- Home

- Forums

- Ships of Scale Build Logs

- Super Detailing Static Models / Other Genres

- Historical Trailways, Guns, Aircraft, and Cars

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1930 Bentley Blower by Aifix 1/12 build log

- Thread starter François

- Start date

- Watchers 34

-

- Tags

- 1930 airfix bentley blower

What printer do you use?

It's the anycubic photon mono m5s 12k with a waterwash resin.

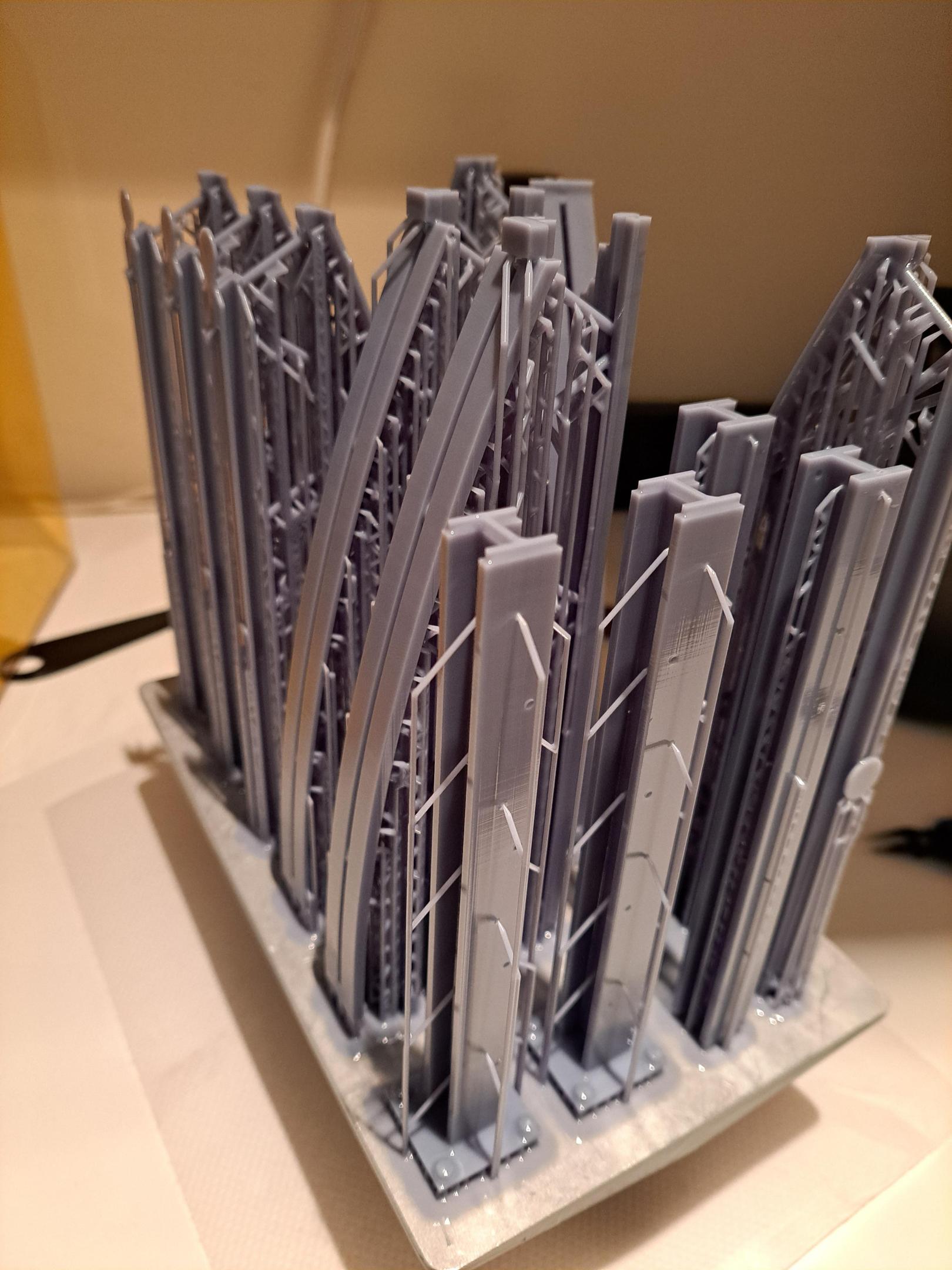

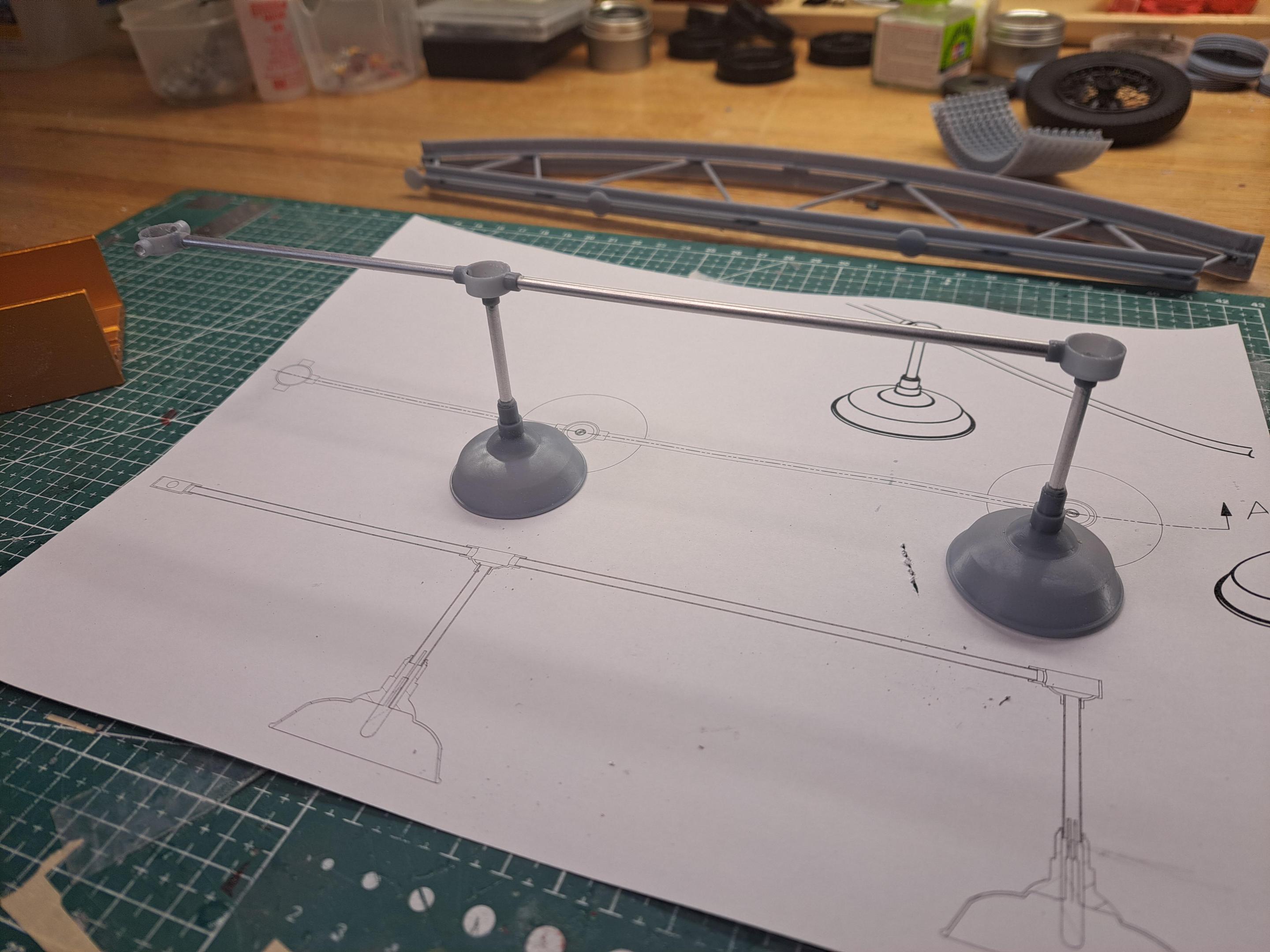

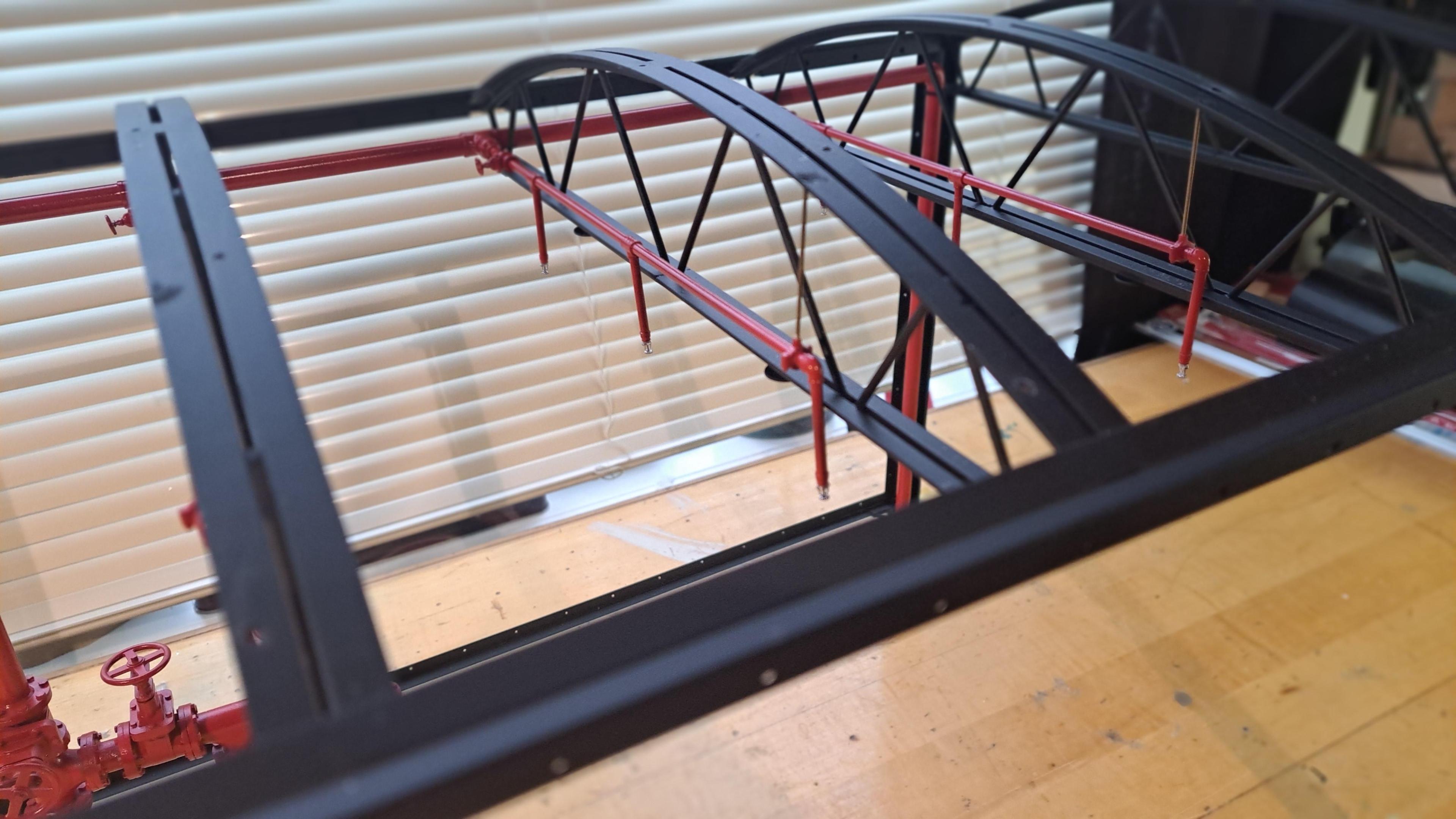

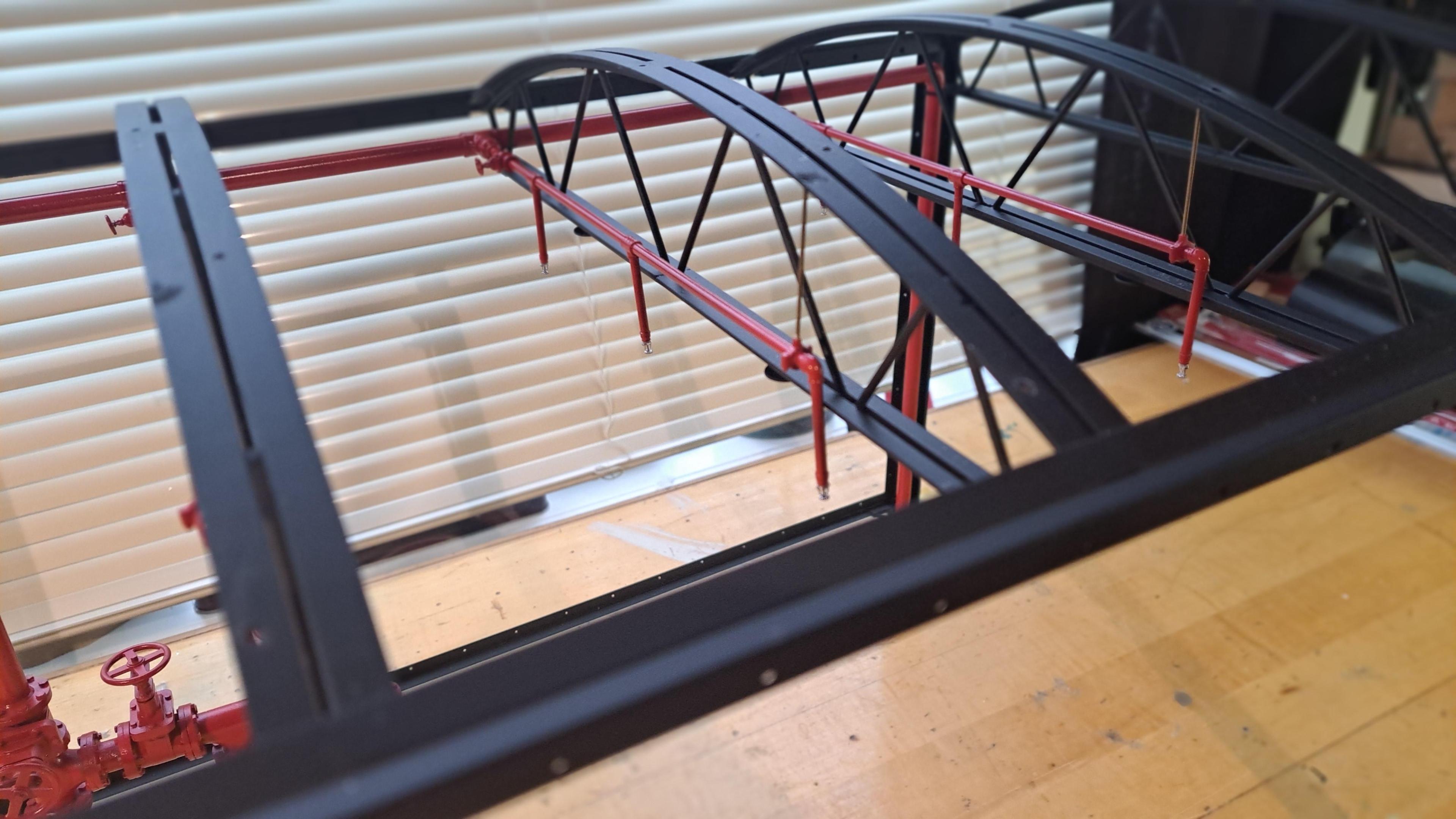

Started some sub assemblies on the display case today.

All 5 trusses are glued

4 H columns

They were too long to print in one piece so I did them in 2. I added a locating feature at the ends of both half to assure a good alignment.

