-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hallo,

ich habe dieses Maschinchen schon etliche Jahre.

Nicht schlecht, aber es gibt bessere für das Geld.

Karl

ENGLISH

I've had this machine for a number of years. Not bad, but better for the money.

Karl

ich habe dieses Maschinchen schon etliche Jahre.

Nicht schlecht, aber es gibt bessere für das Geld.

Karl

ENGLISH

I've had this machine for a number of years. Not bad, but better for the money.

Karl

- Joined

- Oct 9, 2020

- Messages

- 2,190

- Points

- 488

what a good idea. makes the thing a lot more stable. i have mine bolted to a workbench but the disadvantage is that it isn't portable.

yes I wanted to be able to move it out of the way, since my work space is limited.

Thats an excellent idea Smelly. There is another modification of this machine I have seen bigger hand wheels for the X-Y table.

.

.

Nice upgrade, it's the best of all worlds:

- Heavy, stable base

- Portable

- Enough space all around it to clamp it down if needed.

just an update to this thread,

I have returned the proxxon mill back to amazon.

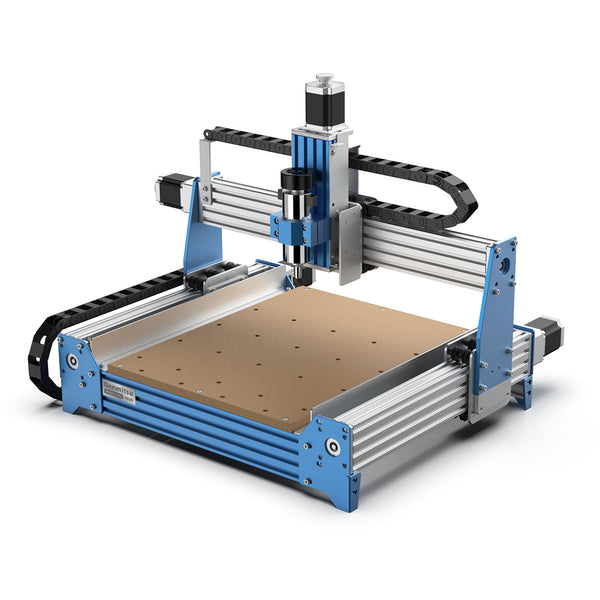

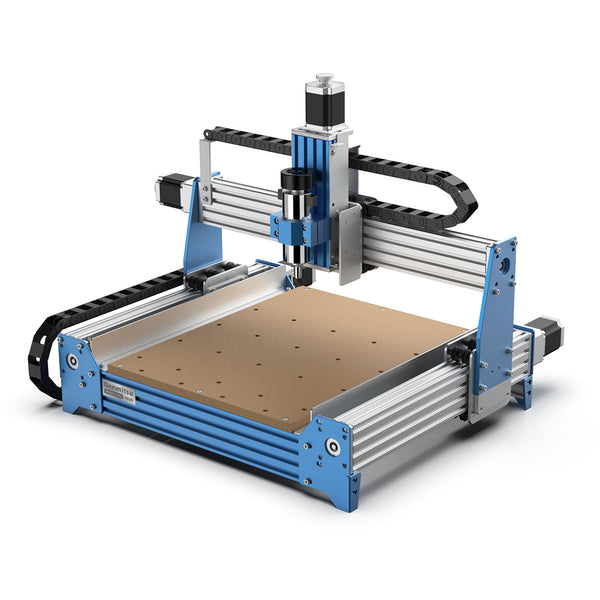

The reason being I did not like it. I have decided to learm cad software ...Freecad.. and tho buy a small desk top router such as the folling like. It is a new model with a stronger spindle.

www.sainsmart.com

www.sainsmart.com

the new model is just what is need to make your own ship parts from photos of the plans, or just design your own.

I have returned the proxxon mill back to amazon.

The reason being I did not like it. I have decided to learm cad software ...Freecad.. and tho buy a small desk top router such as the folling like. It is a new model with a stronger spindle.

PROVerXL 4030 CNC Router with Carveco Maker Subscription

The Genmitsu PROVerXL 4030 Benchtop CNC machine is a new class of easy to assemble and ready to go kits. Capable of working with woods, plastics, foams, and soft metals. You don’t have to limit your projects or your imagination.

www.sainsmart.com

www.sainsmart.com

the new model is just what is need to make your own ship parts from photos of the plans, or just design your own.

Hello Smelly, You may not aware, but a CNC router is in no way a substitution for a mill. While Proxxon mill MF70 relatively small (one of the downsides) it is for sure a precision tool and favorite among scratch builders for budget money.

What exactly you don't like?

What exactly you don't like?

want to do cnc. proxxon plus cnc upgrade is still too small .the router I posted would allow me to do much more for almost the same price.

That $999 price tag really stopped me in my mental tracks!!! I probably don't have that many more years or builds to make it affordable on the cost benefit ratio of reality. I joke at times that "It doesn't cost. . .it pays!" but that doesn't mill out true for me on the Genmitsu. Great looking machine though. Proxon MF70 at around $400 would probably do the work that I need but still would have to learn how to use it . . . I think without the need of CAD learning curve. PT-2 (Rich)Hello Smelly, You may not aware, but a CNC router is in no way a substitution for a mill. While Proxxon mill MF70 relatively small (one of the downsides) it is for sure a precision tool and favorite among scratch builders for budget money.

What exactly you don't like?

yes is a good price with a good spindle... just the right size table too. I think the admiral might like making 3d relief images, decorations themes ect. So gonna save my pennies . learn cad and gimp, then purchase the machine just after christmas.

check this out...

Wow, this let me dreaming. I do not have skill to use this, but it seem really versatile. The video is instructive too and well made.

