-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

-

PRE-ORDER SHIPS IN SCALE TODAY!

The beloved Ships in Scale Magazine is back and charting a new course for 2026!

Discover new skills, new techniques, and new inspirations in every issue.

NOTE THAT OUR FIRST ISSUE WILL BE JAN/FEB 2026

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ZEEHAEN 1639, 1:37.5, Dutch fluit from Dutch Explorer Abel J. Tasman by Marcus

- Thread starter flying_dutchman2

- Start date

- Watchers 16

-

- Tags

- dutch fluit zeehaen

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Jimsky,

Thanks for the compliment and I mentioned it is Sculpey. I have to redo the eyes and create bulging cheeks as well as add a tail. I am more comfortable using clay instead of carving. I will still try to carve some other items.

Marcus

Thanks for the compliment and I mentioned it is Sculpey. I have to redo the eyes and create bulging cheeks as well as add a tail. I am more comfortable using clay instead of carving. I will still try to carve some other items.

Marcus

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Thanks for all the likes

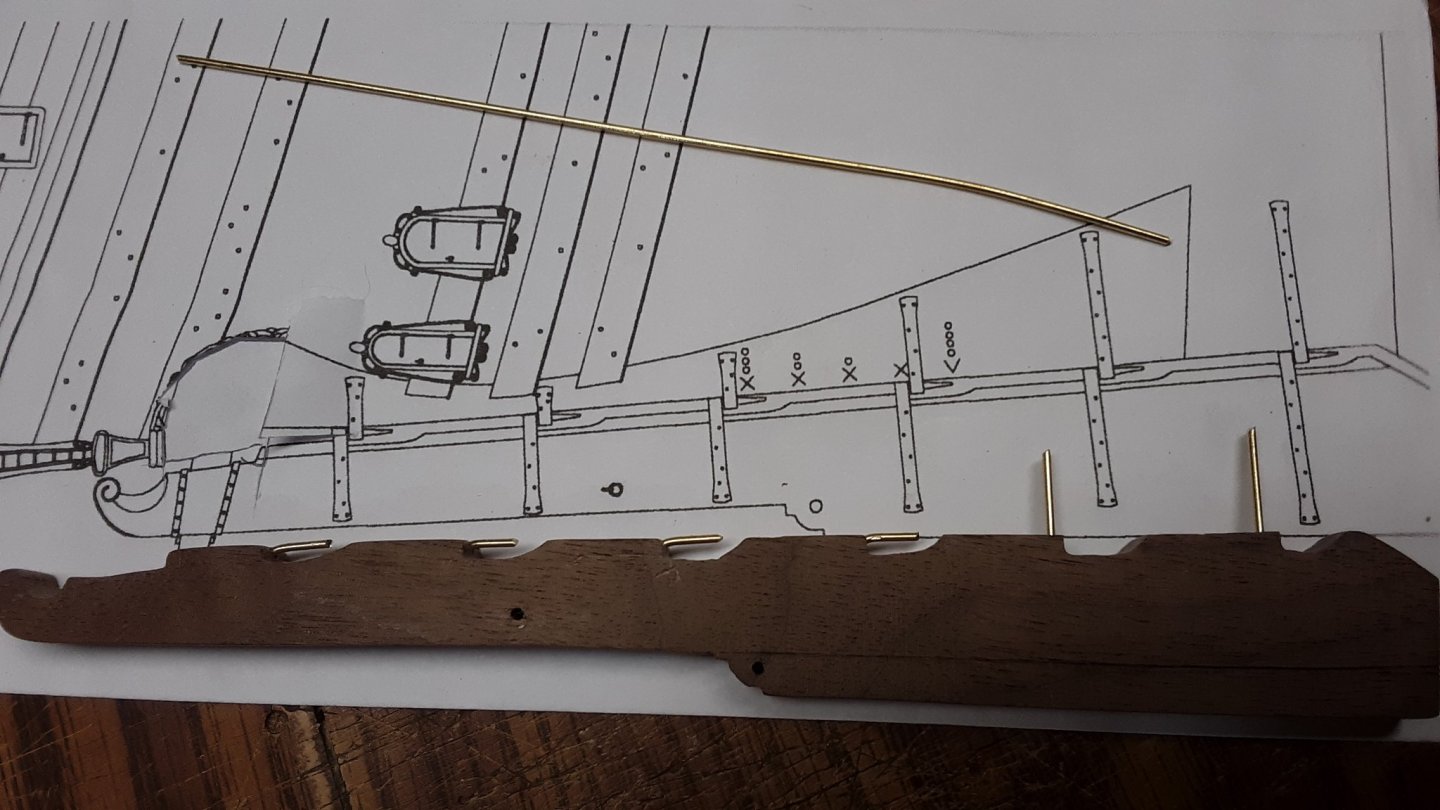

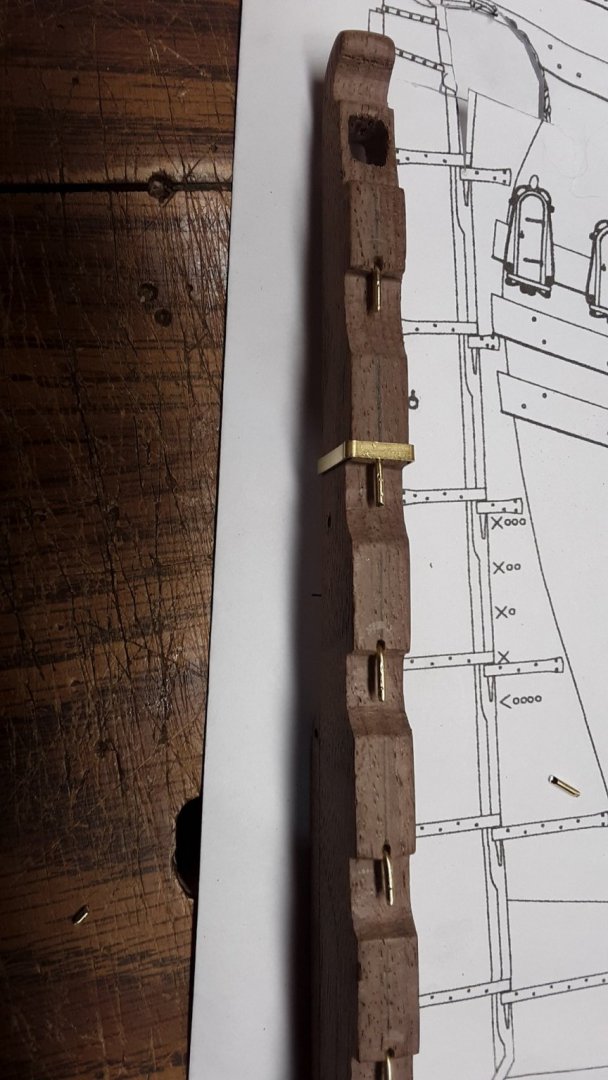

