Hi Guys, I was looking at cnc Conversions for the Proxxon MF 70, on youtube, software required was mach3 on windows pc , and software to generate G code.What would you suggest for a 3D software to generate the G code. Something basic since making ship parts is rather basic.

-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

-

PRE-ORDER SHIPS IN SCALE TODAY!

The beloved Ships in Scale Magazine is back and charting a new course for 2026!

Discover new skills, new techniques, and new inspirations in every issue.

NOTE THAT OUR FIRST ISSUE WILL BE JAN/FEB 2026

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This is far from a comprehensive list I don't even mention Rhino, bobcadd and a bunch of the other high end packages.

The easier the software is the more it costs generally speaking. Mach 3 is $175 now and it just does the machine control part of the system. You kind of need 3 pieces of software to make a part with cnc. I say kind of because there are packages that contain one two or all three parts.

You need a drawing program. Depending on what you're trying to make that could be 2D like Autocad, Actcad, Dolphin or Turbocad, or a bunch of others. Basically something that will create the original drawing and make a file such as a dxf the cam software can understand. A lot of the cam packages have at least some cadd capability but they are often pretty limited. Particularly if they aren't multi thousand dollar software packages.

If you're going to try and do something like carving decorations then you need a 3D drawing program. That would be something like Solidworks or Fusion 360. There are also others like I believe Vectric Aspire but I don't know much about them. Solidworks starts at about $3500 and goes up fast depending on the version you buy. You can get Fusion 360 from autodesk for 1 year free as a hobbiest then the subscription is $495 a year I think, though it usually goes on sale at least once a year for about $300. 3D cad has a pretty steep learning curve.

Next you need the CAM software. It takes the drawing and converts it to G Code. There are a lot of programs that do this, many are parts of other programs. For instance Dolphin does the cadd and the cam portions, it's also pretty simple to use for a 3 axis system. Fusion 360 has a really high level cam system built into it. There are free CAM programs that will do it as well, but most are what is called 2.5D which is what is typically done on a 3 axis mill. Of course as is typical with free software it can be buggy and is typically pretty limited. Freemill and Tinkercadd are a couple free ones.

Then you need the machine control software, that is what Mach3 is. Mach 3 is actually outdated and they sell mach 4. They have kept Mach3 on the market for hobby users. In the DIY market GARBL (there's a perpetual debate as to if that's pronounced gerble or garble) and UCCNC are pretty popular. I'm putting together a small cnc router and decided to go with UCCNC. GARBL has been having issues with off brand controller cards that don't work like expected, it's Arduino based and apparently all Arduinos aren't created equally. The negative for UCCNC is they give you the software free but charge for the controller and a licensing fee for each controller. That could get expensive if you had multiple machines.

That's all just to give you an idea of some of what is out there and things I found while researching this stuff.

I can only make 1 recommendation and that is take a good look at the Dolphin Mill Basic. It's only $99 and will probably do everything you need. Check and see but I think it comes with Partsmaster cadd which has all of the basic drawing tools you would need to do the 2d drawings. I had Dolphin about 10 years ago and at that time it included the cadd program. I used it with my mill and it worked very well. It's the only package I can recommend because it's the only one I've actually used. I should mention I was using it with Mach3 as well. Here's a link to it.

For the machine I'm building. Here's what I'm planning on using for software.

2D drafting I'm going with ActCadd. ActCadd is a clone of Autocad they are so similar it's hard to tell them apart and I've been using autocad for 30+ years so having a cadd program at home that is almost exactly the same is nice. Autocad costs like $1600 a year for a subscription and ActCad is $200 for a perpetual license. $300 for the professional version which also includes 3d but I haven't tried the 3D out yet because of the next paragraph..

I'm planning on using Fusion 360 for my 3D drawing and the Cam portion to create the toolpaths (G Code). Fusion 360 is a steal for someone with a 4 or more axis cnc machine. I'm going to have a 4 axis machine. I will use this for the toolpaths for the 3 axis as well, I just didn't recommend it because I haven't actually used it yet.

For machine control, UCCNC looks like a good balance between cost and capability for machine control, it's $60 to license a single controller. It seems to have all the capability of mach3. UCCNC also takes care of the issue of how to connect to the machine controller in that it can use a USB or Ethernet cable, depending on the version. Mach 3 is designed to communicate through a parallel port. Before anything else figuring out how the computer will be connected to the cnc machine is critical.

The best advice I can give you probably is. If you can find someone that's done a conversion and documented it, you could just do whatever they did, that is how I did my first mill conversion. That kept me from having to figure it all out myself, and I knew there was a good chance of success.

