Welcome back my friends to the show that never ends. We're so glad you could attend, come inside, come inside.

Ralph Waldo Emerson

I am glad you turned your eyes to the next review, folks. Today, I will review the last batch of PE parts I have in my possession from our friend DryDock Models and Parts. And those PE parts are eye pins and hooks. Without further a do... let's begin. BTW, if you came here accidentally, I have the entire set of reviews about DryDock parts (below)

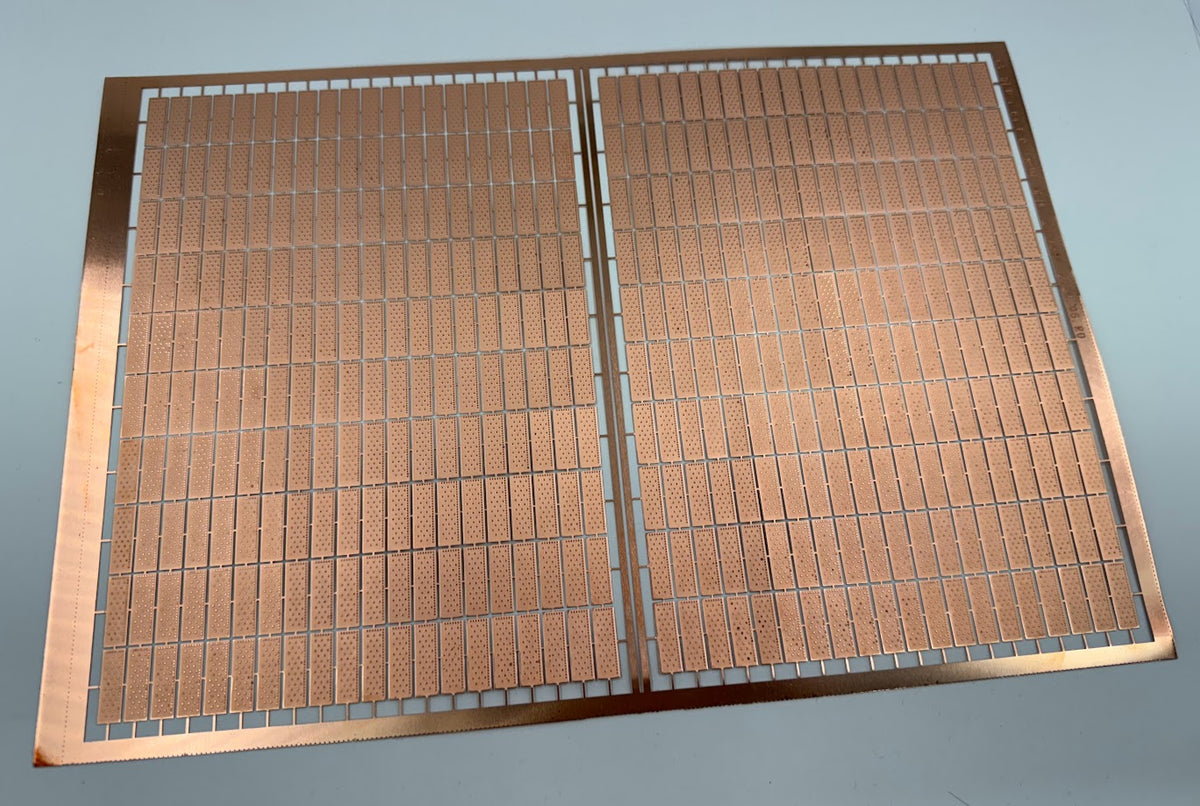

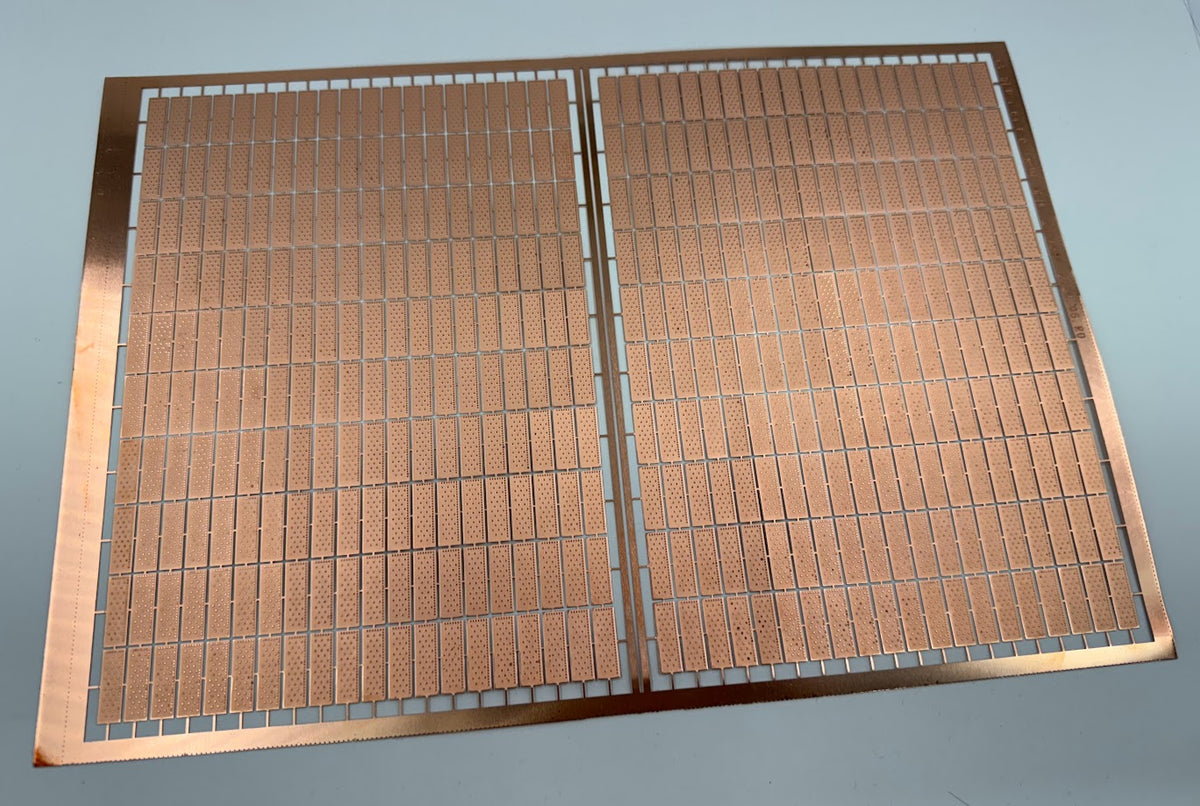

Like most PE parts from DeyDock, the eye pins and hooks are available in 4 scales: 1:48, 1:64, 1: 72, and 1:96. While they are designed for specific scales, you can certainly use them in any scale where they fit in the scale size. Hooks come in a plastic bag (see image above), and contain a single mini-fret with 26 total pieces in a set. BTW, it is priced at 25 pieces, but the fret has 26, I guess you have 1 free (except for the 1:96 scale, the total count in the set is 24)!

Sample fret for 1:48 scale hooks

Sample fret for 1:64 scale

sample fret for 1:72 scale

... the smallest scale is 1:96

Here is the macro image with the relative size comparison from left to right: 1:48, 1:64, 1:72, and 1:96

Let's see the eye pins. They also come in a single mimi-fret with a total of 26 pieces in the set for scales 1:48, 1:64, and 1:72. For the smallest scale: 1:96, the total set count is 24.

Scale 1:48

Scale 1:64

Scale 1:72

relative size comparison

Conclusion:

There is a nice selection of hooks and eye pins (eyebolts imitation) for most of the rigging work. They are uniform and will save many hours to make those from scratch. While they are made with the scales in mind, you can use them interchangeably as long as the size for the given part permits. It is hard to imagine the use of hooks and eyebolts of the same size for all the rigging work. One drawback, they are a bit thin, IMHO, but I have given my feedback to the manufacturer and they assure me that the v2 of the products will be a bit thicker, that's good to know!

I will show those PE parts 'in action' in my next review. I will use those parts to rig the guns from DryDock, It will be Part 3 (the last) of the Aftermarket naval gun parts to upscale.

I hope the review was informative and somewhat will help before you make a decision. I would love to hear from you and share your opinion or even experience if you have purchased those products already, and use them to upscale your models. Thank you for stopping by, will talk to you soon...

Here is the direct link for those parts. (scroll to the middle)

drydockmodelsandparts.com

drydockmodelsandparts.com

Ralph Waldo Emerson