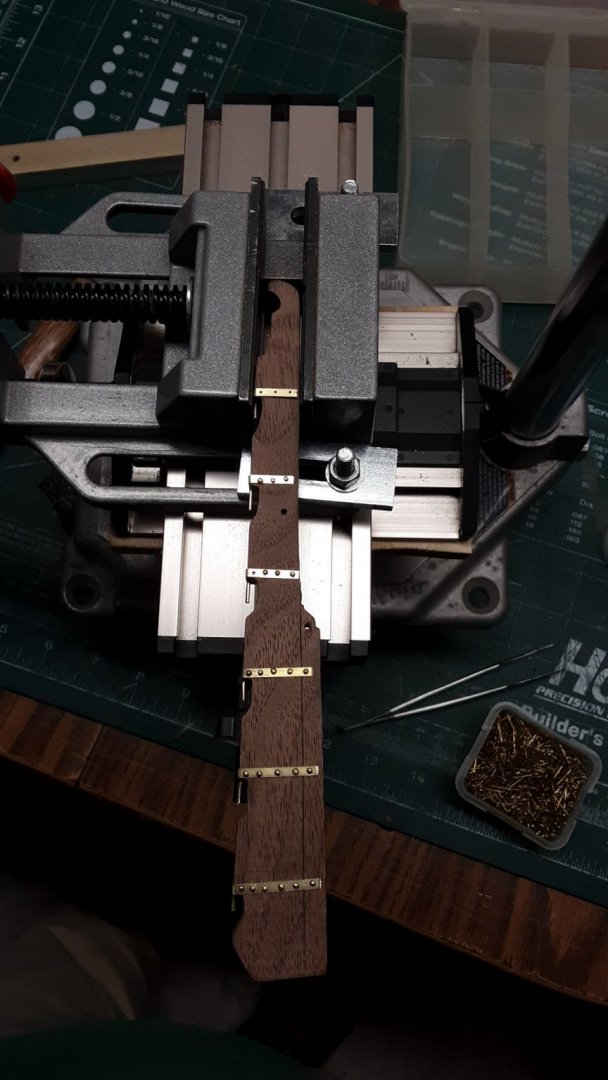

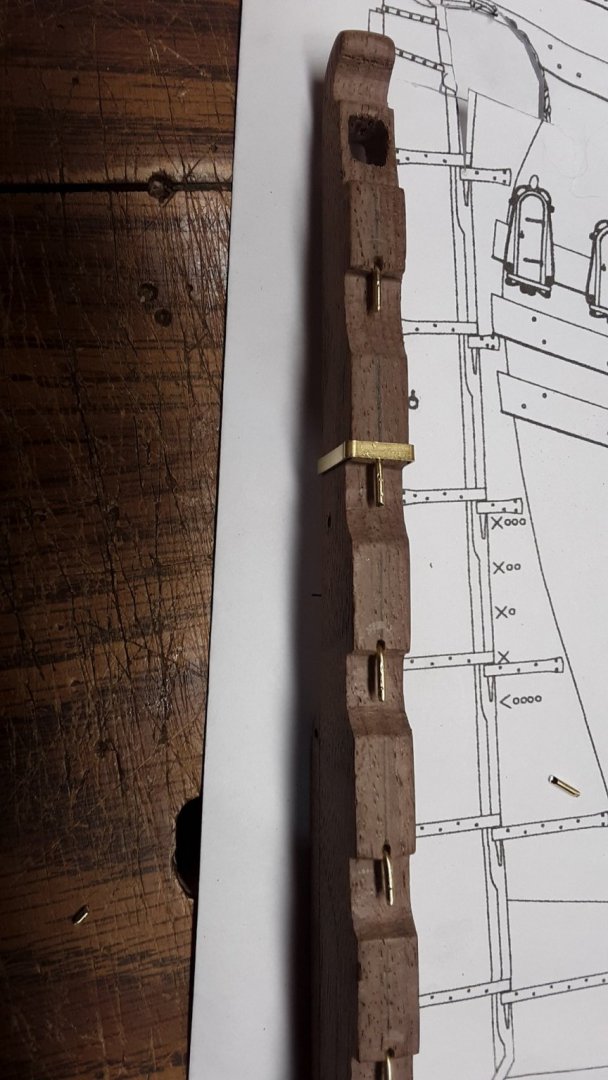

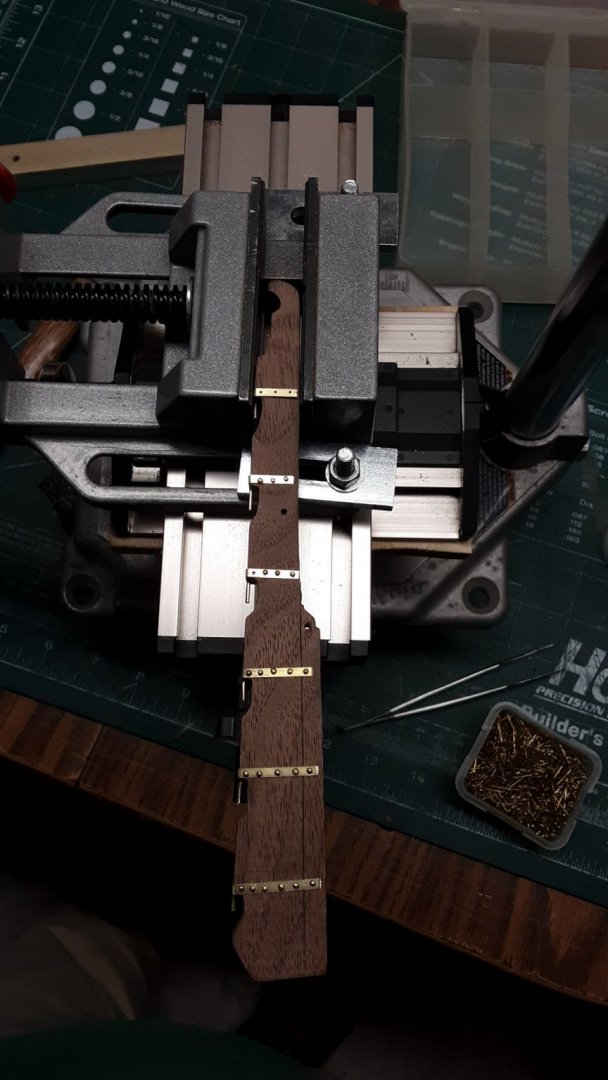

Worked on the rudder and created 6 gudgeons and pintels from brass bars which were 1/64" thick and 3/32" wide.

The top 3 were sanded lightly and painted with matt black oil paint. The bottom 3 and the bottom part of the hull will be painted dirty white.

Started working on the different decks. Lots of measuring.

Yesterday it was in the upper 40's so I put the bandsaw outside and cut 3 inch cedar planks down to an inch thick each. Made 2 birdhouses. They will probably be occupied by the many wren's I have.

Marcus

Worked on the rudder and created 6 gudgeons and pintels from brass bars which were 1/64" thick and 3/32" wide.

The top 3 were sanded lightly and painted with matt black oil paint. The bottom 3 and the bottom part of the hull will be painted dirty white.

Started working on the different decks. Lots of measuring.

Yesterday it was in the upper 40's so I put the bandsaw outside and cut 3 inch cedar planks down to an inch thick each. Made 2 birdhouses. They will probably be occupied by the many wren's I have.

Marcus

