Hello everyone

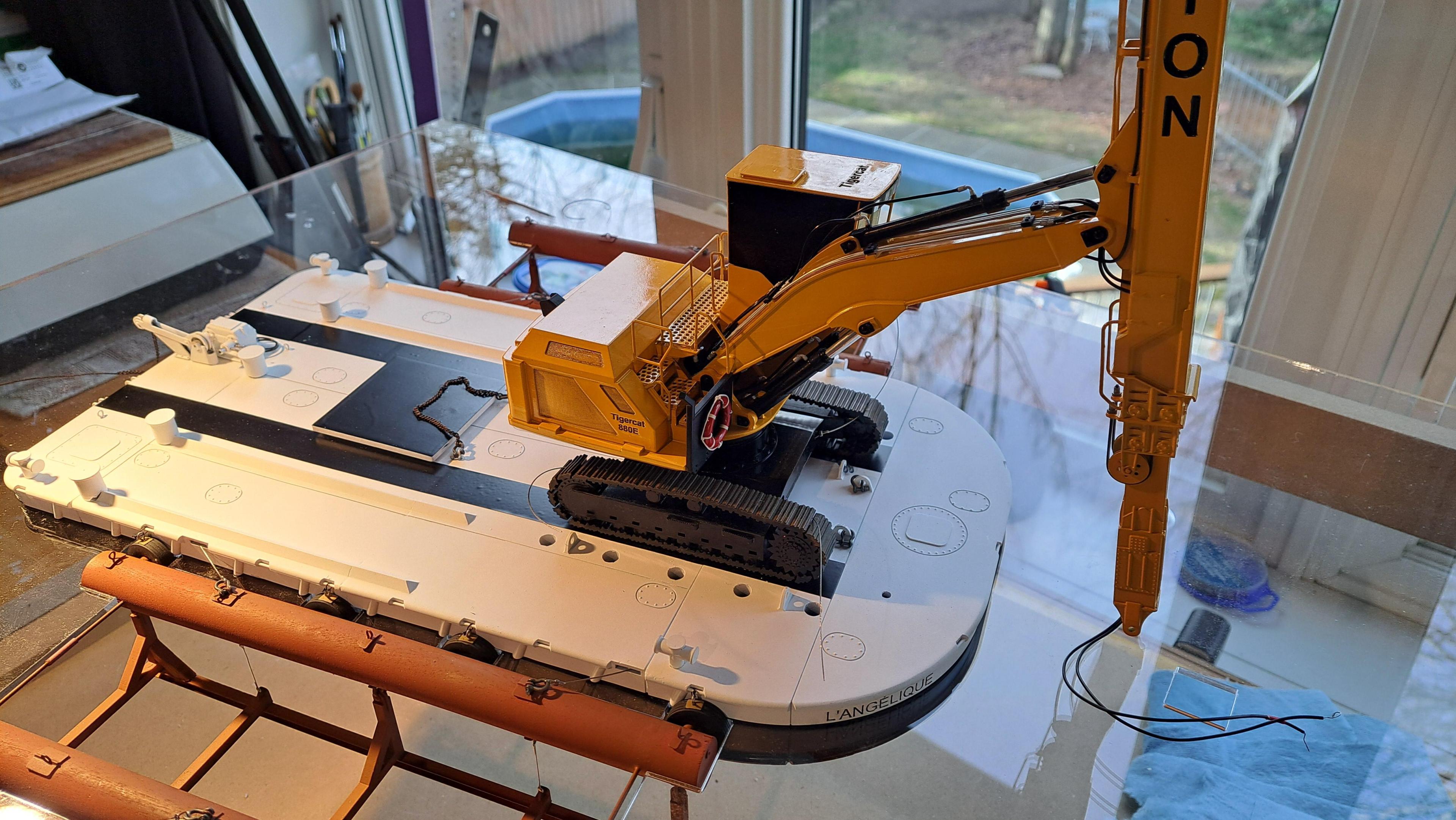

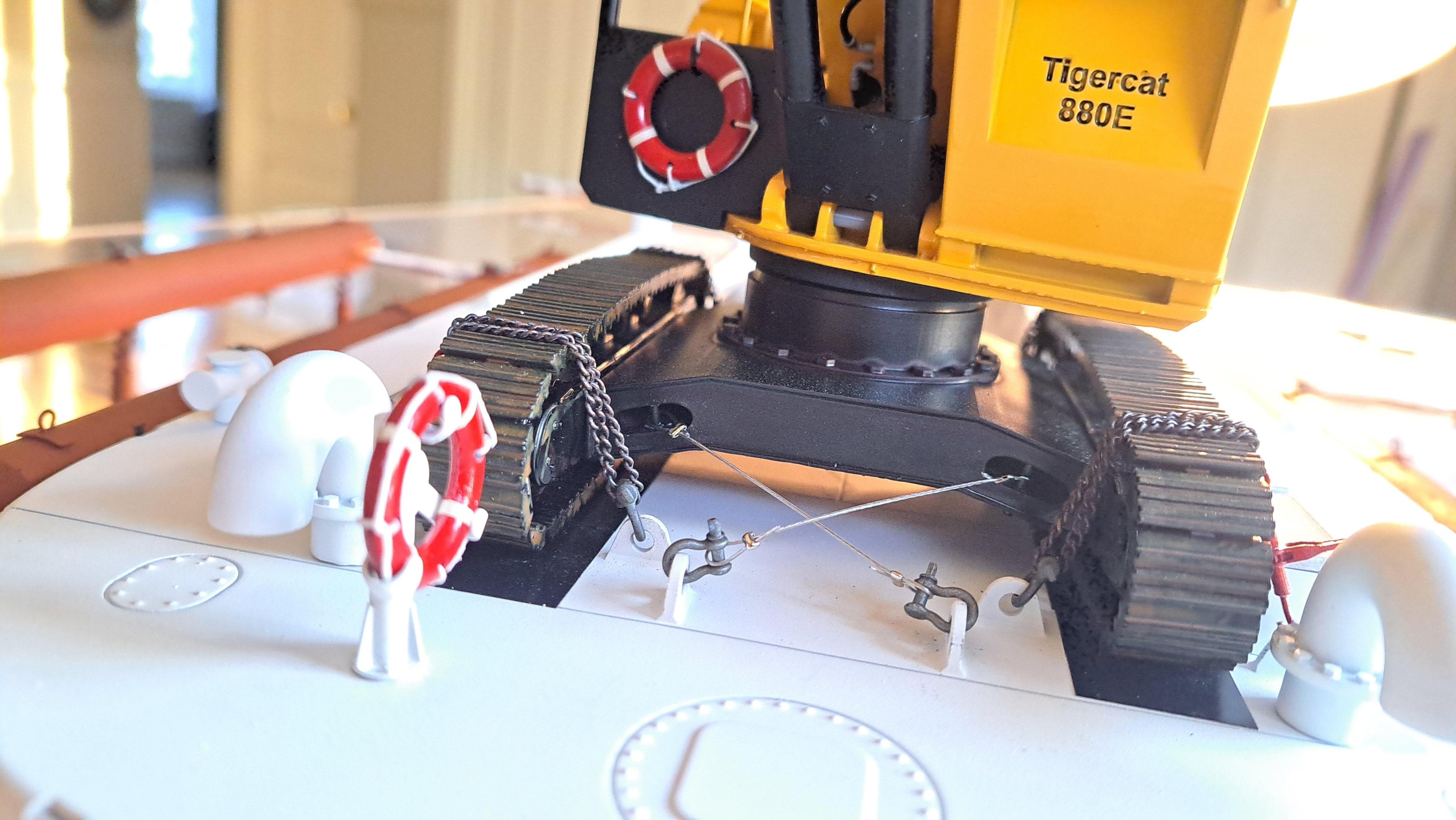

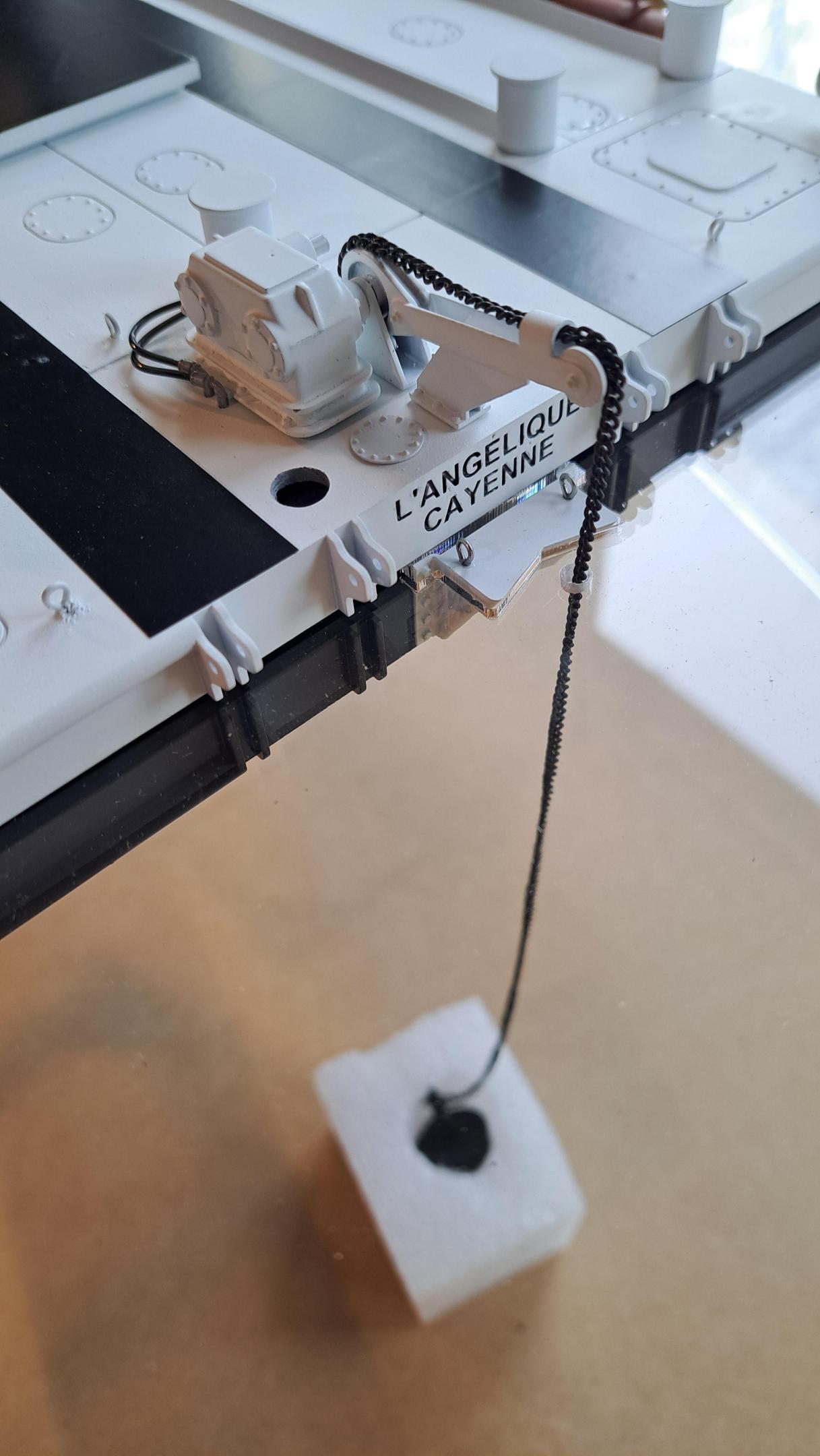

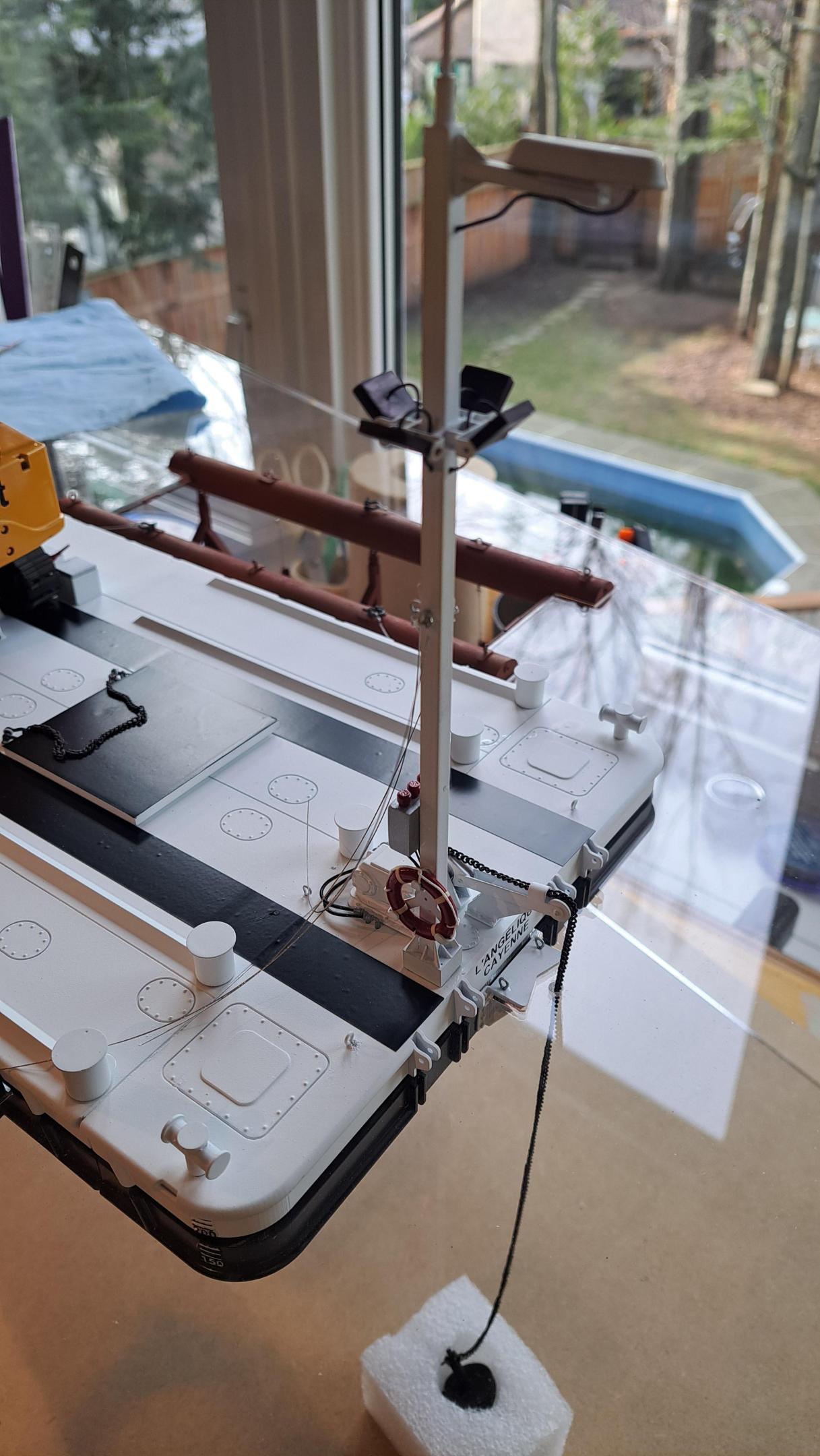

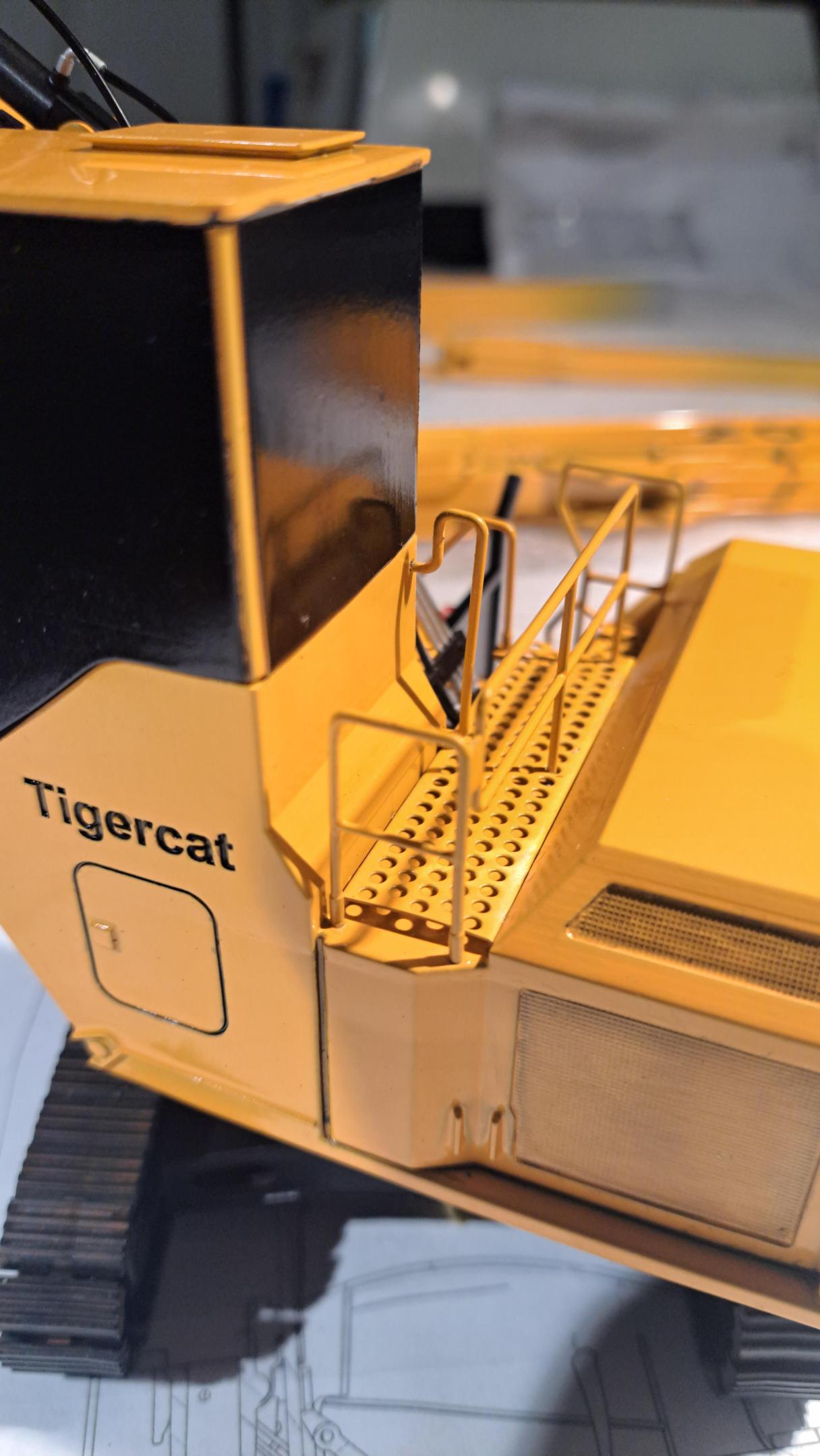

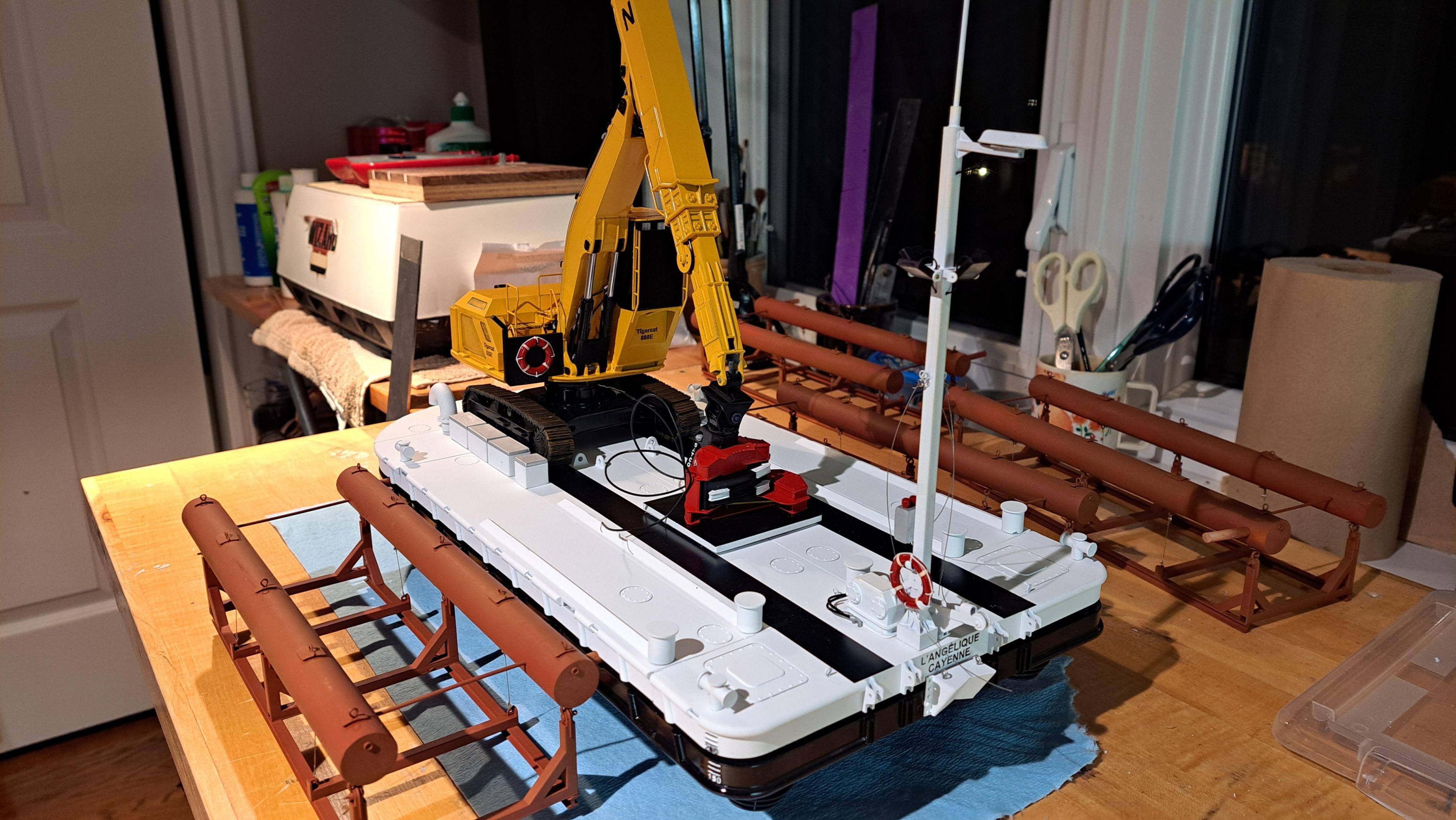

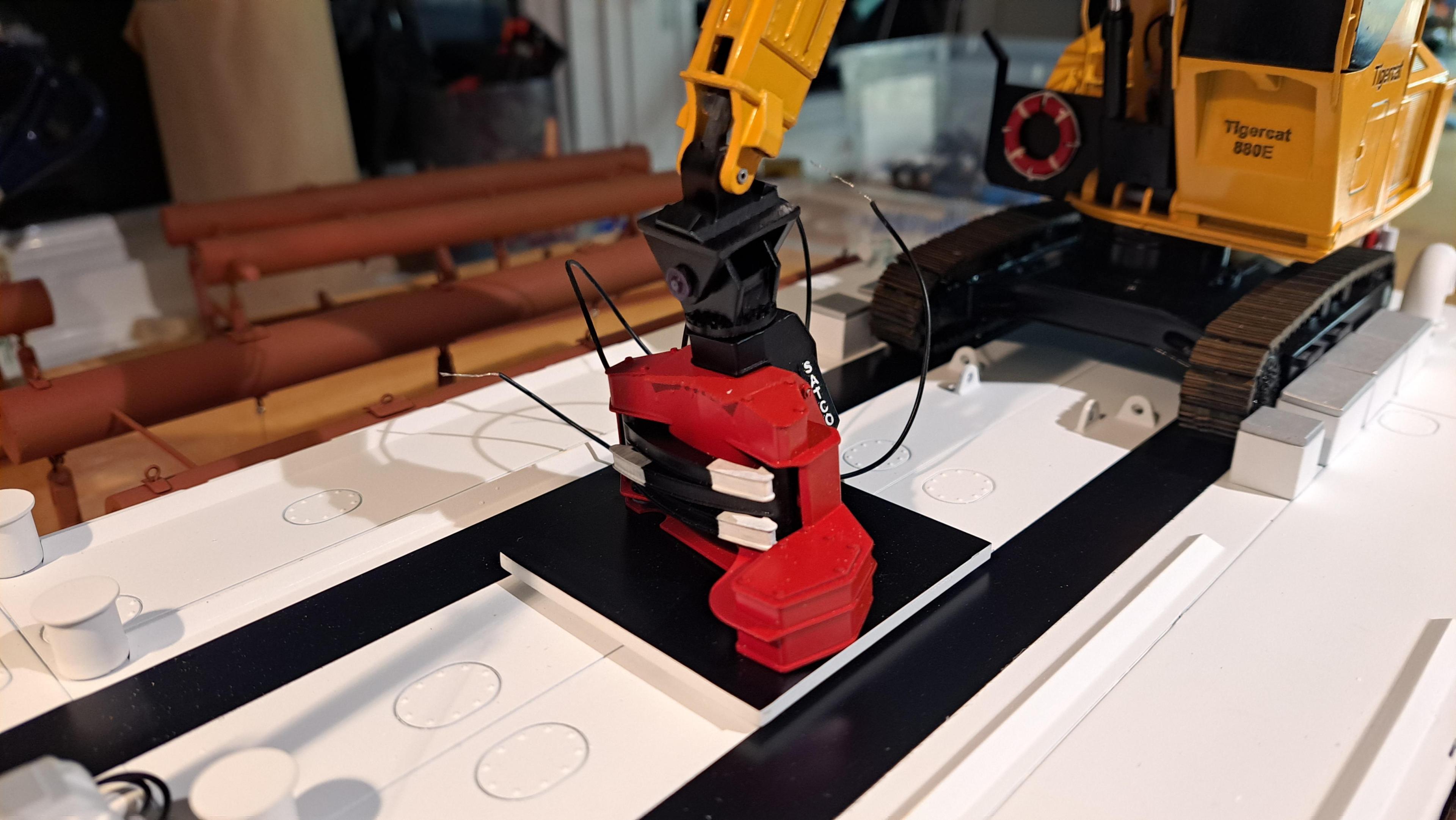

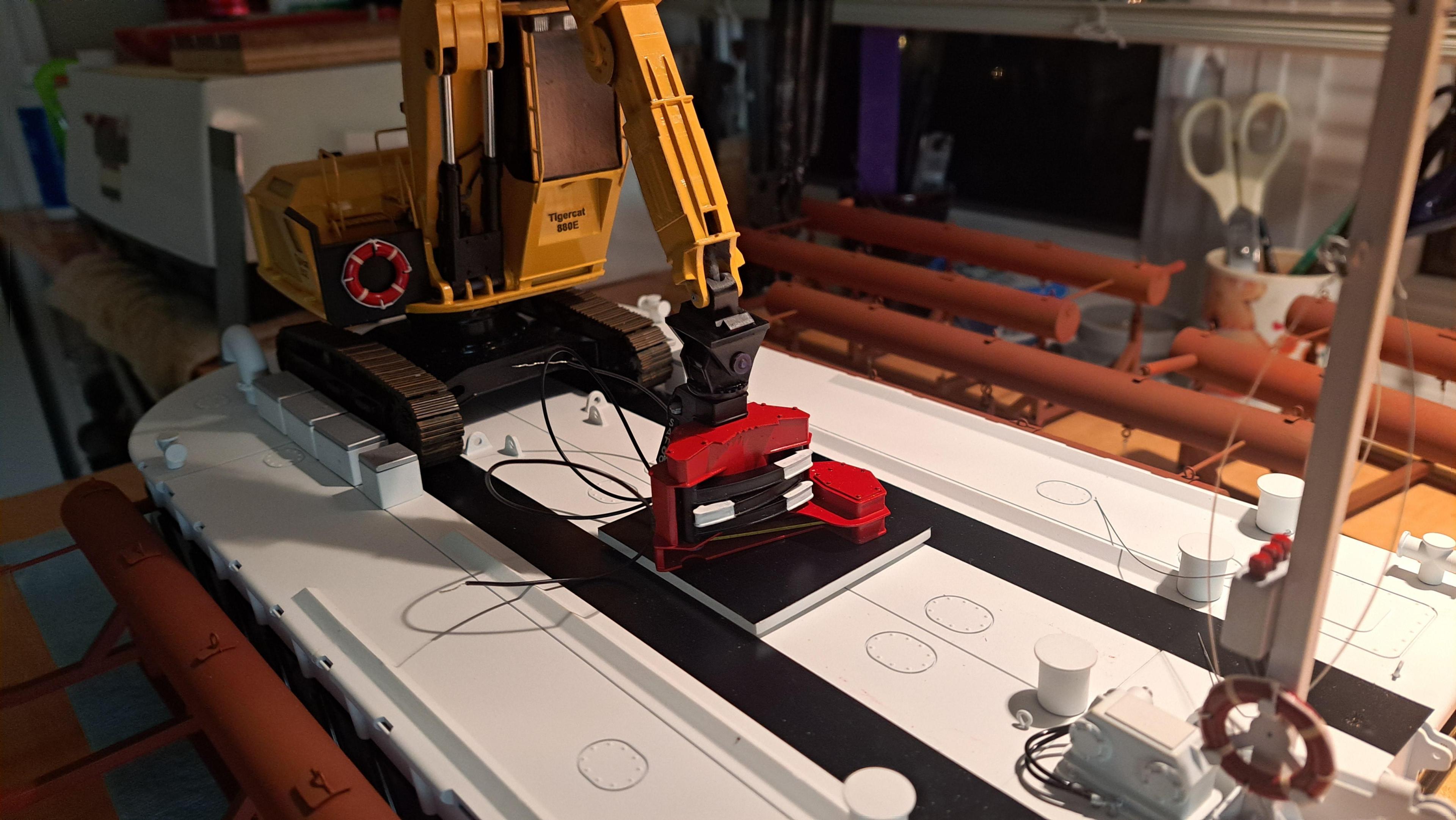

I was asked to 3d model and print a pair of Tigercat logger with a custom arm at 1/48 scale. I wasn't given the green light yet but I decided to go ahead and start the project anyway. Worst case scenario, I'll have a couple of nice loggers to add to my collection. I'm not used to work at such small scale but this logger is a big machine so it will still be a good size model.