I am glad you turned your eyes to the next review, folks. Today, I will review the last batch of PE parts I have in my possession from our friend DryDock Models and Parts. And those PE parts are eye pins and hooks. Without further a do... let's begin. BTW, if you came here accidentally, I have the entire set of reviews about DryDock parts (below)

Aftermarket kits and parts review

Review of available Aftermarket parts and mini kits

shipsofscale.com

Like most PE parts from DeyDock, the eye pins and hooks are available in 4 scales: 1:48, 1:64, 1: 72, and 1:96. While they are designed for specific scales, you can certainly use them in any scale where they fit in the scale size. Hooks come in a plastic bag (see image above), and contain a single mini-fret with 26 total pieces in a set. BTW, it is priced at 25 pieces, but the fret has 26, I guess you have 1 free (except for the 1:96 scale, the total count in the set is 24)!

Sample fret for 1:48 scale hooks

Sample fret for 1:64 scale

sample fret for 1:72 scale

... the smallest scale is 1:96

Here is the macro image with the relative size comparison from left to right: 1:48, 1:64, 1:72, and 1:96

Let's see the eye pins. They also come in a single mimi-fret with a total of 26 pieces in the set for scales 1:48, 1:64, and 1:72. For the smallest scale: 1:96, the total set count is 24.

Scale 1:48

Scale 1:64

Scale 1:72

relative size comparison

Conclusion:

There is a nice selection of hooks and eye pins (eyebolts imitation) for most of the rigging work. They are uniform and will save many hours to make those from scratch. While they are made with the scales in mind, you can use them interchangeably as long as the size for the given part permits. It is hard to imagine the use of hooks and eyebolts of the same size for all the rigging work. One drawback, they are a bit thin, IMHO, but I have given my feedback to the manufacturer and they assure me that the v2 of the products will be a bit thicker, that's good to know!

I will show those PE parts 'in action' in my next review. I will use those parts to rig the guns from DryDock, It will be Part 3 (the last) of the Aftermarket naval gun parts to upscale.

I hope the review was informative and somewhat will help before you make a decision. I would love to hear from you and share your opinion or even experience if you have purchased those products already, and use them to upscale your models. Thank you for stopping by, will talk to you soon...

Here is the direct link for those parts. (scroll to the middle)

Photo-Etch Parts and Accessories

Copper Plates Gun Carriage Detailing Set Rudder Hinges Sweep Port Hinges Hooks Eye Pins Chain Plates

drydockmodelsandparts.com

drydockmodelsandparts.com