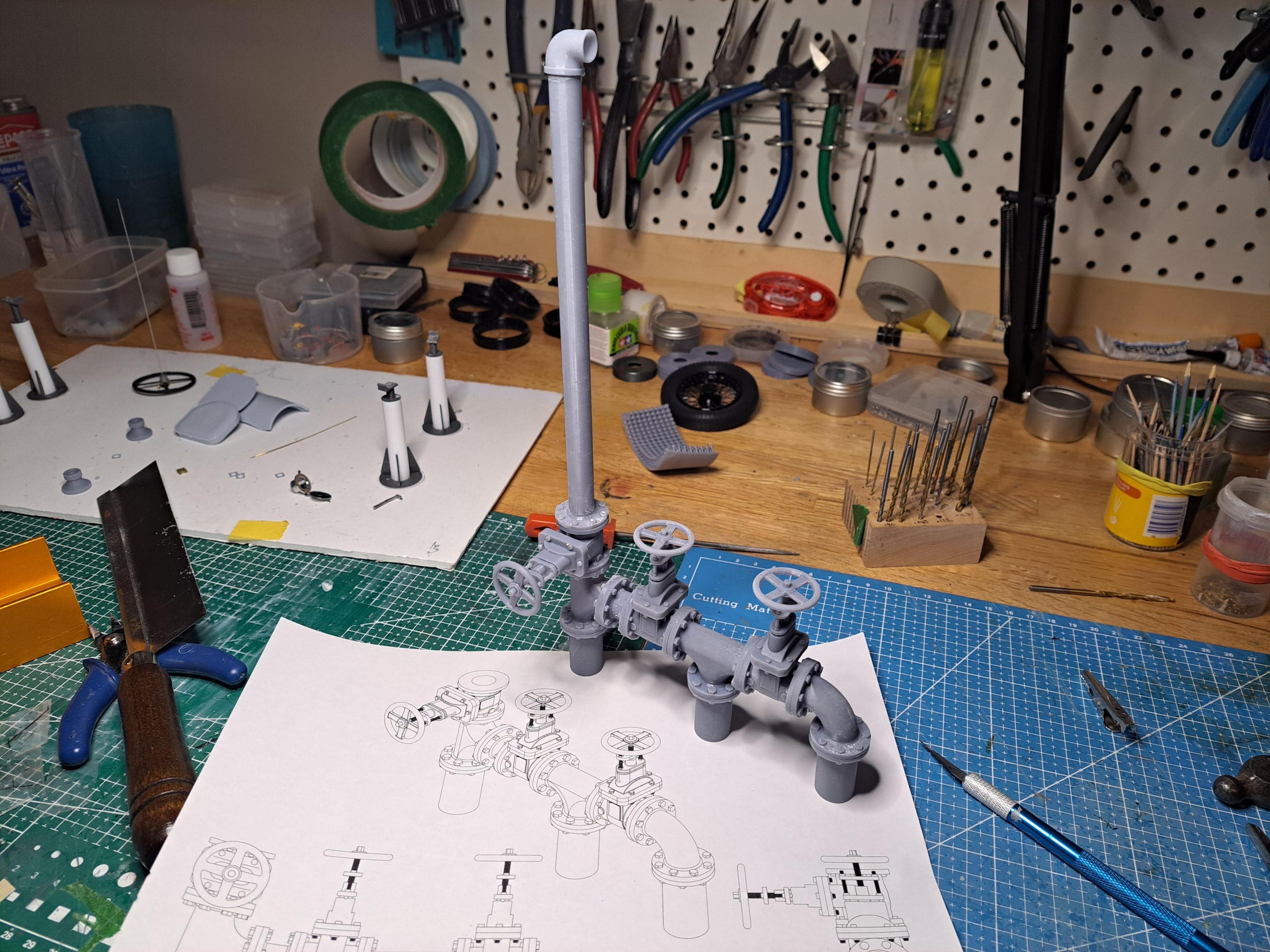

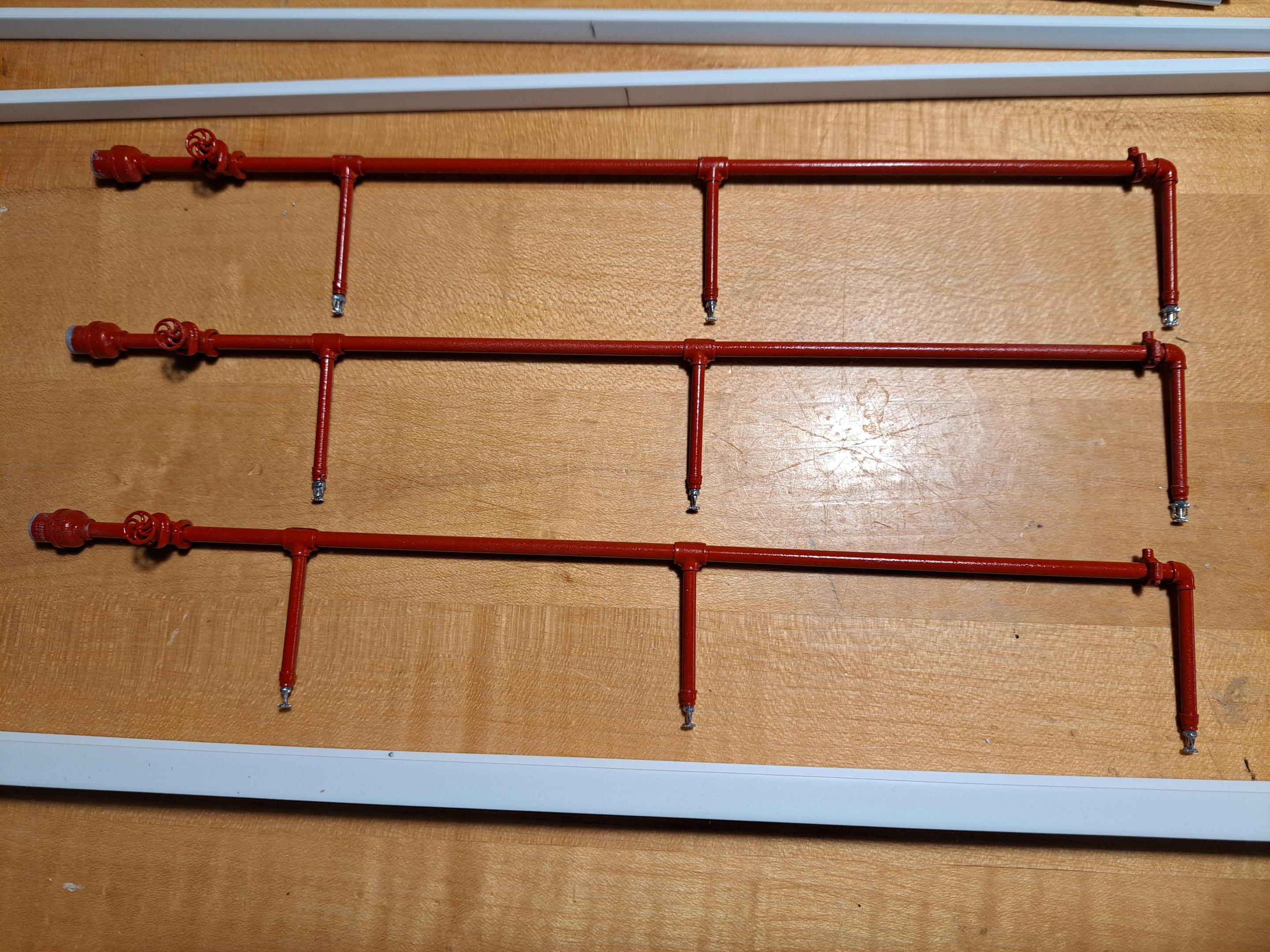

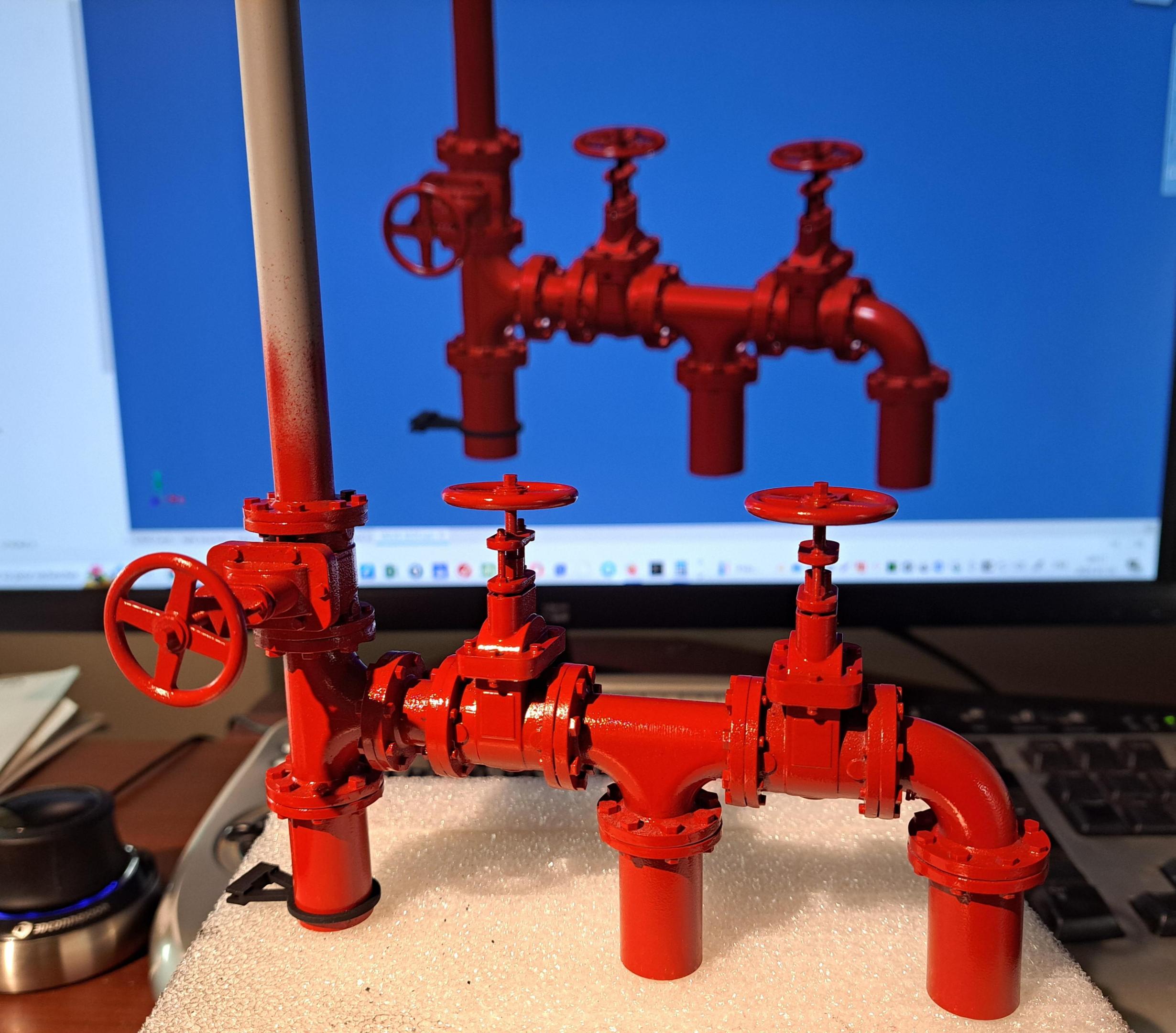

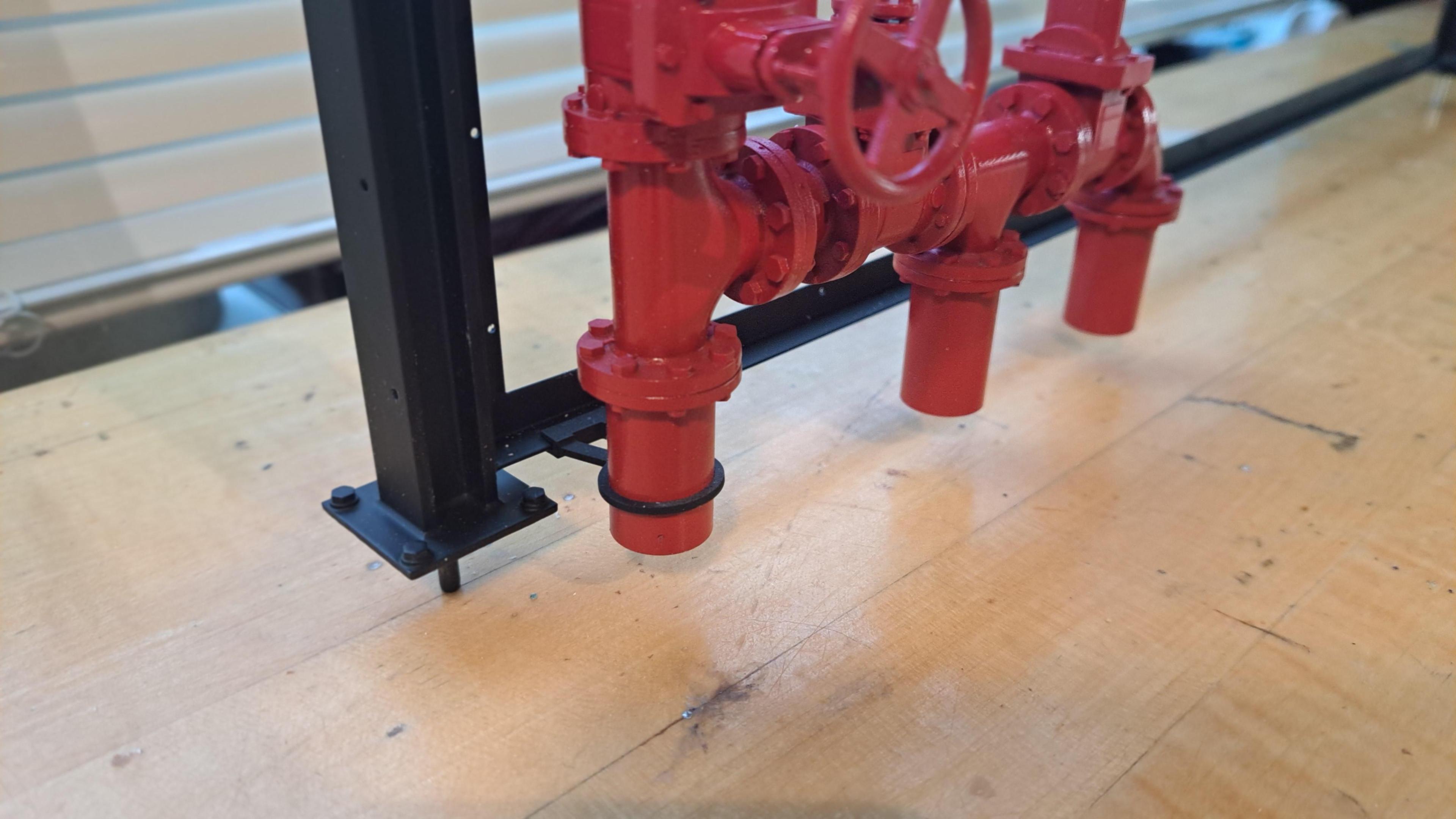

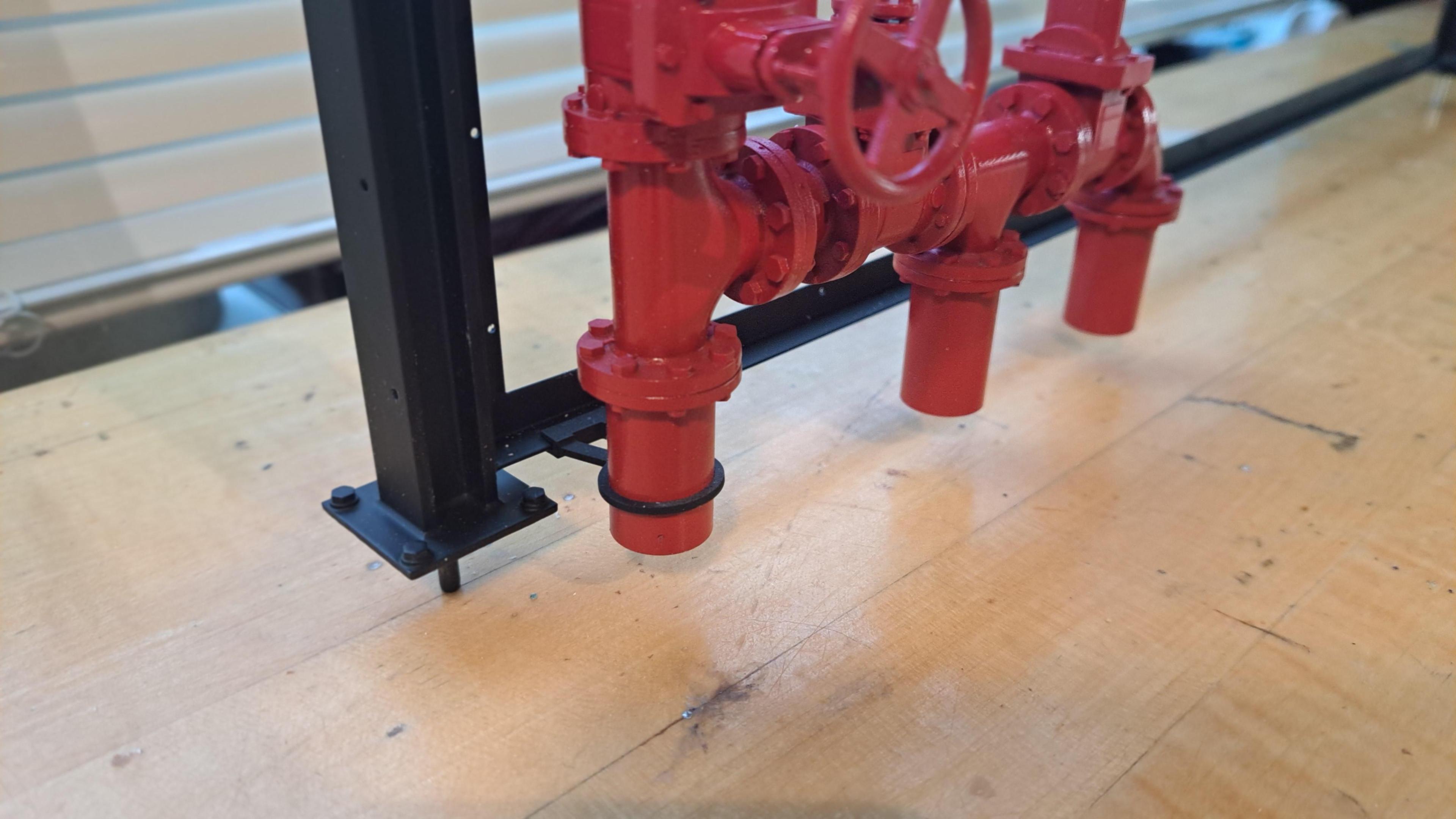

Did the large gate valve assy

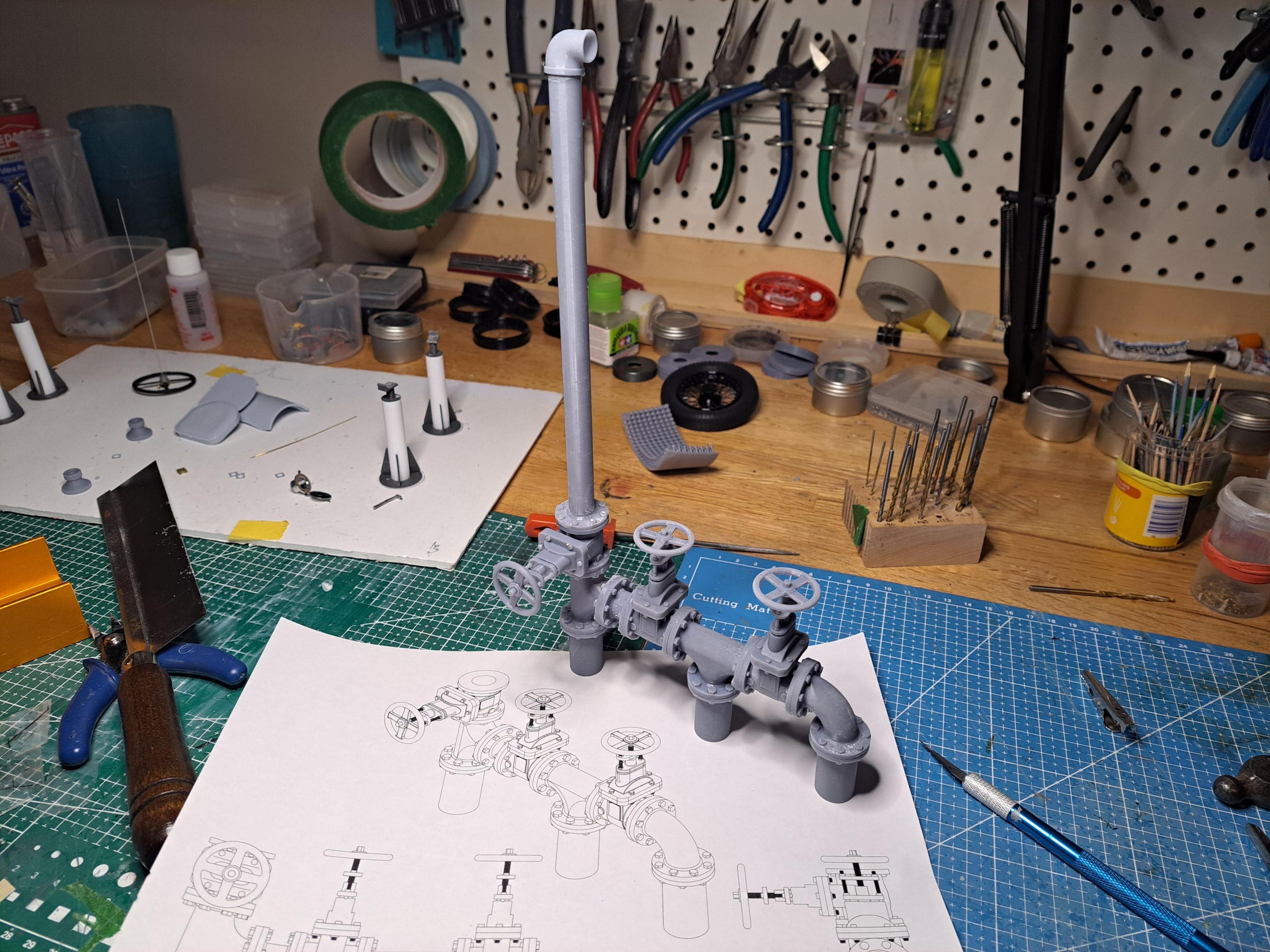

And the 3 sprinkler pipes

This is the only gate valve from my father's inventory that I could fit, there's a small part of him in this.

On an other topic, I found this really old and beat up Pocher rolls royce at my local hobby shop. It's missing many parts. I'm thinking it could be an interesting project, total dismantle, refurbishing, and adding some of my special festures to it. But I would need to get for next to nothing... to be continued...

All 5 trusses are glued

4 H columns

They were too long to print in one piece so I did them in 2. I added a locating feature at the ends of both half to assure a good alignment.

Did the large gate valve assy

And the 3 sprinkler pipes

This is the only gate valve from my father's inventory that I could fit, there's a small part of him in this.

On an other topic, I found this really old and beat up Pocher rolls royce at my local hobby shop. It's missing many parts. I'm thinking it could be an interesting project, total dismantle, refurbishing, and adding some of my special festures to it. But I would need to get for next to nothing... to be continued...

