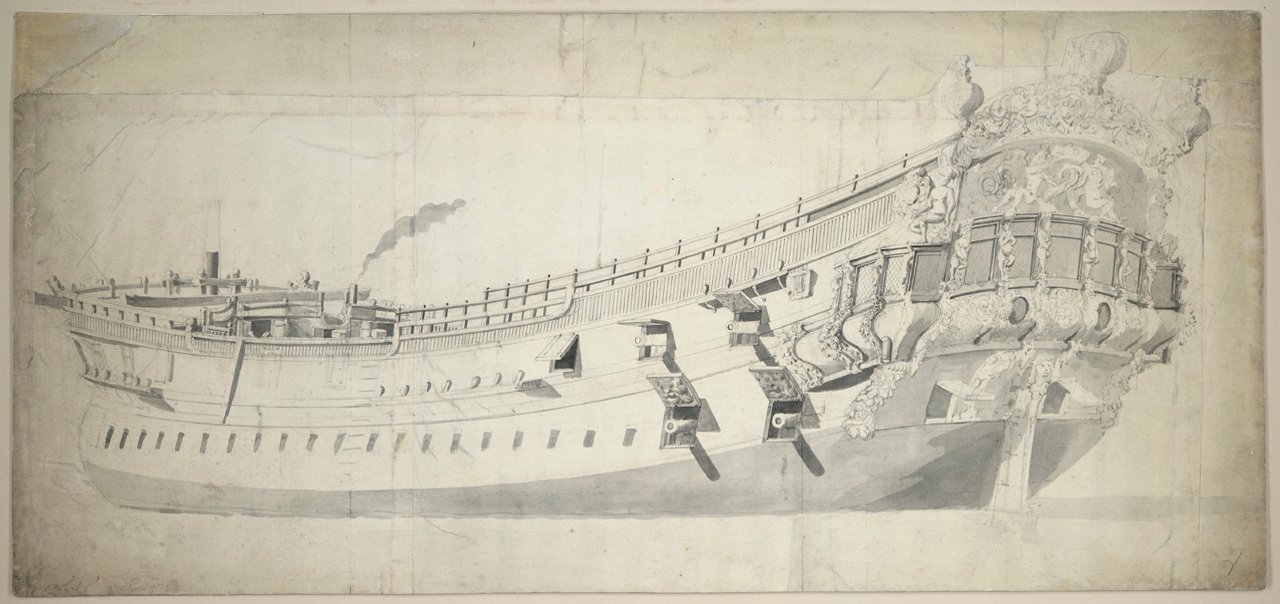

This is a build log of a 17th century British galley frigate that I built for a client a couple years ago, but I thought some members might find it interesting. It is based mainly on a RMG drawing of the Charles Galley built at Woolwich by Phineas Pett in 1676. The model has slight modifications, including one less gun port on each side of the QD and that the side be planked to the sheer rails. Drawings by Van De Velde the Elder show what may be the frames at the area of the top timbers with fillers between frames but no horizontal planking, or this may be vertical covering planks. As it was likely painted blue in any case, it will not be glaring in the final appearance. Both a sketch and a later painting (1677) of her under sail by VDV show no wreaths below the QD which is an anomaly for that time. Information from Richard Endsor's book The Master Shipwrights Secrets including the Charles Galley and a smaller ship, the James Galley are also being consulted extensively. The contemporary contract for the James Galley from the National Archives in Kew is turning out to be a big help as well, albeit with scantlings that are slightly smaller in some cases than would have been appropriate for the Charles Galley. Measuring items such as the keel on the contemporary drawing is confirming this supposition. In addition, photos of a contemporary model of an unnamed royal yacht of 1702 have striking similarities and will be used for such items as gratings, bitts, etc. Lastly, books by Lavery, Goodwin and others are being studied for a number of items. The model will be a POB and will not be rigged. I intend to give a try at the carvings using clay. Failing success in these, I will go back to using wood and my trusty set of chisels from Mihail Kirsanov.