clever idea to "fake" the connection between the gudgeons and pintels - it is not possible to recognize

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Thanks for all the likes and comments.

I was reading the book from Mondfeld and on the pages of the "Head" he talkes about the "seats of ease", the latrines on a ship. He says that modelers rarely add this item. There is a modeler on MSW that built the Victory and he has added them on the head.

I checked the plans of the Zeehaen again and wondered if Cor Emke had added this to the head. I did notice a circle on each side of the head and wondered if that was it.

So I researched examples on other ships and it is rare that you find anything about it. I did find an article about Queens Ann Revenge wreck and divers had located a porta potty of that ship.

I decided to create 2 seats of ease and installed them on the head.

Marcus

I was reading the book from Mondfeld and on the pages of the "Head" he talkes about the "seats of ease", the latrines on a ship. He says that modelers rarely add this item. There is a modeler on MSW that built the Victory and he has added them on the head.

I checked the plans of the Zeehaen again and wondered if Cor Emke had added this to the head. I did notice a circle on each side of the head and wondered if that was it.

So I researched examples on other ships and it is rare that you find anything about it. I did find an article about Queens Ann Revenge wreck and divers had located a porta potty of that ship.

I decided to create 2 seats of ease and installed them on the head.

Marcus

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Thanks for all the likes and comments.

Added a layer of sanding sealer to the outside of the hull. The advantage for me is that when I paint any area of the hull and accidentally get paint on an area which is not to be painted, it wipes off easily without leaving anything behind.

The blue thing is a silicone ice cube tray and it is where I keep the paint I use in.

Painted the upper area of the hull and the little windows on the stern.

Colors used: Yellow Ochre, Chrome Oxide Green and Cadmium Red Deep Hue.

I ran out of maple for the deck planks so instead I am using Baltic Birch which is also nice and light in color, 1/32" (0.79mm) thick. Cut strips of 200mm L, by 6mm W and darkened one edge of it. I know it is not the conventional planking method but it works for me and the end result is about the same.