With this Rolls Royce you can build a diorama of an abandoned workshop.

- Joined

- Aug 6, 2020

- Messages

- 7

- Points

- 53

Keep the original dust!With this Rolls Royce you can build a diorama of an abandoned workshop.

For me, leaving it as is would be boring. I restored a Triumph TR6 back in 2006 and liked the project very much. I would like to do the same with the rolls. There is something extremely gratifying in taking something that at first glance seems dead and with no value and to bring it back to life.

I really like that Rolls for your next build, possibly would be even more of a project then the Bentley

Those 'H' columns - did you add riveted tie plates at the joints or just glue and finish a a single length of steel?

Those 'H' columns - did you add riveted tie plates at the joints or just glue and finish a a single length of steel?

Dave, at about 10 feet in lenght these columns would be made out of 1 piece so that's how I made them, no plates.I really like that Rolls for your next build, possibly would be even more of a project then the Bentley

Those 'H' columns - did you add riveted tie plates at the joints or just glue and finish a a single length of steel?

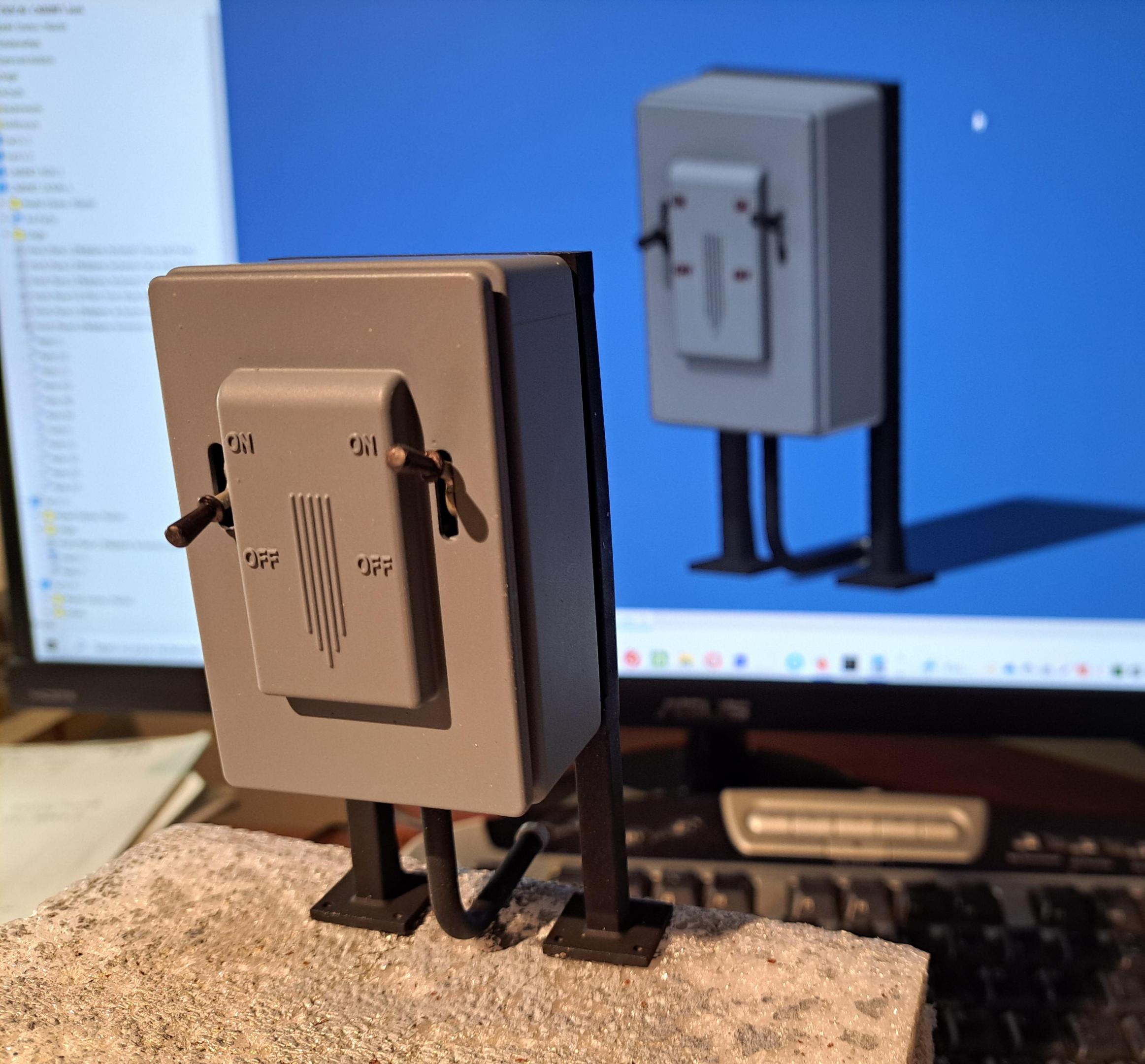

I started painting the different components and fabricated the front and back panel frames. I received 1mm thick plexiglass. I need a thin plexiglass for the curved roof, I'll see how this thickness works for the side panels. I also assembled the electrical box with the 2 switchs.

Here are some shots.

Painted sprinkler pipes

Sprinkler head

Main gate valve painted, l tried to give it a cast look (rugged). I ran out of red paint, wiil get more tomorrow.

The lights painted black with white interior. I might try to simulate some dust on it. Also painted the connection boxes.

