put in in the modelling room. Well you can see what I mean.

The work completed to date is a full set of frames mounted on the keel, keelson and stems and sterns knees installed and a start made on the internal planking (ceiling). The lowest deck clamps have also been installed.

I could not wait to make a start so while still planking BOUNTY and awaiting planking stock for GREYHOUND, I made the bow pieces and assembled it for a trial fit to the stem.

Well things didn't quite go to plan and although my bow piece is correct to the drawing it did not fit the stem. As can be seen in Image 2 there is a sizeable gap but on measuring the frame to stem (and rabbit)I realised the shape of the stem is not quite right so I will shim it then shape to fit the bow pieces.

At this time I then noticed that not all the frames sit vertically in the hull. I also noticed that the gunport seemed to be different shapes and not running nicely along the sheer line. While I was going to adjust the gun ports first I realised that I would first need to remedy the verticality of the frames so that is what I am in the process of doing now. To assist, I have milled up some 4x4mm Tasmanian Oak to use as internal and external battens running the full length of the ship. These replaced the short lengths that were there when she arrived.

I have just about finished realigning the middle half of the Starboard side so I will work forward and back to the bow and stern respectively. All the frames are checked off against the framing plan that sits under the ship on the building board.