The easier the software is the more it costs generally speaking. Mach 3 is $175 now and it just does the machine control part of the system. You kind of need 3 pieces of software to make a part with cnc. I say kind of because there are packages that contain one two or all three parts.

You need a drawing program. Depending on what you're trying to make that could be 2D like Autocad, Actcad, Dolphin or Turbocad, or a bunch of others. Basically something that will create the original drawing and make a file such as a dxf the cam software can understand. A lot of the cam packages have at least some cadd capability but they are often pretty limited. Particularly if they aren't multi thousand dollar software packages.

If you're going to try and do something like carving decorations then you need a 3D drawing program. That would be something like Solidworks or Fusion 360. There are also others like I believe Vectric Aspire but I don't know much about them. Solidworks starts at about $3500 and goes up fast depending on the version you buy. You can get Fusion 360 from autodesk for 1 year free as a hobbiest then the subscription is $495 a year I think, though it usually goes on sale at least once a year for about $300. 3D cad has a pretty steep learning curve.

Next you need the CAM software. It takes the drawing and converts it to G Code. There are a lot of programs that do this, many are parts of other programs. For instance Dolphin does the cadd and the cam portions, it's also pretty simple to use for a 3 axis system. Fusion 360 has a really high level cam system built into it. There are free CAM programs that will do it as well, but most are what is called 2.5D which is what is typically done on a 3 axis mill. Of course as is typical with free software it can be buggy and is typically pretty limited. Freemill and Tinkercadd are a couple free ones.

Then you need the machine control software, that is what Mach3 is. Mach 3 is actually outdated and they sell mach 4. They have kept Mach3 on the market for hobby users. In the DIY market GARBL (there's a perpetual debate as to if that's pronounced gerble or garble) and UCCNC are pretty popular. I'm putting together a small cnc router and decided to go with UCCNC. GARBL has been having issues with off brand controller cards that don't work like expected, it's Arduino based and apparently all Arduinos aren't created equally. The negative for UCCNC is they give you the software free but charge for the controller and a licensing fee for each controller. That could get expensive if you had multiple machines.

That's all just to give you an idea of some of what is out there and things I found while researching this stuff.

I can only make 1 recommendation and that is take a good look at the Dolphin Mill Basic. It's only $99 and will probably do everything you need. Check and see but I think it comes with Partsmaster cadd which has all of the basic drawing tools you would need to do the 2d drawings. I had Dolphin about 10 years ago and at that time it included the cadd program. I used it with my mill and it worked very well. It's the only package I can recommend because it's the only one I've actually used. I should mention I was using it with Mach3 as well. Here's a link to it.

For the machine I'm building. Here's what I'm planning on using for software.

2D drafting I'm going with ActCadd. ActCadd is a clone of Autocad they are so similar it's hard to tell them apart and I've been using autocad for 30+ years so having a cadd program at home that is almost exactly the same is nice. Autocad costs like $1600 a year for a subscription and ActCad is $200 for a perpetual license. $300 for the professional version which also includes 3d but I haven't tried the 3D out yet because of the next paragraph..

I'm planning on using Fusion 360 for my 3D drawing and the Cam portion to create the toolpaths (G Code). Fusion 360 is a steal for someone with a 4 or more axis cnc machine. I'm going to have a 4 axis machine. I will use this for the toolpaths for the 3 axis as well, I just didn't recommend it because I haven't actually used it yet.

For machine control, UCCNC looks like a good balance between cost and capability for machine control, it's $60 to license a single controller. It seems to have all the capability of mach3. UCCNC also takes care of the issue of how to connect to the machine controller in that it can use a USB or Ethernet cable, depending on the version. Mach 3 is designed to communicate through a parallel port. Before anything else figuring out how the computer will be connected to the cnc machine is critical.

The best advice I can give you probably is. If you can find someone that's done a conversion and documented it, you could just do whatever they did, that is how I did my first mill conversion. That kept me from having to figure it all out myself, and I knew there was a good chance of success.

Last edited:

Well thank you very much for the good info, will have to do a bit of research for sure.

will have to do a bit of research for sure.

Try for 3rd program (cnc control) LinuxCNC ( http://linuxcnc.org/). It's free. I've been using it for about 10 years and am quite satisfied.