Electrical box painted and assembled

Working switchs

View attachment 20240326_200858.mp4

View attachment 20240326_200805.mp4

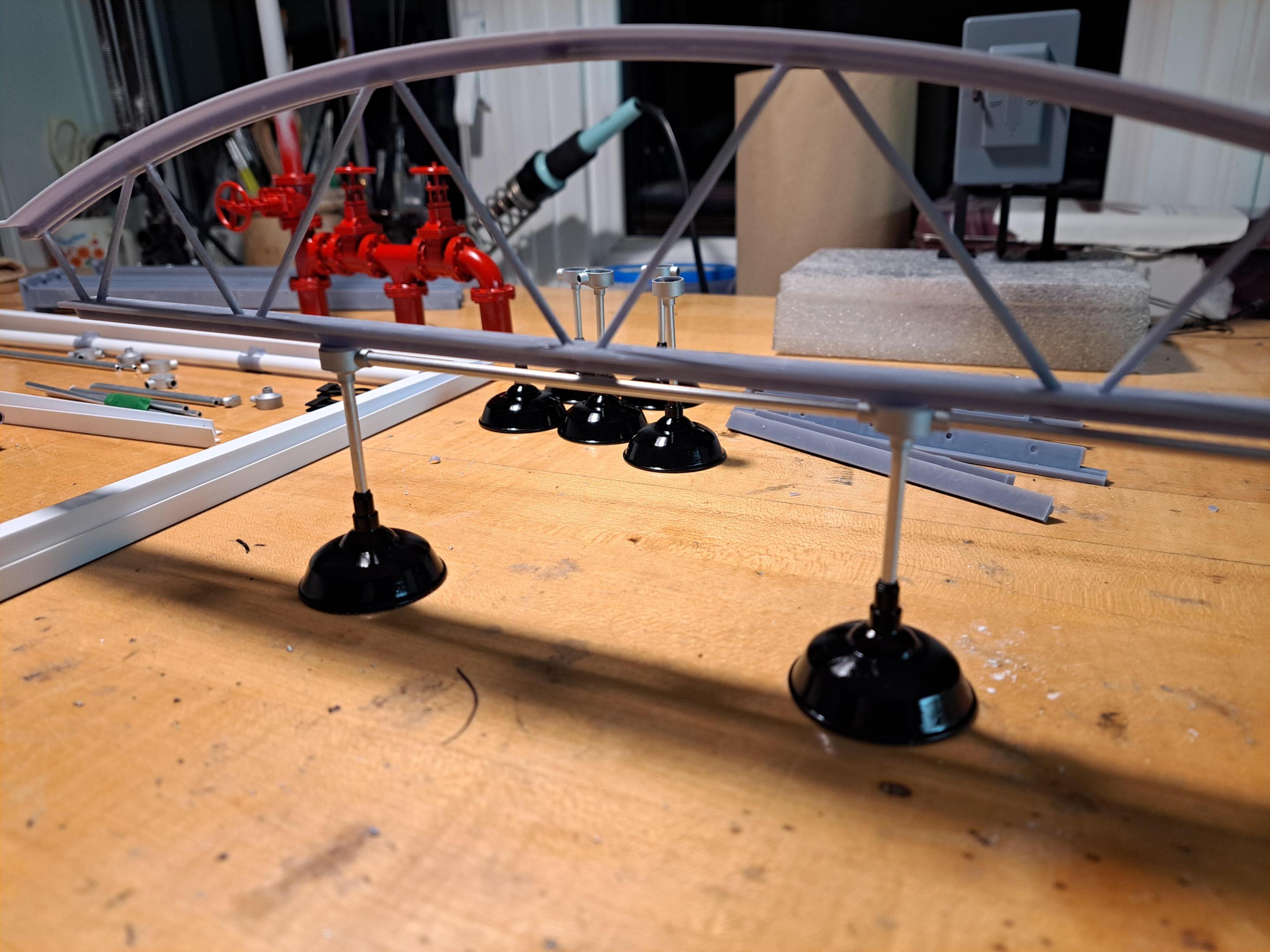

The display case structure is glued up. I should be ready to paint it shortly. I temporarily installed the pipes and lights and placed the car in to see what it will look like. I have to say that I'm very happy with the result.

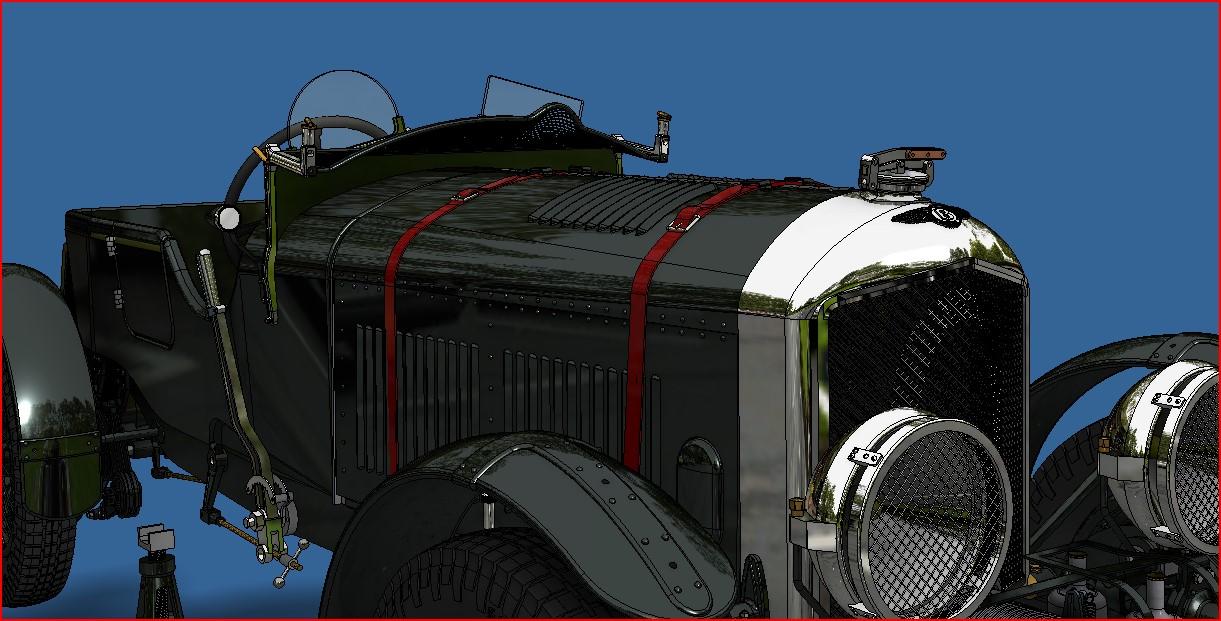

Here's a screen shot of the 3d model

And a few pictures of my set up

I still need to do some research on how to print the picture of the real car on a plastic film of some sort and to have it translucide.

Here's a screen shot of the 3d model

And a few pictures of my set up

I still need to do some research on how to print the picture of the real car on a plastic film of some sort and to have it translucide.

Could you use the acetate sheet that is made for printing things on t shirts and the like? It is smooth on one side but rough on the other to allow printing. Otherwise it is translucent.

