Thanks for all the likes and comments

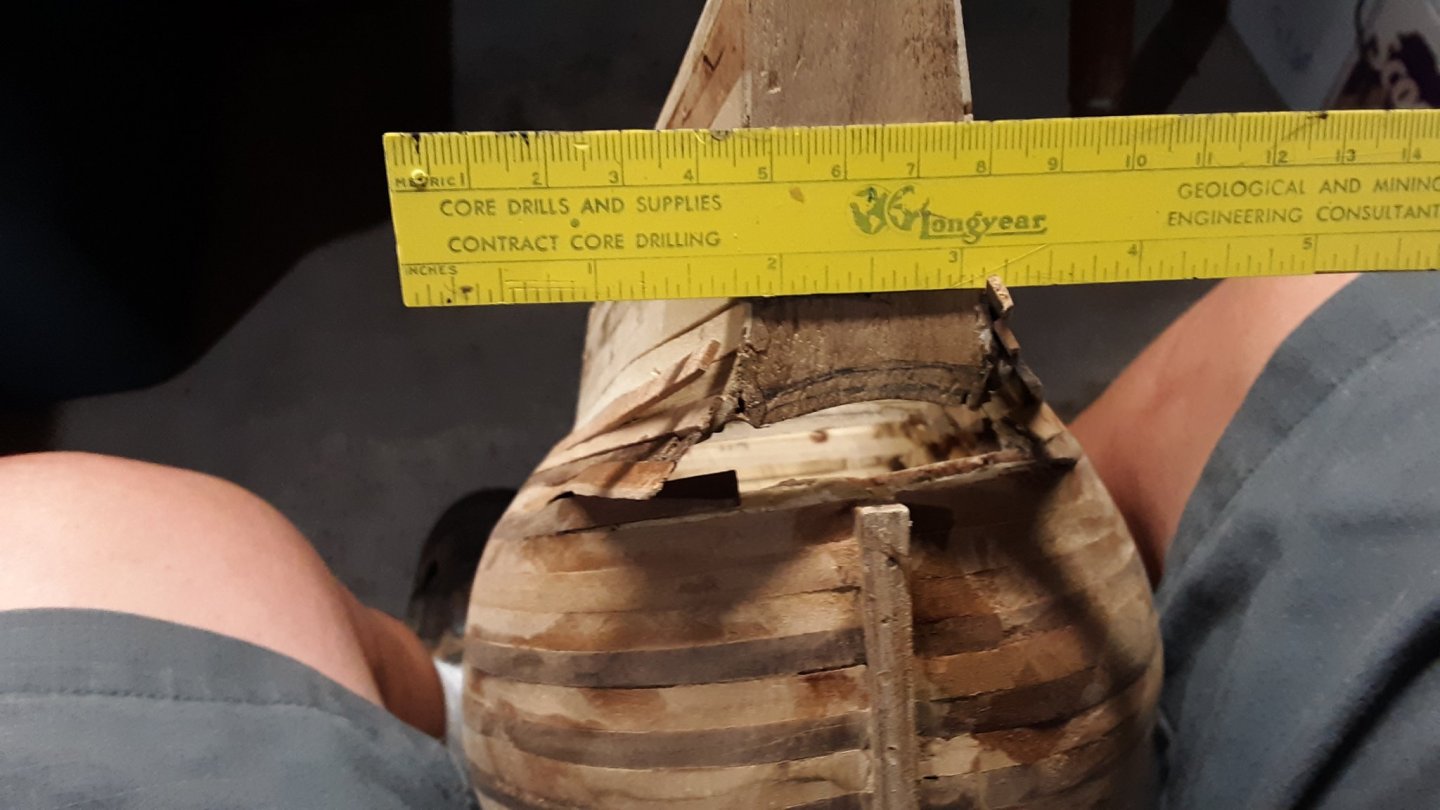

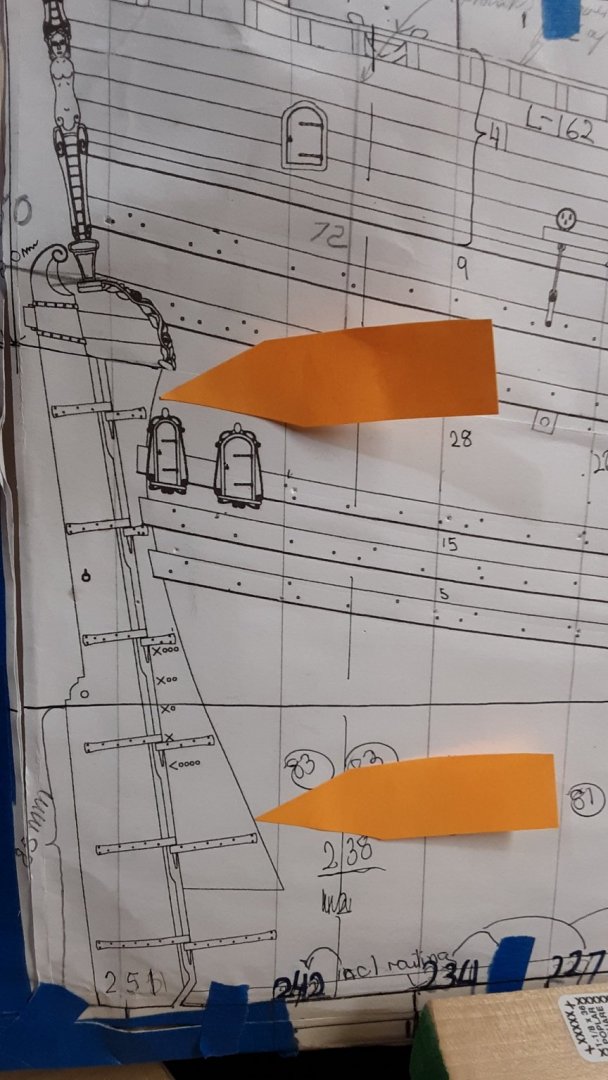