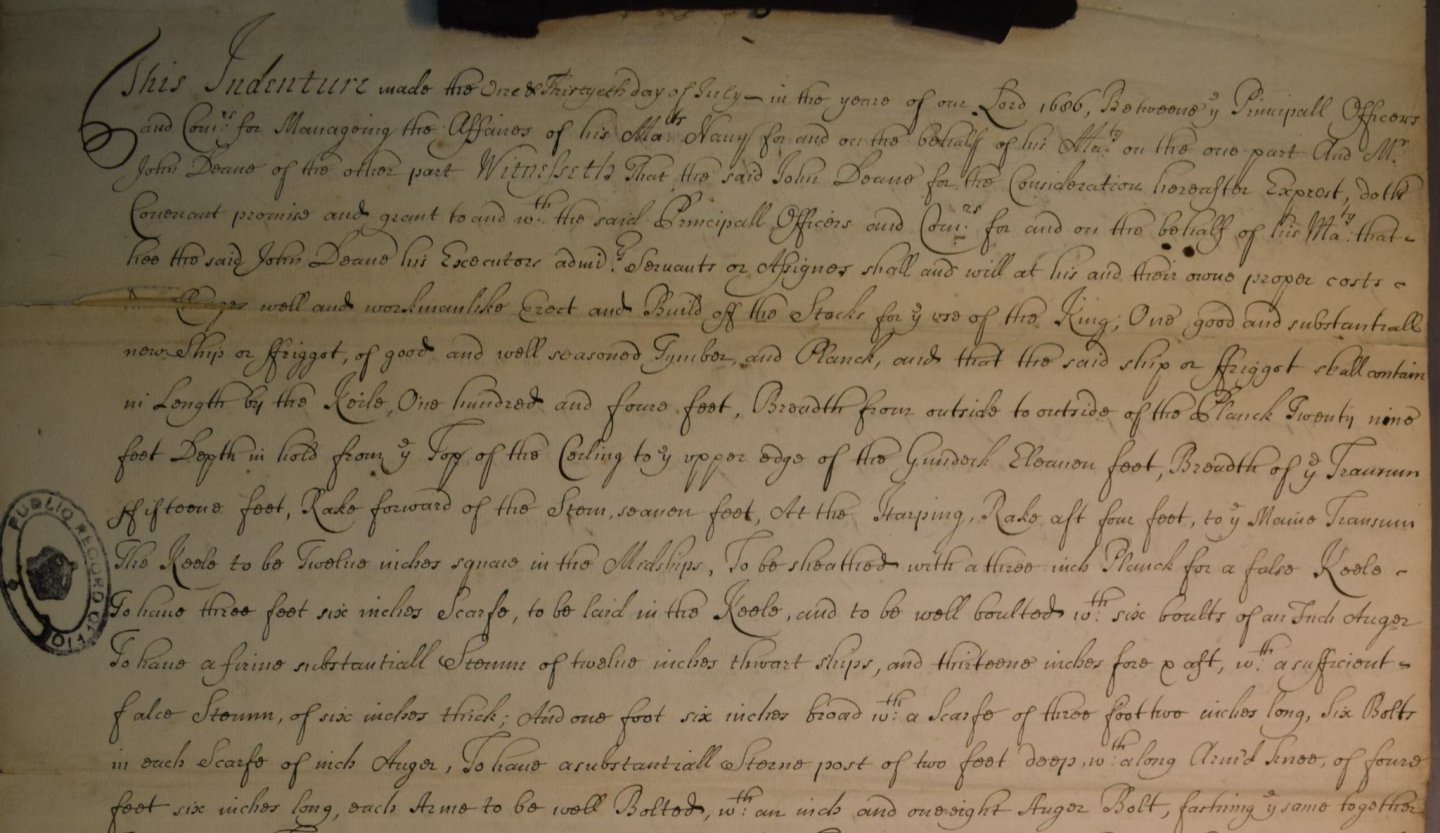

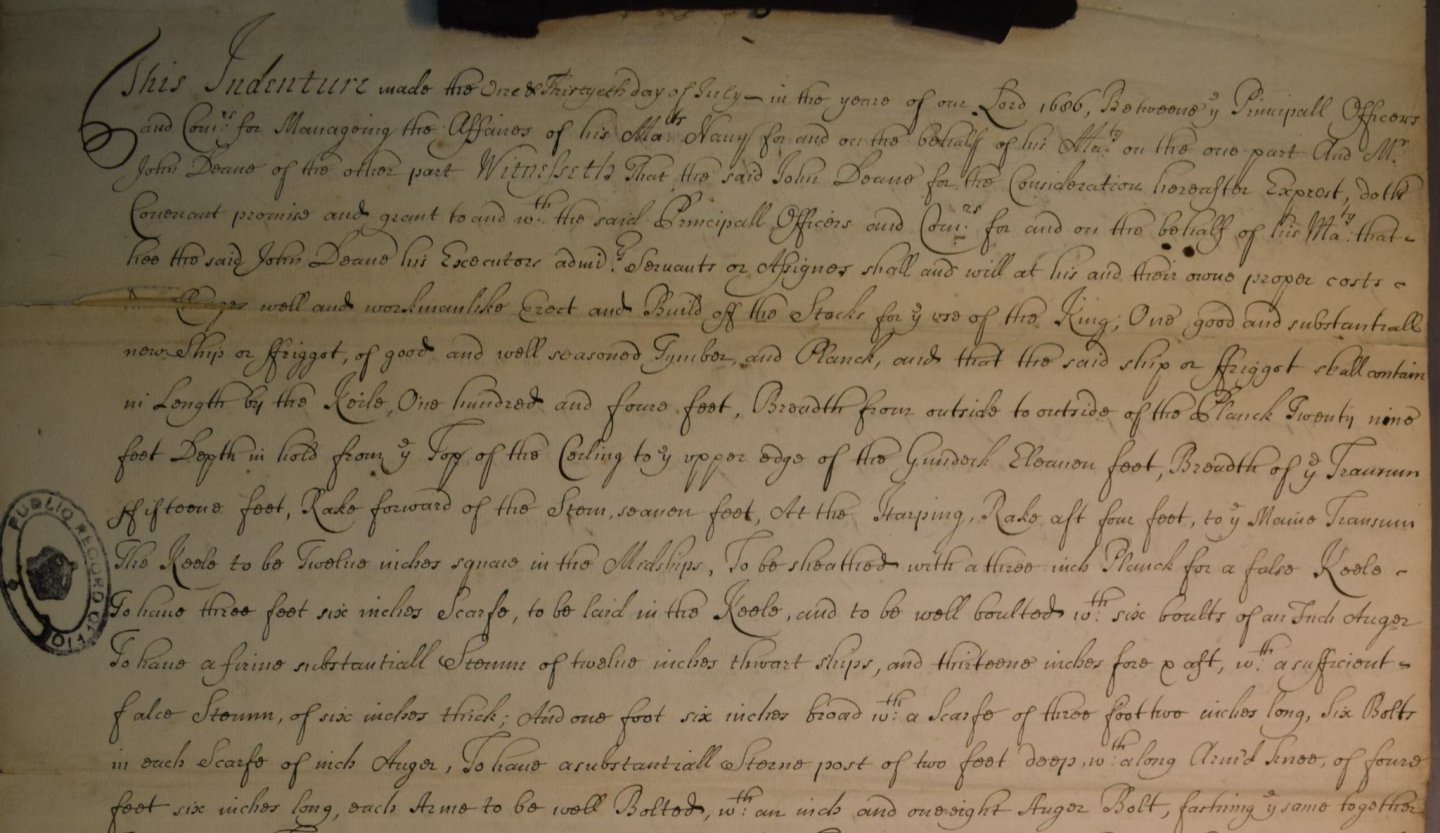

Note that the topic title should have the word Friggot. This is not a misspelling but rather the spelling used in the contract. Transcribing the contract took a few days even though the scribes had handwriting that could be deciphered more easily than others that I have transcribed in in the past. Still, there were some words that had me baffled but a friend that has studied numerous contracts and studying the paleography tutorial on the National Archives, Kew web site was a huge help.

The below is a portion of the transcription and the original contract. These can be immensely helpful in sizing various things for any build, scratch or kit. Note that the spelling, grammar, capitalizing, punctuation &c. are as in the contract. For those who have not tried to read one of these contracts, it is a fun, and often frustrating, experience.