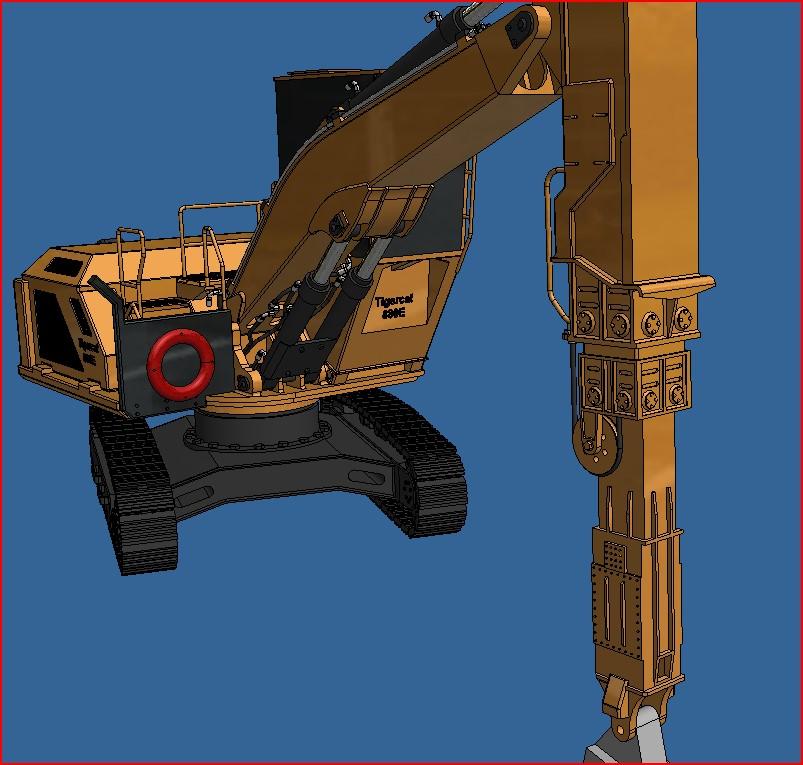

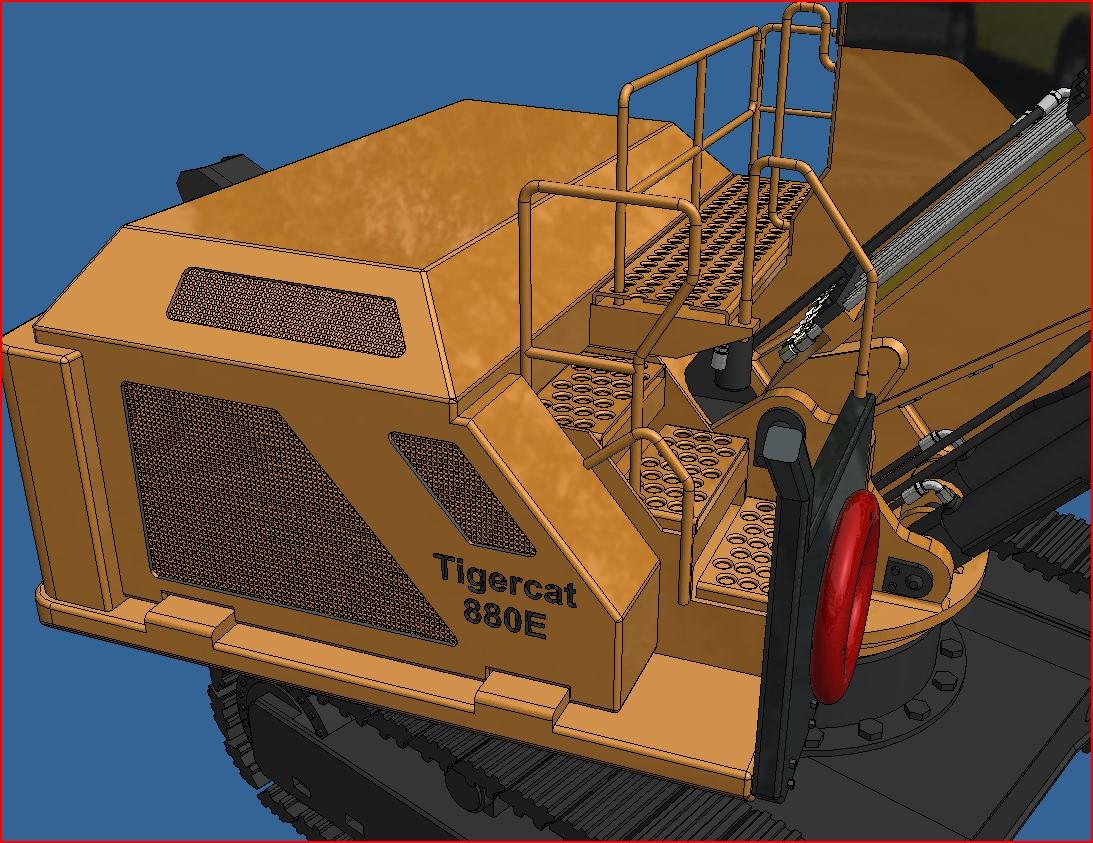

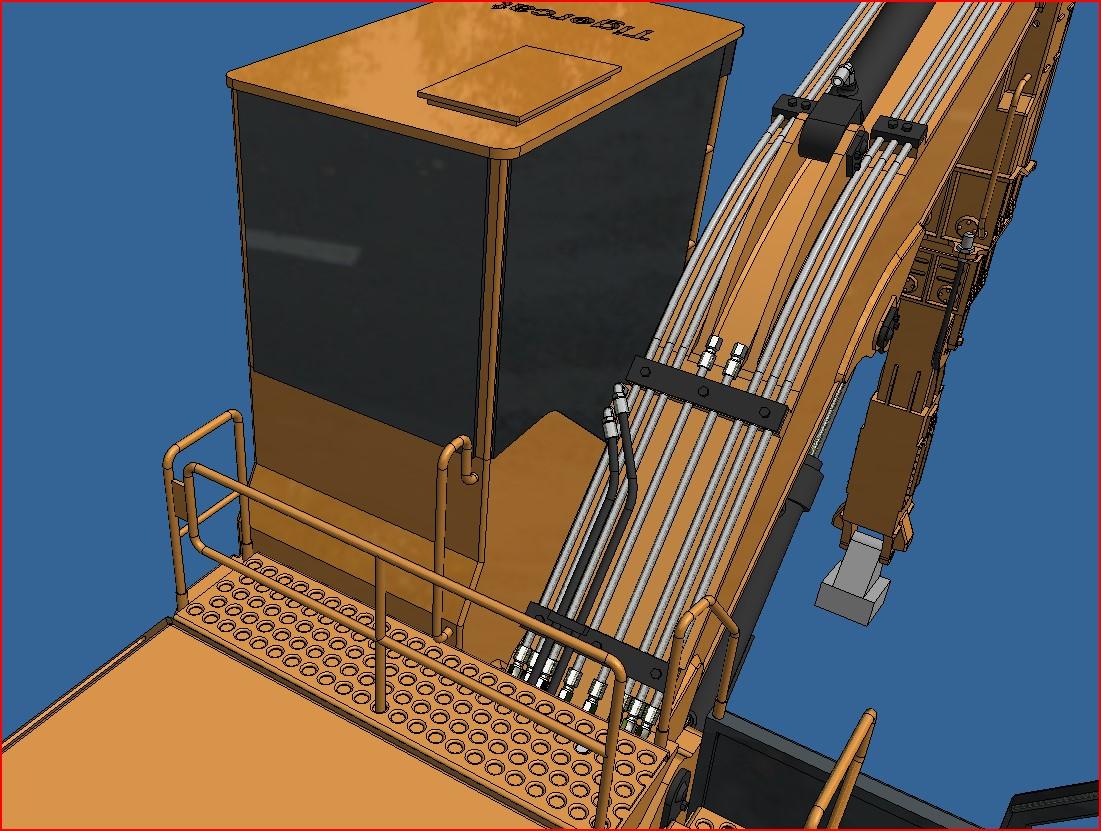

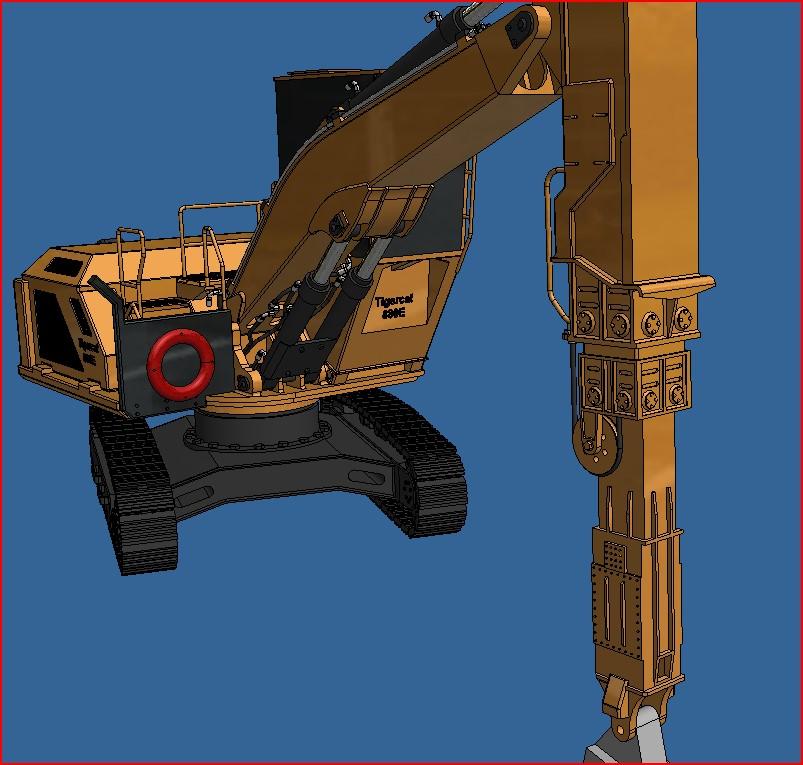

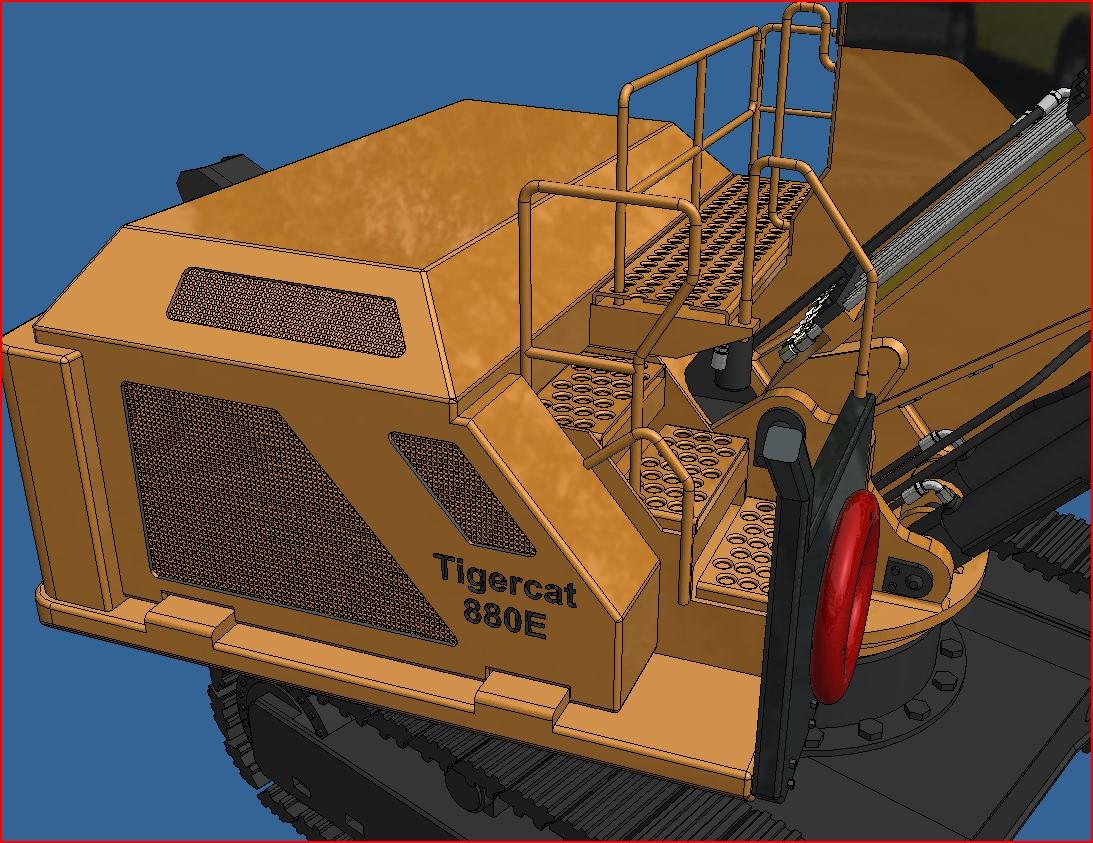

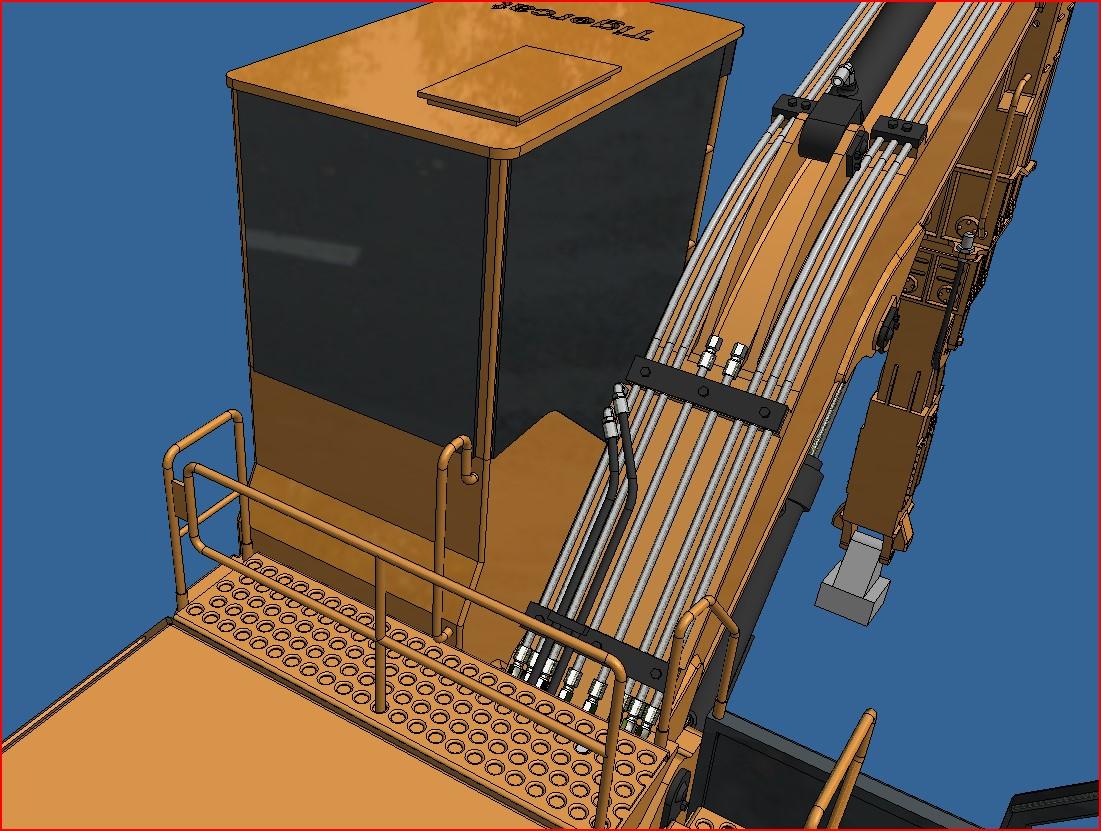

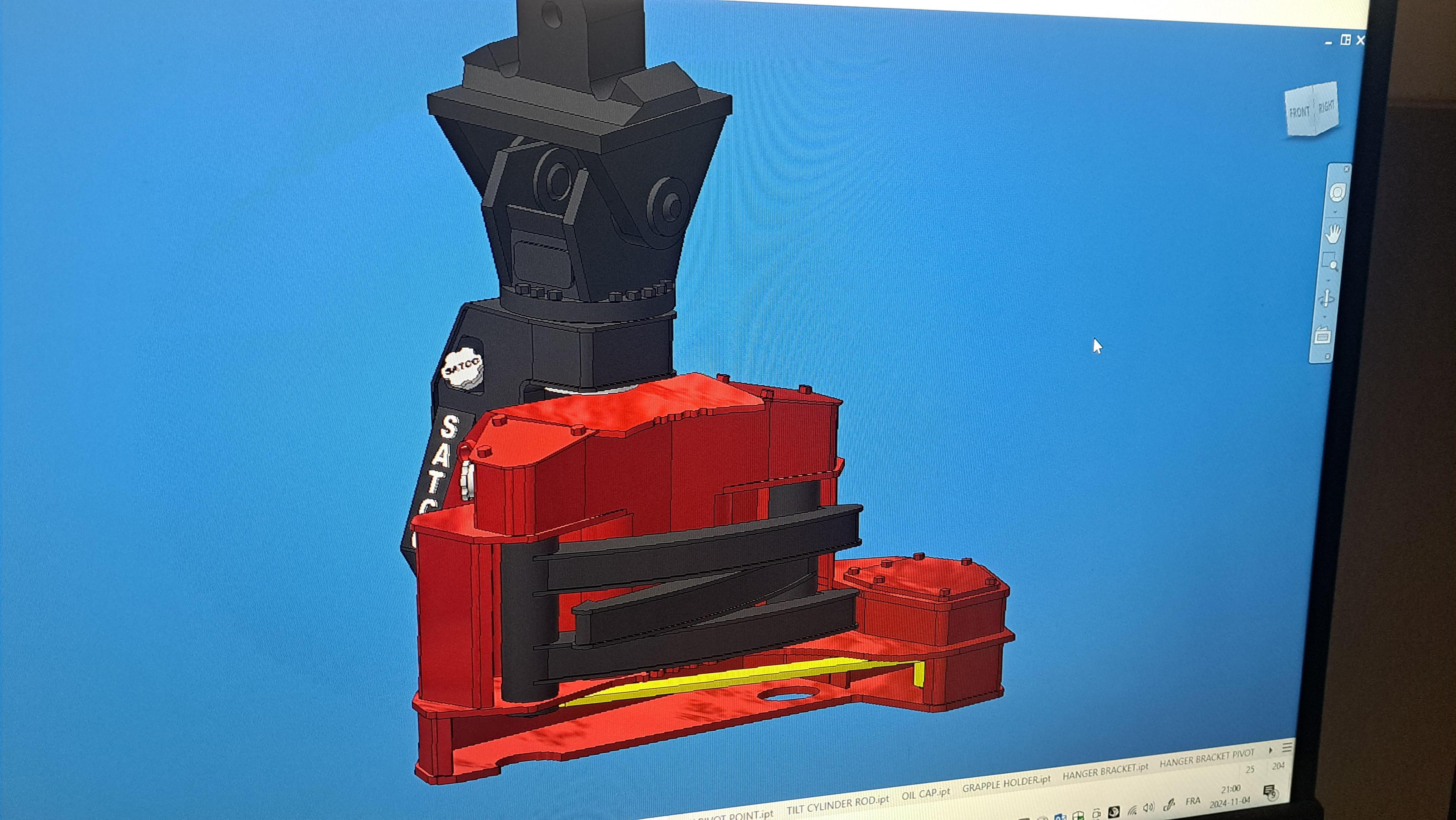

Here are a few shots of the 3d model

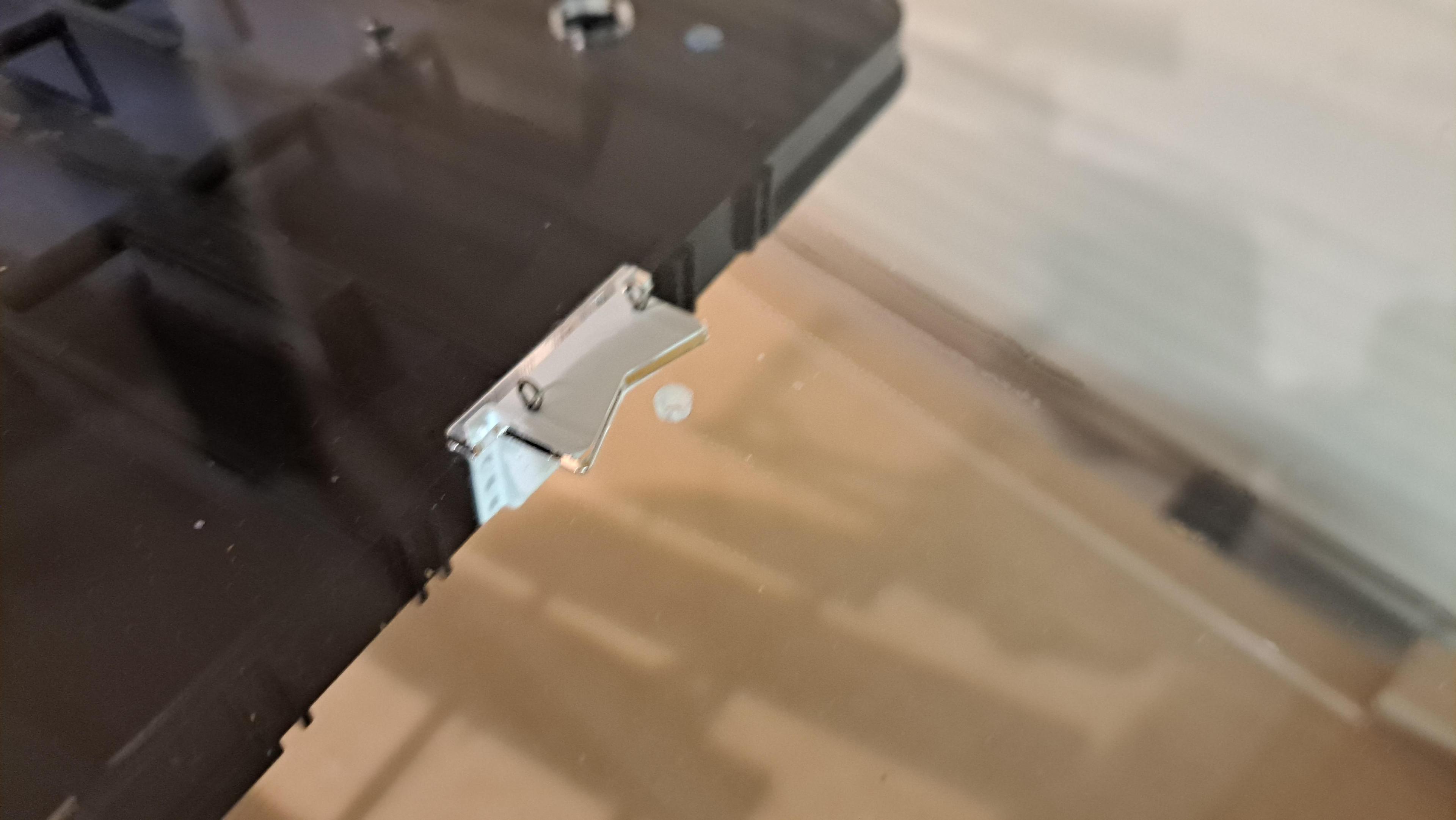