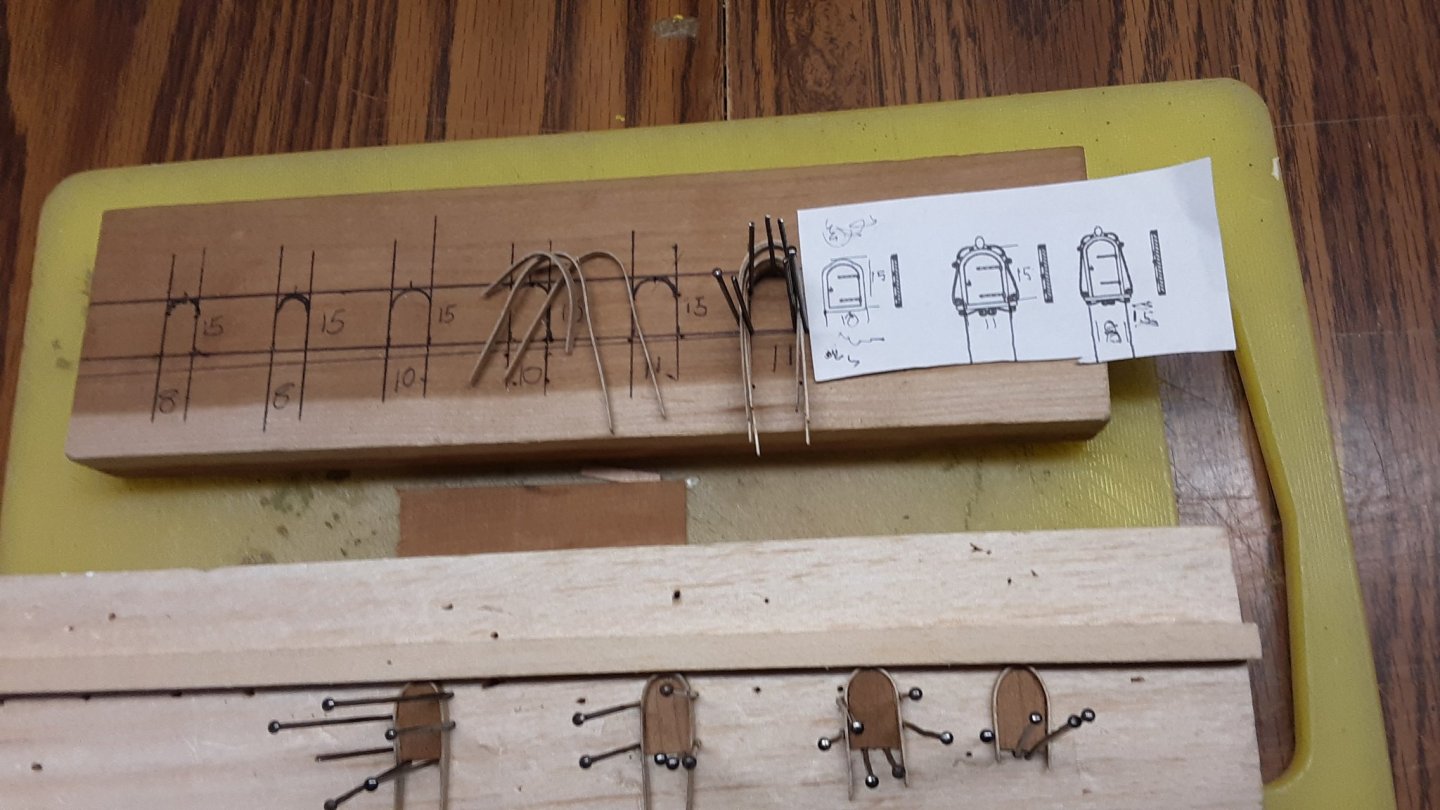

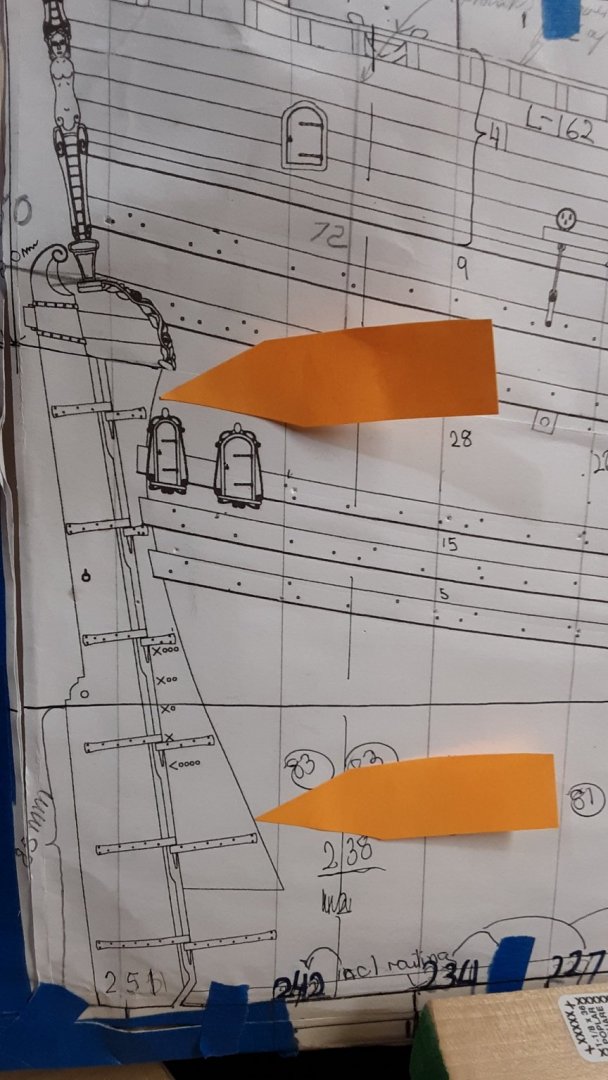

Made a template from the area that is glued on top of the sternpost.