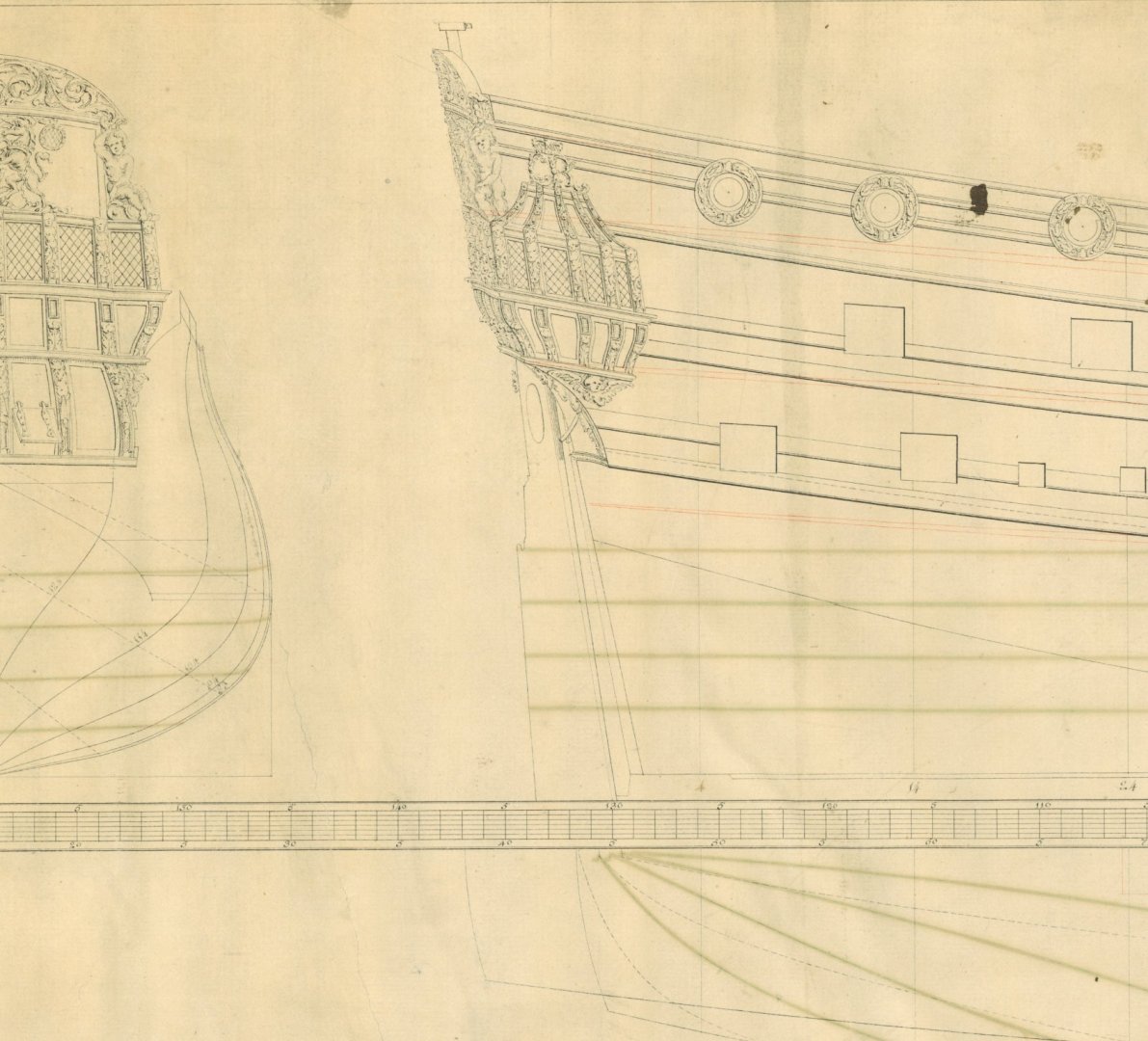

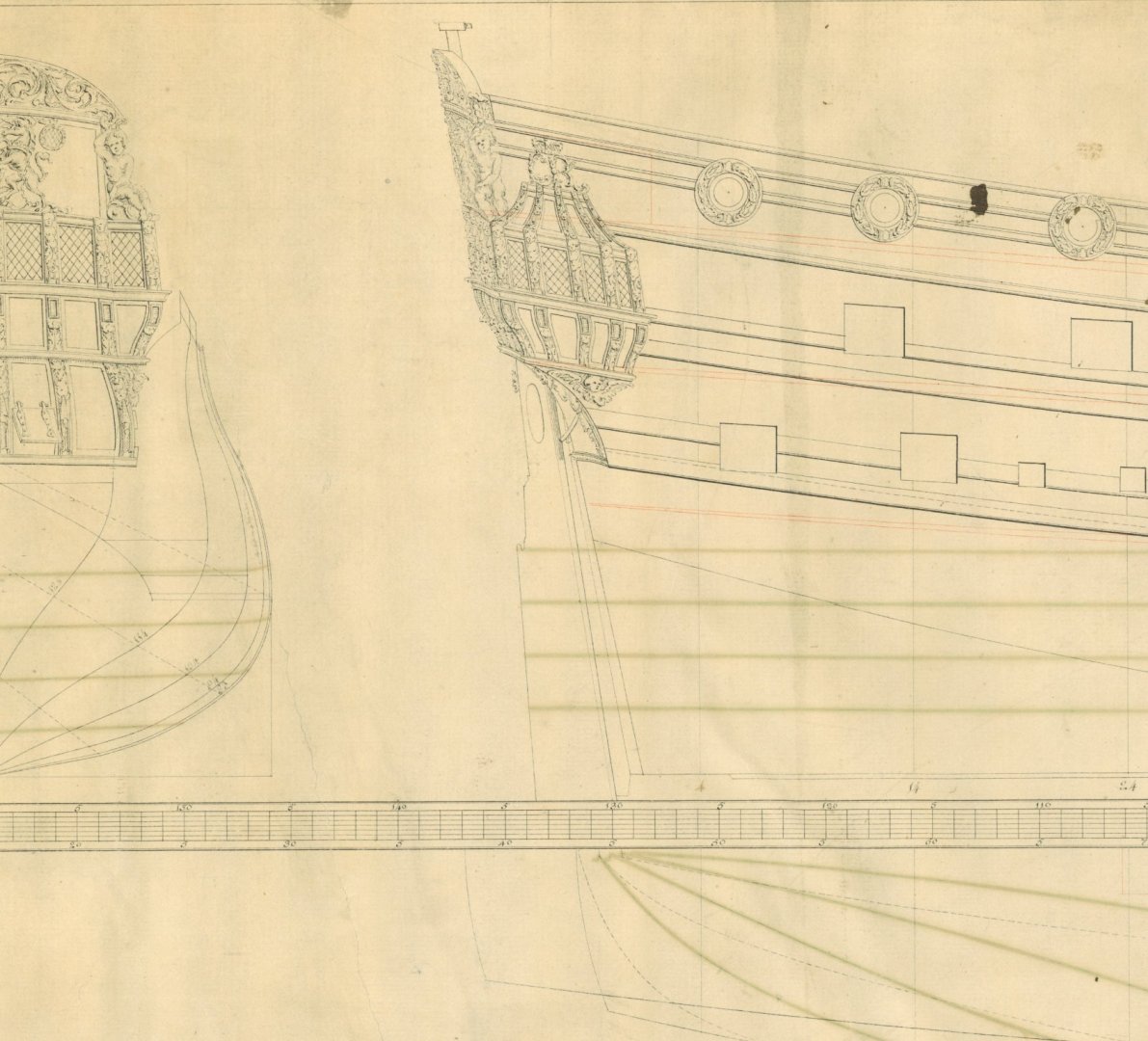

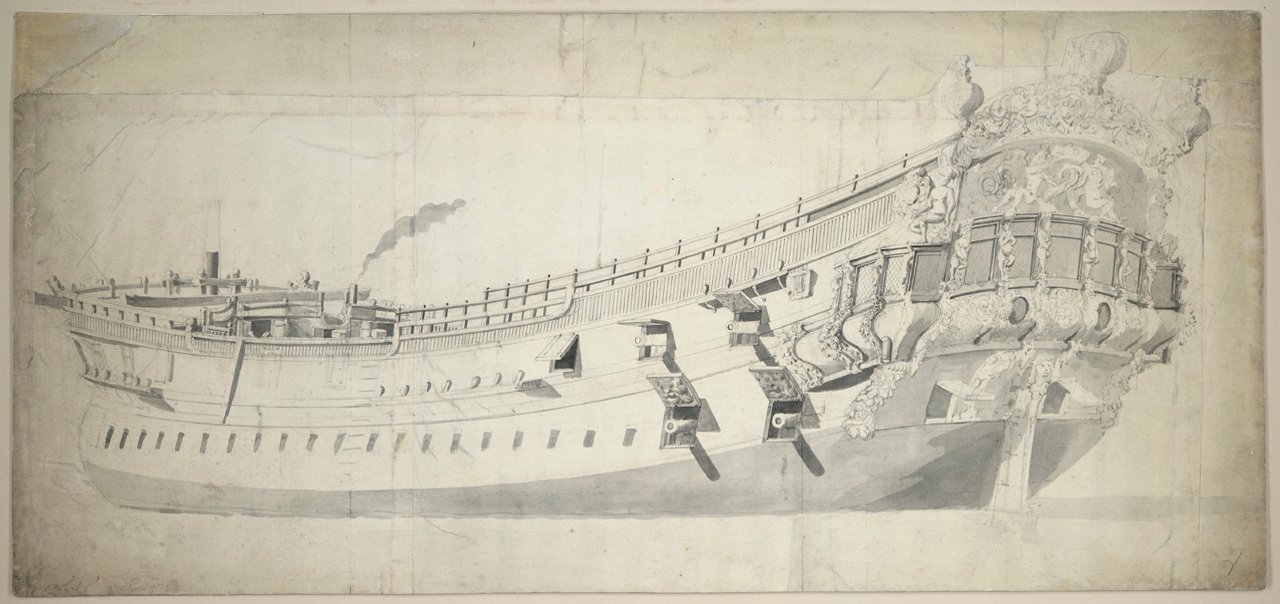

The drawing below from RMG is shown in part, as well as one of the VDV drawings.

Allan

This Indenture made the One and Thirtyeth Day of July in the year of our Lord 1686 Betweene ye Principall Officers and Com.rs for Managing the Affaires of his Matys Navy for and on behalf of His Majesty on the one part and Mr. John Deane of the other part Witnesseth that the said John Deane for the Considerations hereafter Exprest, doth covenant, promise and grant to and with your principall officers and commissioners for and behalf of His Majesty that hee, the said John Deane, his executors , admins servants or assigns, shall and will at his and their own proper costs and charges well and workmanlike will erect and build off the stocks for the use of the King, one substantial new Ship or Friggot of good and well seasoned Tymber and Planck and that the said Ship shall contain in Length by the keel one hundred and four feet, Breadth from outside to outside of the Planck Twenty nine