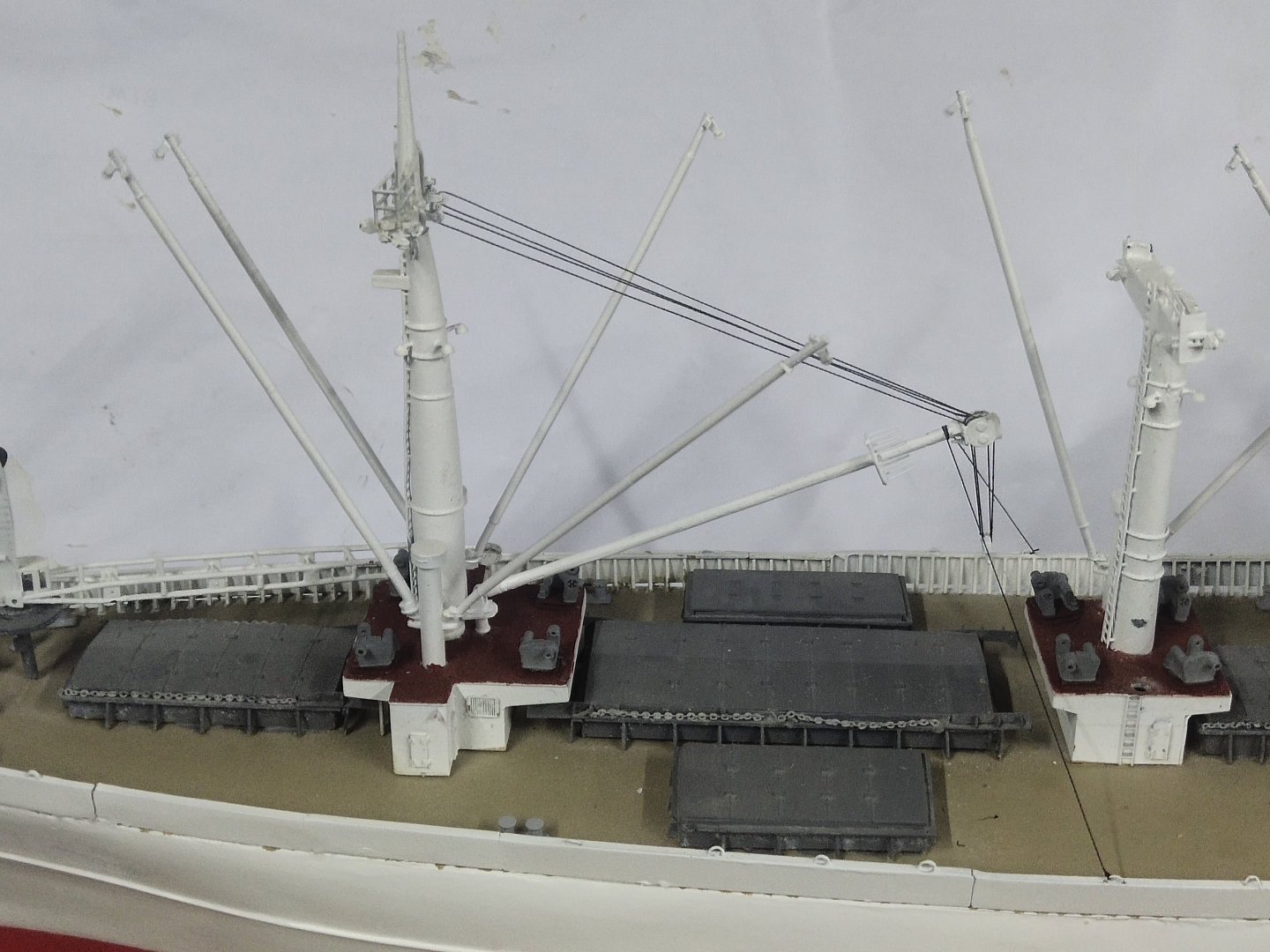

It was about time to do what I avoided to do lately. To paint the hull.

Body was prepared by sanding it with 400,600 and 1500 grit sandpaper.

For this size of hull an air compressor with a medium pistol would be ideal. Spray cans are far away from appropriate. The museum models are painted with colors from automobile industry therefore looks so impressive even bit unnatural.

Then I layered tape strips and start spraying. The curved rear area was troublesome to tape. This hull also requires 3 colors, white, red and brown.

After finishing the layers it took me another week working on evenings to get the desired outcome. Finally a medium gloss varnish was used.

Body was prepared by sanding it with 400,600 and 1500 grit sandpaper.

For this size of hull an air compressor with a medium pistol would be ideal. Spray cans are far away from appropriate. The museum models are painted with colors from automobile industry therefore looks so impressive even bit unnatural.

Then I layered tape strips and start spraying. The curved rear area was troublesome to tape. This hull also requires 3 colors, white, red and brown.

After finishing the layers it took me another week working on evenings to get the desired outcome. Finally a medium gloss varnish was used.