Gratings:

Started glueing 1mm x 1mm strips of basswood on basswood squares. Once dry I will cut them in 3mm pieces. Then I will turn them on edge and glue the pieces together. Once dry, a frame will be made around it and

installed on the decks. (I am using the example on pg 113, 114 of Ship Modeler's Shop Notes 1 from the NRG).

Deck planking:

Next, slowly planking the deck. The wood strips that are located where the gratings go are 8mm and 9mm wide and all other strips are 6mm wide. The average length on all of them is 200mm. Planking the decks towards the edge of the inside of the hull wall is another exercise of patience. Unlike most

ships the hull wall goes straight up but on the Fluit it bends inward. Lots of trail and error.

Stern windows

Next I will start making the different deck items.

Marcus

Added a layer of sanding sealer to the outside of the hull. The advantage for me is that when I paint any area of the hull and accidentally get paint on an area which is not to be painted, it wipes off easily without leaving anything behind.

The blue thing is a silicone ice cube tray and it is where I keep the paint I use in.

Painted the upper area of the hull and the little windows on the stern.

Colors used: Yellow Ochre, Chrome Oxide Green and Cadmium Red Deep Hue.

I ran out of maple for the deck planks so instead I am using Baltic Birch which is also nice and light in color, 1/32" (0.79mm) thick. Cut strips of 200mm L, by 6mm W and darkened one edge of it. I know it is not the conventional planking method but it works for me and the end result is about the same.

Gratings:

Started glueing 1mm x 1mm strips of basswood on basswood squares. Once dry I will cut them in 3mm pieces. Then I will turn them on edge and glue the pieces together. Once dry, a frame will be made around it and

installed on the decks. (I am using the example on pg 113, 114 of Ship Modeler's Shop Notes 1 from the NRG).

Deck planking:

Next, slowly planking the deck. The wood strips that are located where the gratings go are 8mm and 9mm wide and all other strips are 6mm wide. The average length on all of them is 200mm. Planking the decks towards the edge of the inside of the hull wall is another exercise of patience. Unlike most

ships the hull wall goes straight up but on the Fluit it bends inward. Lots of trail and error.

Stern windows

Next I will start making the different deck items.

Marcus

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Thanks for all the likes and comments.

Last couple of days have been in the 70's F (20°C) (rare watm weather) so spend time cleaning up the flower beds and edible garden.

Finished the tiller and whipstaff. I will install this when I am ready to put the back deck in. I built it in a way that once installed it actually works.

The nosy cat, Boomer at 18 years.

Gratings have been glued together and need a good sanding. Also made the mast holders (don't know the name) and the railings with the reiling pillars.

Cut out all the different types of bits and started shaping them.

Did some more Sculpey work. These two faces/heads need to be identical, but they are not. Will need to adjust this or leave it as is.

Marcus

Last couple of days have been in the 70's F (20°C) (rare watm weather) so spend time cleaning up the flower beds and edible garden.

Finished the tiller and whipstaff. I will install this when I am ready to put the back deck in. I built it in a way that once installed it actually works.

The nosy cat, Boomer at 18 years.

Gratings have been glued together and need a good sanding. Also made the mast holders (don't know the name) and the railings with the reiling pillars.

Cut out all the different types of bits and started shaping them.

Did some more Sculpey work. These two faces/heads need to be identical, but they are not. Will need to adjust this or leave it as is.

Marcus

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Thanks for all the likes, suggestions and comments.

This is wat the Zeehaen presently looks like.

Made the railings. Cut numerous little blocks from square dowels and glued them in place, then added a strip of wood on top and painted it all with Acrylic Mars Black which is matt.

Railings

Front area which has not been glued on the ship yet. The davits have been glued on an angle in place.

Railings on an angle.

All gratings were made from walnut and added 4 rings to the large and medium grate an 2 rings to the smaller one.

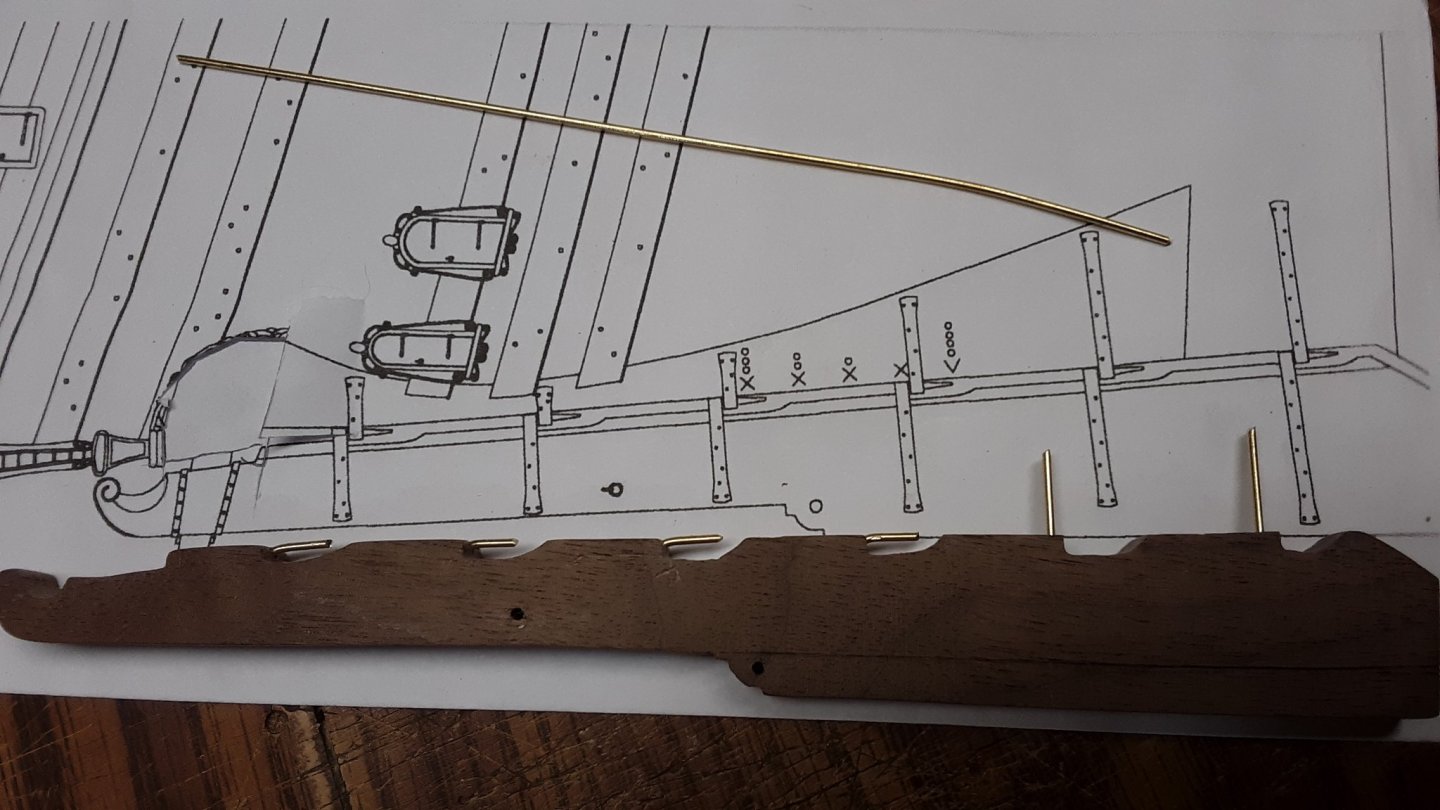

Starting to work on the channels.

As the weather gets warmer, I spend less time building and more time in the garden. This year my edible garden will be intense.

Marcus

This is wat the Zeehaen presently looks like.

Made the railings. Cut numerous little blocks from square dowels and glued them in place, then added a strip of wood on top and painted it all with Acrylic Mars Black which is matt.

Railings

Front area which has not been glued on the ship yet. The davits have been glued on an angle in place.

Railings on an angle.

All gratings were made from walnut and added 4 rings to the large and medium grate an 2 rings to the smaller one.

Starting to work on the channels.

As the weather gets warmer, I spend less time building and more time in the garden. This year my edible garden will be intense.

Marcus

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Hi Heinrich,Hello Marcus. You are making good progress! I like the idea that the two faces are not identical. Please tell us the name of the zeeduivel!

I suggest you come up with a name.

Marcus

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Still working on the deck items but have a question about the rigging of the fluit.

What are the rules for determining the dimensions of rope for standing and running rigging?

Especially large ships such as man-of-war, Pinas, East Indiaman, etc.

When I scratch built the Utrecht, the Boyer and other smaller Dutch ships, I guessed the rigging and the results were good. Now I am building a larger ship en cannot guess the rigging anymore.

Books I have:

C. G. Davis, The Ship model builder's assistant

G. Biddlecombe, The art of rigging (pretty good explanations lots of tables but not how they got the numbers)

R. C. Anderson, The rigging of ships in the days of the spritsail Topmast 1600-1720

W. zu Mondfeld, Historic ship models (reasonable explanation)

M. Roth, Ship Modeling from stem to stern (very extensive explanations)

D.Steel The Art of Rigging (1796)

Are there other books, Excel spreadsheets, and URLs where the given question is discussed?

What are the math formulas with answers?

Can someone give me and write down an example?

Thank you very much.

Marcus

What are the rules for determining the dimensions of rope for standing and running rigging?

Especially large ships such as man-of-war, Pinas, East Indiaman, etc.

When I scratch built the Utrecht, the Boyer and other smaller Dutch ships, I guessed the rigging and the results were good. Now I am building a larger ship en cannot guess the rigging anymore.

Books I have:

C. G. Davis, The Ship model builder's assistant

G. Biddlecombe, The art of rigging (pretty good explanations lots of tables but not how they got the numbers)

R. C. Anderson, The rigging of ships in the days of the spritsail Topmast 1600-1720

W. zu Mondfeld, Historic ship models (reasonable explanation)

M. Roth, Ship Modeling from stem to stern (very extensive explanations)

D.Steel The Art of Rigging (1796)

Are there other books, Excel spreadsheets, and URLs where the given question is discussed?

What are the math formulas with answers?

Can someone give me and write down an example?

Thank you very much.

Marcus

Pictures of my fluit are posted on https://shipsofscale.com/sosforums/threads/dutch-fluit-from-hoving-plans.4672/. The spread sheet I used for rigging in 1/64 scale is attached. I apologize for it being somewhat cryptic but all the data is there.Still working on the deck items but have a question about the rigging of the fluit.

What are the rules for determining the dimensions of rope for standing and running rigging?

Especially large ships such as man-of-war, Pinas, East Indiaman, etc.

When I scratch built the Utrecht, the Boyer and other smaller Dutch ships, I guessed the rigging and the results were good. Now I am building a larger ship en cannot guess the rigging anymore.

Books I have:

C. G. Davis, The Ship model builder's assistant

G. Biddlecombe, The art of rigging (pretty good explanations lots of tables but not how they got the numbers)

R. C. Anderson, The rigging of ships in the days of the spritsail Topmast 1600-1720

W. zu Mondfeld, Historic ship models (reasonable explanation)

M. Roth, Ship Modeling from stem to stern (very extensive explanations)

D.Steel The Art of Rigging (1796)

Are there other books, Excel spreadsheets, and URLs where the given question is discussed?

What are the math formulas with answers?

Can someone give me and write down an example?

Thank you very much.

Marcus

Attachments

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

- Joined

- Aug 8, 2019

- Messages

- 5,592

- Points

- 738

you're welcome. In the sheet of mine you don't have to give a scale. When the main mast on your model is in the right scale, measure that and use that value.

- Joined

- Mar 11, 2020

- Messages

- 213

- Points

- 143

Presently not doing any building except on rainy days. Since the beginning of May it has been great weather, so most of my time is spent outside in the flower and edible garden.

Marcus

Marcus