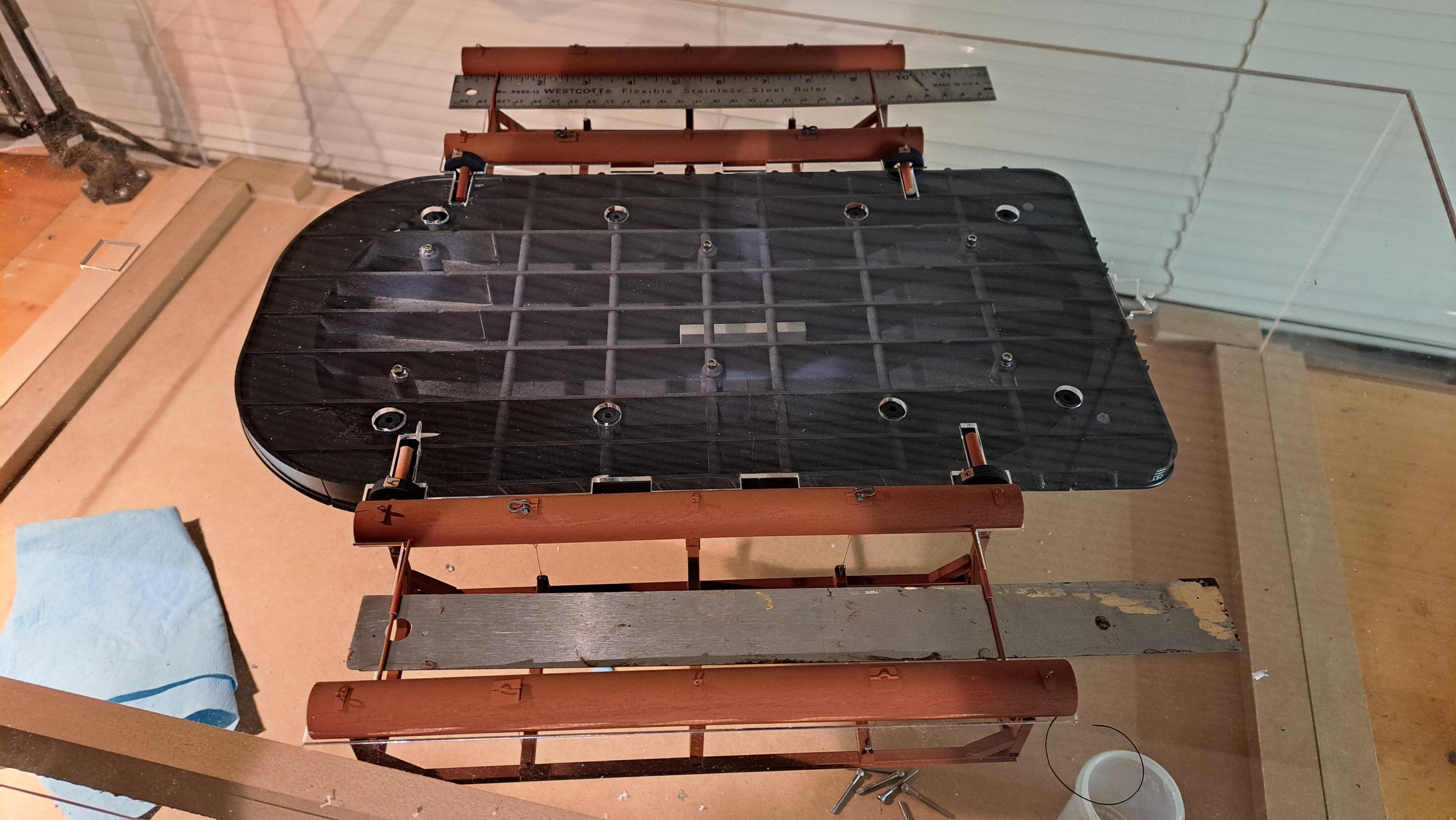

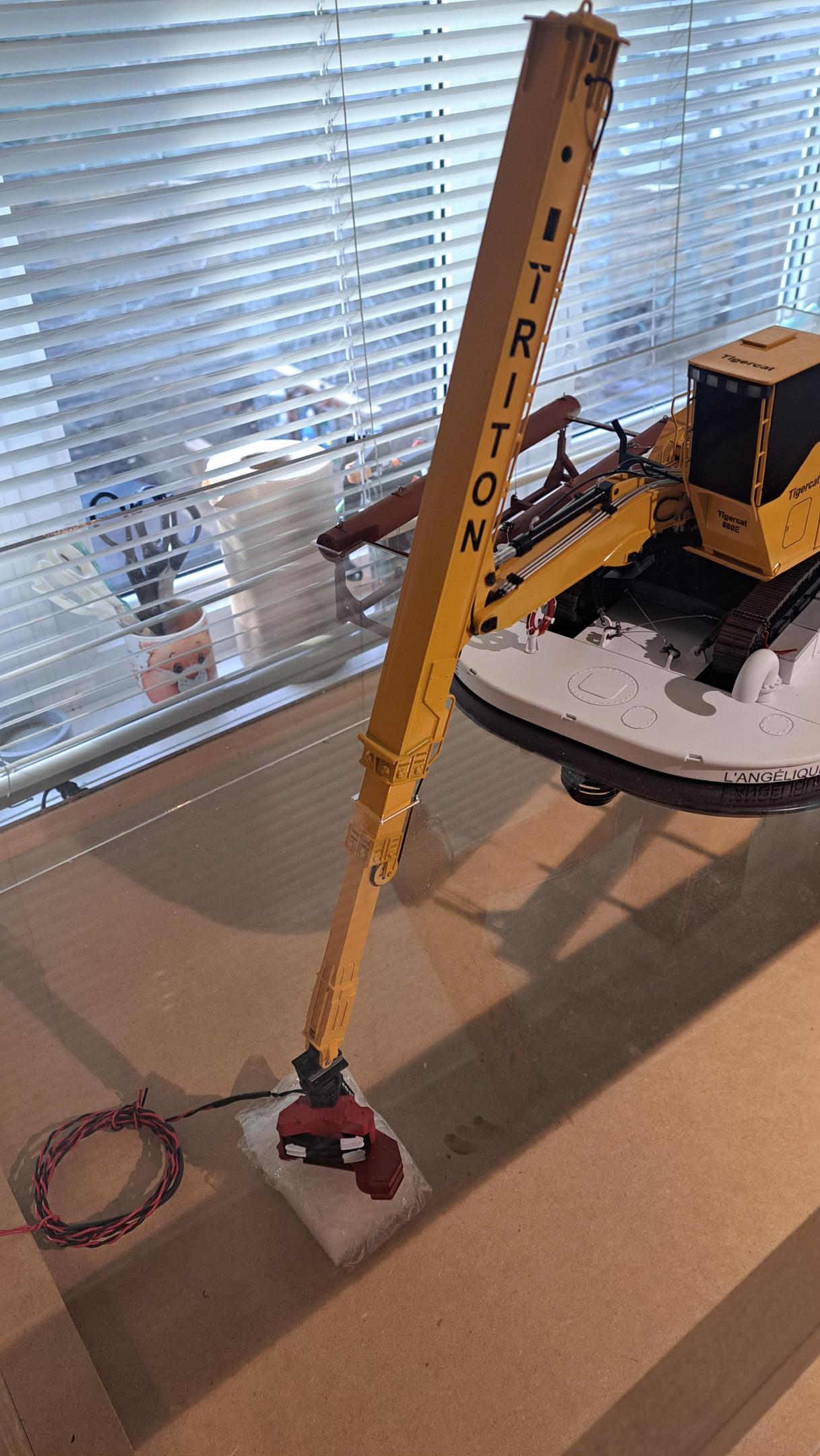

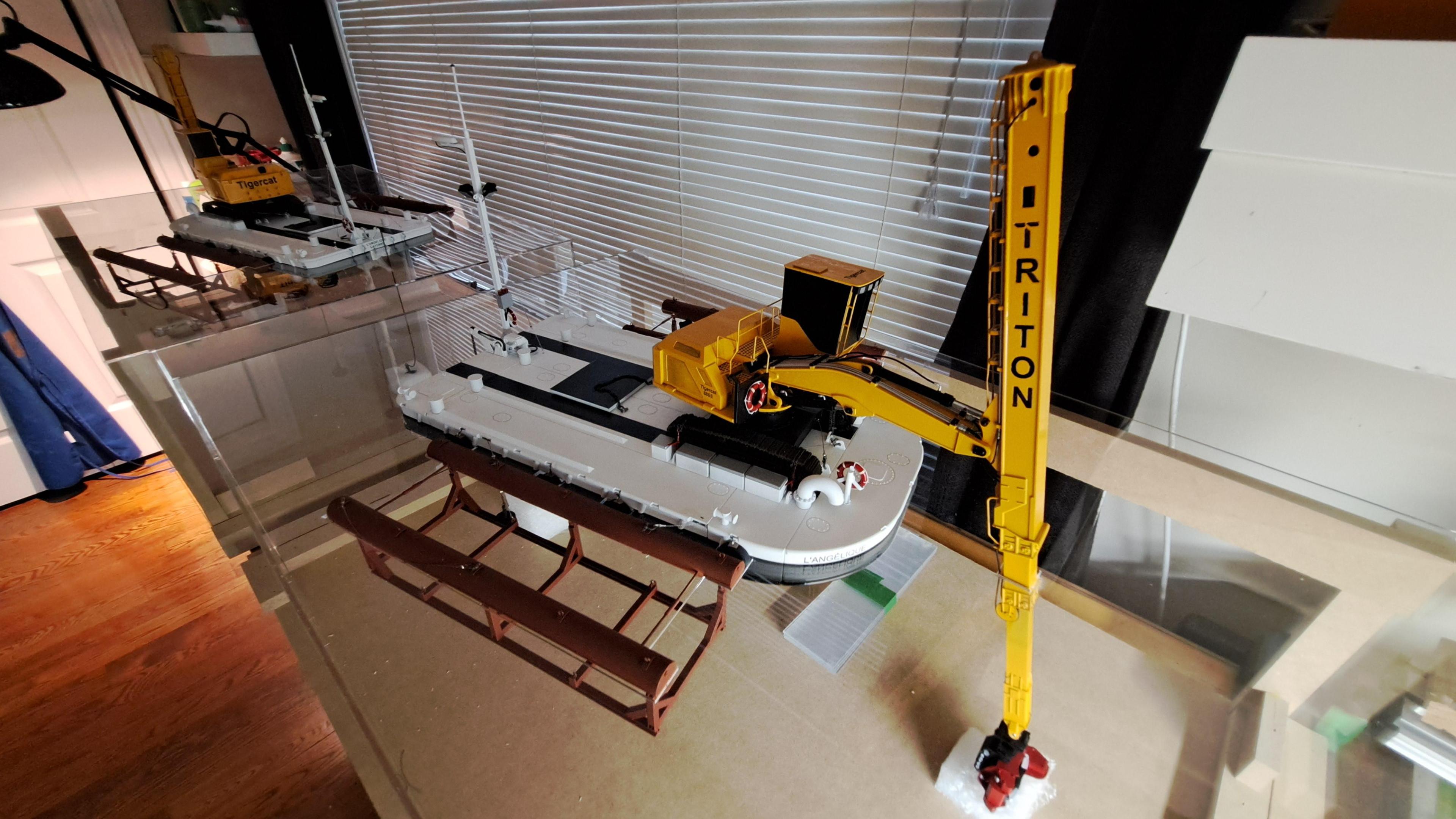

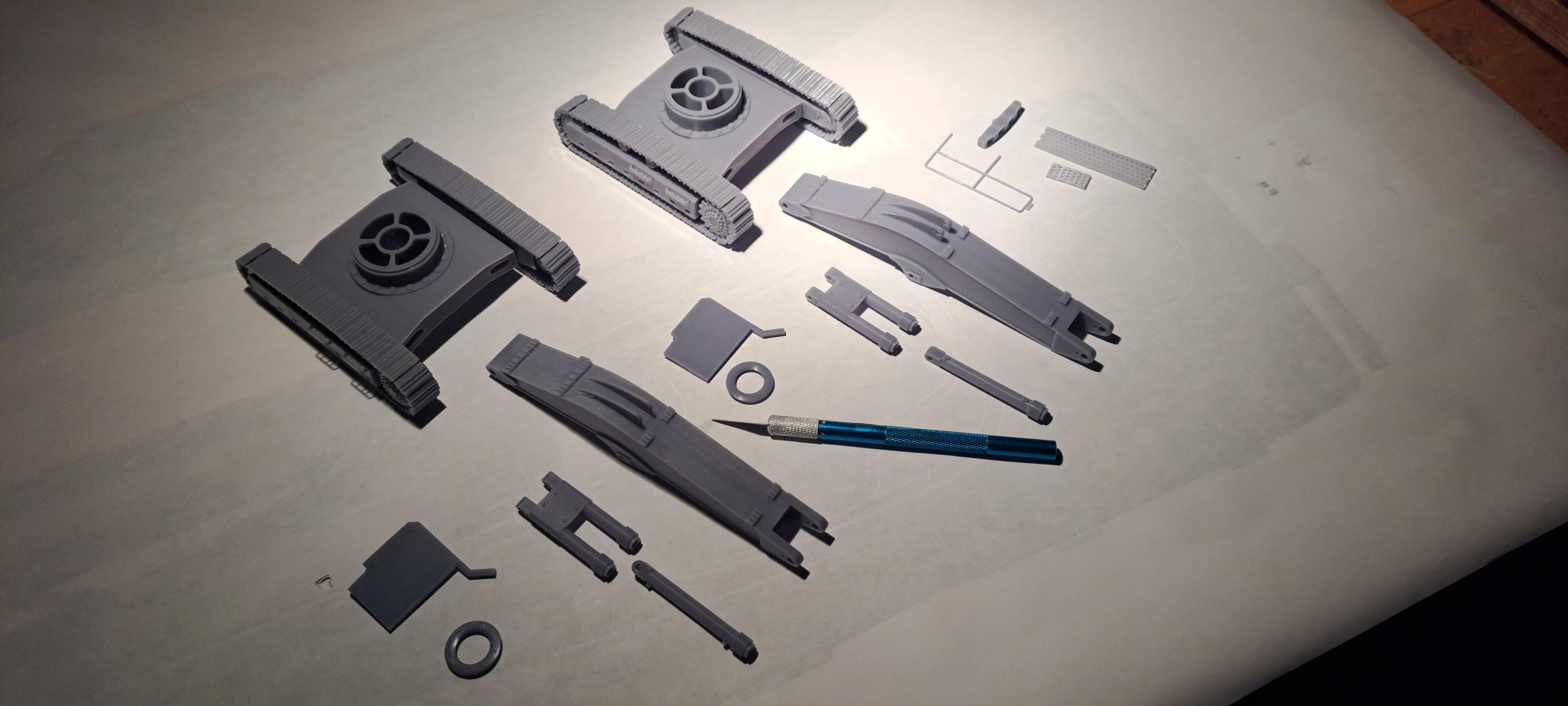

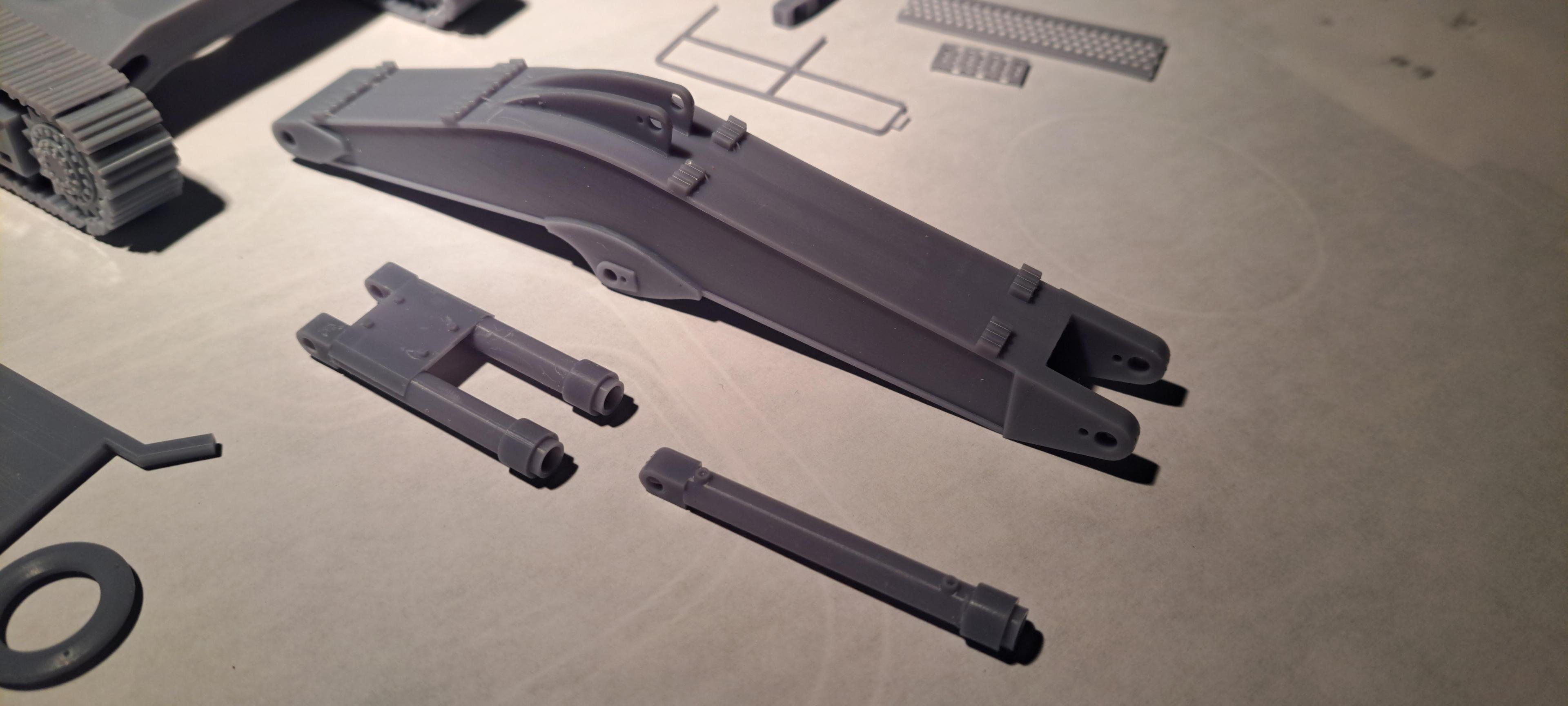

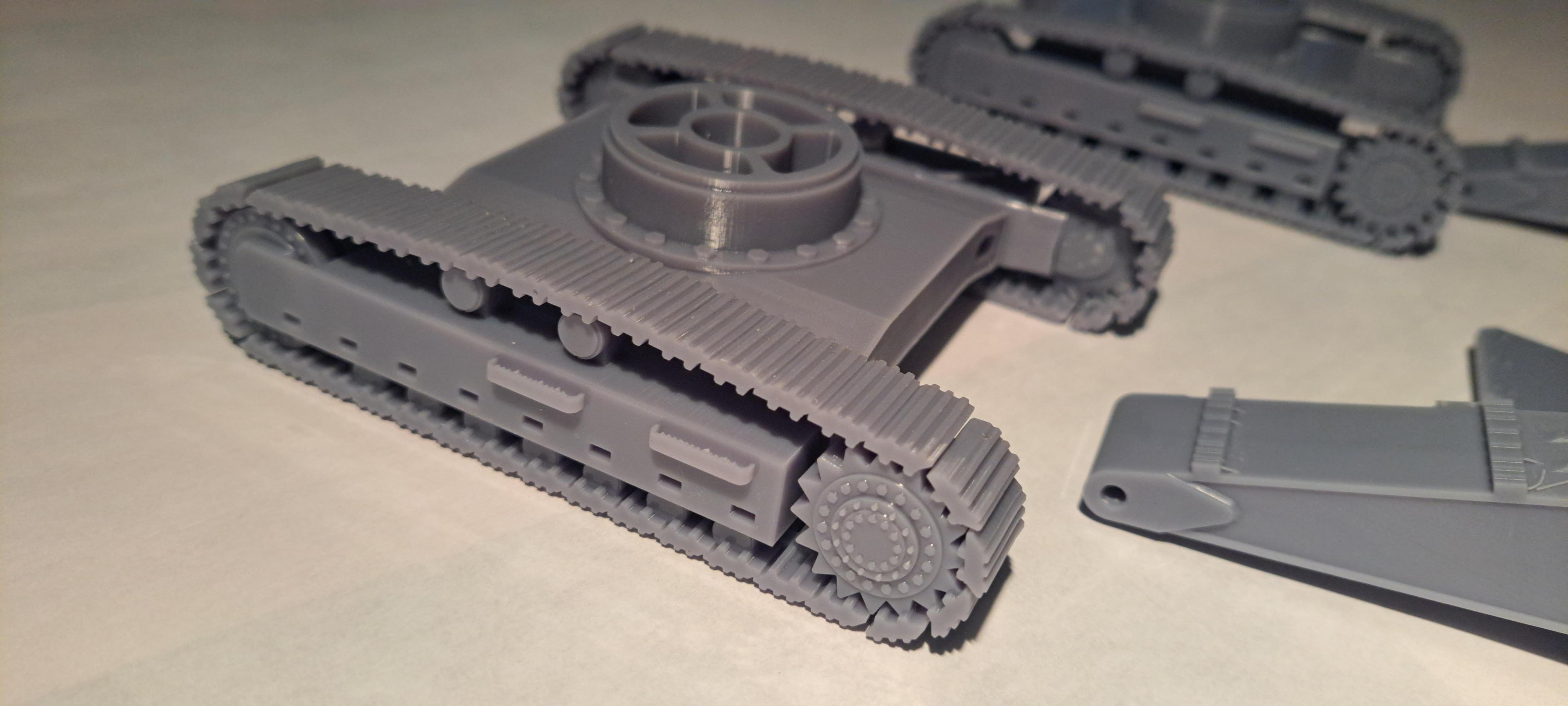

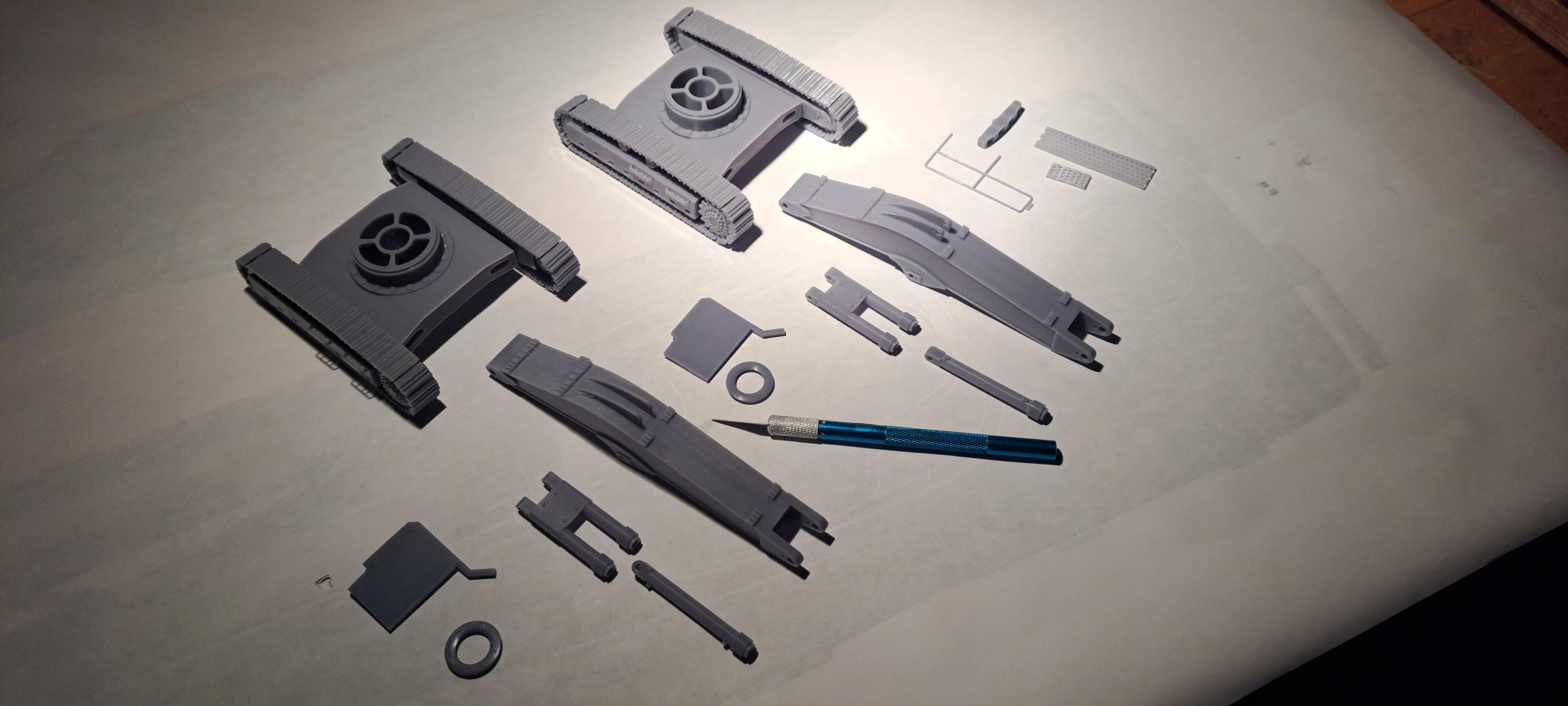

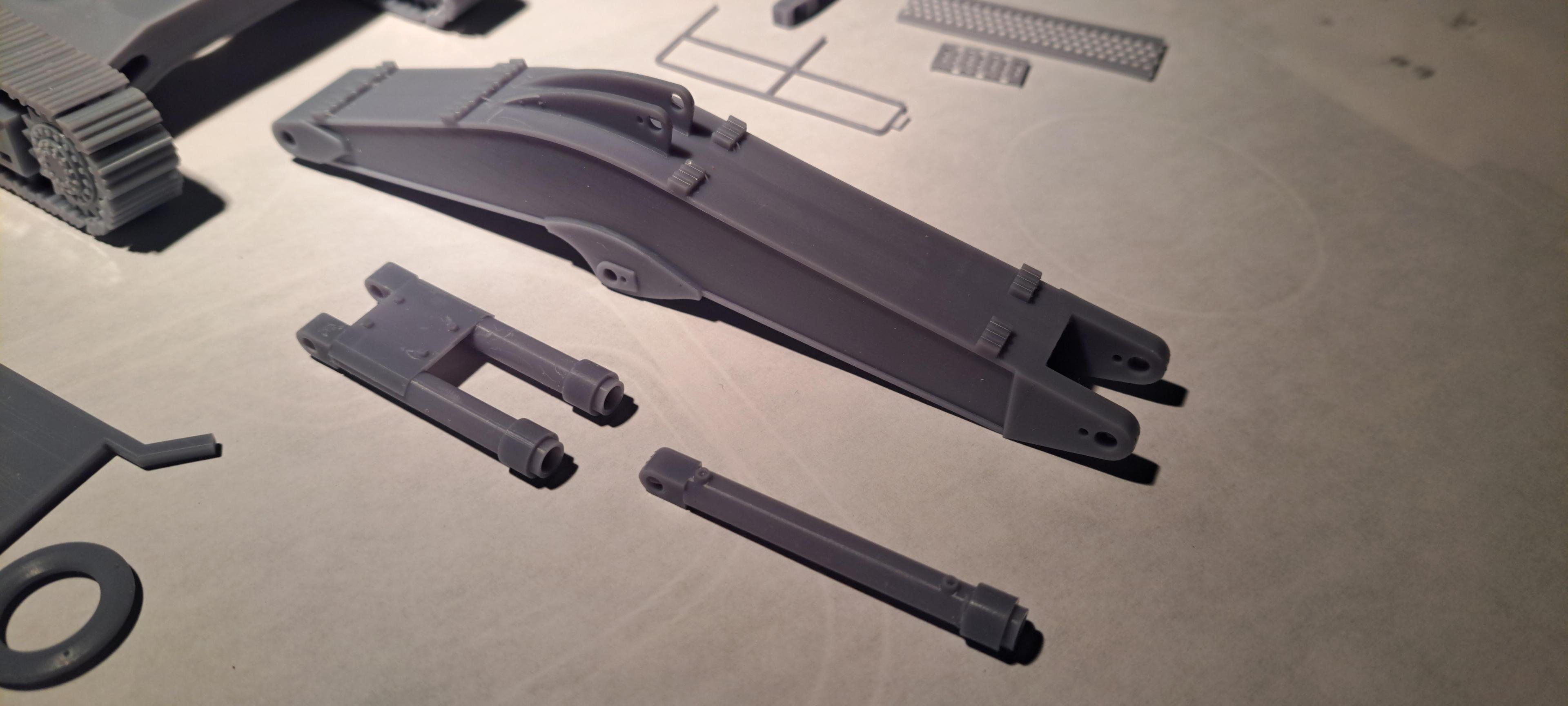

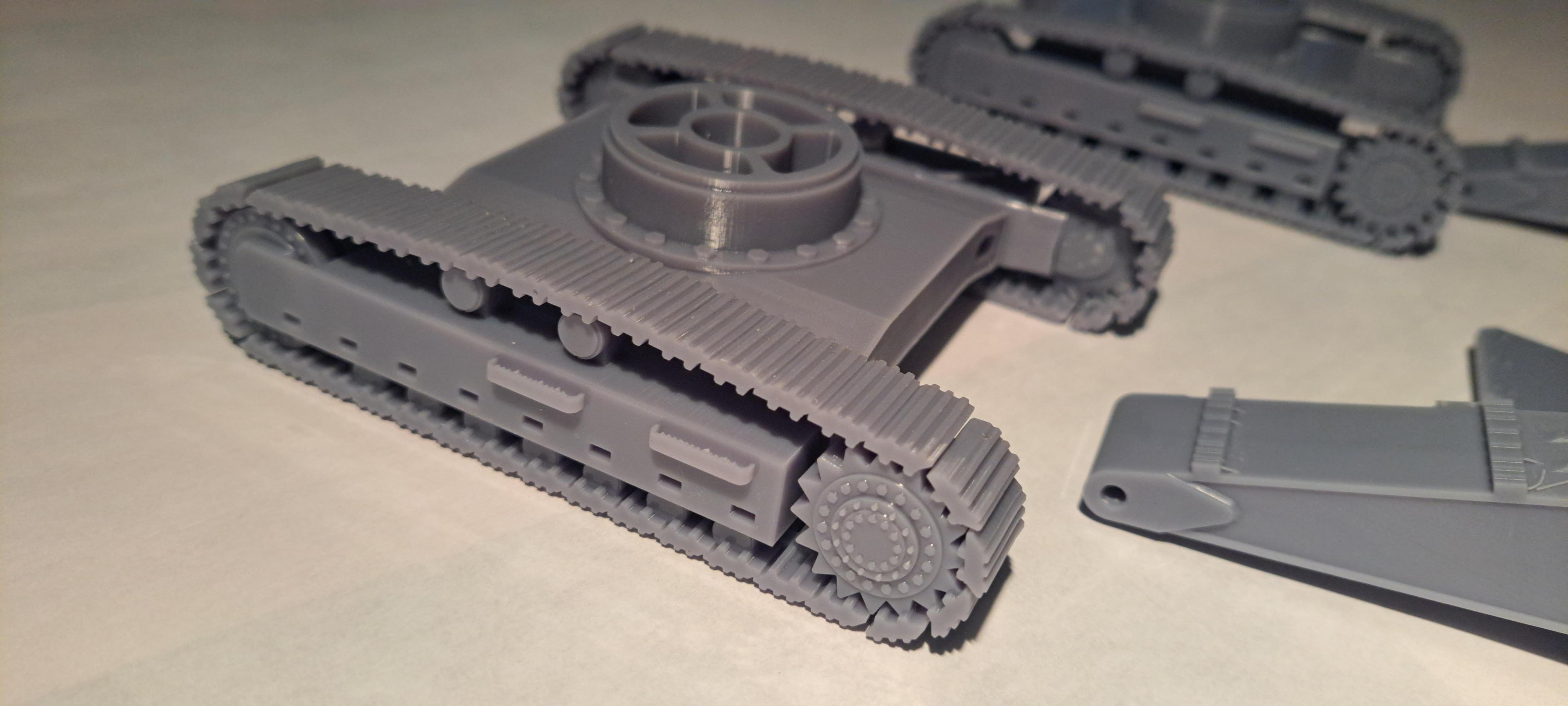

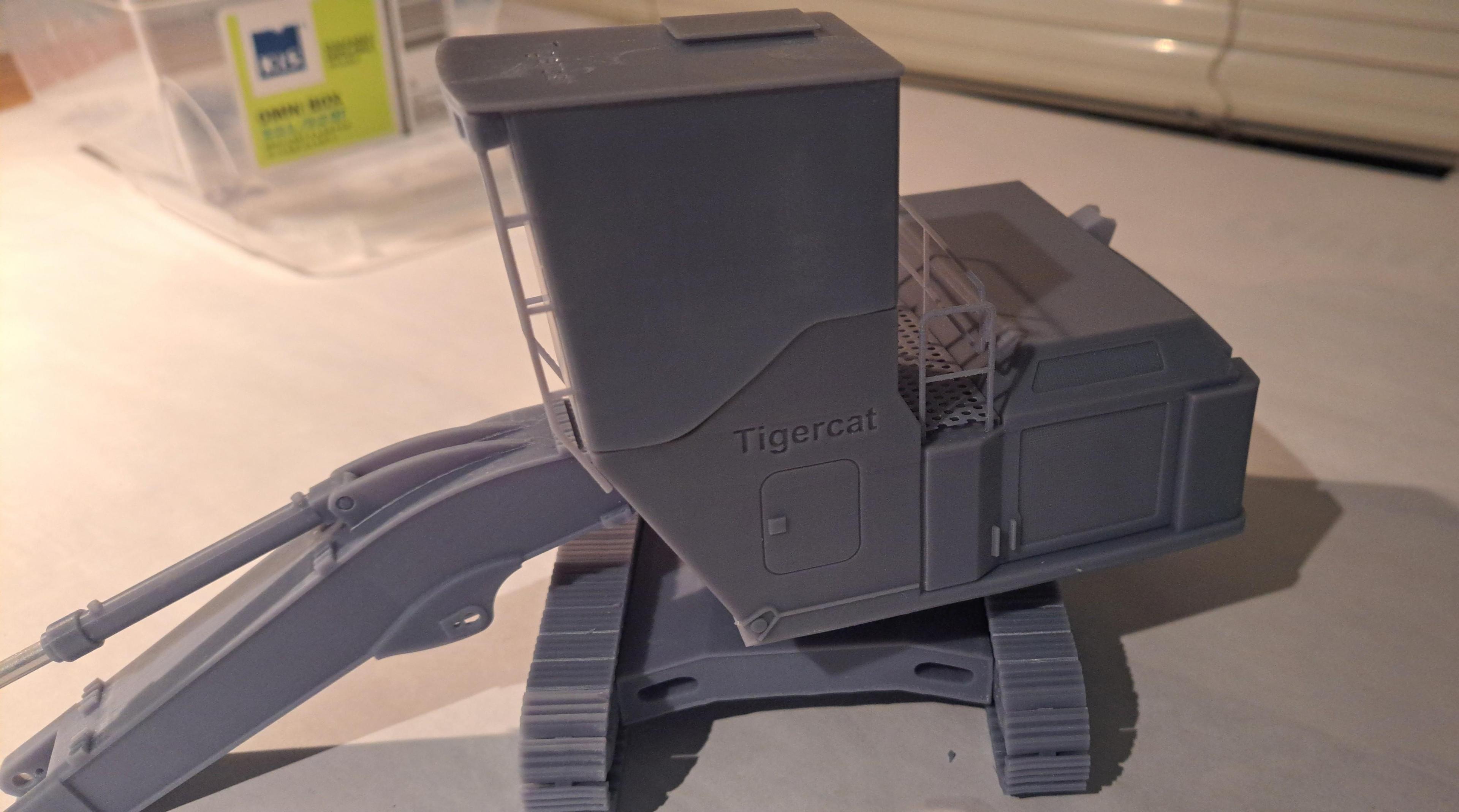