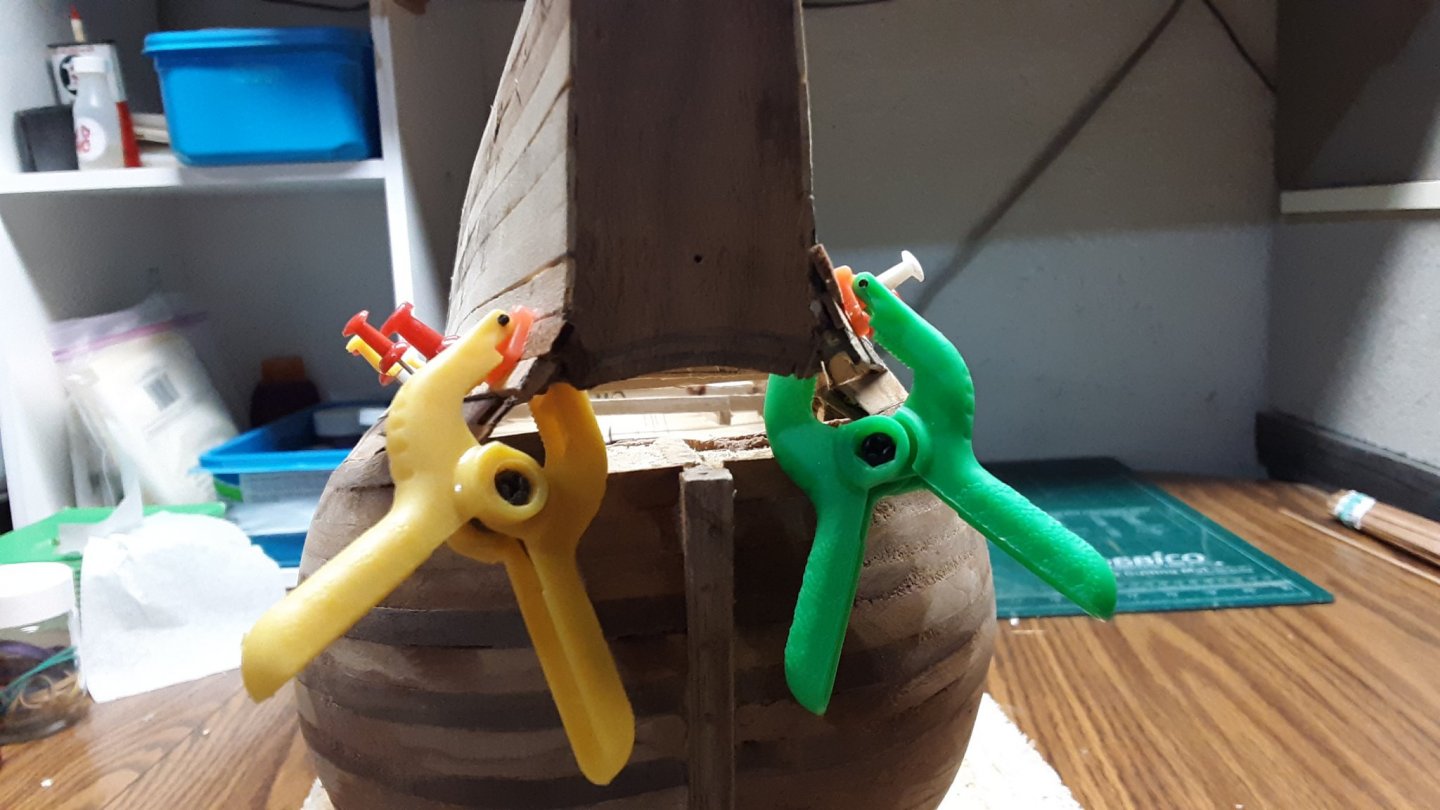

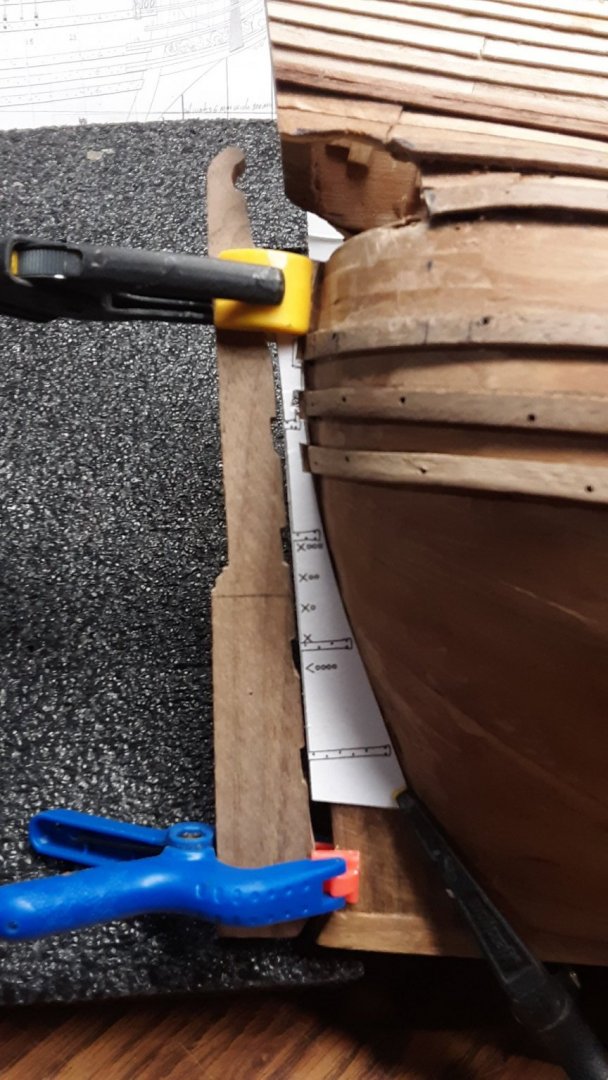

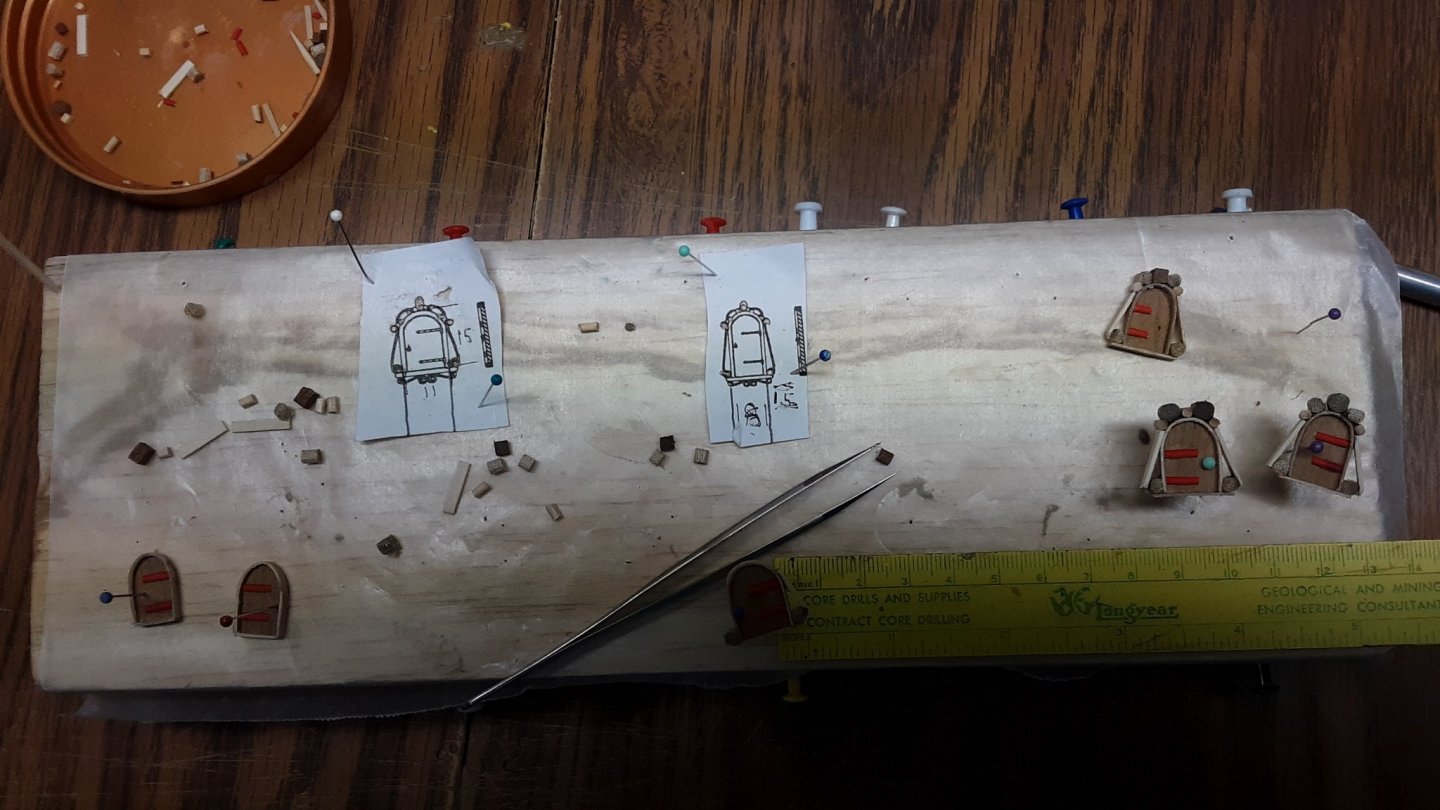

Created a 1mm thick veneer by glueing 0.5mm plywood and 0.5mm walnut veneer together. Used the template to create those 2 pieces and glued them to the sternpost. At the same time it will hide the square dowel added to the sternpost.

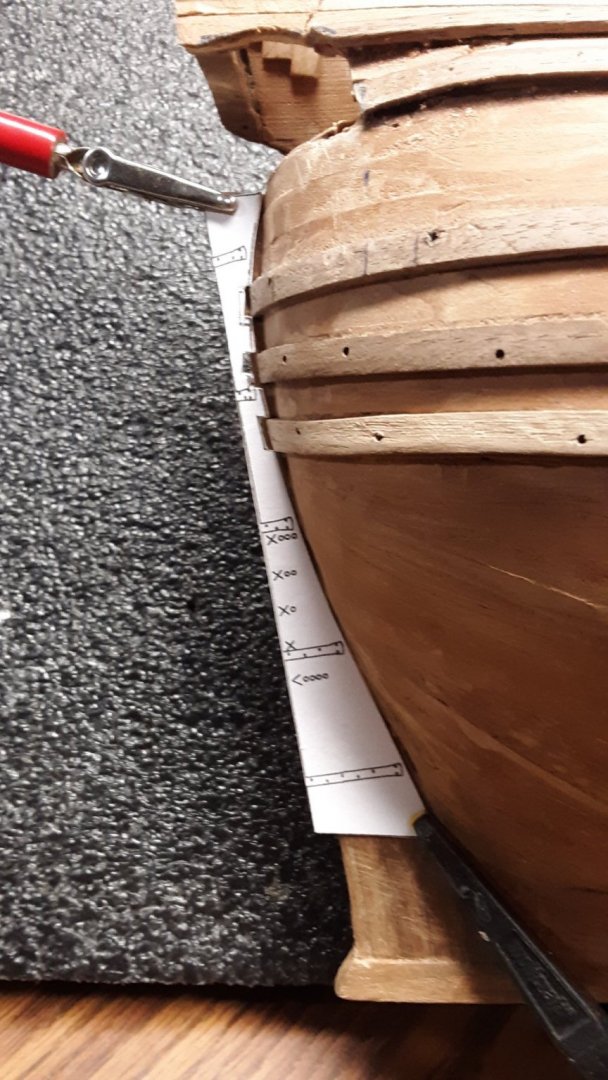

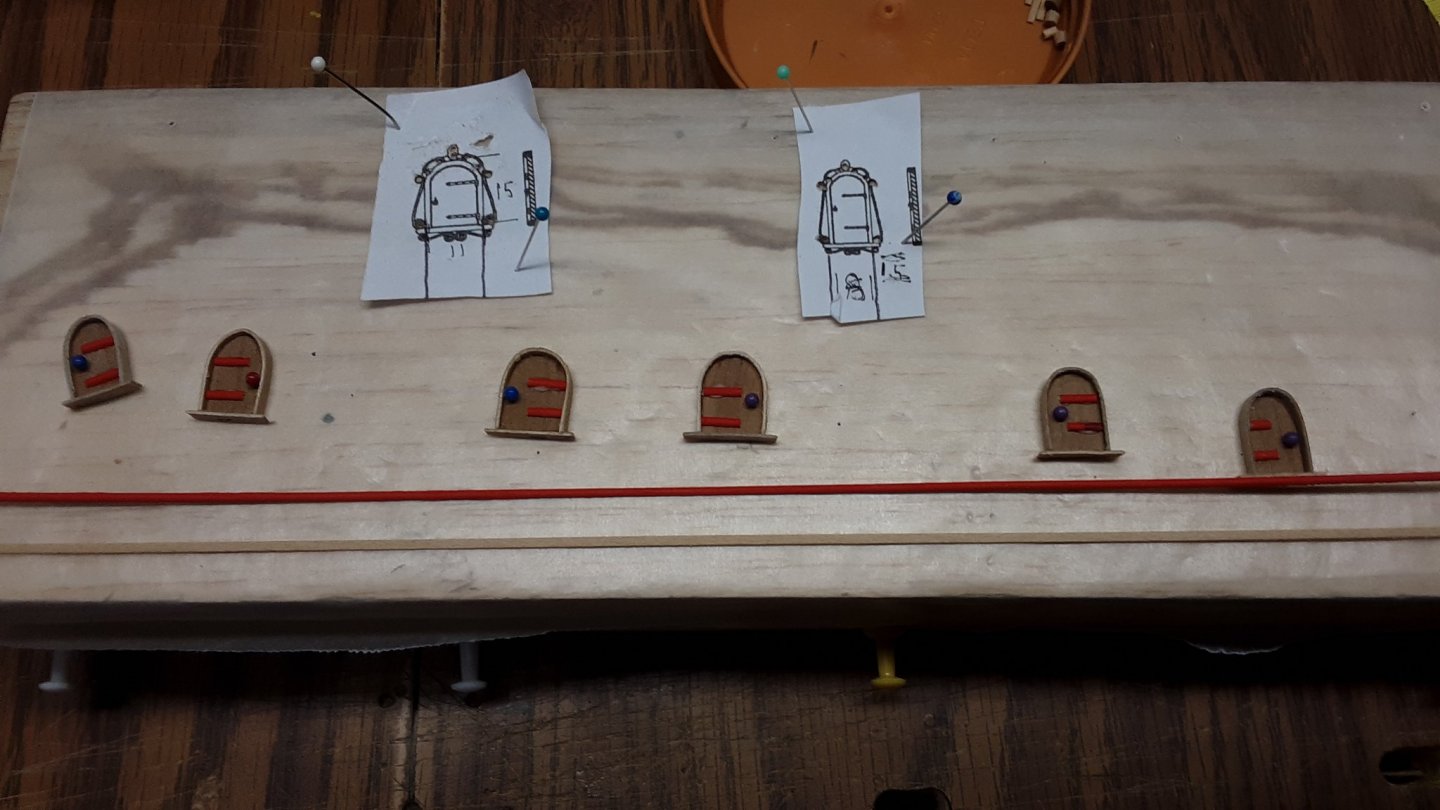

Now the area where the tiller goes in. In Dutch it's called het "hennegat".

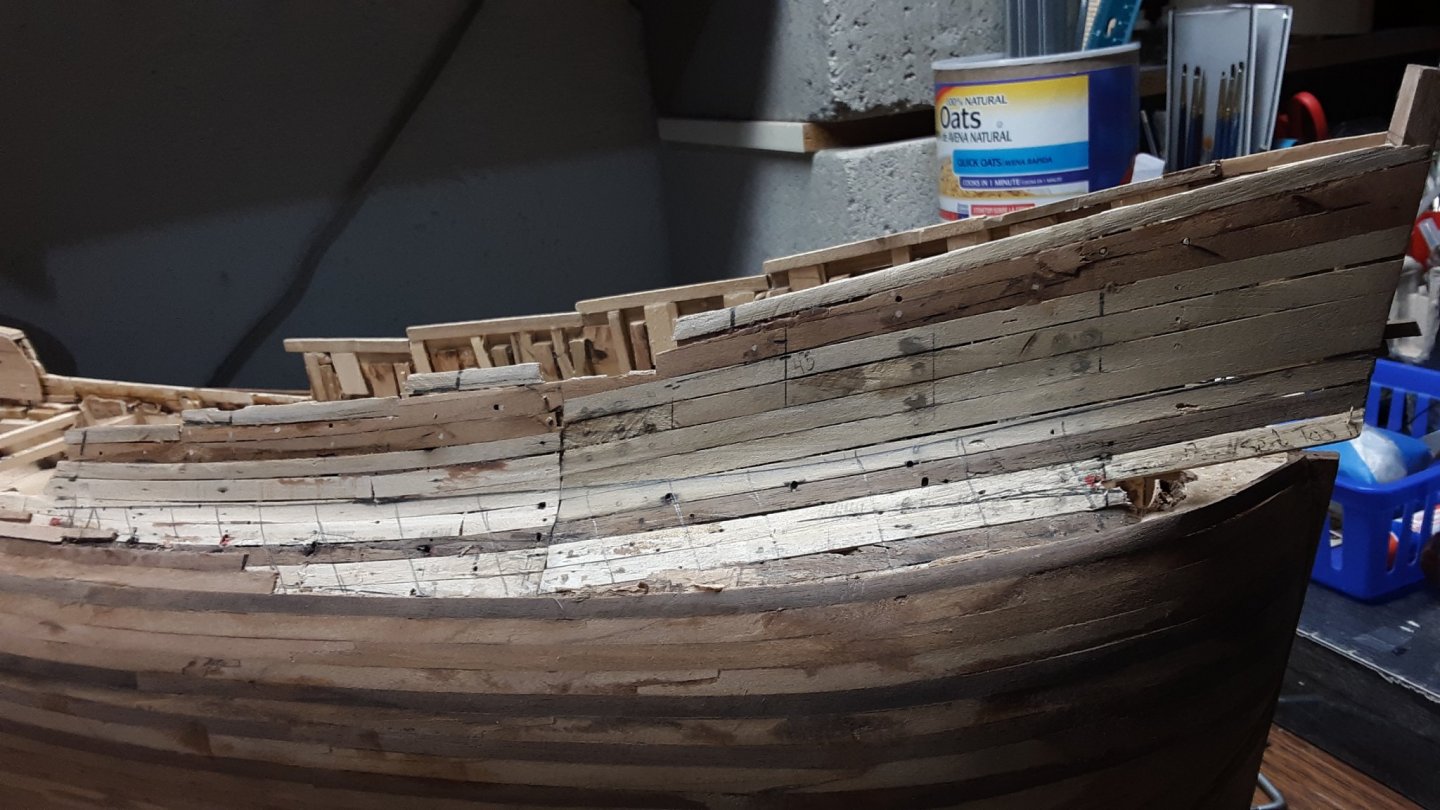

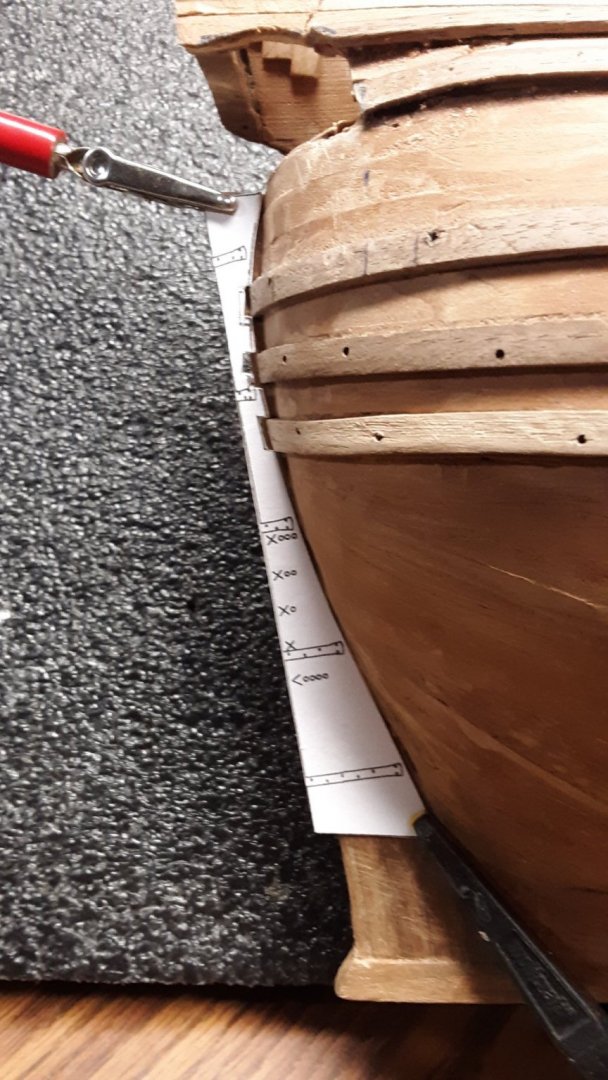

Removed with a x-acto knife and saw the two upper wales on both sides. Then sanded it even.

Created a template from a round dowel. Both sides of the dowel have the same angle as each of the sides of the Fluit