feet, depth with hold from ye Top of the Ceiling to ye upper edge of the Gundeck eleavon feet, Breadth of ye transom fifteen feet, Rake forward of the Stem, seavon feet, At the Harping, Rake aft four feet, to ye Maine Transome The Keele to be Twelve inches square in the Mid Ships, To be sheathed with a three inch Planck for a false Keel ~ To have three feet six inches Scarfs, to be laid in the Keele, and to be well boulted with six boults of an inch auger To have a firme substantiall Stemme of twelve inches thwart ships, and thirteene inches fore and aft, wth a sufficient False Stem, of six inches thick, And one foot six inches broad wth a Scarfe of three feet two inches long, six bolts in each Scarfe of inch Auger, To have substantiall Sterne post of two feet deep wth a long Armed Knee, of foure feet six inches long, each Arme to be well Bolted, wth an inch and one eight Auger Bolt, fastening ye same together

Original

Allan

Note that the topic title should have the word Friggot. This is not a misspelling but rather the spelling used in the contract. Transcribing the contract took a few days even though the scribes had handwriting that could be deciphered more easily than others that I have transcribed in in the past. Still, there were some words that had me baffled but a friend that has studied numerous contracts and studying the paleography tutorial on the National Archives, Kew web site was a huge help.

The below is a portion of the transcription and the original contract. These can be immensely helpful in sizing various things for any build, scratch or kit. Note that the spelling, grammar, capitalizing, punctuation &c. are as in the contract. For those who have not tried to read one of these contracts, it is a fun, and often frustrating, experience.

The drawing below from RMG is shown in part, as well as one of the VDV drawings.

Allan

This Indenture made the One and Thirtyeth Day of July in the year of our Lord 1686 Betweene ye Principall Officers and Com.rs for Managing the Affaires of his Matys Navy for and on behalf of His Majesty on the one part and Mr. John Deane of the other part Witnesseth that the said John Deane for the Consideration

Original

Allan

Last edited: