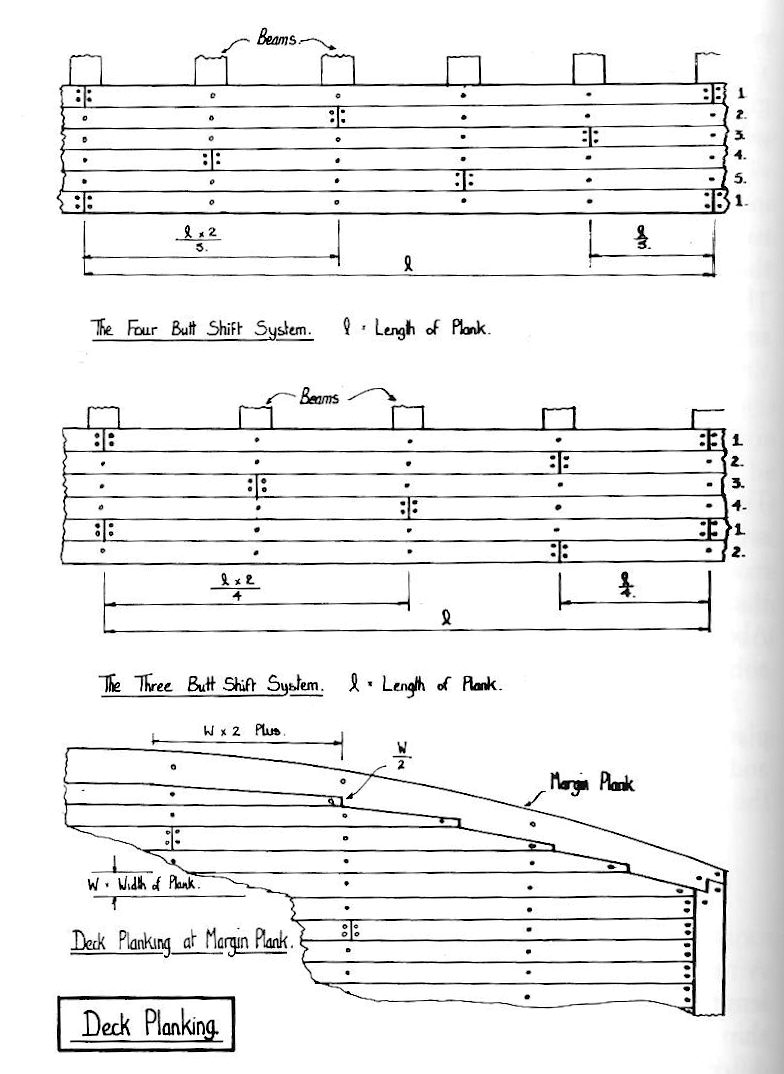

Well, after some reading and finishing the base layer of planking for my armed launch. I decided to do the second layer in shorter strips rather than longer ones. I read that most original ships were built from shorter pieces of wood anyway. I decided to use a three step planking method. I cut most of the strips in 70mm lengths with several in 35mm lengths and several in 17.5mm lengths. Then I started the planking with a full length strip, the next row I started with a 35mm strip and the next row a 17.5mm strip. Starting the fourth row I went back to the 70mm strip and so on. By doing this none of the joints from the base layer matched up to the second layer which should add structural stability to the hull as I finish. It was also much easier to plank the curved sections of the hull using shorter planks.

When I begin the final exterior layer of planking I will switch to a 90mm, 45 mm and 22.5mm lengths. Again, this will keep any joints from the second layer from lining up with the final layer. It will also make a nice planking pattern as I finish. (I hope!!)

As I finish the second layer I will post some photos of the planking and then some more as I get into the final layer of planking. The biggest differences are it takes much more time to cut the shorter strips and fit them cleanly against each other to keep any gaps from developing. But, it does make it easier than using full length strips. Maybe I figured out how I should have been doing it anyway or, I'm doing it all wrong. But, it is working well and the planking pattern looks much better than with the long strips.

I'm open to thoughts, advice, criticism and even a little laughter.............

When I begin the final exterior layer of planking I will switch to a 90mm, 45 mm and 22.5mm lengths. Again, this will keep any joints from the second layer from lining up with the final layer. It will also make a nice planking pattern as I finish. (I hope!!)

As I finish the second layer I will post some photos of the planking and then some more as I get into the final layer of planking. The biggest differences are it takes much more time to cut the shorter strips and fit them cleanly against each other to keep any gaps from developing. But, it does make it easier than using full length strips. Maybe I figured out how I should have been doing it anyway or, I'm doing it all wrong. But, it is working well and the planking pattern looks much better than with the long strips.

I'm open to thoughts, advice, criticism and even a little laughter.............