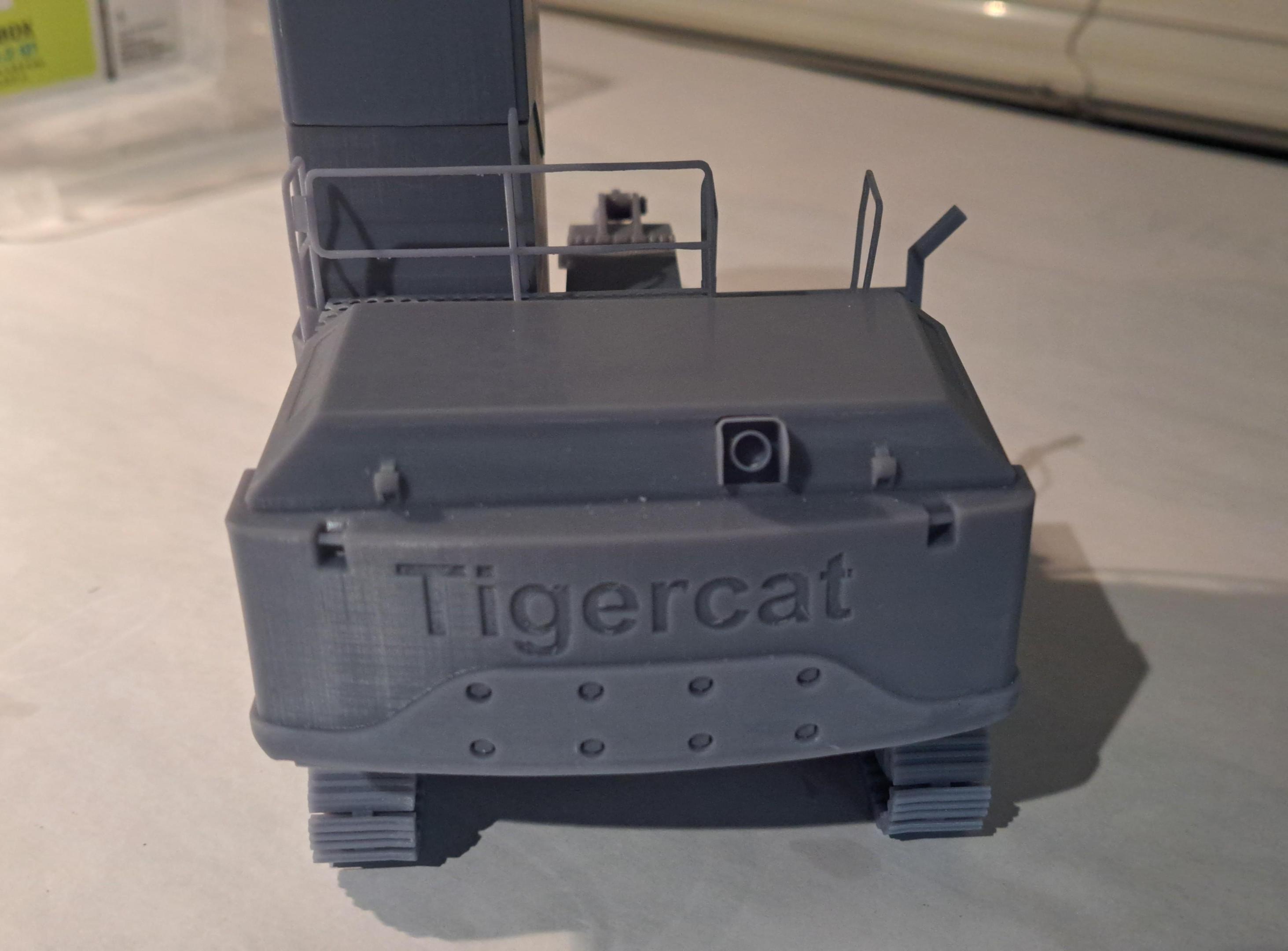

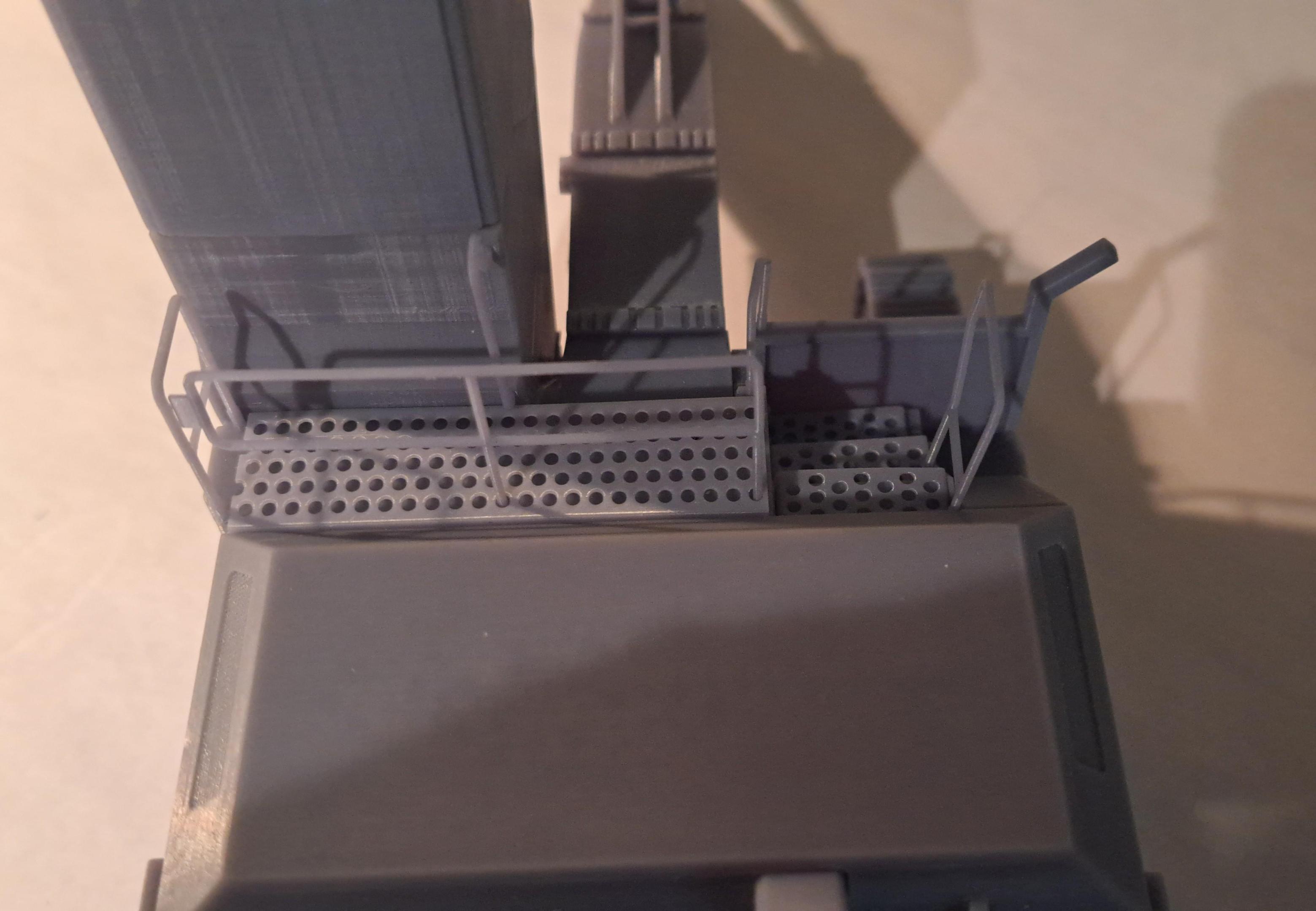

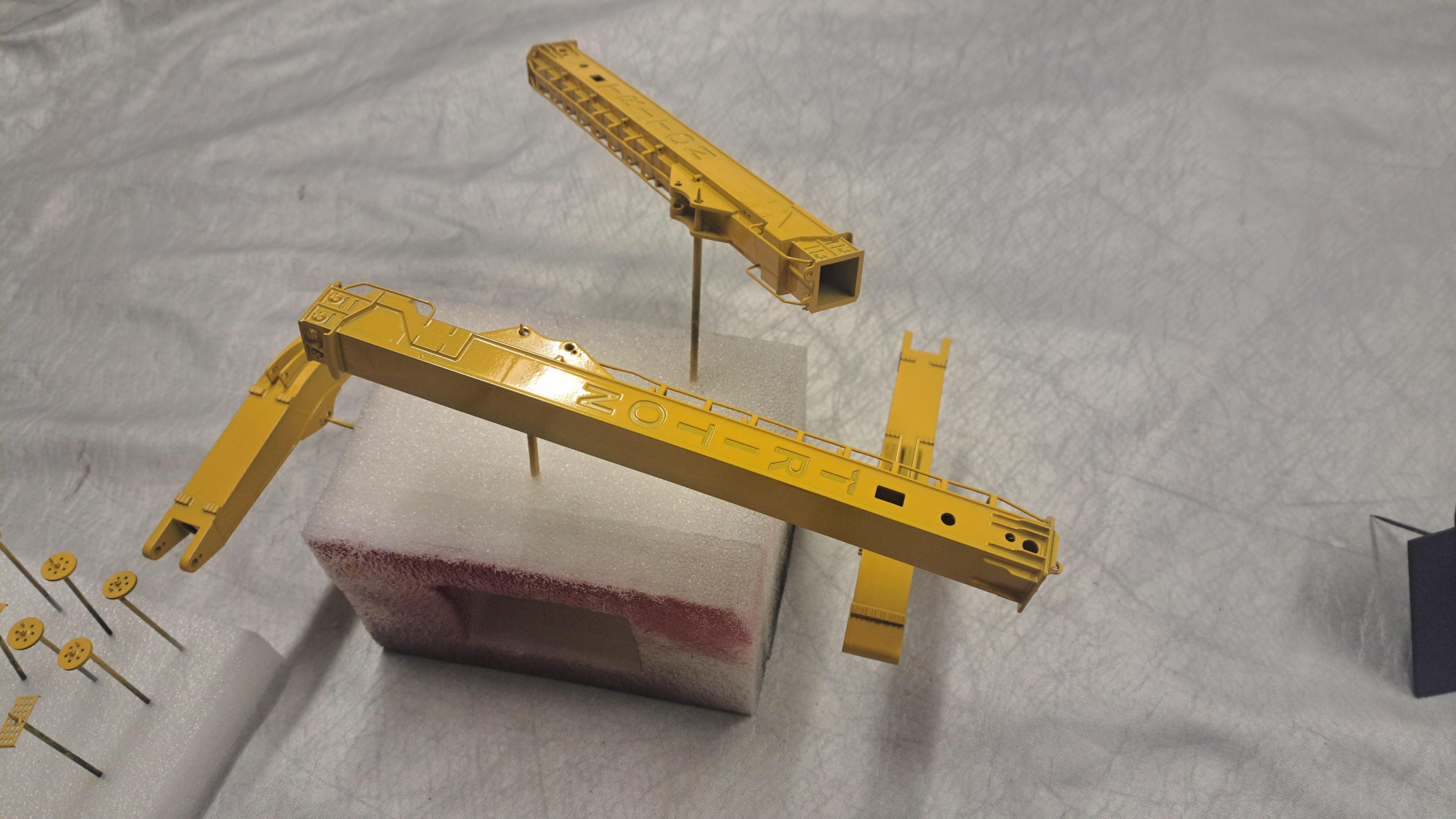

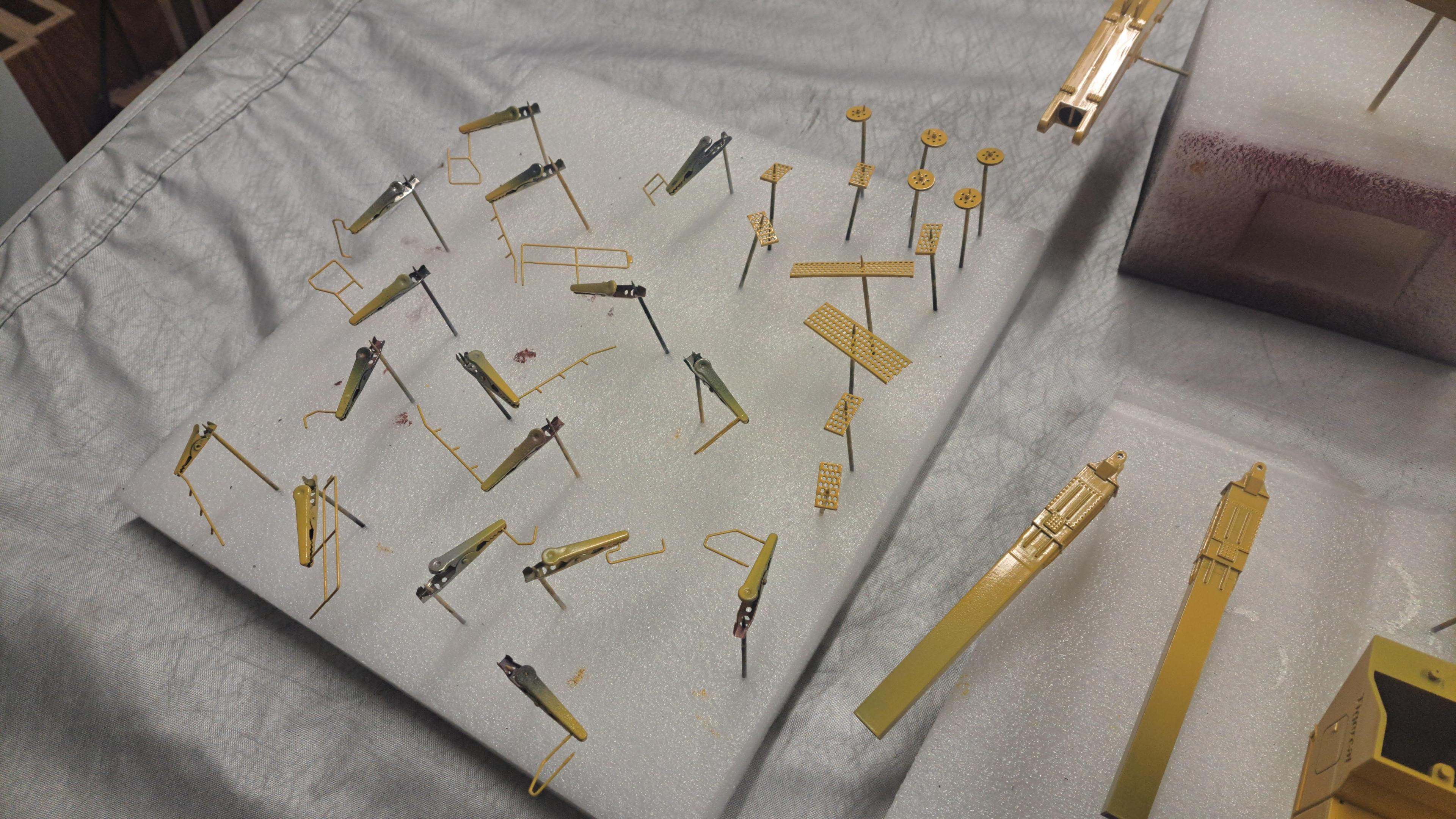

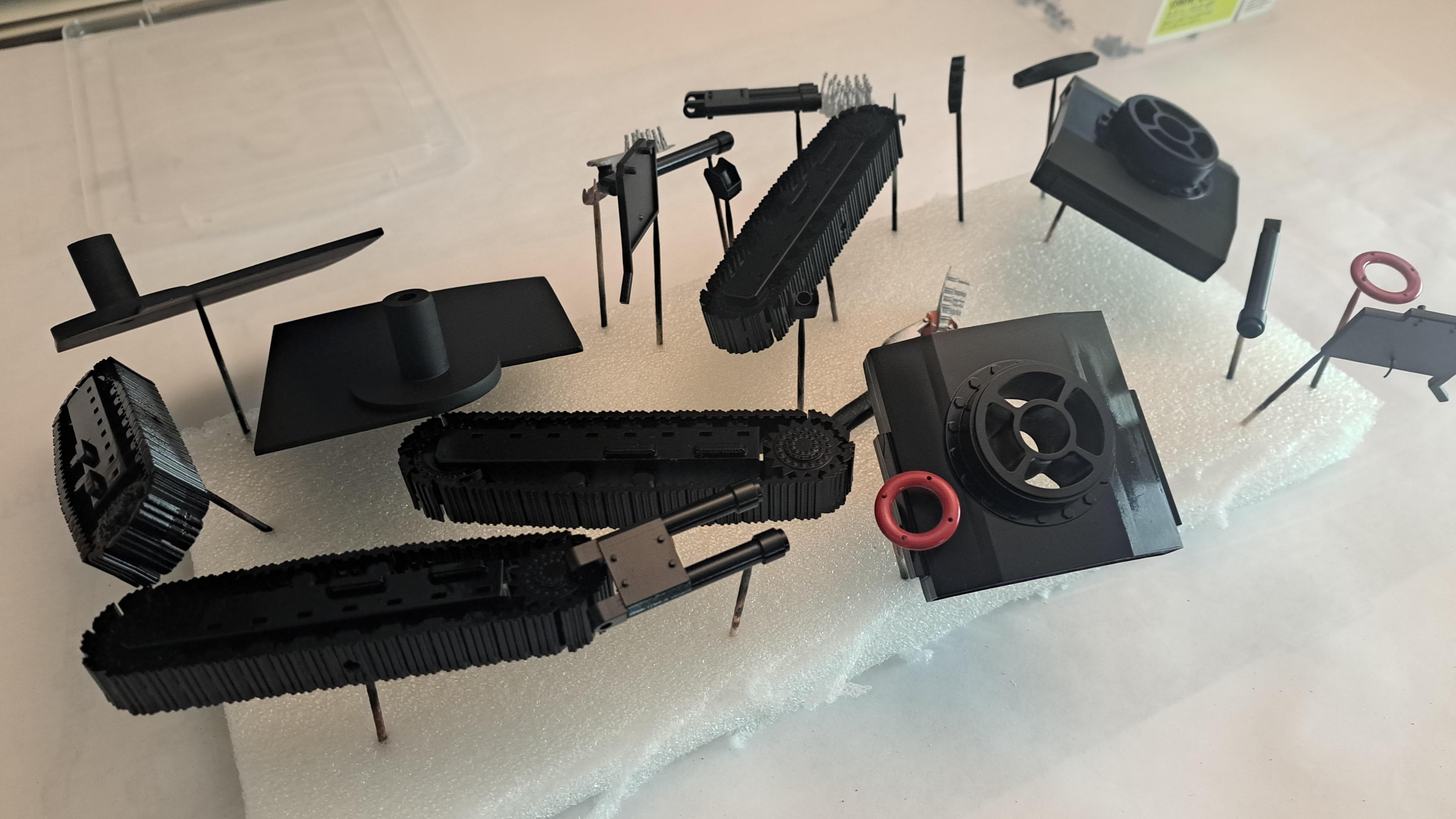

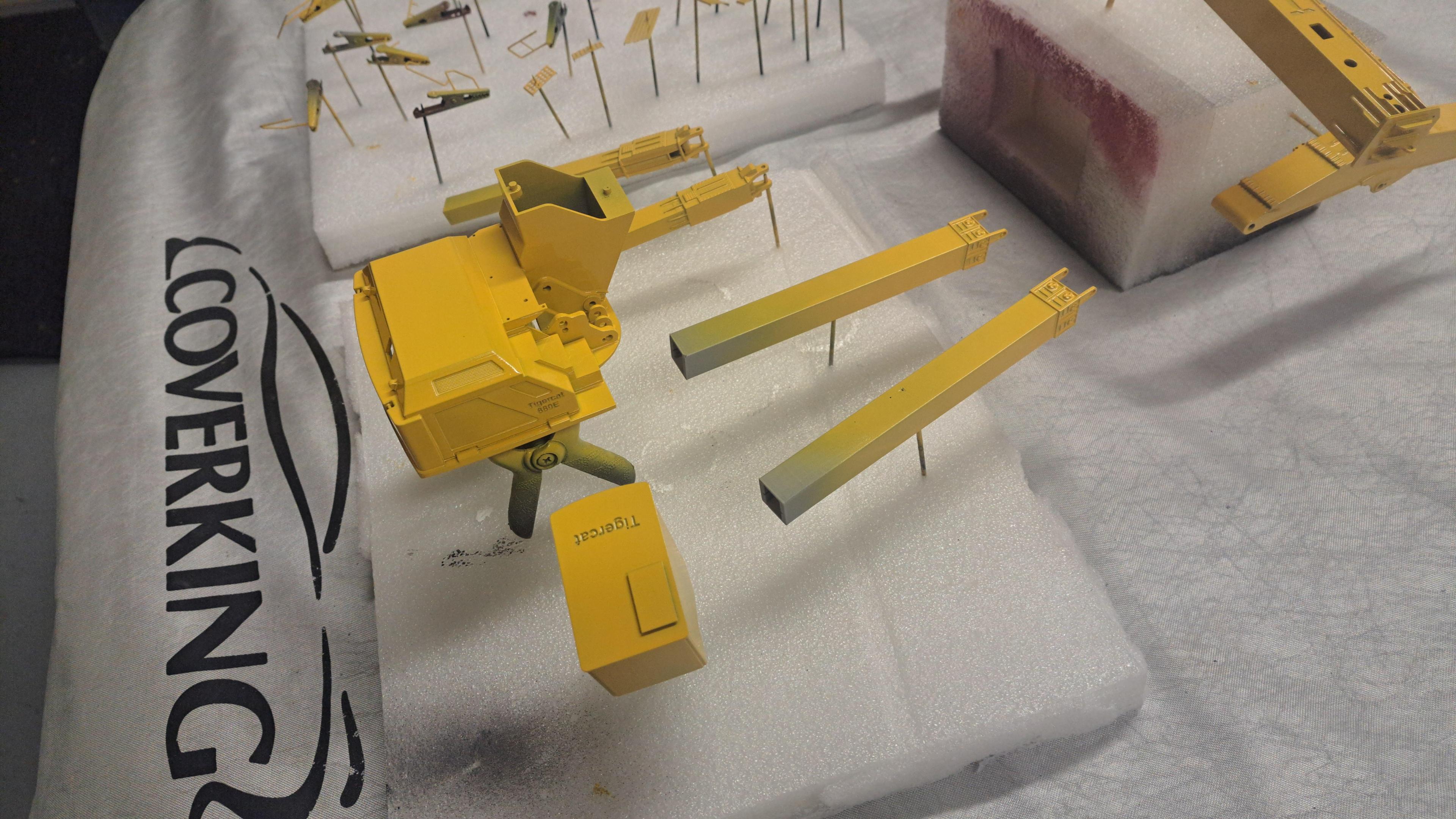

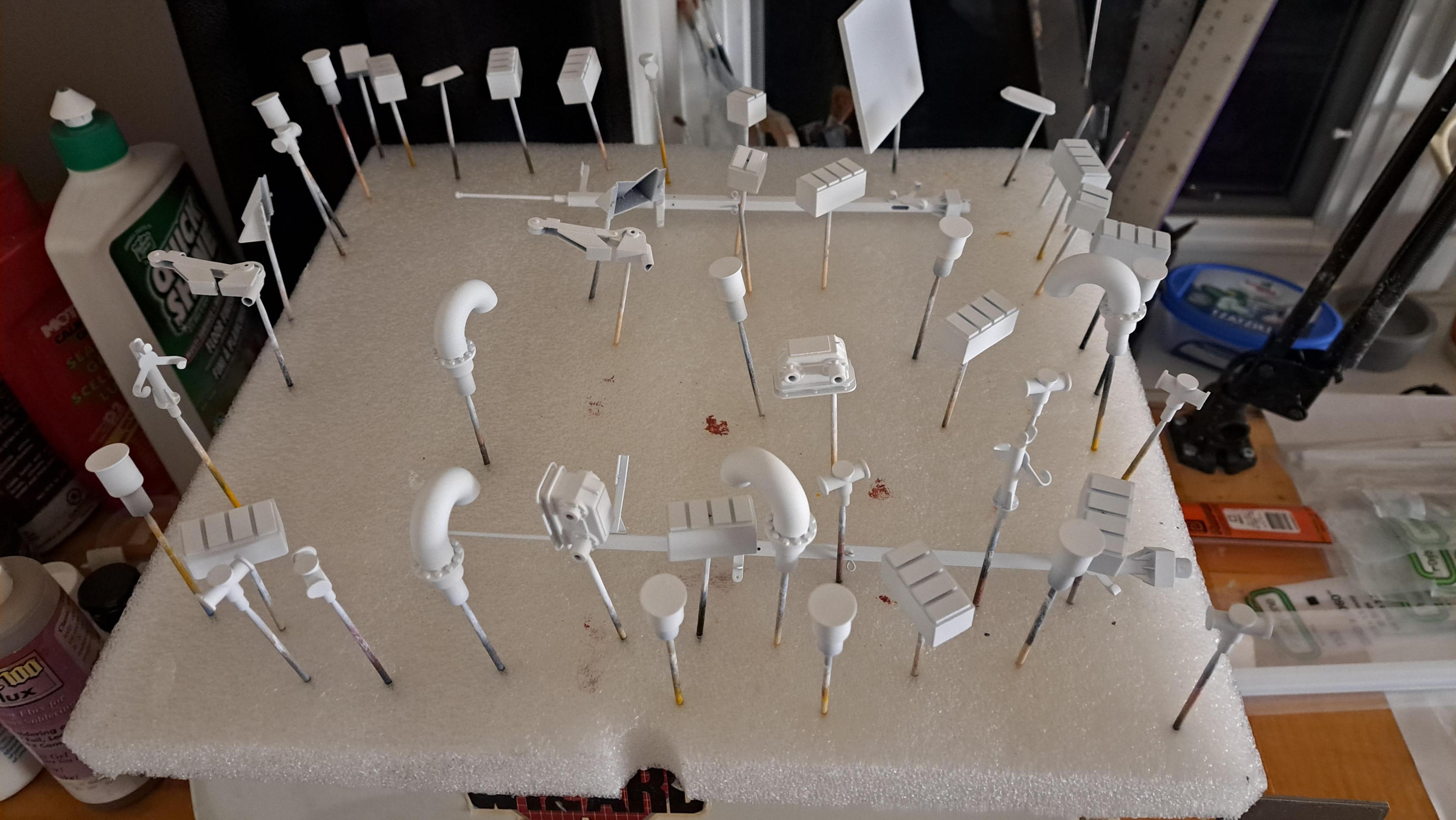

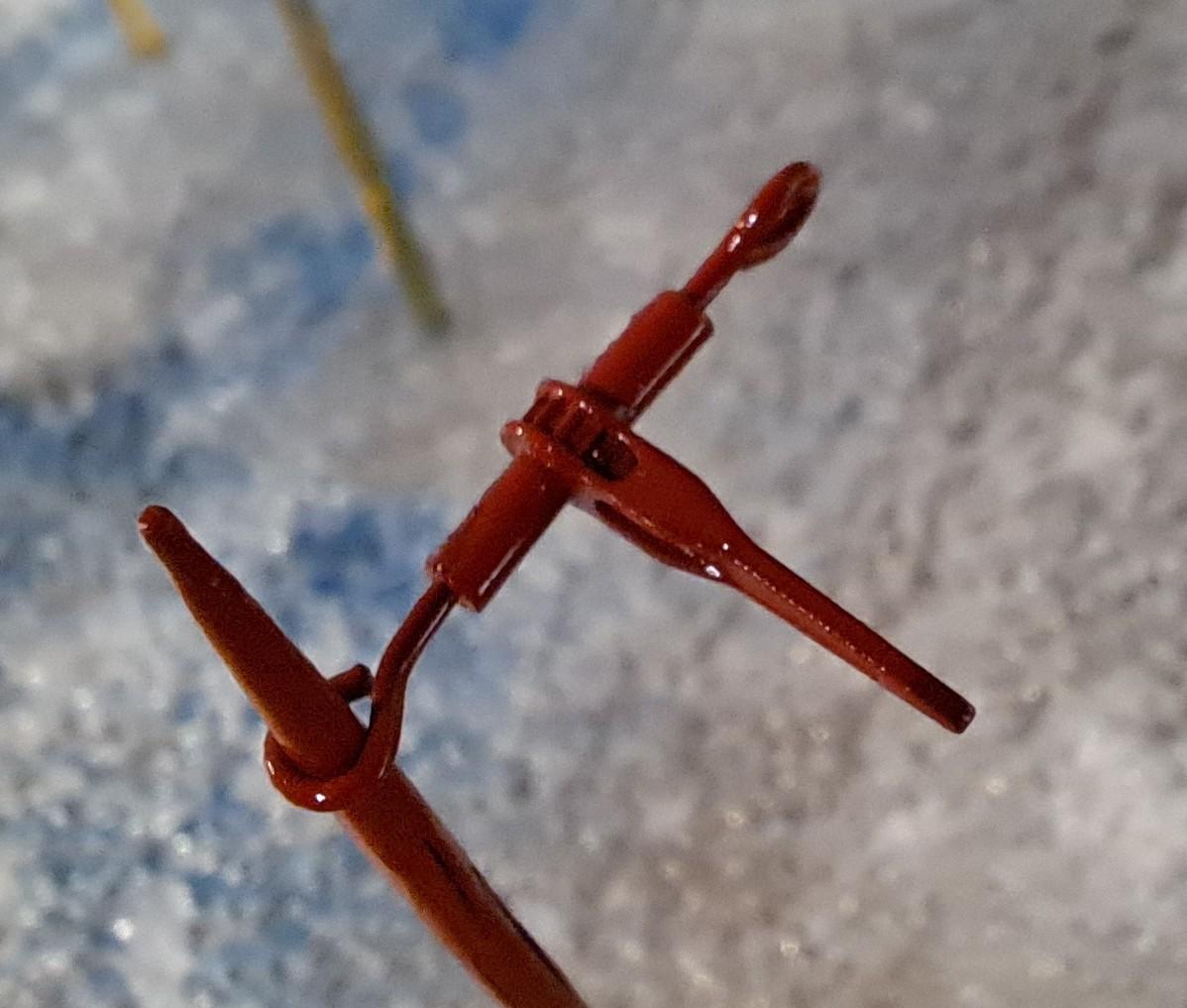

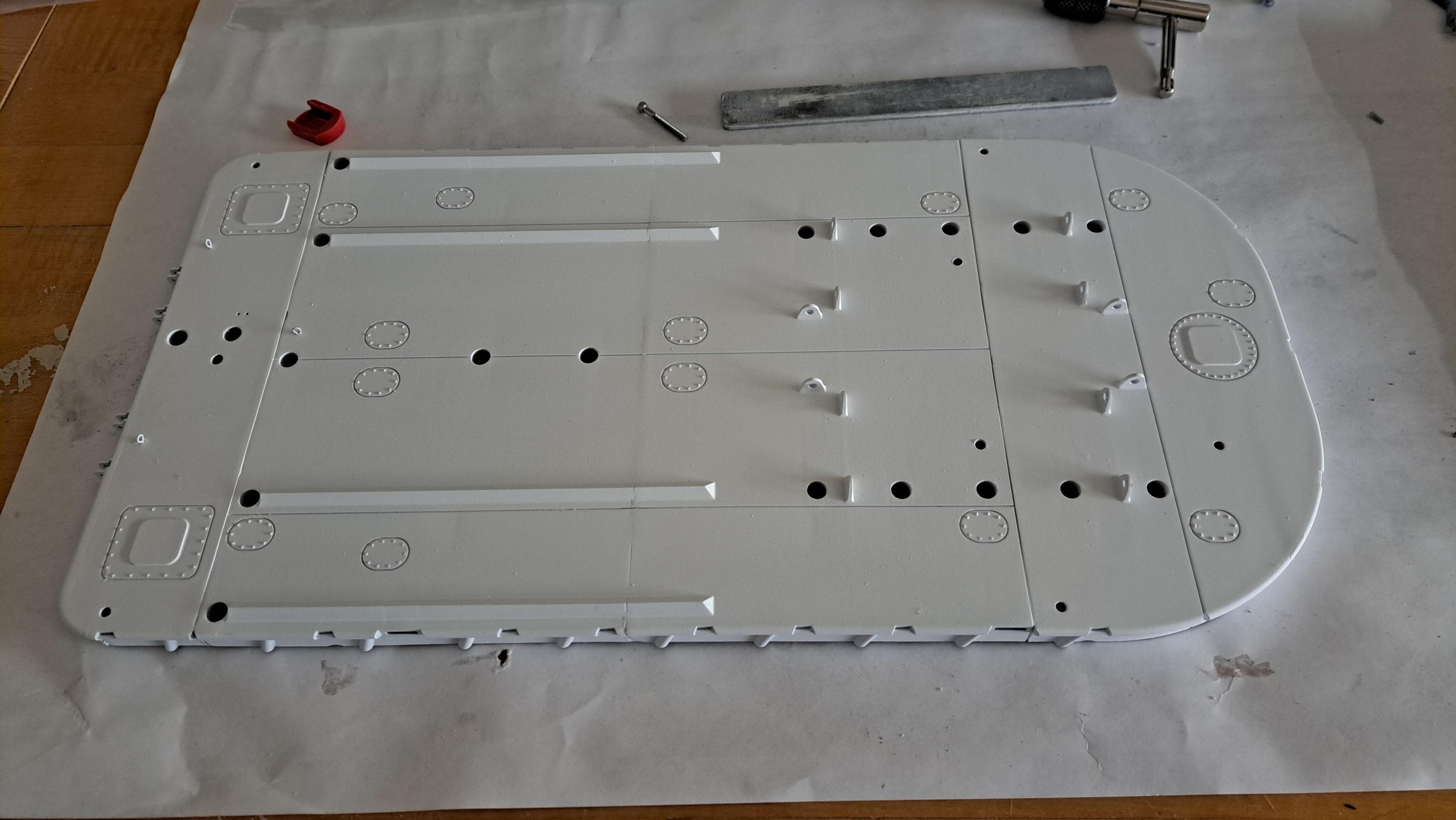

