-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

- Home

- Forums

- Welcome to Ships of Scale Forum

- Beginners Corner - How to Get Started

- Basic Tools Needed

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Jul 11, 2023

- Messages

- 306

- Points

- 168

Value is unfortunately in the eyes of the beholder. I personally think it is worth it long term, since it is built for both precision and durability. I have one on its way right now. Should arrived within the next couple days.

A search here, will give you some insight on what people think (all positive beside the price). I found this review useful (sorry for the re-direct):

modelshipworld.com

modelshipworld.com

A search here, will give you some insight on what people think (all positive beside the price). I found this review useful (sorry for the re-direct):

Ultimation Slicer, Sander and Repeater

Last week I purchased the Ultimation Slicer and Sander with the Repeater attachment. I got a little carried away and posted a mini review on the “What Did You Receive Today” forum. I thought I would post a more complete review of the tools here. These items can be purchased individually, but I pu...

modelshipworld.com

modelshipworld.com

Last edited:

Hello Toolman,

"Worth the price" is a pretty subjective standard, but I'll try to give some insight...

First of all, I consider a disc sander my most valuable tool, as well as my most often used tool. I actually have several. Variable speed and reversing disc rotation are both features that earn high marks from me.

But the disc sander I use the most is the one you are asking about. Why? First of all, my other disc sanders are relegated to my garage and the Ultimation sander can be used indoors as it does not spin sawdust over everything. Next, the adjustable fence is super handy (though I rarely change it from 90 degrees) because it is fixed in place. Finally, it really does provide the ultimate speed control which allows me to fine-tune parts without concern.

With all that said, it is lousy for high production work or for bulk material removal...(I go to the garage for that).

I cannot defend the crazy price ($225 for a sander without a motor????) - but it is VERY well built.

If I broke mine, I can honestly say I would buy another one. Would I skip groceries in order to acquire this 'unnecessary' sander? Probably not. But I do find it has enhanced my hobby experience and that makes me happy.

Hope this helps a bit.

"Worth the price" is a pretty subjective standard, but I'll try to give some insight...

First of all, I consider a disc sander my most valuable tool, as well as my most often used tool. I actually have several. Variable speed and reversing disc rotation are both features that earn high marks from me.

But the disc sander I use the most is the one you are asking about. Why? First of all, my other disc sanders are relegated to my garage and the Ultimation sander can be used indoors as it does not spin sawdust over everything. Next, the adjustable fence is super handy (though I rarely change it from 90 degrees) because it is fixed in place. Finally, it really does provide the ultimate speed control which allows me to fine-tune parts without concern.

With all that said, it is lousy for high production work or for bulk material removal...(I go to the garage for that).

I cannot defend the crazy price ($225 for a sander without a motor????) - but it is VERY well built.

If I broke mine, I can honestly say I would buy another one. Would I skip groceries in order to acquire this 'unnecessary' sander? Probably not. But I do find it has enhanced my hobby experience and that makes me happy.

Hope this helps a bit.

Well said on all points Paul however, the way this thing is built I can't imagine how one could break this. If such a thing happened to me I may give up donuts for a while and purchased another.Hello Toolman,

"Worth the price" is a pretty subjective standard, but I'll try to give some insight...

First of all, I consider a disc sander my most valuable tool, as well as my most often used tool. I actually have several. Variable speed and reversing disc rotation are both features that earn high marks from me.

But the disc sander I use the most is the one you are asking about. Why? First of all, my other disc sanders are relegated to my garage and the Ultimation sander can be used indoors as it does not spin sawdust over everything. Next, the adjustable fence is super handy (though I rarely change it from 90 degrees) because it is fixed in place. Finally, it really does provide the ultimate speed control which allows me to fine-tune parts without concern.

With all that said, it is lousy for high production work or for bulk material removal...(I go to the garage for that).

I cannot defend the crazy price ($225 for a sander without a motor????) - but it is VERY well built.

If I broke mine, I can honestly say I would buy another one. Would I skip groceries in order to acquire this 'unnecessary' sander? Probably not. But I do find it has enhanced my hobby experience and that makes me happy.