Thanks

Thanks

I think, there is a big misconception with terminology. I am trying to explain that a Milling machine and CNC router are not the same types of machinery. They designed for different jobs! CNC is Computer numerical control. It is a term that is used in reference to either the automated specialized machinery (sometimes called machining centers) that can remove material from a stock piece (also called a workpiece or blank) or to the service that performs those machining operations.That $999 price tag really stopped me in my mental tracks!!! I probably don't have that many more years or builds to make it affordable on the cost benefit ratio of reality. I joke at times that "It doesn't cost. . .it pays!" but that doesn't mill out true for me on the Genmitsu. Great looking machine though. Proxon MF70 at around $400 would probably do the work that I need but still would have to learn how to use it . . . I think without the need of CAD learning curve. PT-2 (Rich)

What is the keyword? Yes, automated, e.g. automate the process of a specialized machine. So, Mill is one of the types of machinery that can be automated using CNC. Router - is another machinery that can be automated using CNC. But they designed for different types of jobs!

For many years I have had thoughts to invest into 3D software & machines to produce parts I need for my models more accurately, easier and faster than with old school methods. This is why I already purchased a 3-axle router for this purpose together with CAD & CAM software supplied with the machine. And after hard and long lasting learning of the software finally got the machine working and producing the parts I needed. But this only for 2D and 2.5D parts.

To be able to expand my skills into 3D parts I downloaded a trial version of a popular 3D software and started to learn it by watching numerous tutorials available in internet. However after a few month's intense learning I finally found that I will never reach such a level of skill to produce parts with enough details which I would be satisfied with. And to produce these it would have been necessary to purchase the fourth axle with all soft- and hardware for my router as well.

So for this reason I finally made decision to stay with 2D and 2.5D parts and build rest with old school methods by sawing, filing and sanding.

Having told all this I really emphasize people thinking of buying a CNC machine to think twice. And not to rely too much on machine vendor's stories about the easiness of using them. To buy a machine is the easiest part of the whole process. Then starts the difficult part to buy all the software and learn to use them together with the machine.

However this is only a hobby for most of us and not production work of which one's living is depending. So if making some very detailed parts takes a little longer with traditional methods, isn't that quite acceptable.

To be able to expand my skills into 3D parts I downloaded a trial version of a popular 3D software and started to learn it by watching numerous tutorials available in internet. However after a few month's intense learning I finally found that I will never reach such a level of skill to produce parts with enough details which I would be satisfied with. And to produce these it would have been necessary to purchase the fourth axle with all soft- and hardware for my router as well.

So for this reason I finally made decision to stay with 2D and 2.5D parts and build rest with old school methods by sawing, filing and sanding.

Having told all this I really emphasize people thinking of buying a CNC machine to think twice. And not to rely too much on machine vendor's stories about the easiness of using them. To buy a machine is the easiest part of the whole process. Then starts the difficult part to buy all the software and learn to use them together with the machine.

However this is only a hobby for most of us and not production work of which one's living is depending. So if making some very detailed parts takes a little longer with traditional methods, isn't that quite acceptable.

Well said and advised. PT-2For many years I have had thoughts to invest into 3D software & machines to produce parts I need for my models more accurately, easier and faster than with old school methods. This is why I already purchased a 3-axle router for this purpose together with CAD & CAM software supplied with the machine. And after hard and long lasting learning of the software finally got the machine working and producing the parts I needed. But this only for 2D and 2.5D parts.

To be able to expand my skills into 3D parts I downloaded a trial version of a popular 3D software and started to learn it by watching numerous tutorials available in internet. However after a few month's intense learning I finally found that I will never reach such a level of skill to produce parts with enough details which I would be satisfied with. And to produce these it would have been necessary to purchase the fourth axle with all soft- and hardware for my router as well.

So for this reason I finally made decision to stay with 2D and 2.5D parts and build rest with old school methods by sawing, filing and sanding.

Having told all this I really emphasize people thinking of buying a CNC machine to think twice. And not to rely too much on machine vendor's stories about the easiness of using them. To buy a machine is the easiest part of the whole process. Then starts the difficult part to buy all the software and learn to use them together with the machine.

However this is only a hobby for most of us and not production work of which one's living is depending. So if making some very detailed parts takes a little longer with traditional methods, isn't that quite acceptable.

Its all relative CNC, Laser & 3d printer. 3D Printer is additive ( adds layers to build, CNC is subtractive ( carves away to build) & laser precise cuts/ engraves . Fortunately I have all three ( albeit hobby versions). The CNC was not hard to learn for 2d & 2.5. The laser is 2d only and easier ( if you can draw in AI, Inkscape) you can cut on a cnc & laser. if you remember x y z plotting from school you halfway there. I love my xcarve / XYZ carve. Try cutting anything with curves on the proxon Mill!. Like anytool ( scroll saw, bandsaw etc) it just takes a little practice., but a whole load of FUN. It is not expensive for a quality hobby unit. Software is either free or if your into 3d reliefs around $350 for vcarve desktop.

I bought CNC 3018 Plus router from Ali Express in last December. The machine costs $365 and shipping to Japan is $70. This is same as Genmitsu selling.

It took half a day to assemble the kit. The spindle is 500W and has enough power to make small parts. I made a few window frame for Royal William. End mills sold by Amazon or several hobby shops are quite expensive, but good price end mills are available from Ali Express. I guess most of consumer level cutting blades are made in China.

It took half a day to assemble the kit. The spindle is 500W and has enough power to make small parts. I made a few window frame for Royal William. End mills sold by Amazon or several hobby shops are quite expensive, but good price end mills are available from Ali Express. I guess most of consumer level cutting blades are made in China.