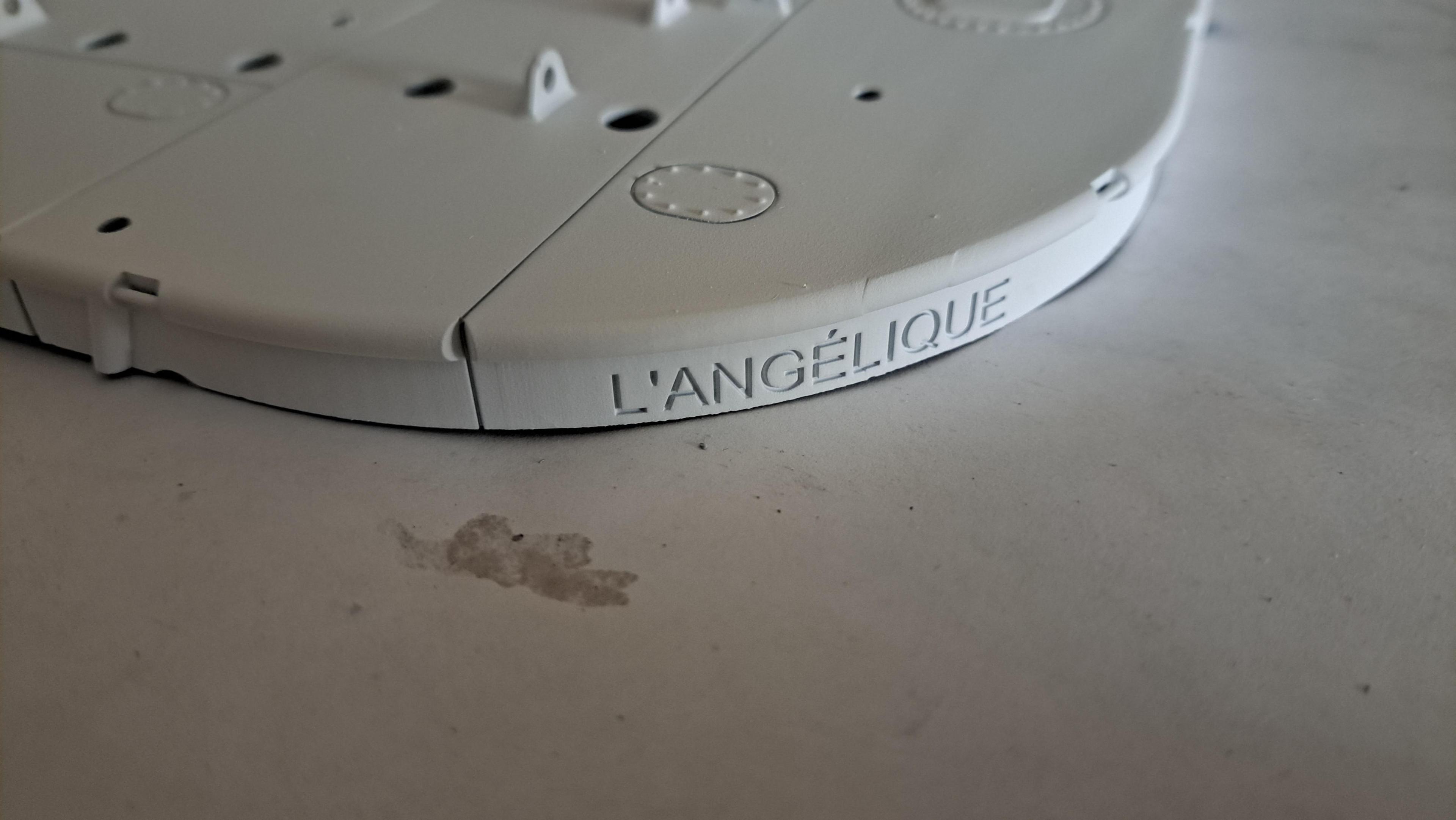

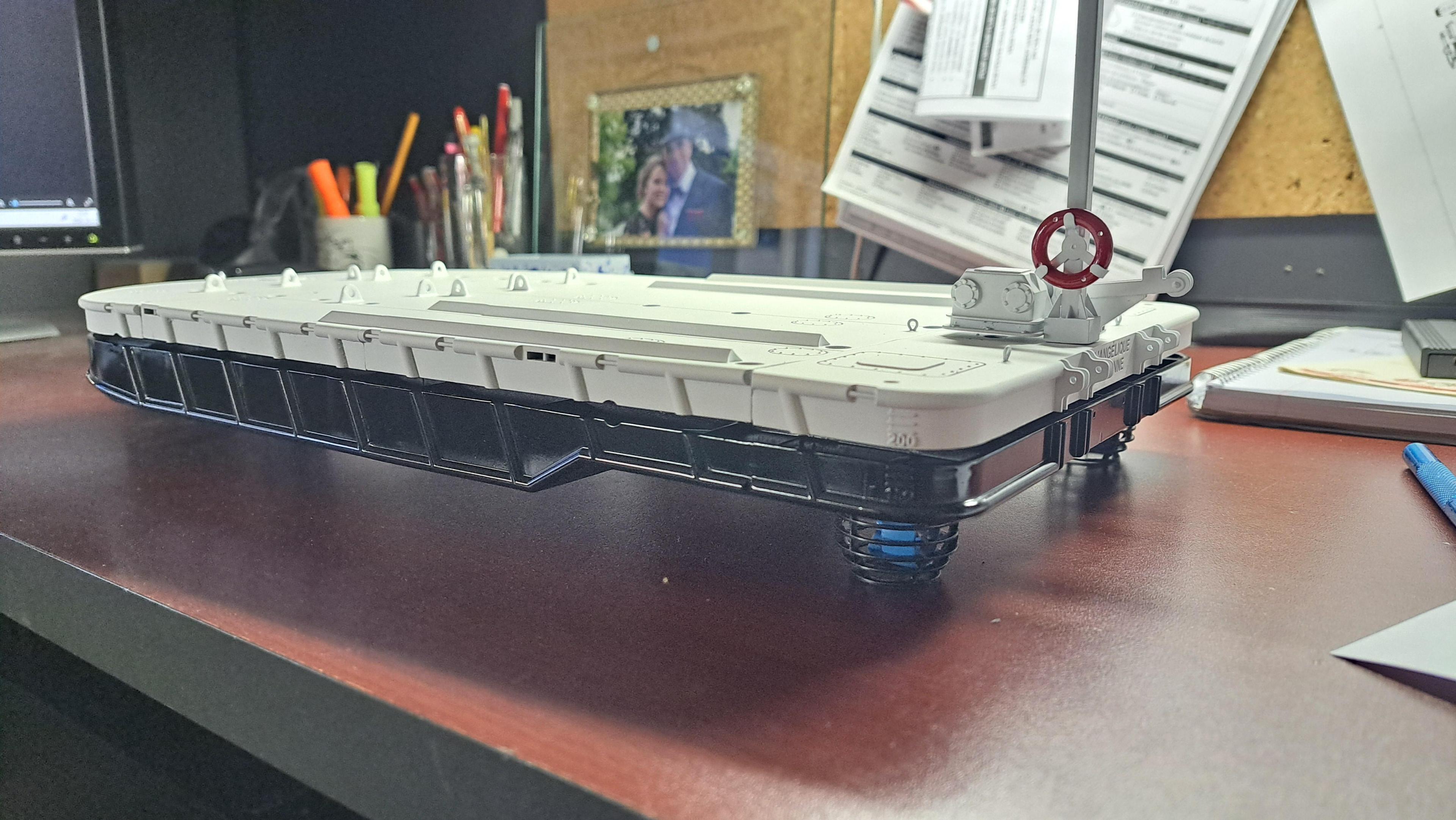

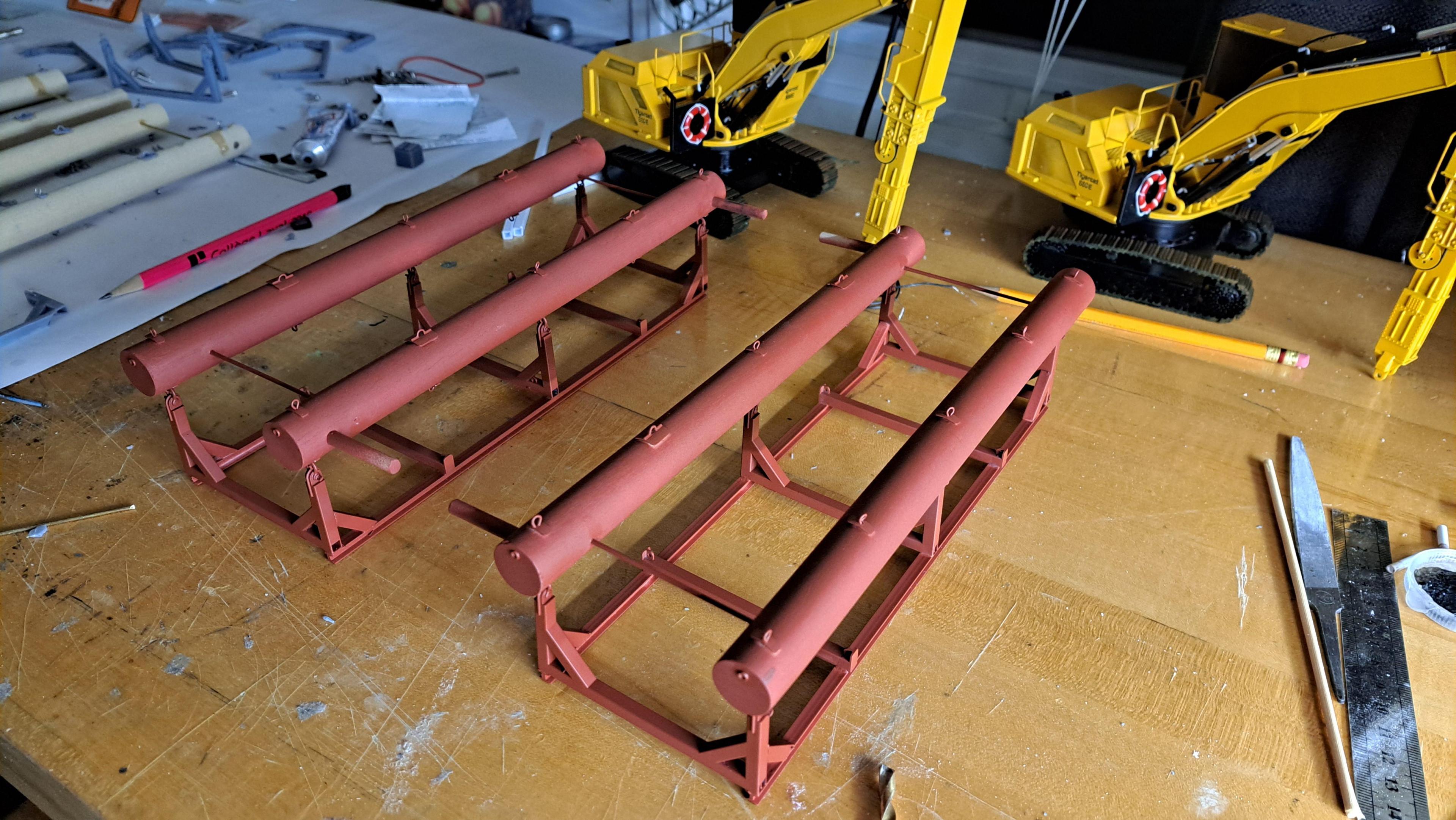

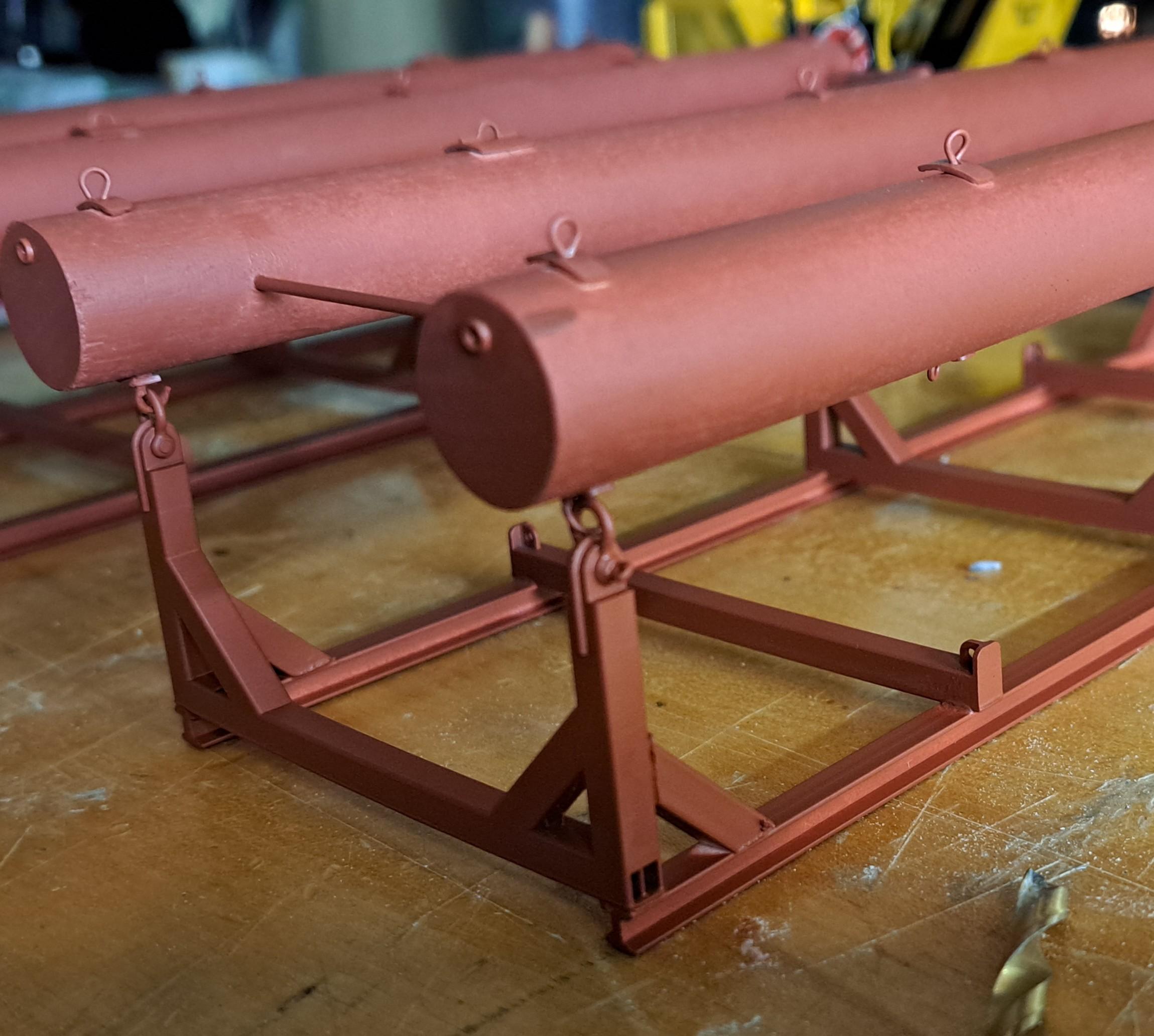

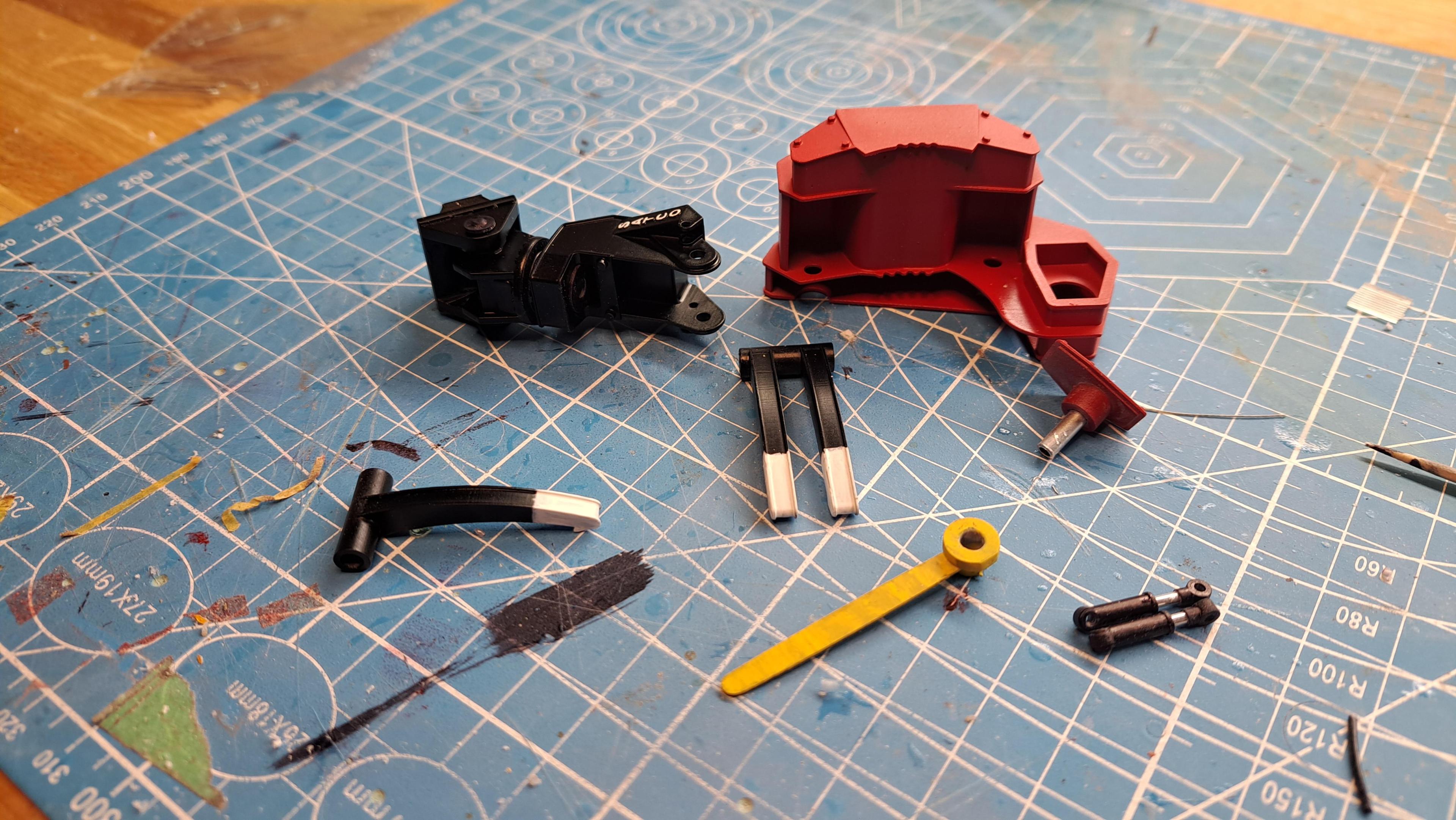

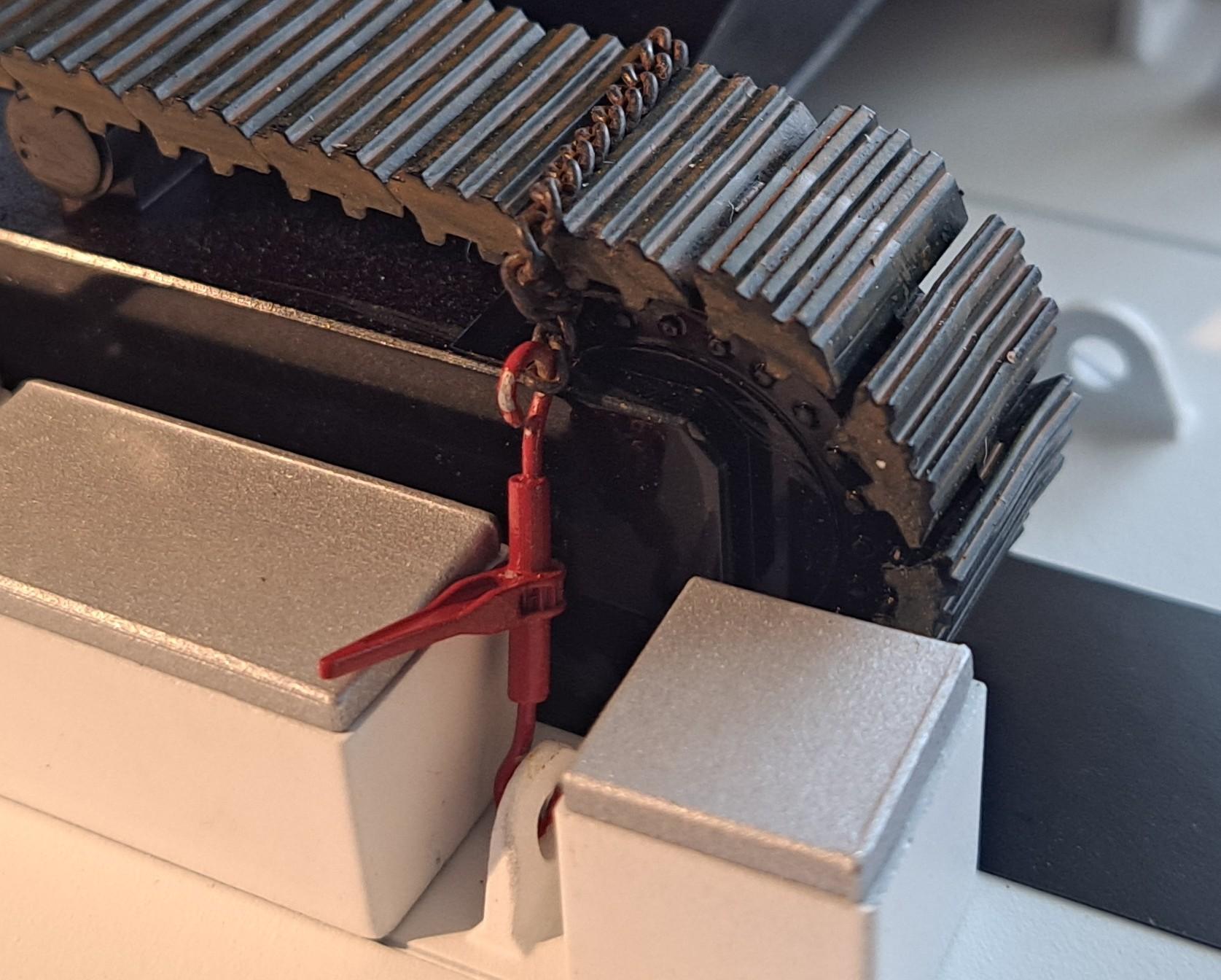

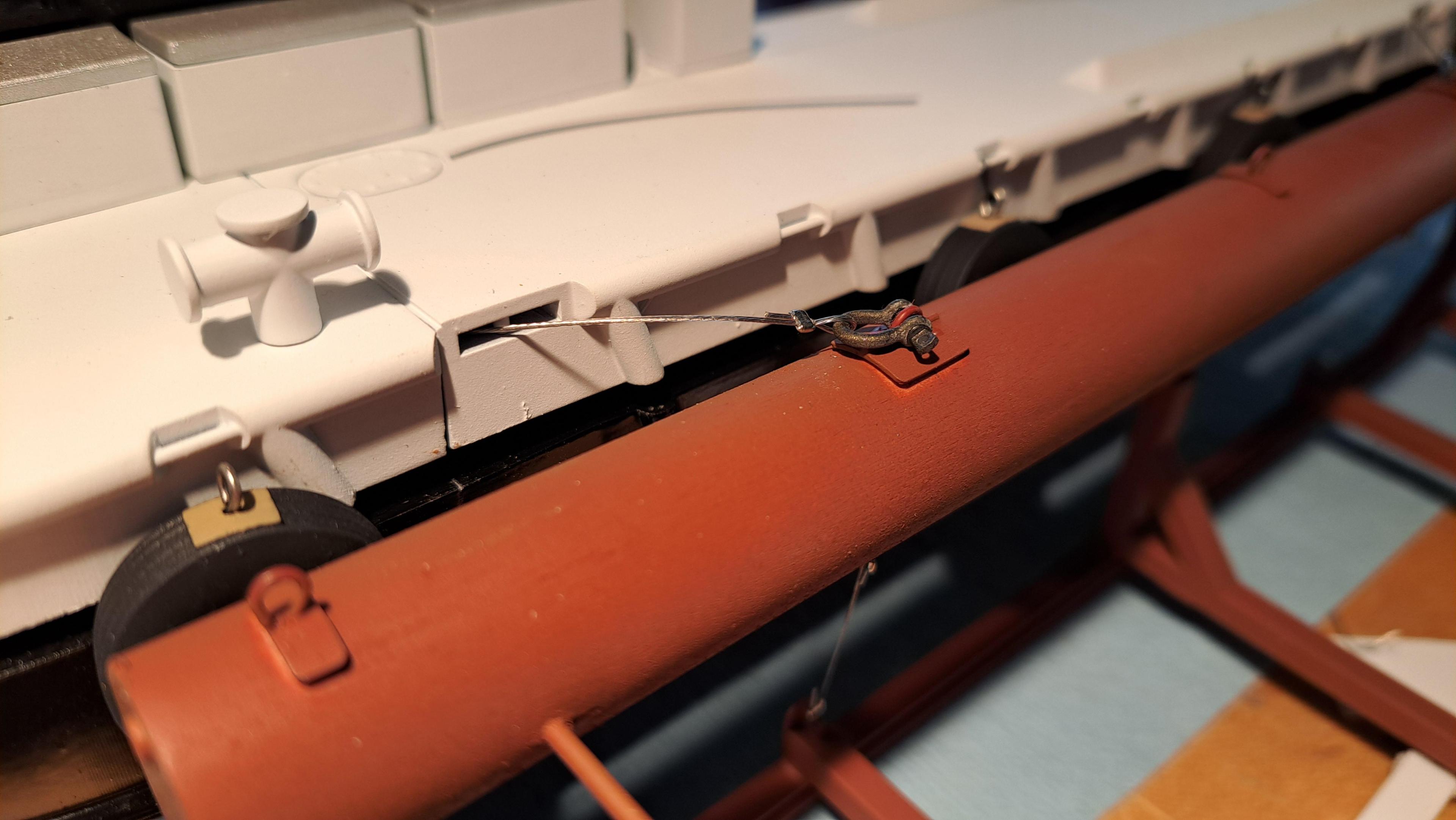

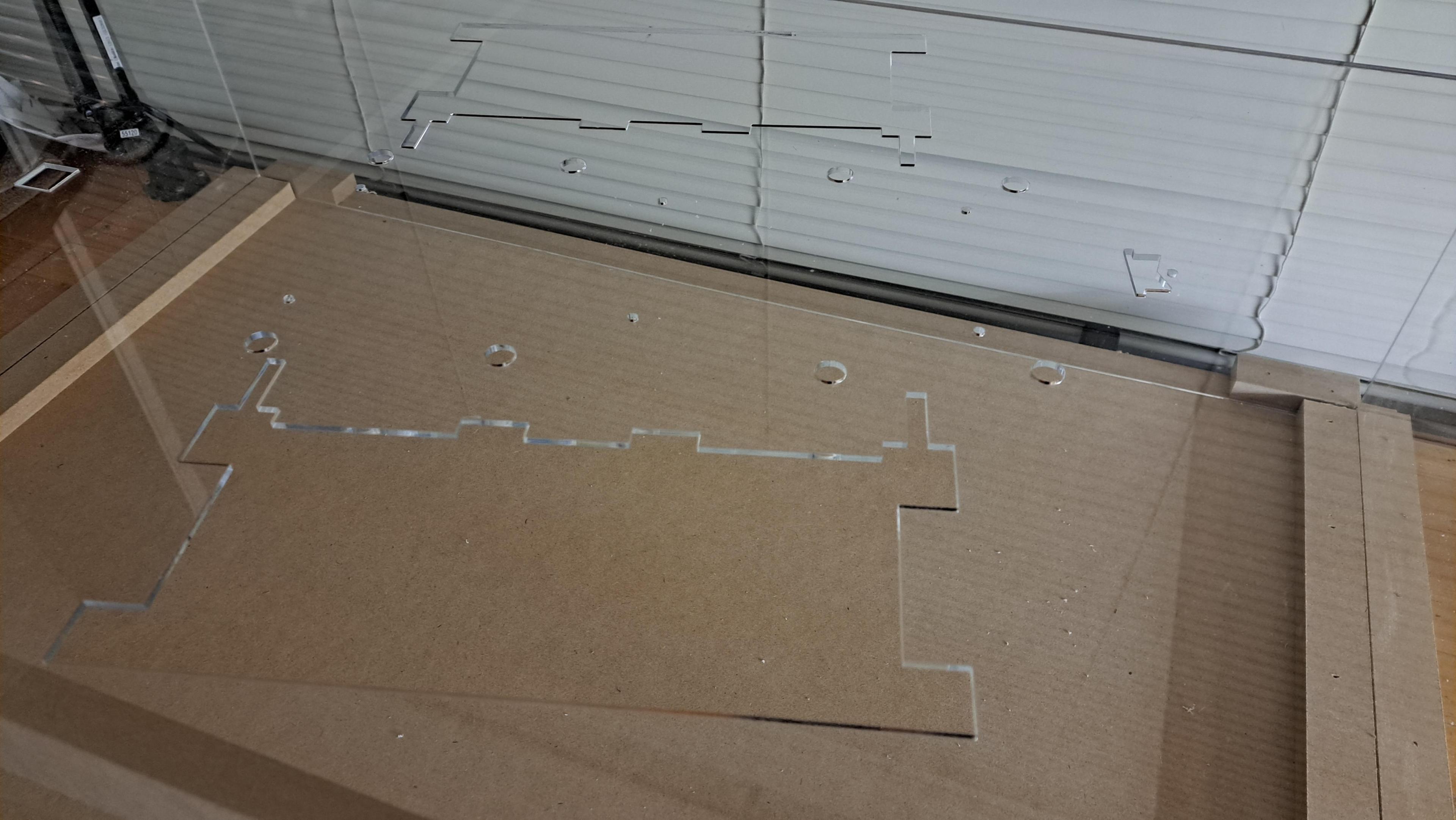

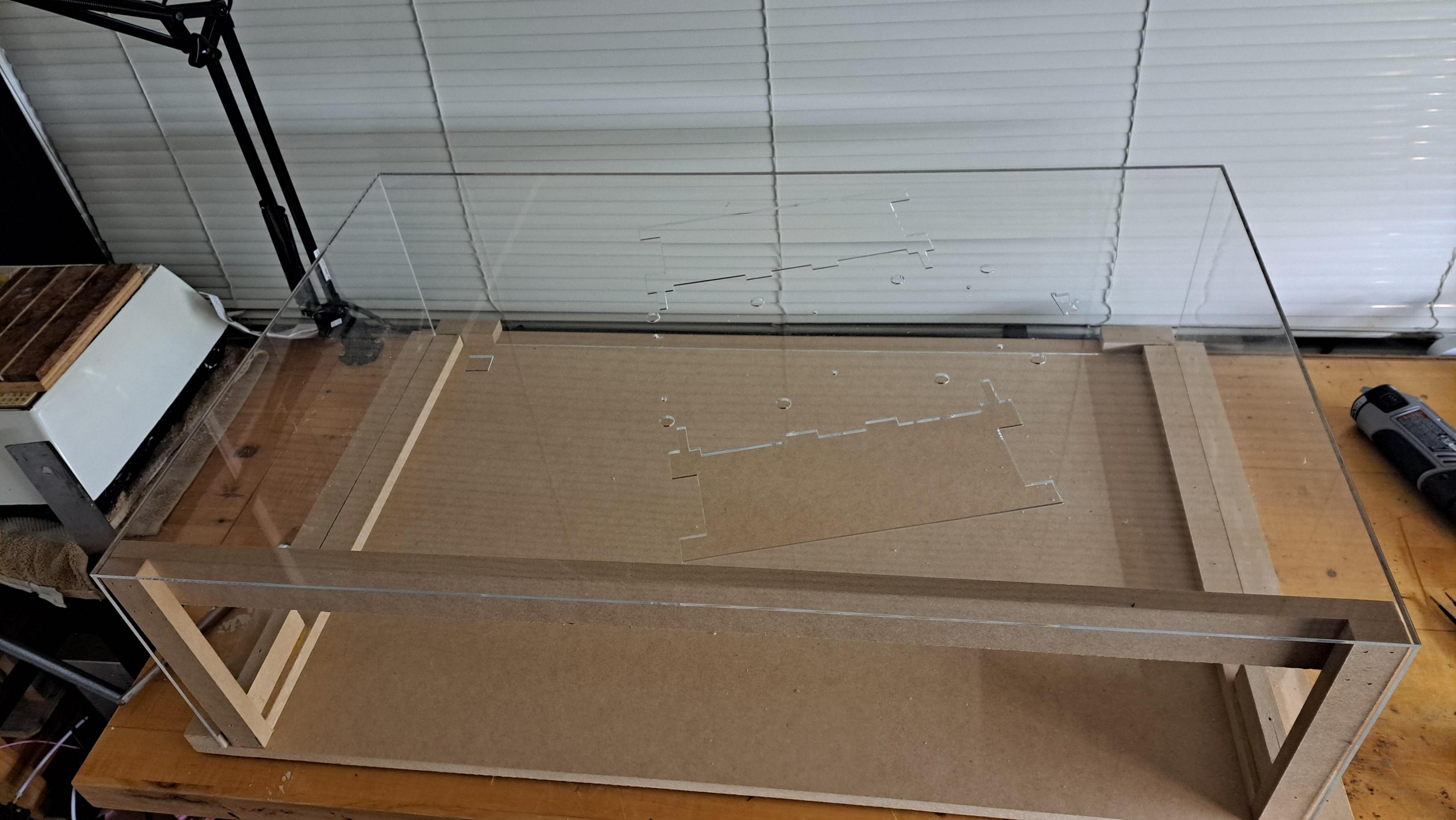

And a few of some of the printed parts

I was asked to 3d model and print a pair of Tigercat logger with a custom arm at 1/48 scale. I wasn't given the green light yet but I decided to go ahead and start the project anyway. Worst case scenario, I'll have a couple of nice loggers to add to my collection. I'm not used to work at such small scale but this logger is a big machine so it will still be a good size model.