Hope this helps a bit.

I have one. Use it all of the time. Love it for the control and lack of dust. Takes very little effort to remove laser char from those few pieces that are square. It is expensive but is finely built and will last for my lifetime and longer. I don't think you'd regret owning one.

I am pretty sure, that this tool is a good one.

I am also very often use my disc sander, but is electric driven (a Hegner) - there are in my eyes some advantages with the hand-driven tool, but I like to have my part controled with two hand or minimum two fingers, and this is not possible when you need one hand for playing "motor"

At the end it is really subjective

But a disc sander (with or without motor) is one of the most needed and helpful tool

I am also very often use my disc sander, but is electric driven (a Hegner) - there are in my eyes some advantages with the hand-driven tool, but I like to have my part controled with two hand or minimum two fingers, and this is not possible when you need one hand for playing "motor"

At the end it is really subjective

But a disc sander (with or without motor) is one of the most needed and helpful tool

I have to agree with the other posts above, especially Paul’s @dockattner insight. I purchased one some months ago as well as the Slicer and other accessories. I am very impressed with the quality and how useful they have become to me.

With tools I ask myself the same question I do after a meal in a restaurant. Would I have it again? With these Ultimation tools it’s a resounding yes.

With tools I ask myself the same question I do after a meal in a restaurant. Would I have it again? With these Ultimation tools it’s a resounding yes.

I agree with the above comments. I have both the sander and the slicer. Expensive YES. Well engineered and built? Absolutely!

Jan

Jan

- Joined

- Jul 11, 2023

- Messages

- 306

- Points

- 168

@AllanKP69, I have not tried boxwood or ebony, pear wood yes (only 1.5mm thick). Others may have feedback too on something larger.