- Joined

- Oct 9, 2020

- Messages

- 2,258

- Points

- 488

I am glad to see this post. I have the proxxon mill and I purchased a CNC conversion kit. I haven't actually added it on yet because I am trying to figure out a way to attach limit switches to the XY table. There is room on the control card for this. It used GRBL and not Mach 4. You see, the x travel concerns me most on this XY table. It is not very long and I would hate to crash the mill. So I will keep you posted as I figure things out. PS I purchased this from a German guy on Ebay. No issues with the quality and it works because I tried the motors without actually having them connected to the mill.

Last edited by a moderator:

I have seen an Italien site with a upgrade for the proxxon mf 70 ,would like to do this but the 3d programs to make g code are ridicullisly expensive.I have been surfing the web, but have not found some thing for less that 100 dollars per year.

www.ideegeniali.it

www.ideegeniali.it

All you need to convert proxxon mf70 to cnc

Electronic board, mechanical retrofit parts, stepper motors, power supply, pc connection cable, software in a big saving pack.

- Joined

- Oct 9, 2020

- Messages

- 2,258

- Points

- 488

i would lookup FreeCad. I just downloaded it the other day.

- Joined

- Oct 9, 2020

- Messages

- 2,258

- Points

- 488

any of these software good for you?

www.vectric.com

www.vectric.com

Products Compare Page | Vectric

will check it out thank you

The freecad looks amazing, Now I will just have to learn how to use it. Since I know nothing about cad may take some time.

fusion 360 is only free for one year

Renewable...fusion 360 is only free for one year

I still believe that the freecad would be better since it is open source.... not a company trying to steal your money at a exhorbitant cost.

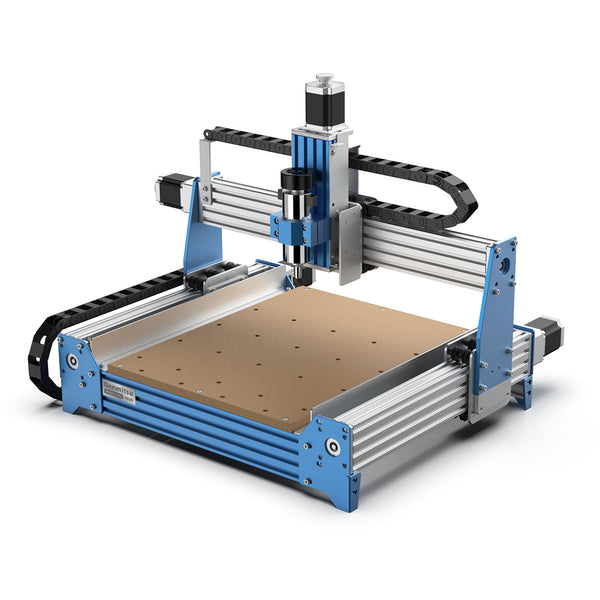

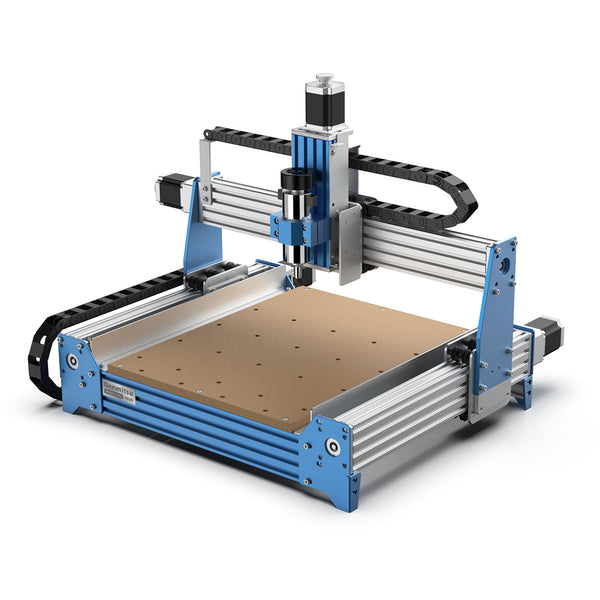

hey check this out, I want this

www.sainsmart.com

www.sainsmart.com

PROVerXL 4030 CNC Router with Carveco Maker Subscription

The Genmitsu PROVerXL 4030 Benchtop CNC machine is a new class of easy to assemble and ready to go kits. Capable of working with woods, plastics, foams, and soft metals. You don’t have to limit your projects or your imagination.

www.sainsmart.com

www.sainsmart.com

CNC software can seem intimidating at first, but it doesn't have to be. The term "for dummies" doesn't mean you're stupid; it just means you're new to the subject. With the right software and a bit of practice, anyone can learn how to use CNC machines to create intricate designs and objects.