Here are a few shots of the 3d model

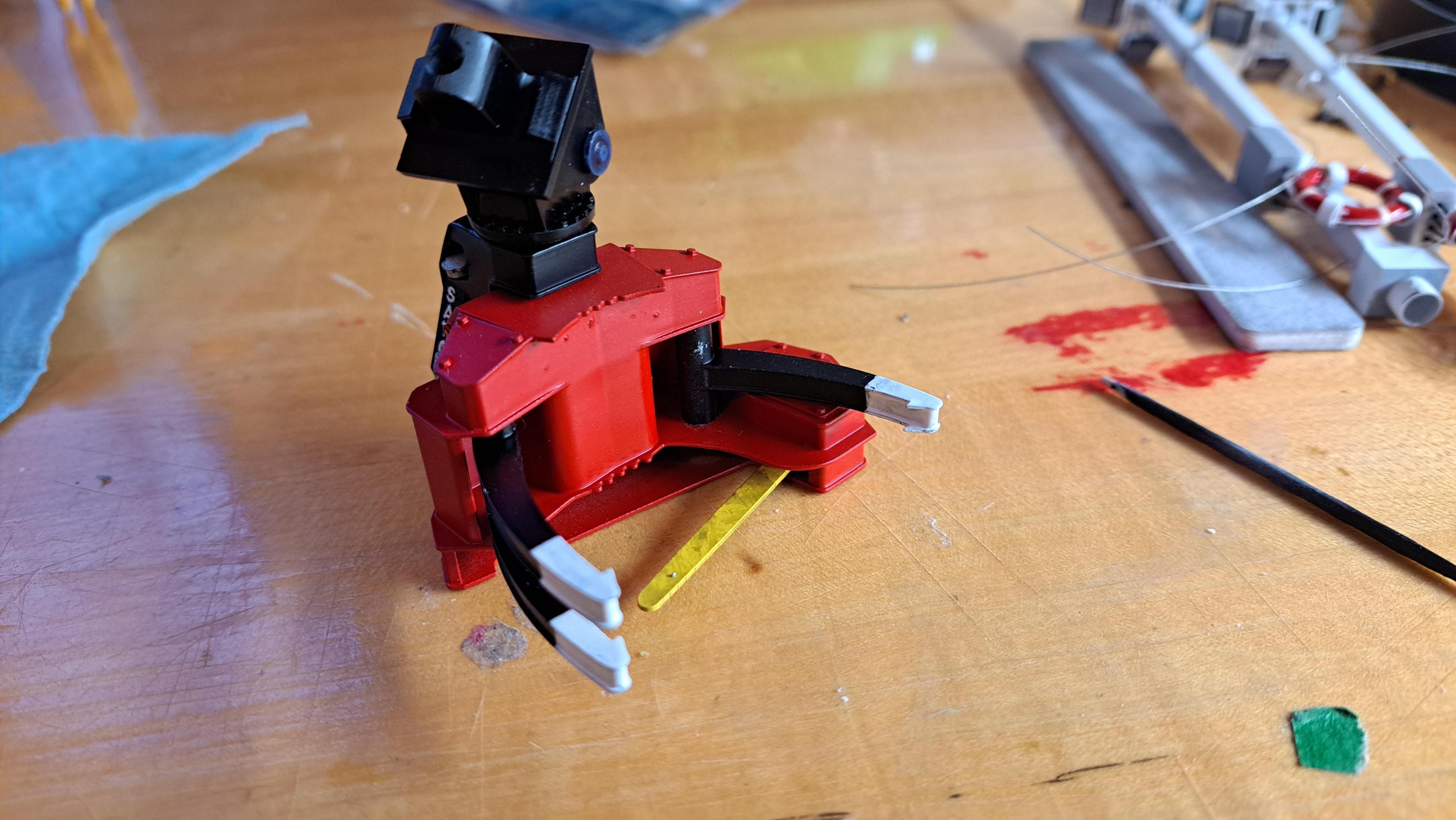

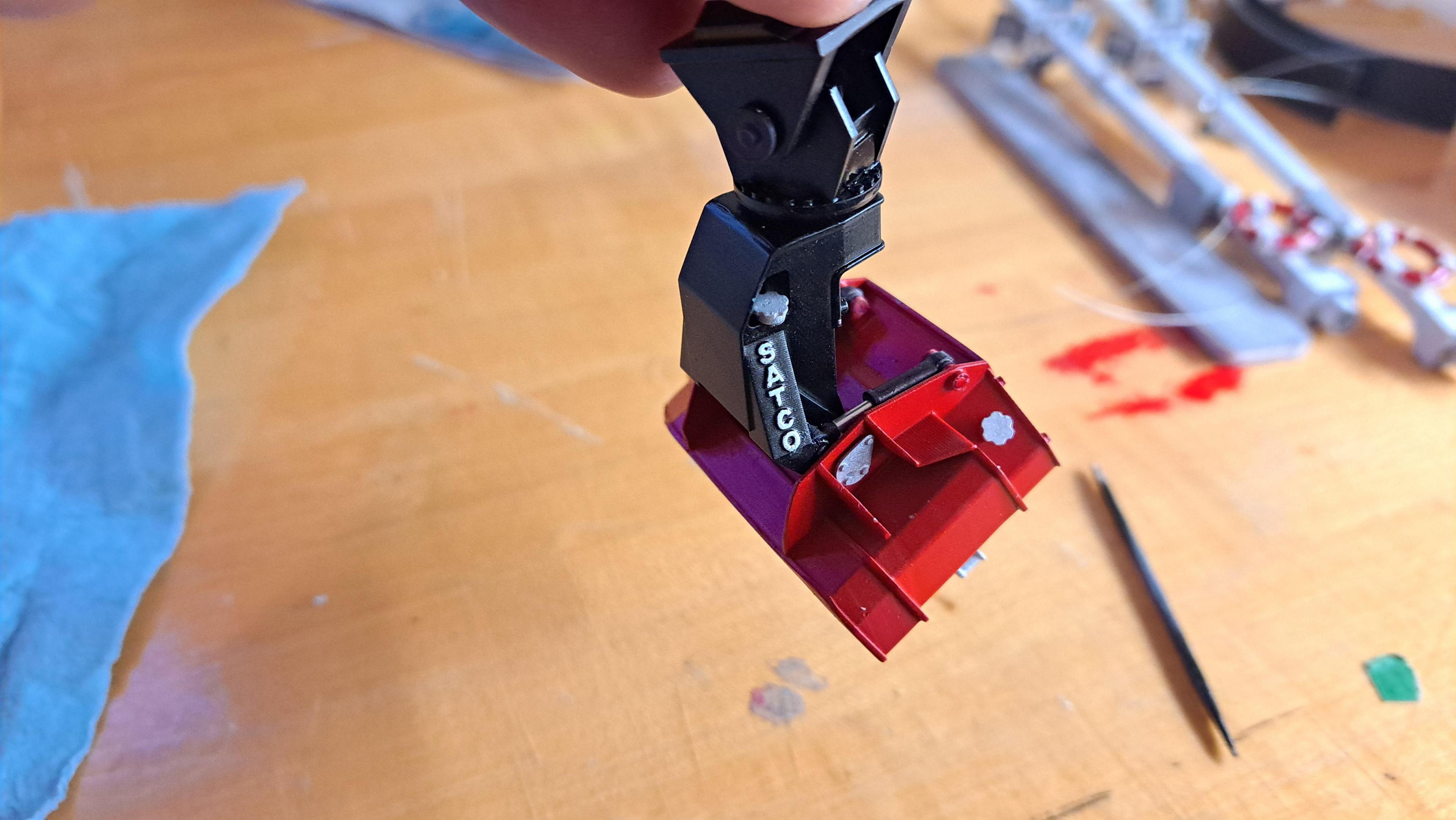

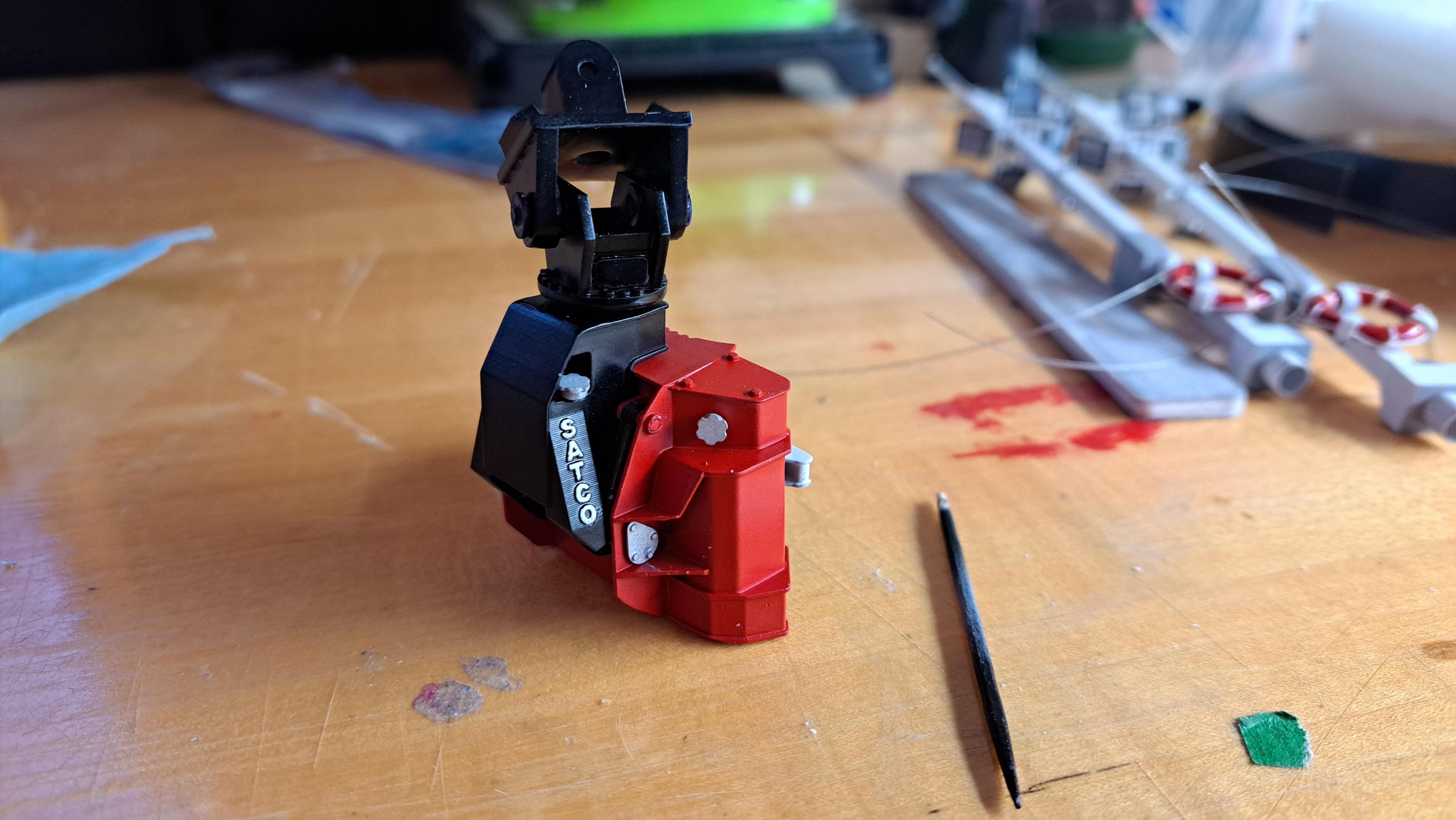

And a few of some of the printed parts

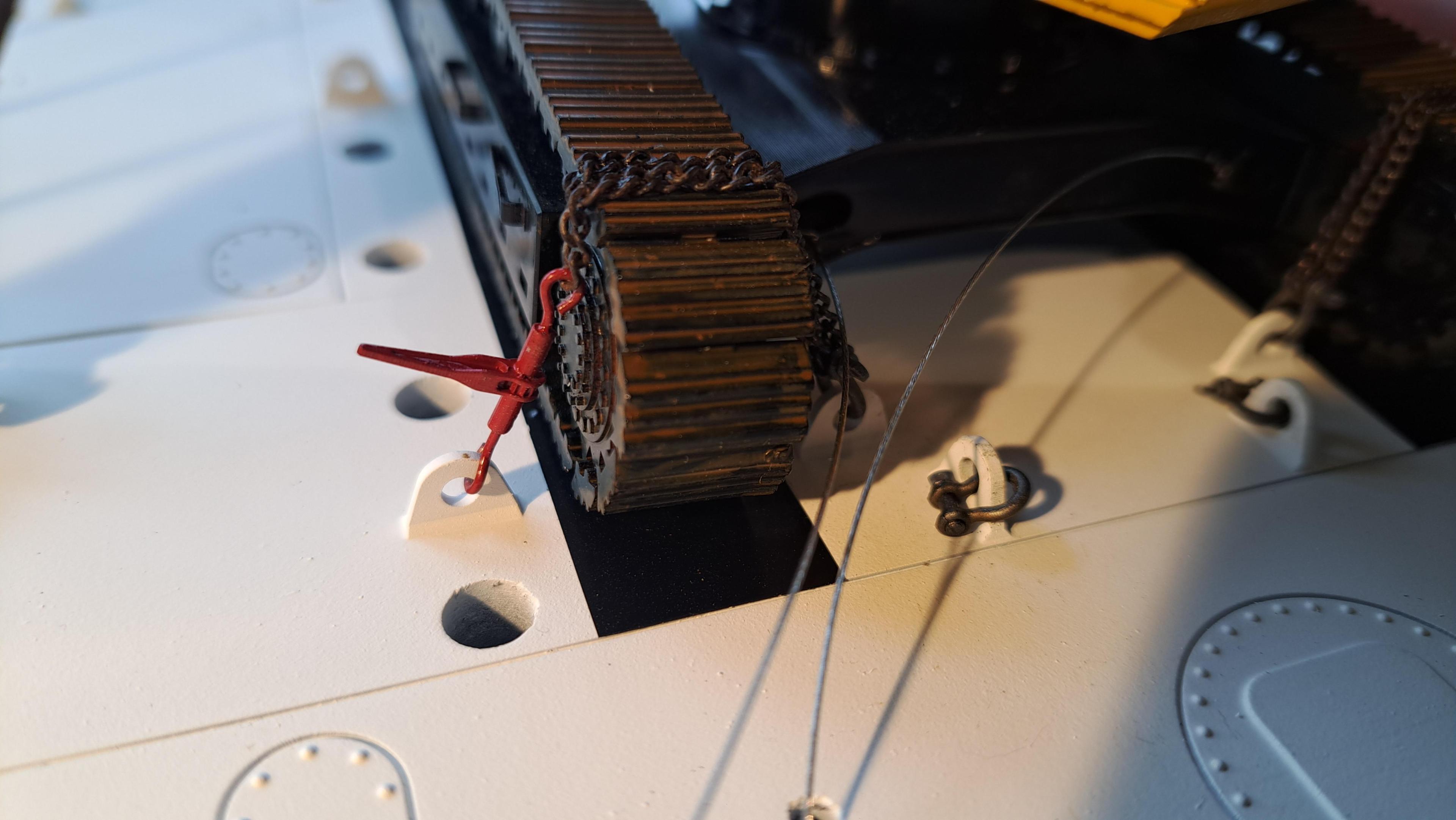

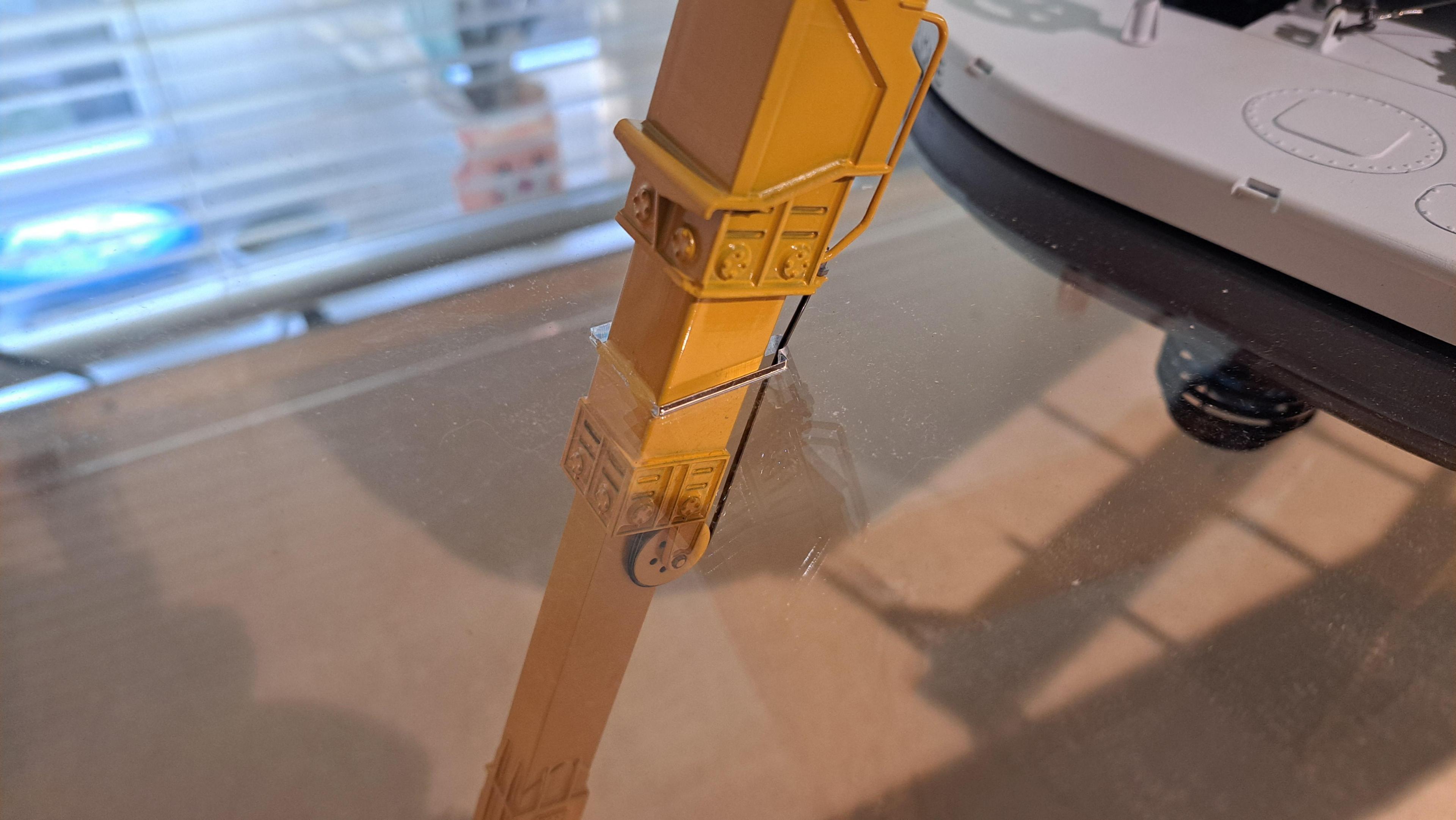

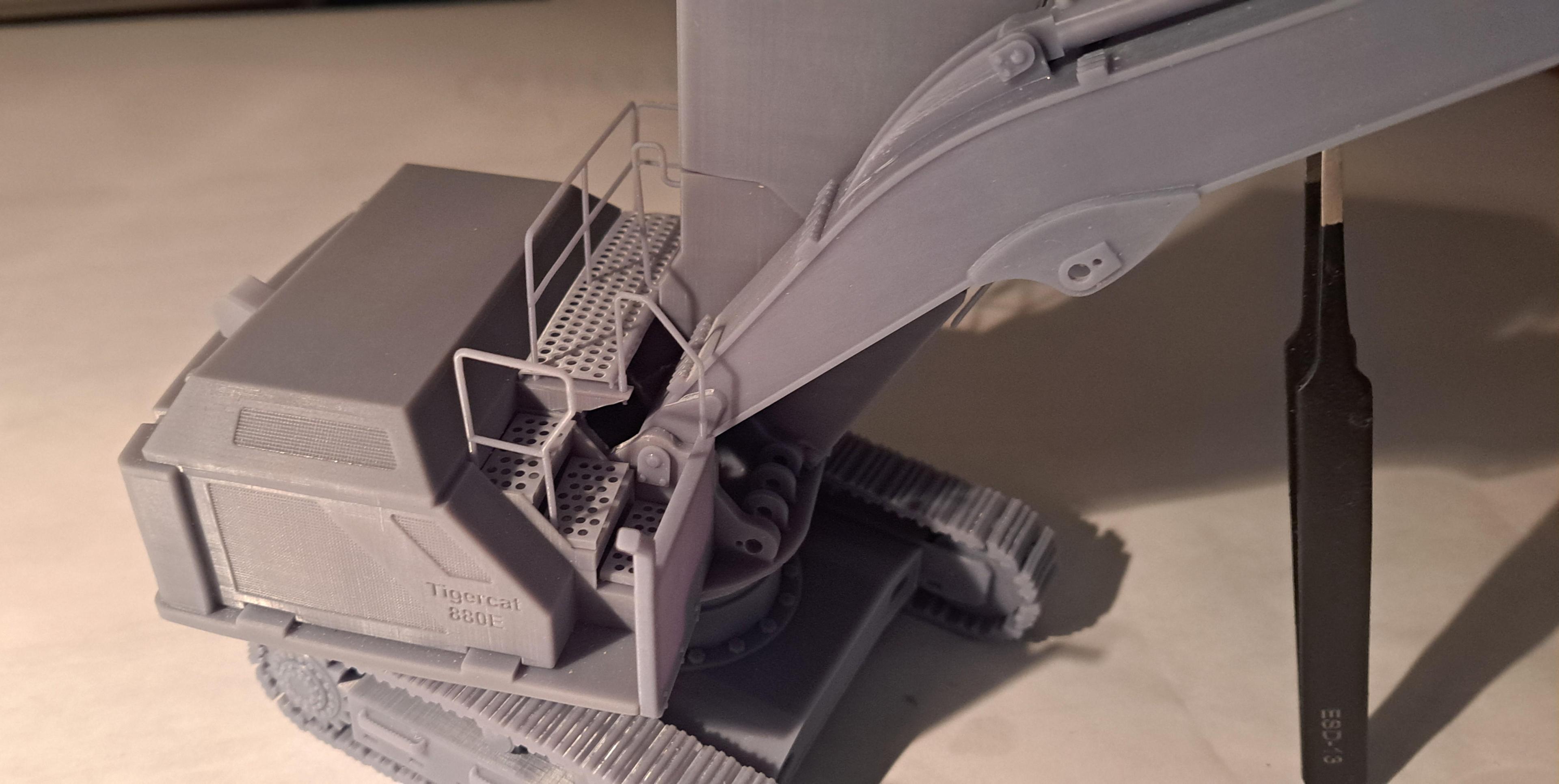

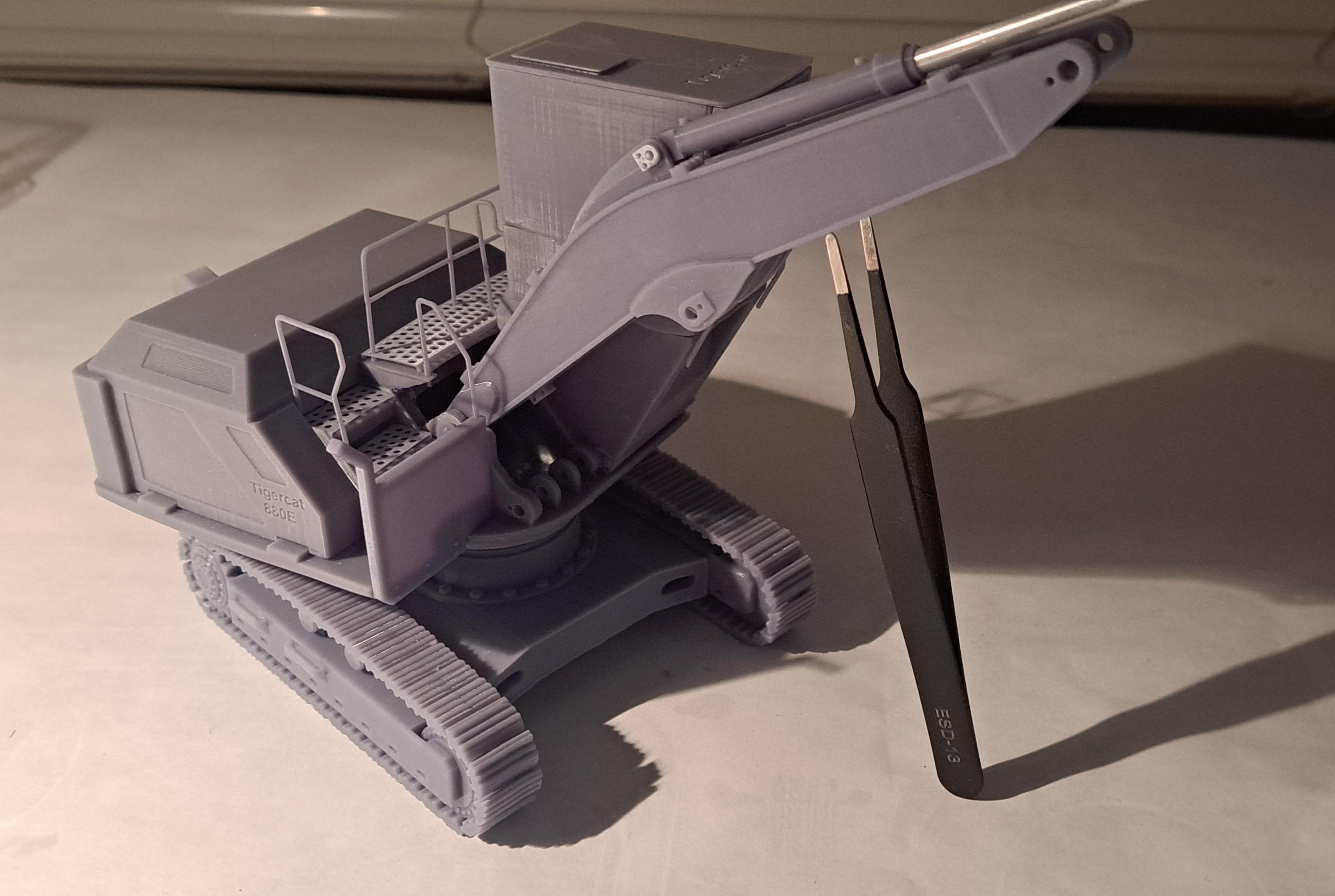