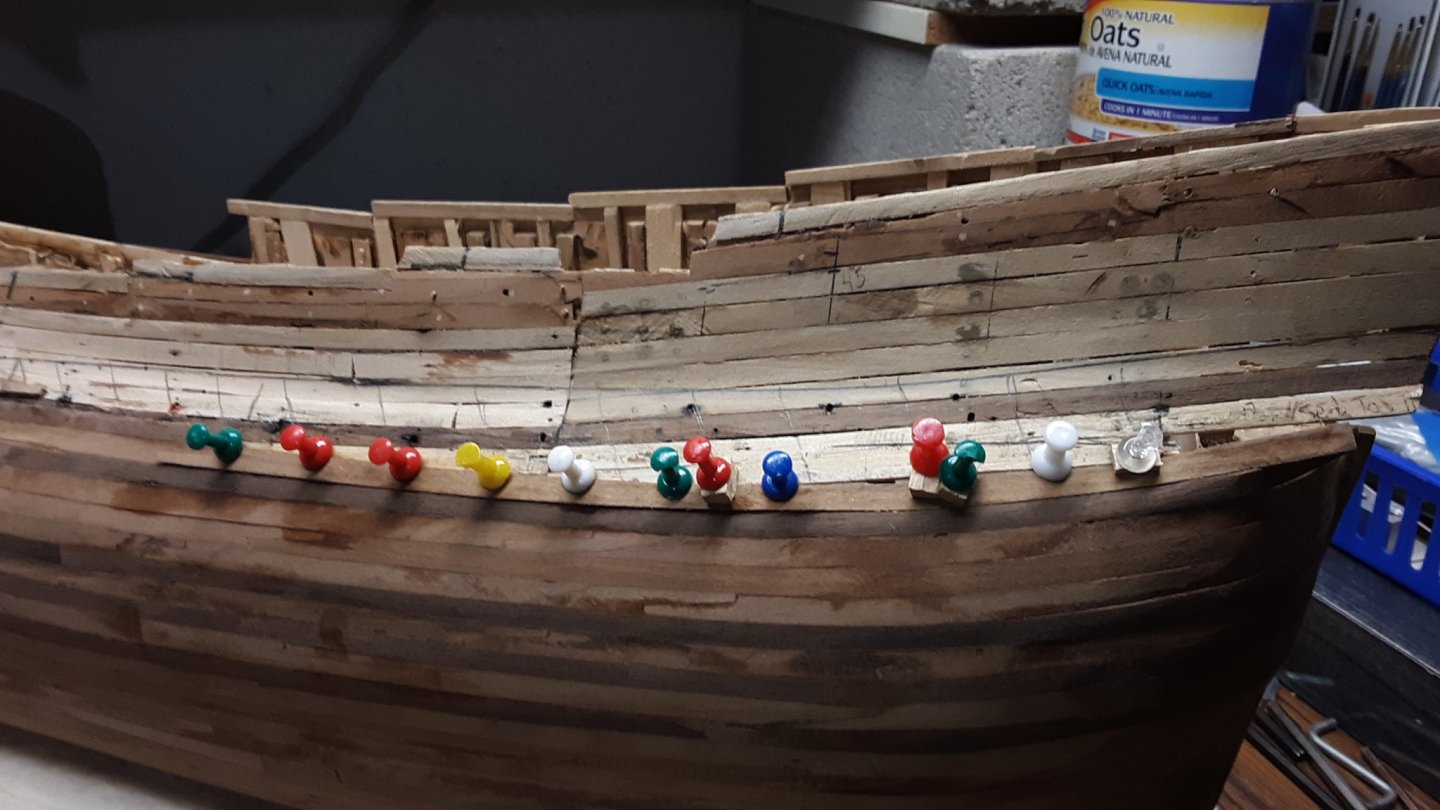

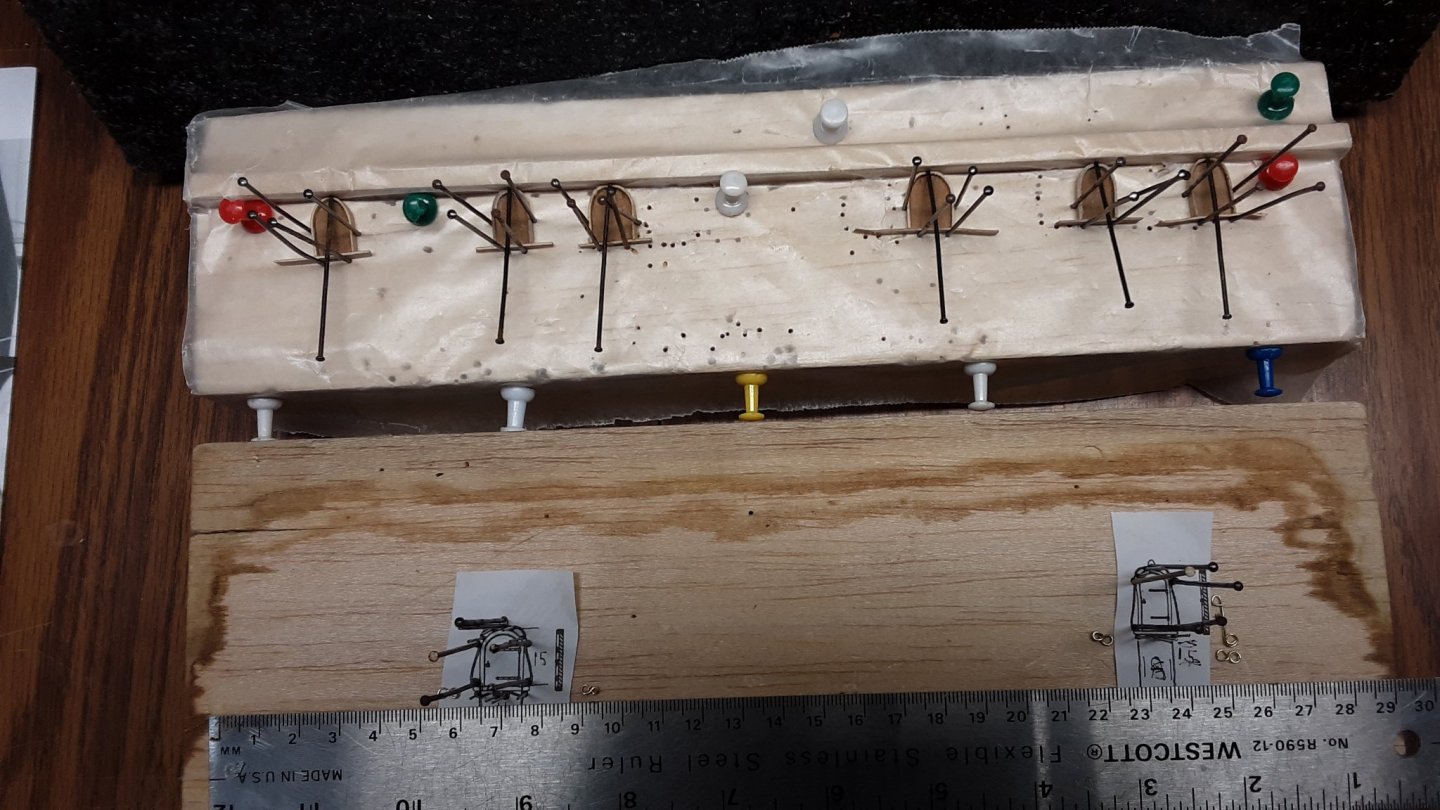

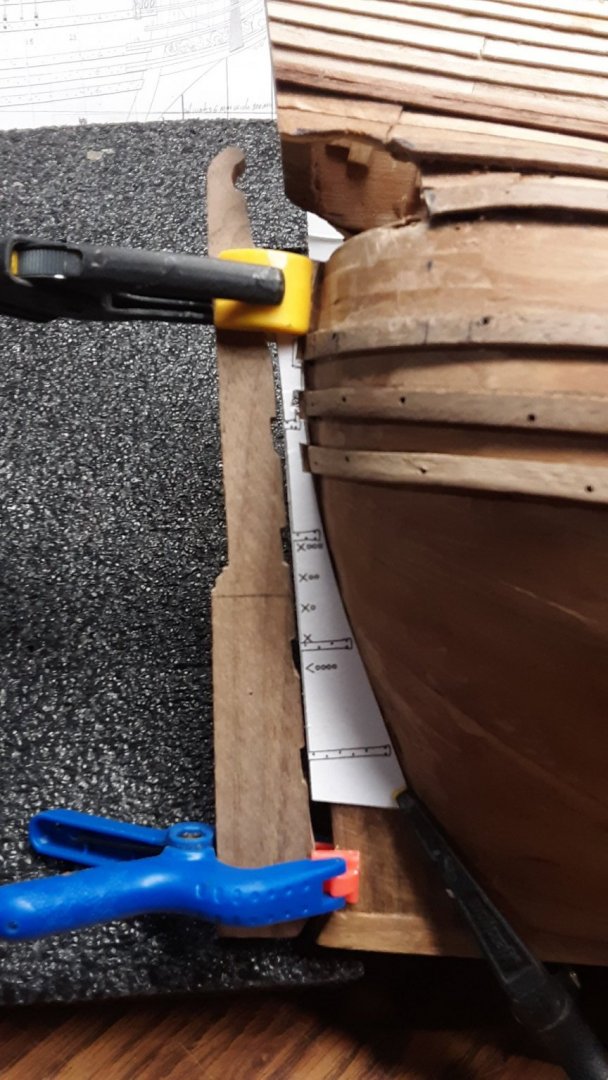

With a combination of glue and sawdust re - installed the upper wales. The glue / sawdust combo was also added to the inside of the planks to create a hard structure.

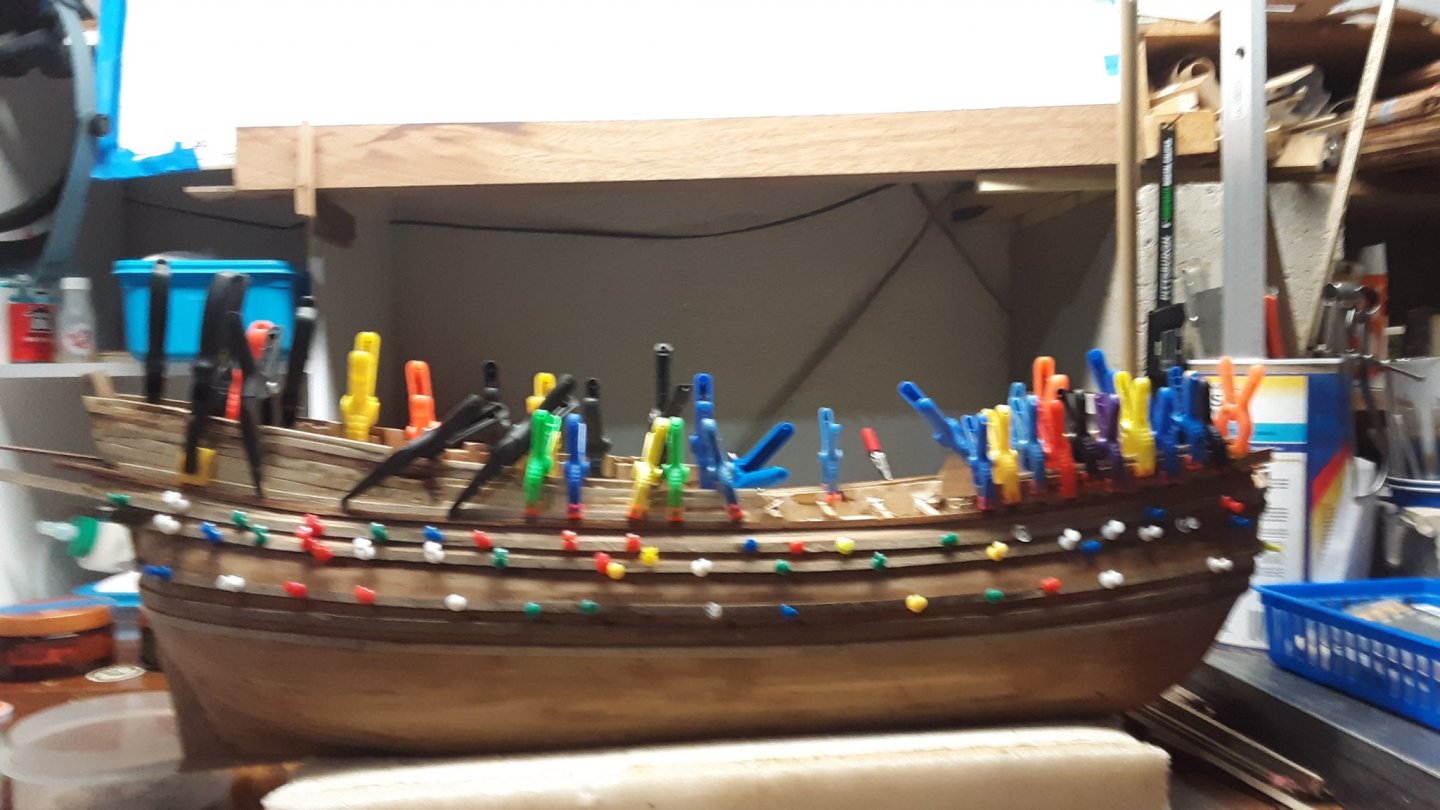

The newly glued on planks were held together with painters tape. The planks are thin as second layer will be installed on the first layer.

0.5mm thick small piece of plywood was soaked for 30 min in water. Shaped it around the round dowel. This piece follows the curve of the area where the tiller goes in.

If this does not work I will go back to the drawing table and figure something else out. Eventually I will find a solution. I refuse to trash this and start over correctly..

The bend 0.5mm thick plywood has been formed and installed where the tiller goes in and filled with the combo glue / sawdust.

Once this is dried and hardened I can make a rectangular hole wher the tiller goes through. After that I will plank it with walnut planks that are 0.5mm thick by 2mm wide strip wood.

The wales have been redone. Still needs much sanding

Marcus