the canadian one I must pay shiping 2337.05 tax and shiping

yes thanks for the pics... i will purchase this model later this fall.Hi Smelly,

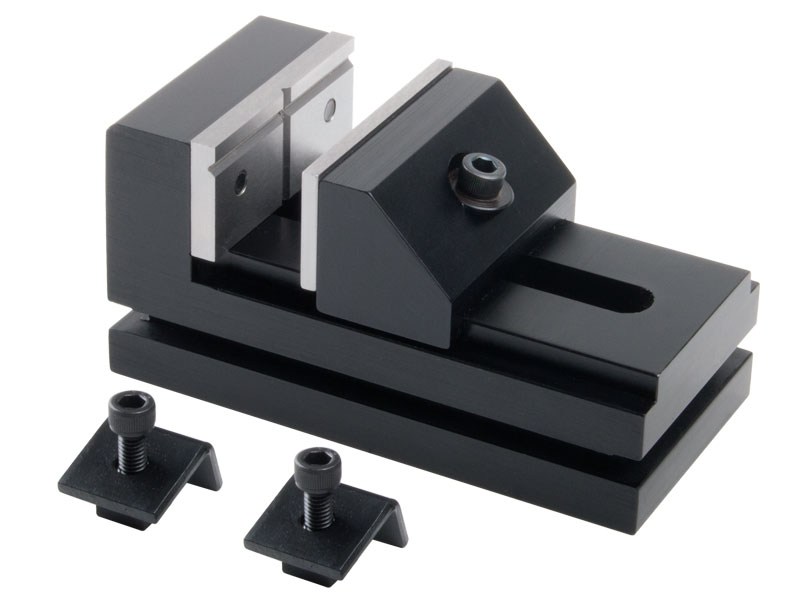

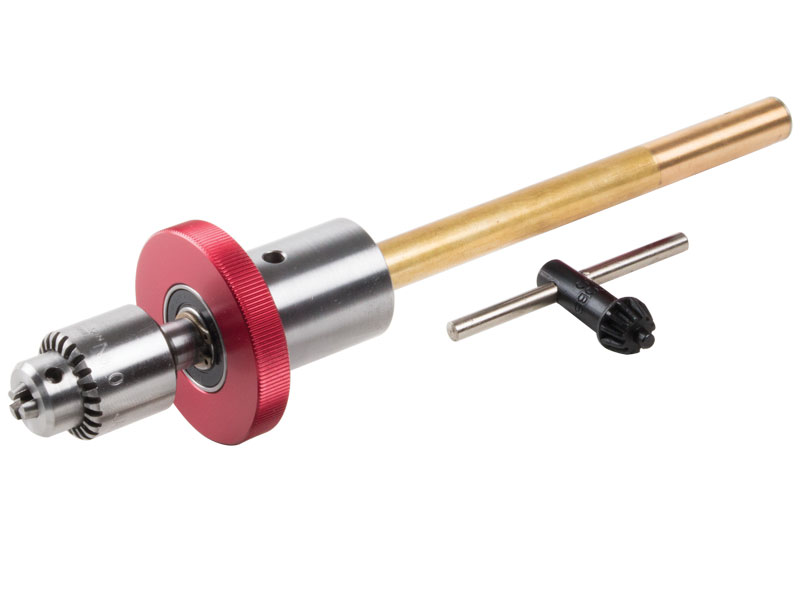

I too was in the market for a tool to help me make more precise, cuts, rebates, form fitting pieces, etc. I came across and purchased a Sherline Milling machine that I've been very happy with. I did a lot of research before buying. The model I bought was their base machine, BUT, and this was a big factor in driving my purchase, it is scale-able. You can purchase stepper motors to convert it into a CNC machine at a later date, or you can purchase the CNC ready model, or a true CNC model that comes with it's own dedicated computer, software, etc. I was not sure I needed a CNC machine, so I opted for the base model with 1 upgrade, the digital read out (DRO), which makes using it sooooo much easier for someone not familiar with milling machines. Allowing you to reset ZERO at any point. Their machines are not cheap, but building mini lathes and milling machines is all they do and they are a leader in the field. Their customer service is amazing also.

Below is the link to their site along with a photo of my machine. https://www.sherline.com/

View attachment 176157

View attachment 176158

View attachment 176159

View attachment 176160

My response may not be exactly on-point in answering your question, but I just couldn't help myself. I believe Donny also uses Sherline machines.

Cheers,

Ken.