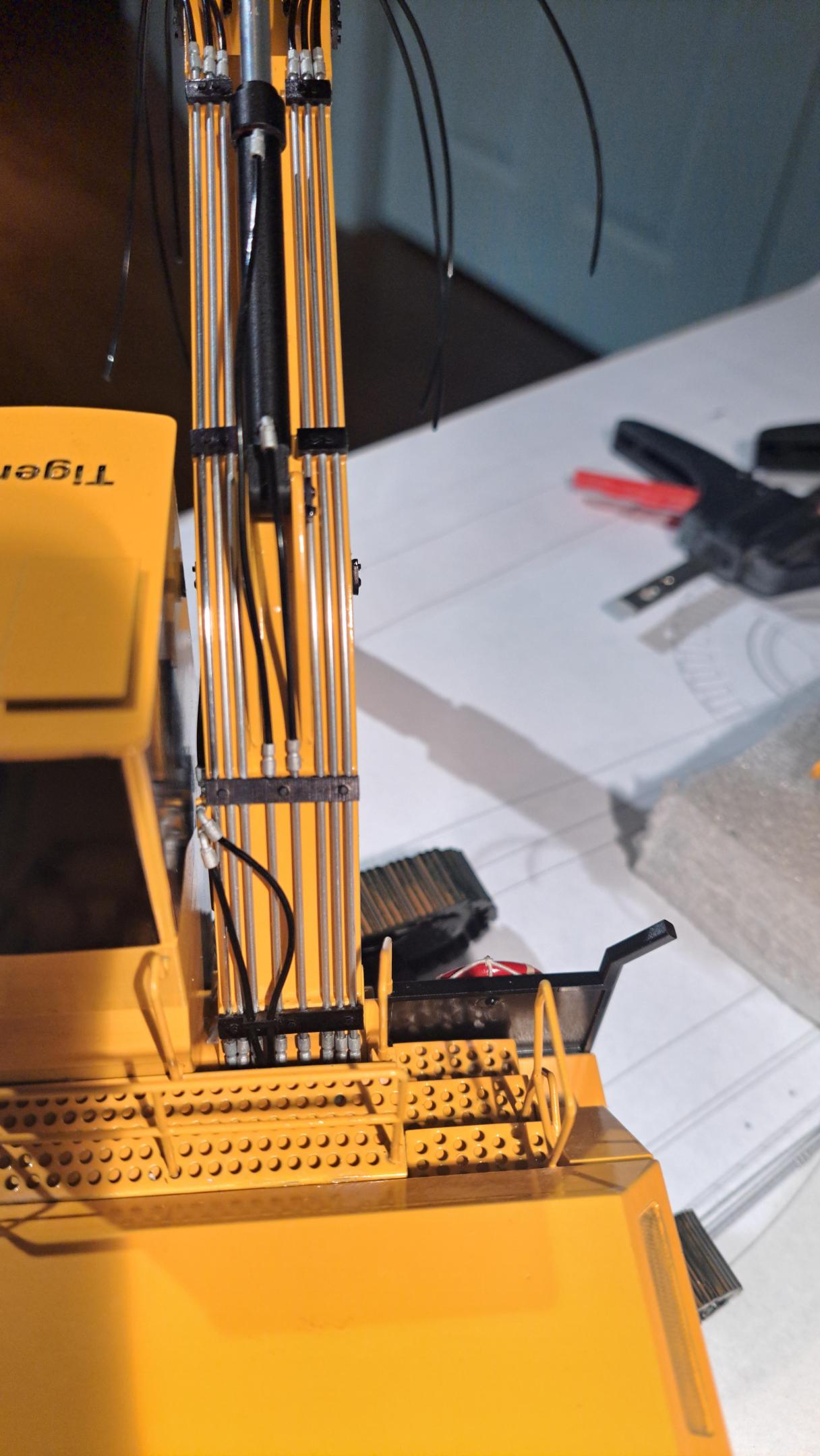

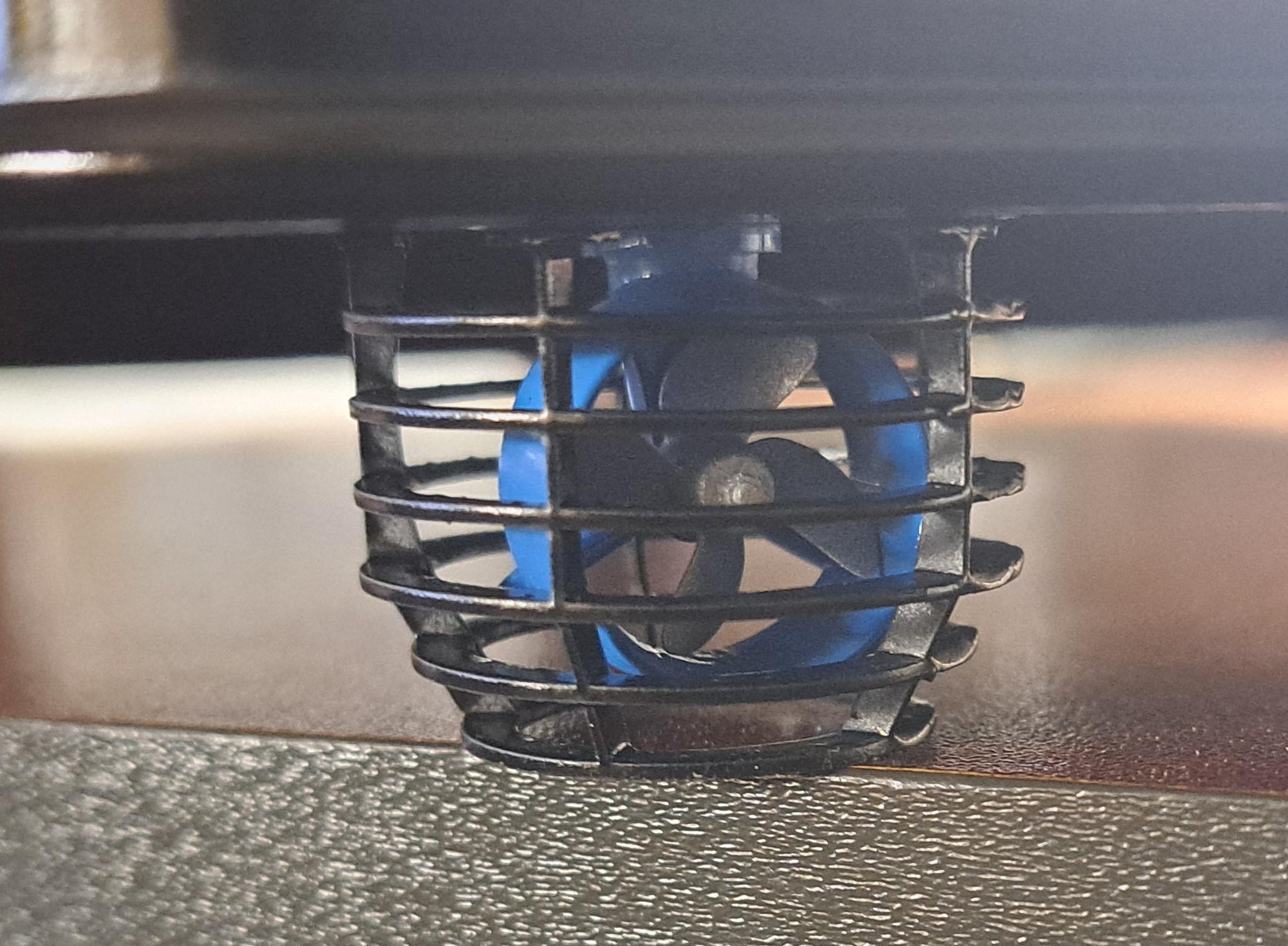

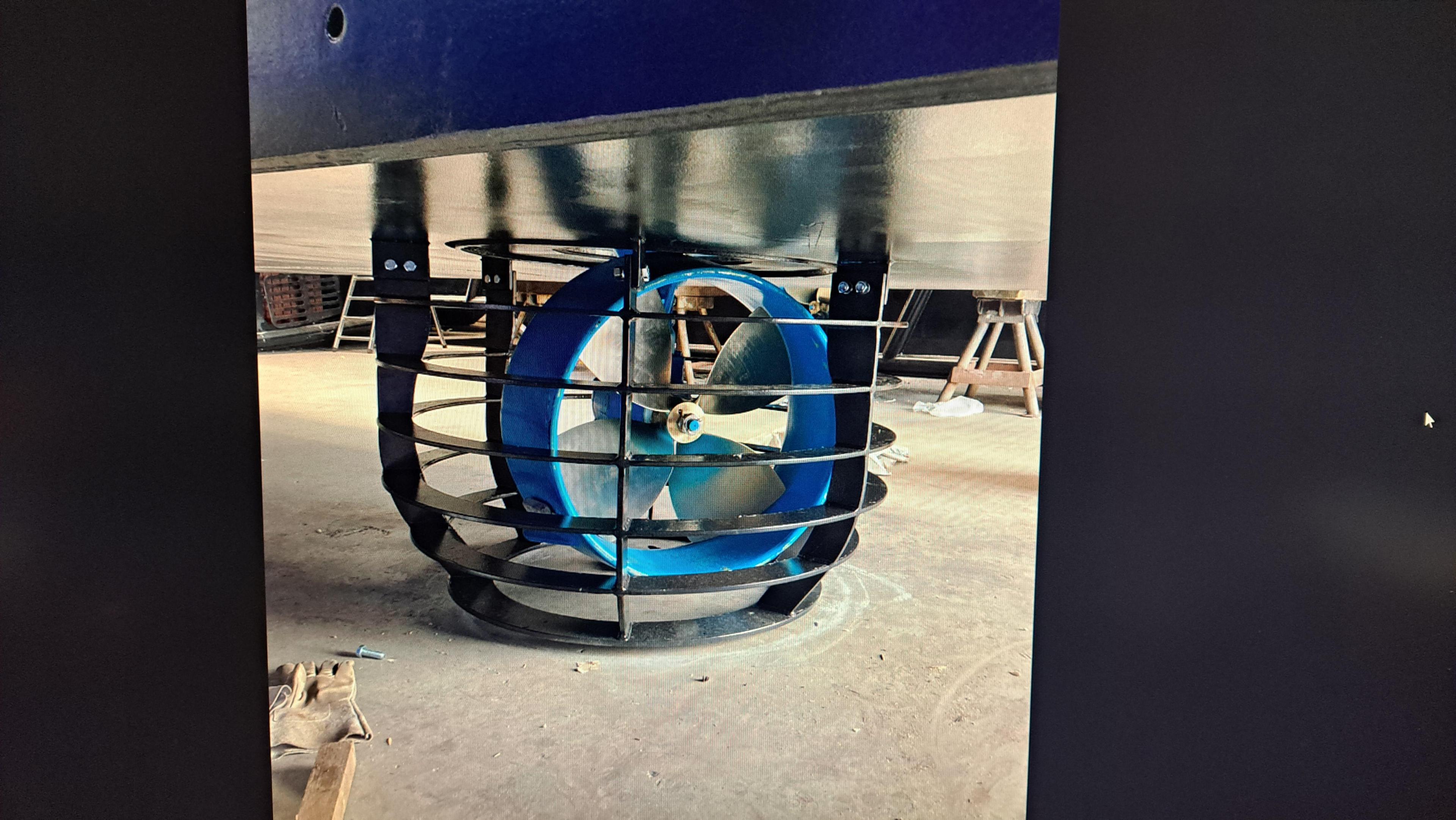

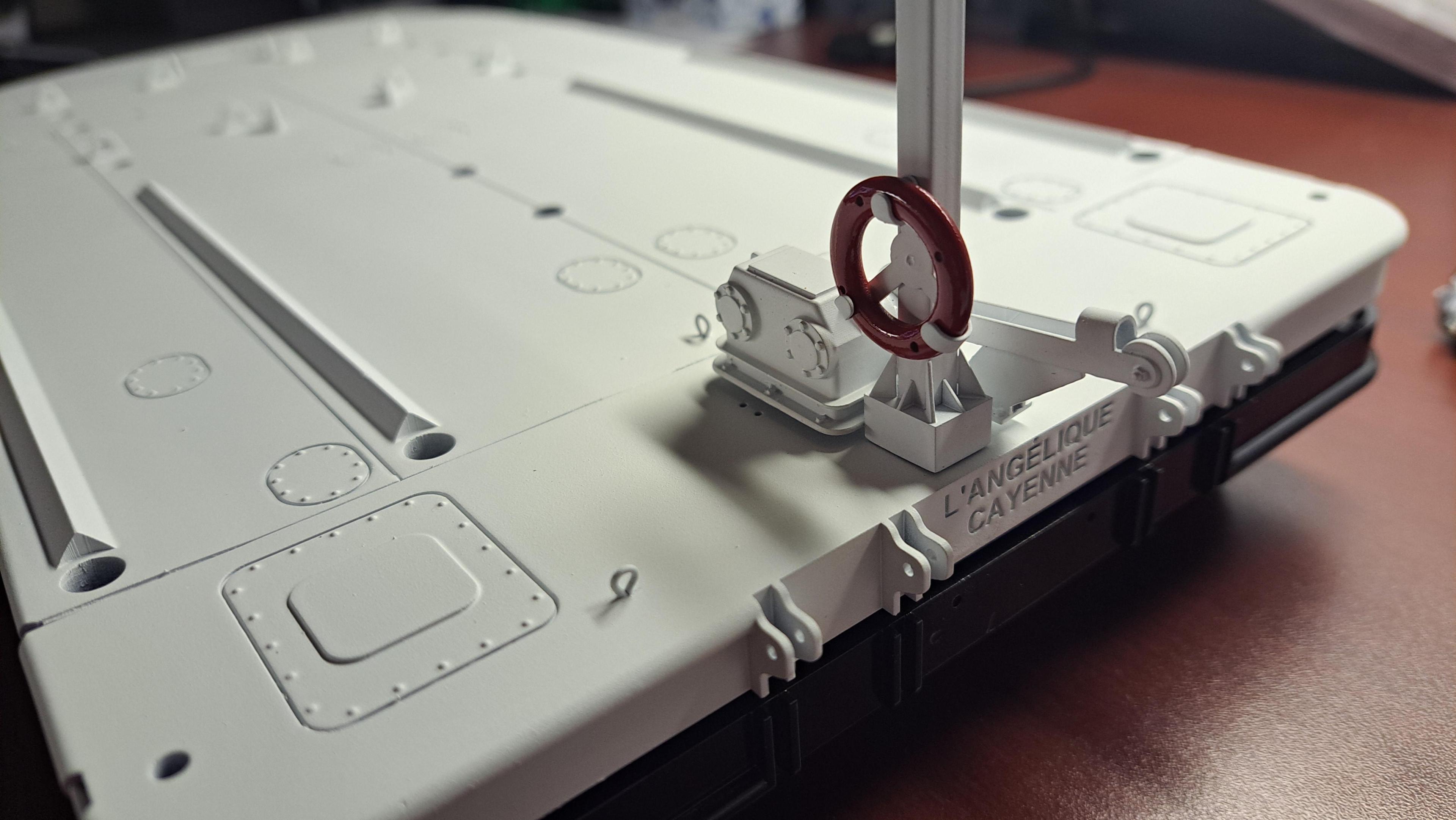

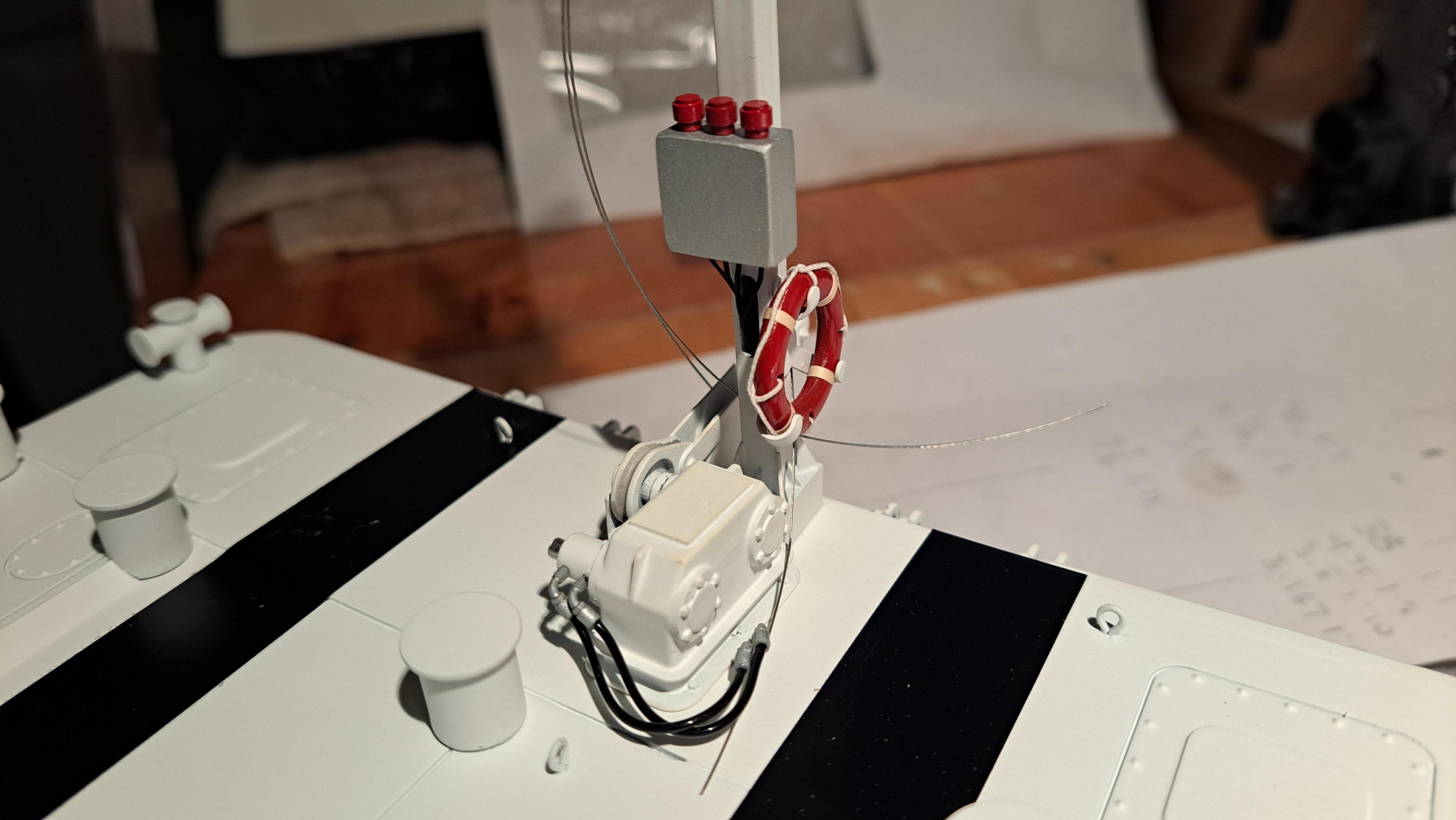

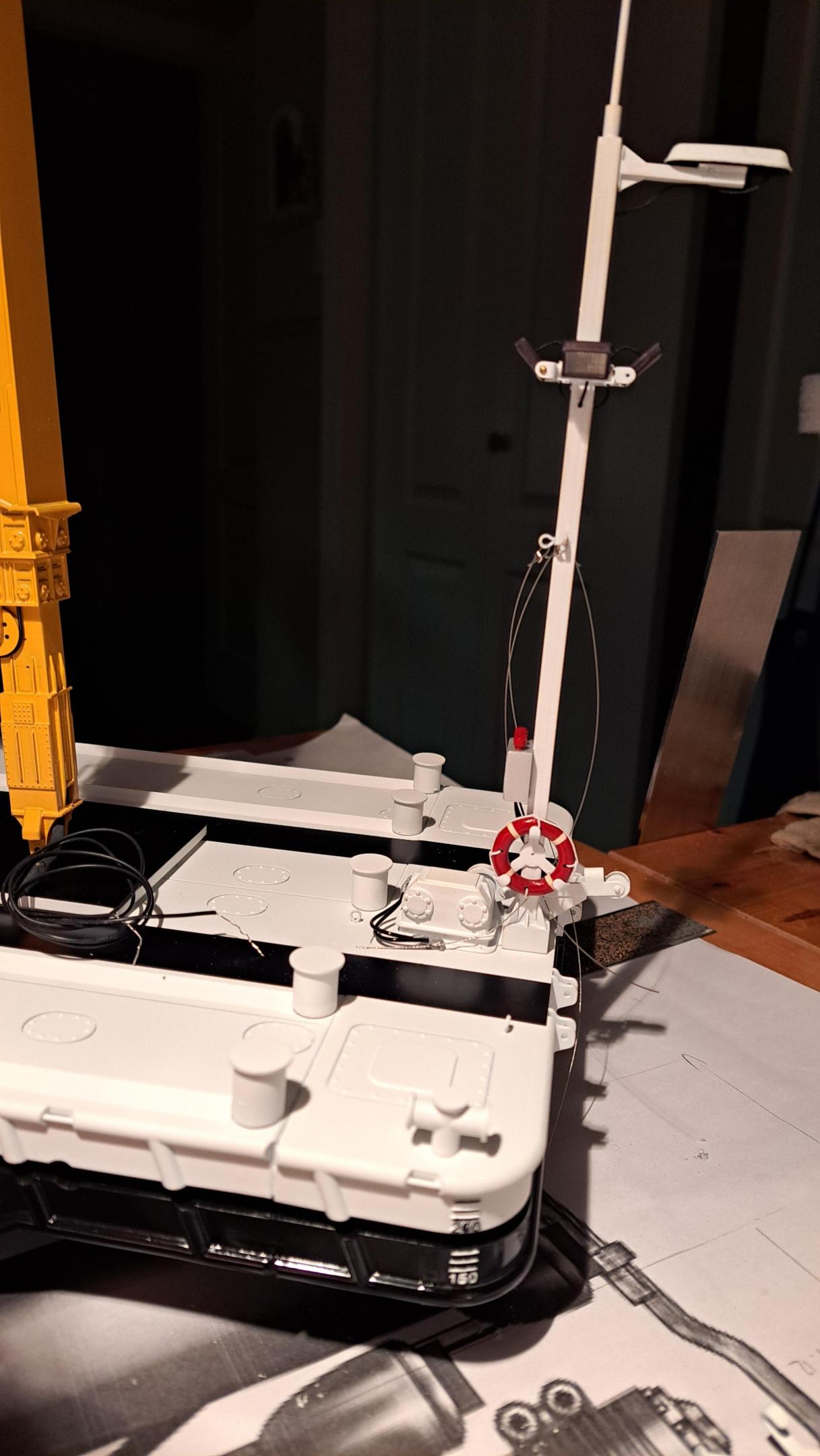

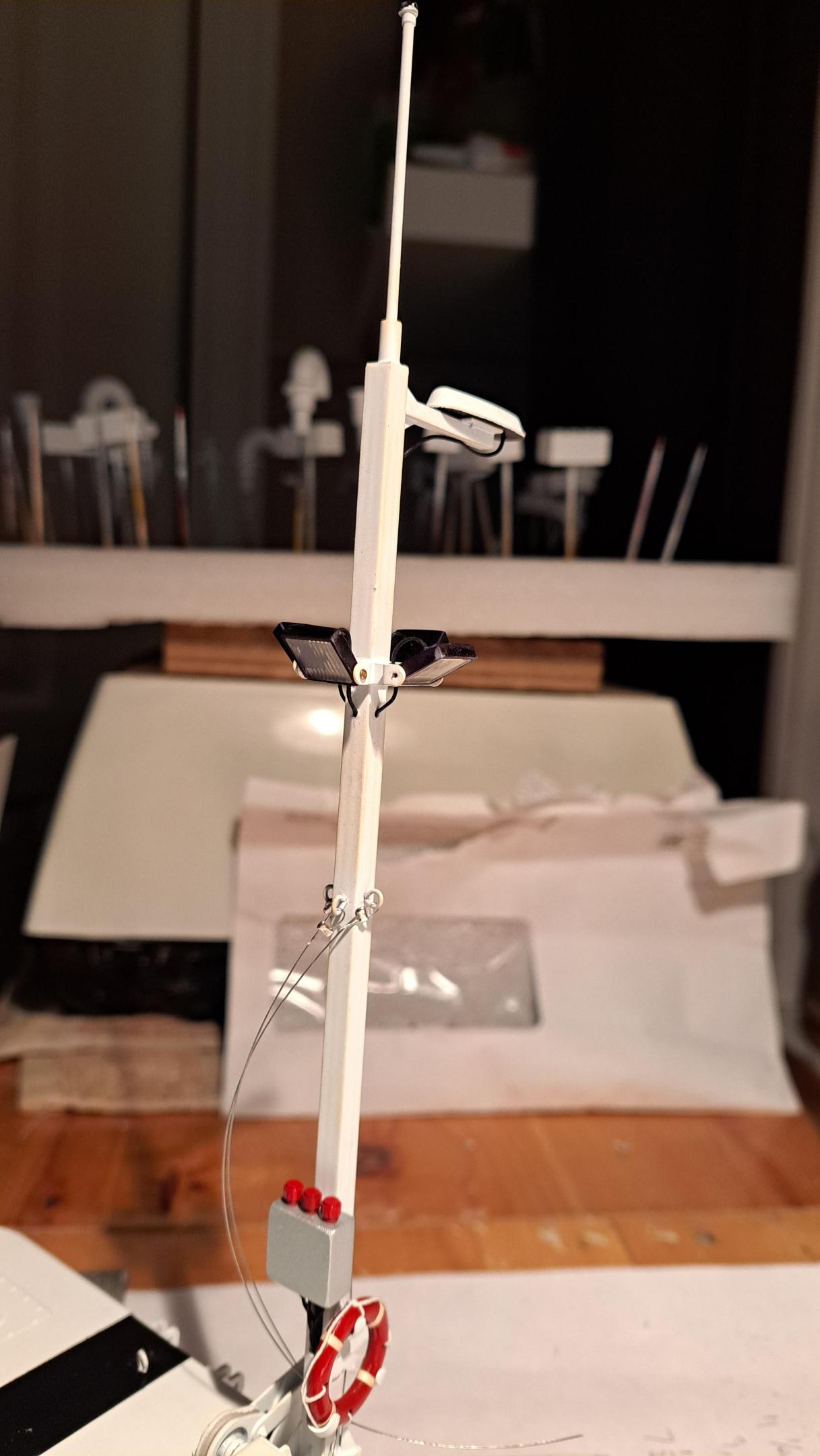

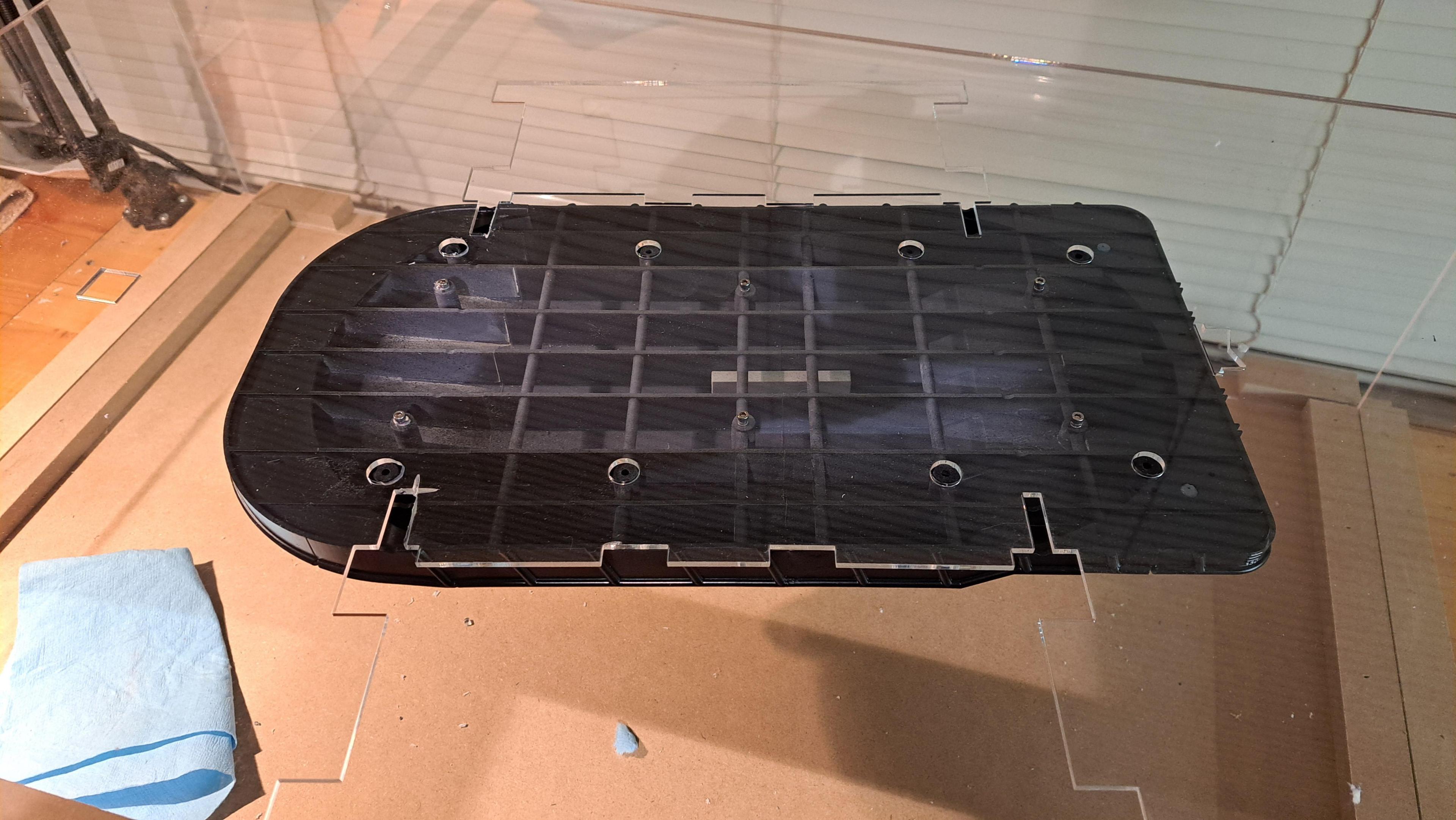

deflector installed

deflector installed