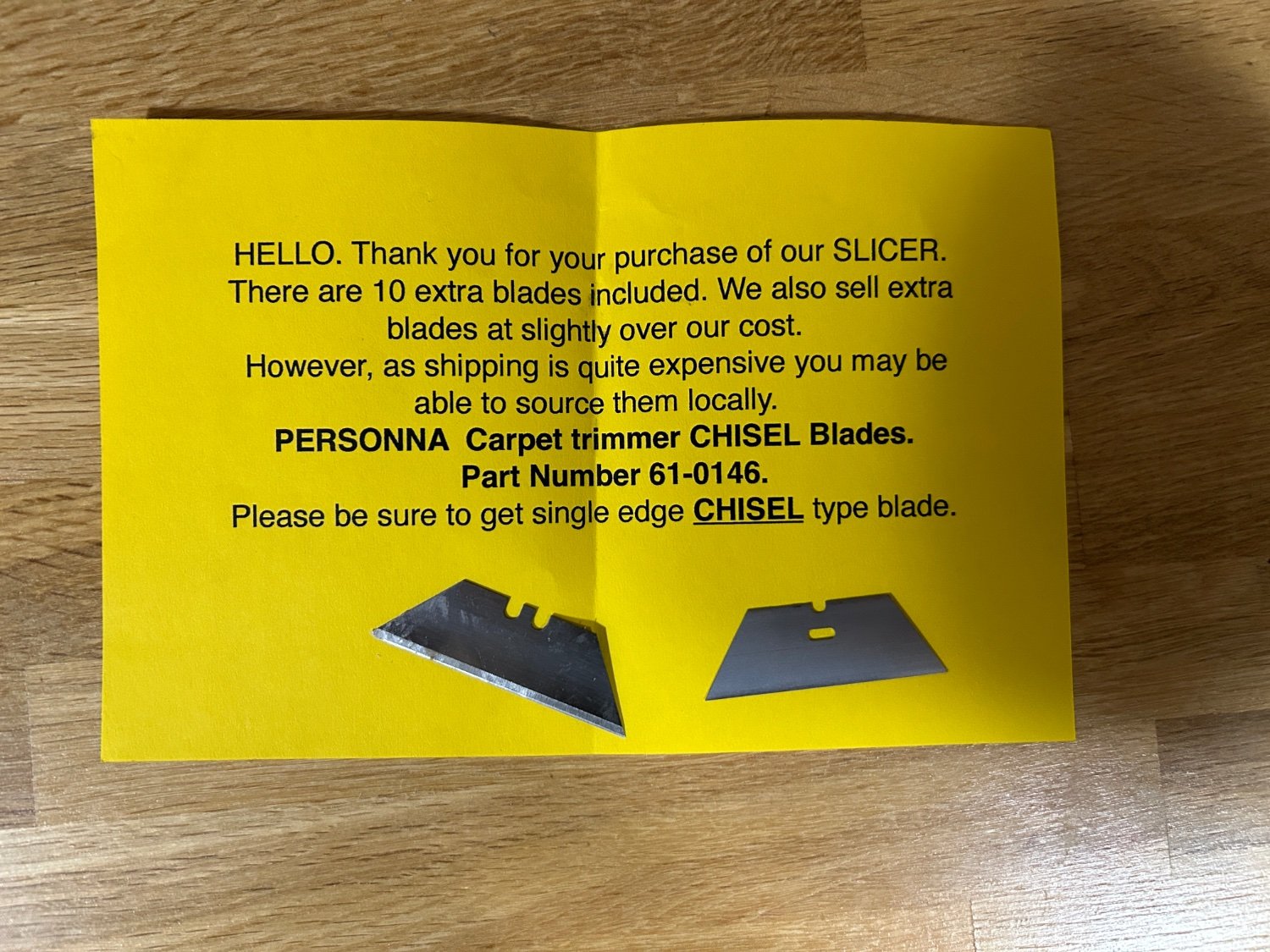

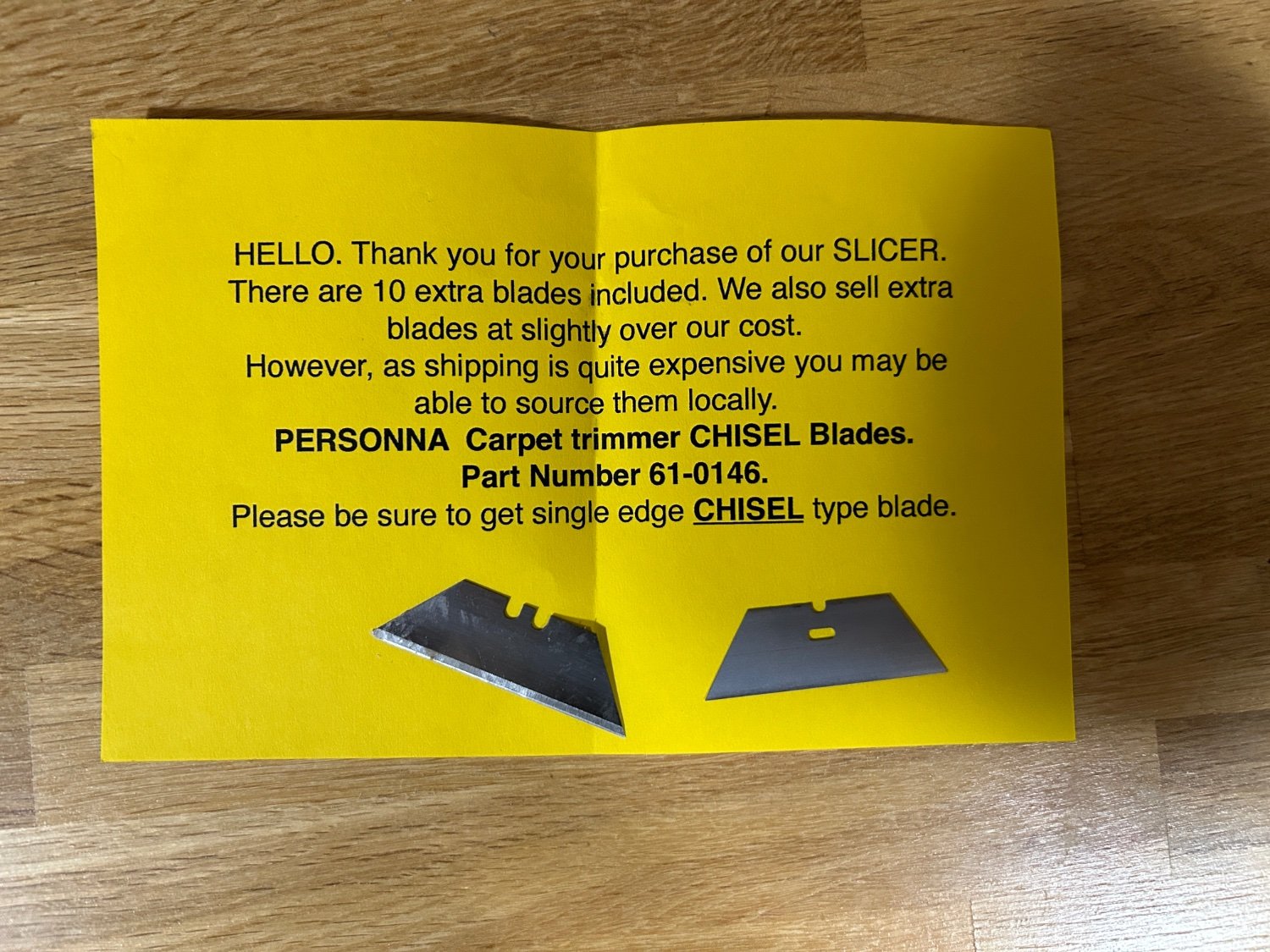

However, if you look at the picture below, it will give you an idea of the sturdiness. The frame and arm are partly the most critical, and made of solid steel. The arm is 3/16 inch thick, the joins 1/8 inch thick. Large steel bolts. The arm is 6 inch long, for plenty of leverage. The blades are sharp and bevel on one side. Overall, I'm sure it can handle any hardwood to a reasonable thickness.

However, if you look at the picture below, it will give you an idea of the sturdiness. The frame and arm are partly the most critical, and made of solid steel. The arm is 3/16 inch thick, the joins 1/8 inch thick. Large steel bolts. The arm is 6 inch long, for plenty of leverage. The blades are sharp and bevel on one side. Overall, I'm sure it can handle any hardwood to a reasonable thickness.

Last edited:

I just cut 2mm x 6mm boxwood and it didn't blink. I also tried 4mm x 4mm box and the piece slid to the left creating an angled cut. But I then went back and was able to square off that cut end rather easily. There is a stop that you can put on the horizontal arm and that should prevent the slide to the left...How well does the slicer work on hard wood species such as boxwood, pear, ebony, etc?

Thanks

Allan

BTW - using this thing as a repeater is where I use it most often, Allan. Otherwise, I just cut what I'm working on with a saw or knife and then square off the end on a disc sander. It is an 'extra' in my little model shop (not an essential).

BTW - using this thing as a repeater is where I use it most often,

Thanks Paul, that was what I thought might be the case. Like cutting 100 front and 100 rear cannon carriage axles for a first rate or maybe multiple carlings and ledges for the deck structure.

Thanks again

Allan

No crushing, the single sided blade is quite sharp. The 'left' side of the cut is always perfect - there can be some chip-out on the right side which is not a problem once you know to keep the part you want to use to the left (which means you do need to square up the chipped side). The larger the stock the more the chip-out (at least with boxwood - it can be pretty brittle).Thanks Paul, that was what I thought might be the case. Like cutting 100 front and 100 rear cannon carriage axles for a first rate or maybe multiple carlings and ledges for the deck structure.I just worried that this kind of device crushes the wood, but based on all the positive comments that does not appear to be the case.

Thanks again

Allan

Thickness & wood density are the two areas for consideration, IMHO. The following examples are cut with a new blade. The blades themselves have one side straight and one side with a bevel.

The first photo shows the bevel on the right side of the cut and on the left side the chipping which I assume is a result of the wood thickness and bevel on the blade. You can also see the slight bevel on the left side.

The second photo shows the bevel but no chipping of the left side.

Both of these are with a relatively soft wood.

