One of the first things I look for when purchasing brass or any metal I plan on "blackening", is to make sure it is not "coated". Coating the metal is a property that's added purposefully during the manufacturing process to PREVENT tarnishing, the exact opposite of what we want. After all, we are trying to tarnish it. Who wants brass and other non-ferrous metals protected? Jewelers. Depending on the brass manufacturer, most "coated" brass sheets will say so, in small print on their label.

I learned this the hard way, of course. I used Acetone to remove the coating. It doesn't take a lot. A shallow, glass dish, nitrile gloves, and a small brush. Submerge your brass, let it sit for 30 seconds, and then brush the dissolved coating away. Gloves aren't necessary, as Acetone is not caustic, but it has a very low evaporation temperature. If you use ungloved hands, it will feel cold and will evaporate quickly from your hands, taking your skin's natural oils with it. Nothing a little hand lotion won't fix. And you can always just use tweezers and the brush without gloves. And it only takes 2 minutes, so you can just do it outside, boom! Once the coating is gone, you just follow Jim's steps, and you will have beautifully blackened brass.

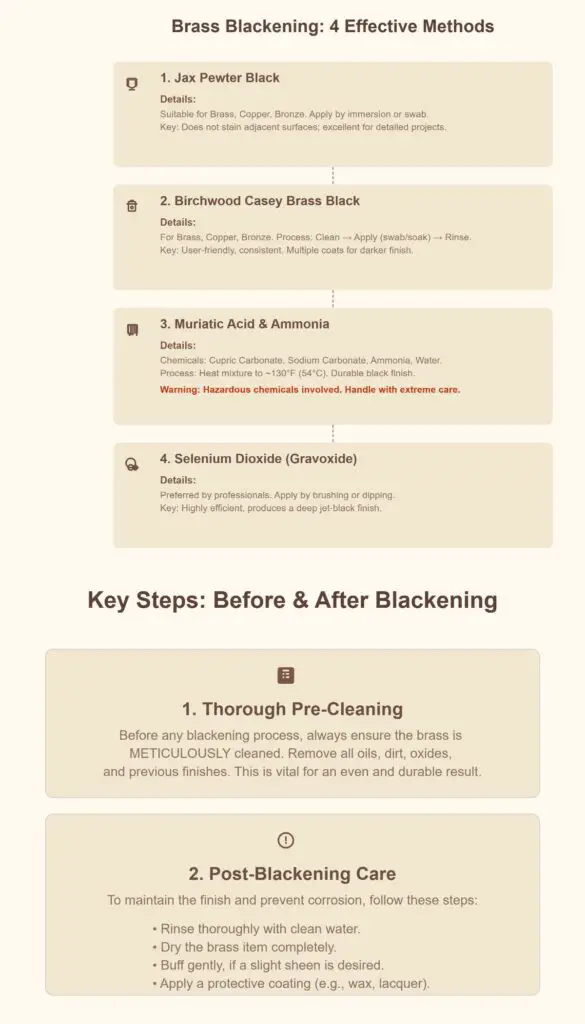

I use two blackeners, but my go-to is Casey's.

I do have some experience with solvents and their application. I once took some MEK (Methyl Ethyl Ketone), and decided to use it to remove some tar from the rocker boards, under the front doors of my 1976 Lincoln Mark V. It removed the tar no problem, along with the factory baked-on paint. BOOM, I was down to bare metal in 1 minute flat.

Sometimes I wonder how I reached my current age.