The third photo of a 2x6mm maple strip shows the bevel but no chipping

The piece I want to use is always on the left side of the blade (Non beveled side)

I always nip a slice off the right side piece to give me and true surface to start another cut.

I always stay under 2x8mm and have not seen any errant cuts. To me thickness is the key. Anything thicker is what my Byrnes table saw is for.

I recently cut strips for a 'deck' on a display stand which were made from 2x8 maple and all cuts were excellent. As long as I remembered to nip off a slice before cutting the next 'plank;

Ultimation has some videos which may provide more insight to its usage.

The first photo shows the bevel on the right side of the cut and on the left side the chipping which I assume is a result of the wood thickness and bevel on the blade. You can also see the slight bevel on the left side.

The second photo shows the bevel but no chipping of the left side.

Both of these are with a relatively soft wood.

The third photo of a 2x6mm maple strip shows the bevel but no chipping

The piece I want to use is always on the left side of the blade (Non beveled side)

I always nip a slice off the right side piece to give me and true surface to start another cut.

I always stay under 2x8mm and have not seen any errant cuts. To me thickness is the key. Anything thicker is what my Byrnes table saw is for.

I recently cut strips for a 'deck' on a display stand which were made from 2x8 maple and all cuts were excellent. As long as I remembered to nip off a slice before cutting the next 'plank;

Ultimation has some videos which may provide more insight to its usage.

I have both the slicer and the sander and both work great, buy the pair if you can afford them, in my opinion well worth the money. If you buy the cutter purchase spare blades at the same time. Will save on shipping cost later. I also purchased the spare round cutting mats but you can cut your own out of obsolete / used cutting mats.

So…OK…quality tools always enhance the work, the results, and the longevity of the tool. A question I ask myself is whether the intended use justifies the cost of a quality upper end tool. Not always. I have a relatively inexpensive variable speed 5 inch disk sander from MicroMark that is more than adequate for my needs at a current price of $110. Works great!

- Joined

- Oct 12, 2019

- Messages

- 150

- Points

- 88

I own both of these tools and they are fantastic!

Built heavy, extremely precision built and All Collins stands behind his products.

I've been building a 1/16 scale 1950's Dairy barn for my wife's best friend's grandson. I copied it from the barn from the great grandmothers homestead.I made all the lumber from common 1 x 10 pine boards. ALL parts were ripped on my table saw then cut to length using a miter rite hobby saw, angled parts were cut on my Protein miter saw.

Every piece has been finished on the Ultimation sander, the finished joints are unbelievabley tight!!

The slicer I've used making balsa airplane models it is also a great tool. Cuts balsa and bass wood like butter!

Yes, they are expensive but you buy them one time and they will outlast their owner!!

I'm a very happy owner/user of Al's tools.

He told me once he's working on a precision miter saw to - I'm waiting!!!!

Treat yourself, your worth it!!

Steveidean

Built heavy, extremely precision built and All Collins stands behind his products.

I've been building a 1/16 scale 1950's Dairy barn for my wife's best friend's grandson. I copied it from the barn from the great grandmothers homestead.I made all the lumber from common 1 x 10 pine boards. ALL parts were ripped on my table saw then cut to length using a miter rite hobby saw, angled parts were cut on my Protein miter saw.

Every piece has been finished on the Ultimation sander, the finished joints are unbelievabley tight!!

The slicer I've used making balsa airplane models it is also a great tool. Cuts balsa and bass wood like butter!

Yes, they are expensive but you buy them one time and they will outlast their owner!!

I'm a very happy owner/user of Al's tools.

He told me once he's working on a precision miter saw to - I'm waiting!!!!

Treat yourself, your worth it!!

Steveidean

- Joined

- Oct 12, 2019

- Messages

- 150

- Points

- 88

That's Proxxon

- Joined

- Jun 30, 2024

- Messages

- 30

- Points

- 48

Would love the slicer and sander but they are pricey enough without figuring in the cost of postage to get to me in the UK. Plus I would probably have to pay import duty on them.

I haven't found a UK stockist of them, so unless you know different, I'll just sit here in envy

I haven't found a UK stockist of them, so unless you know different, I'll just sit here in envy