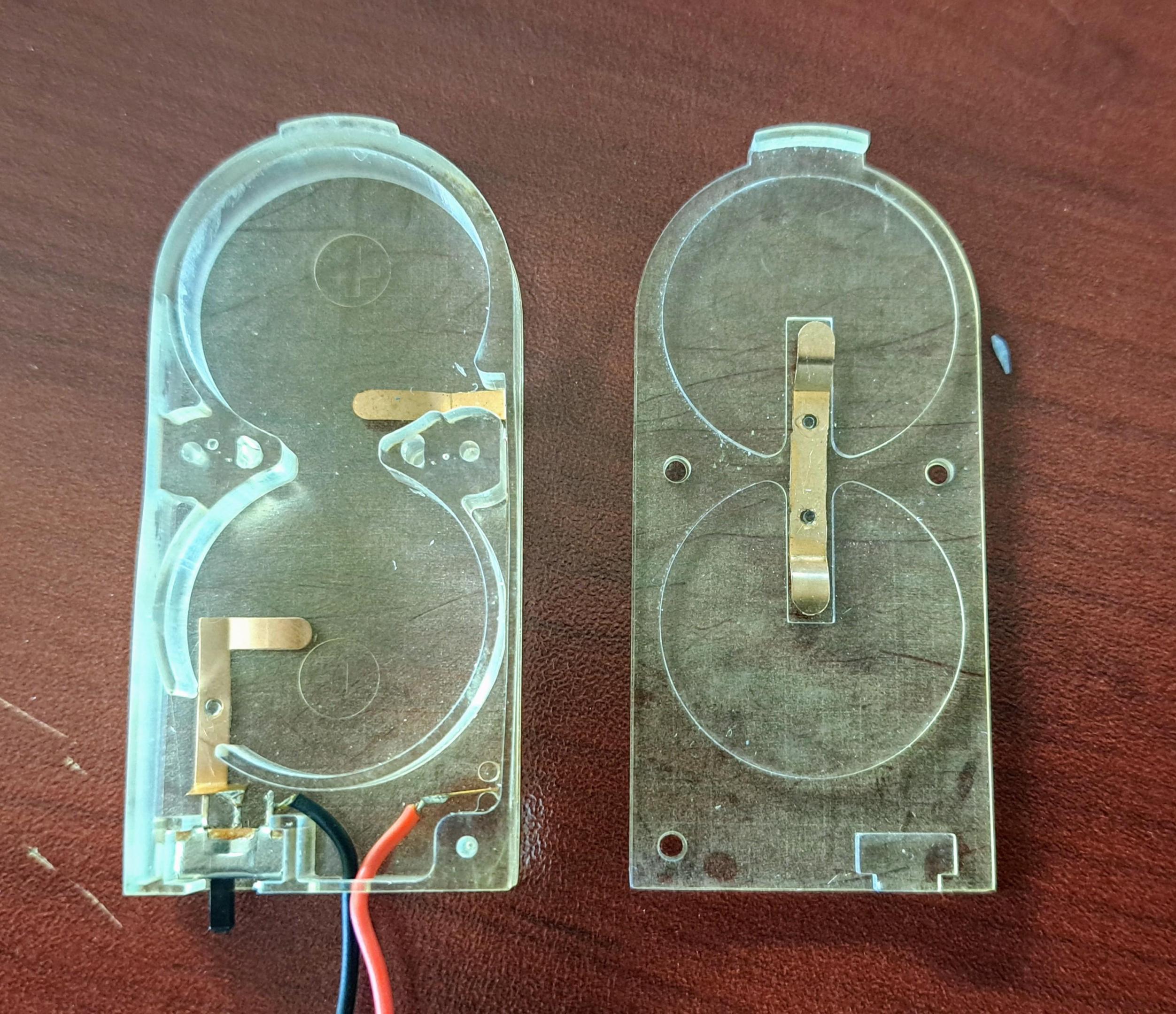

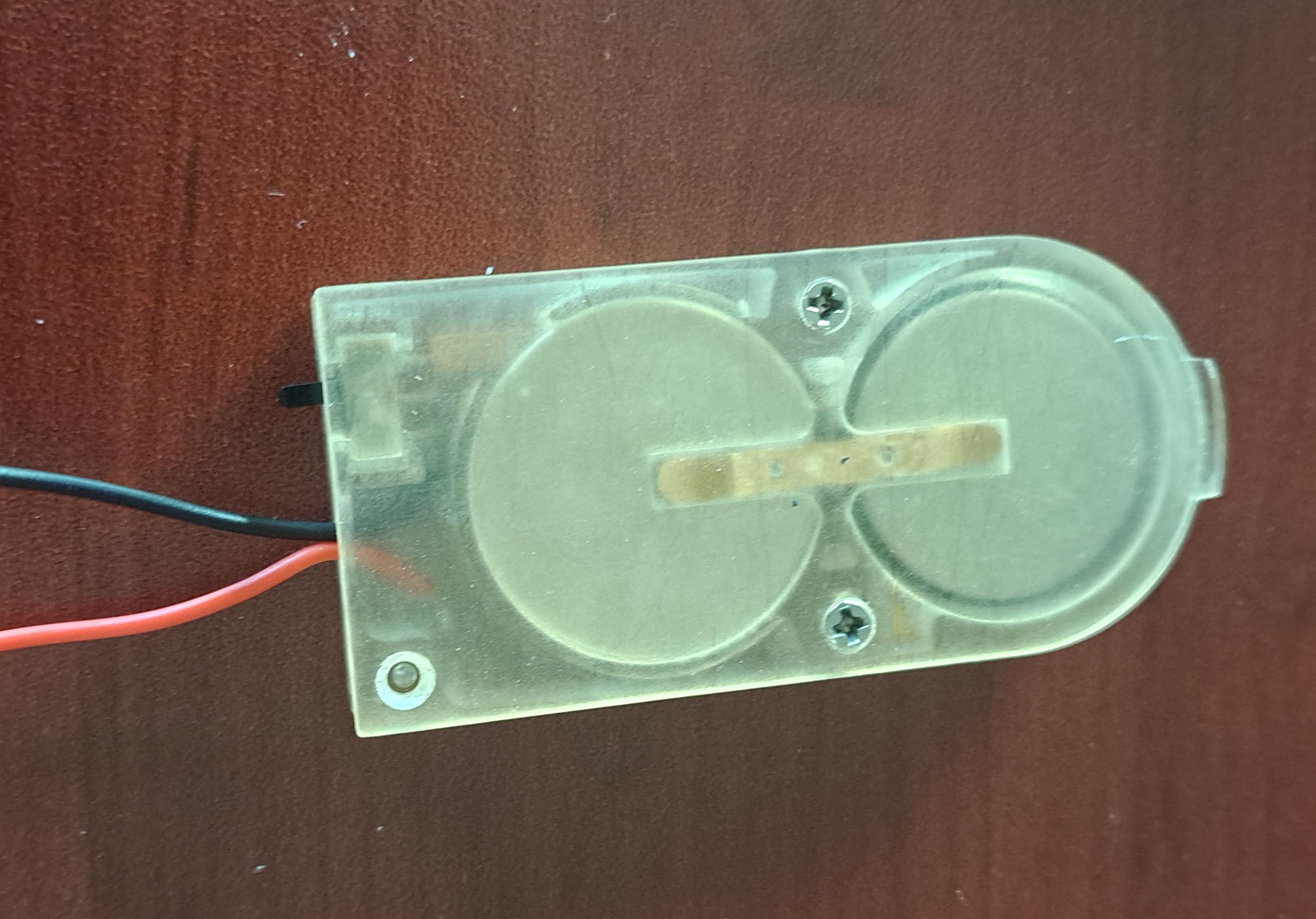

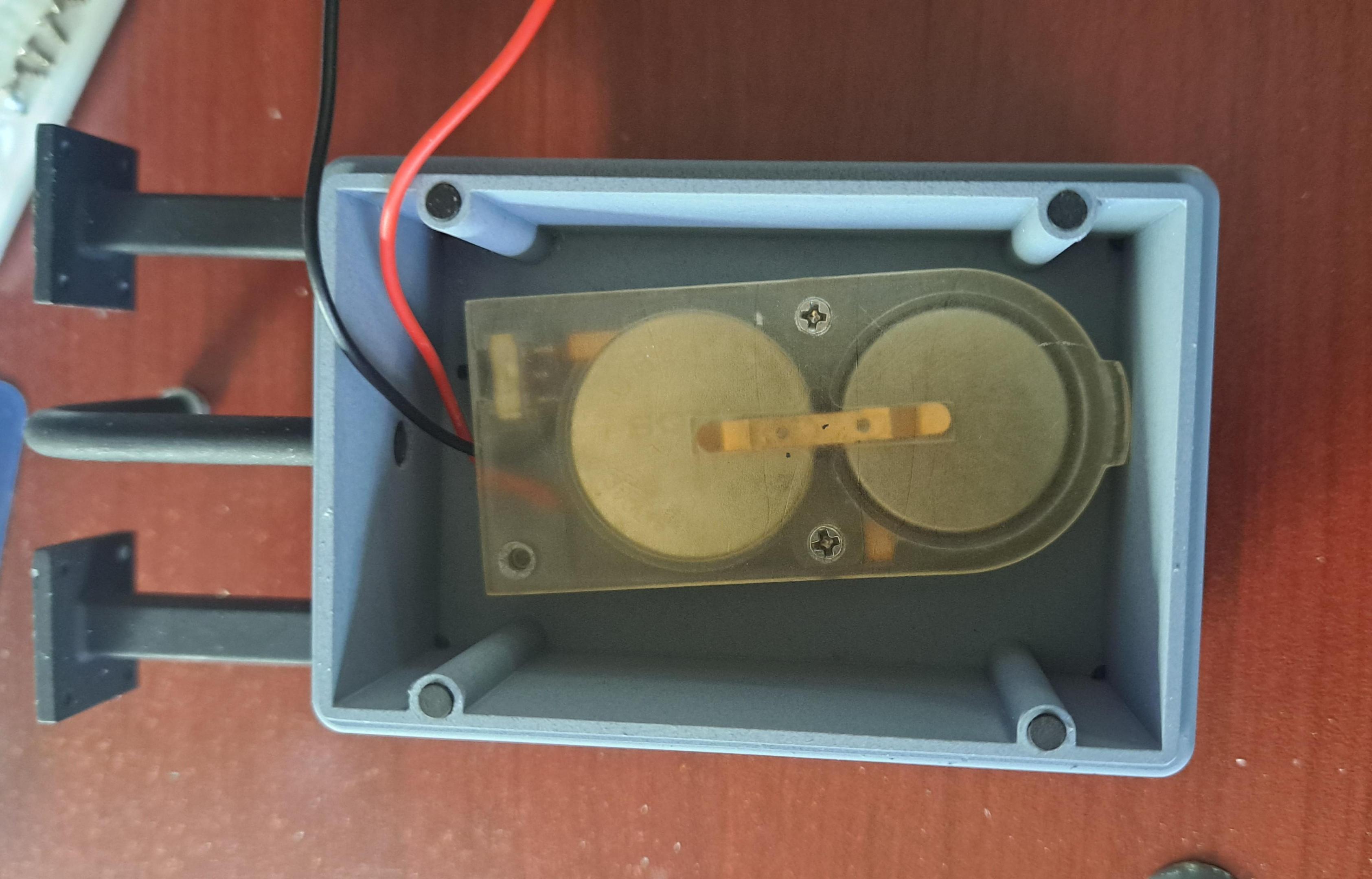

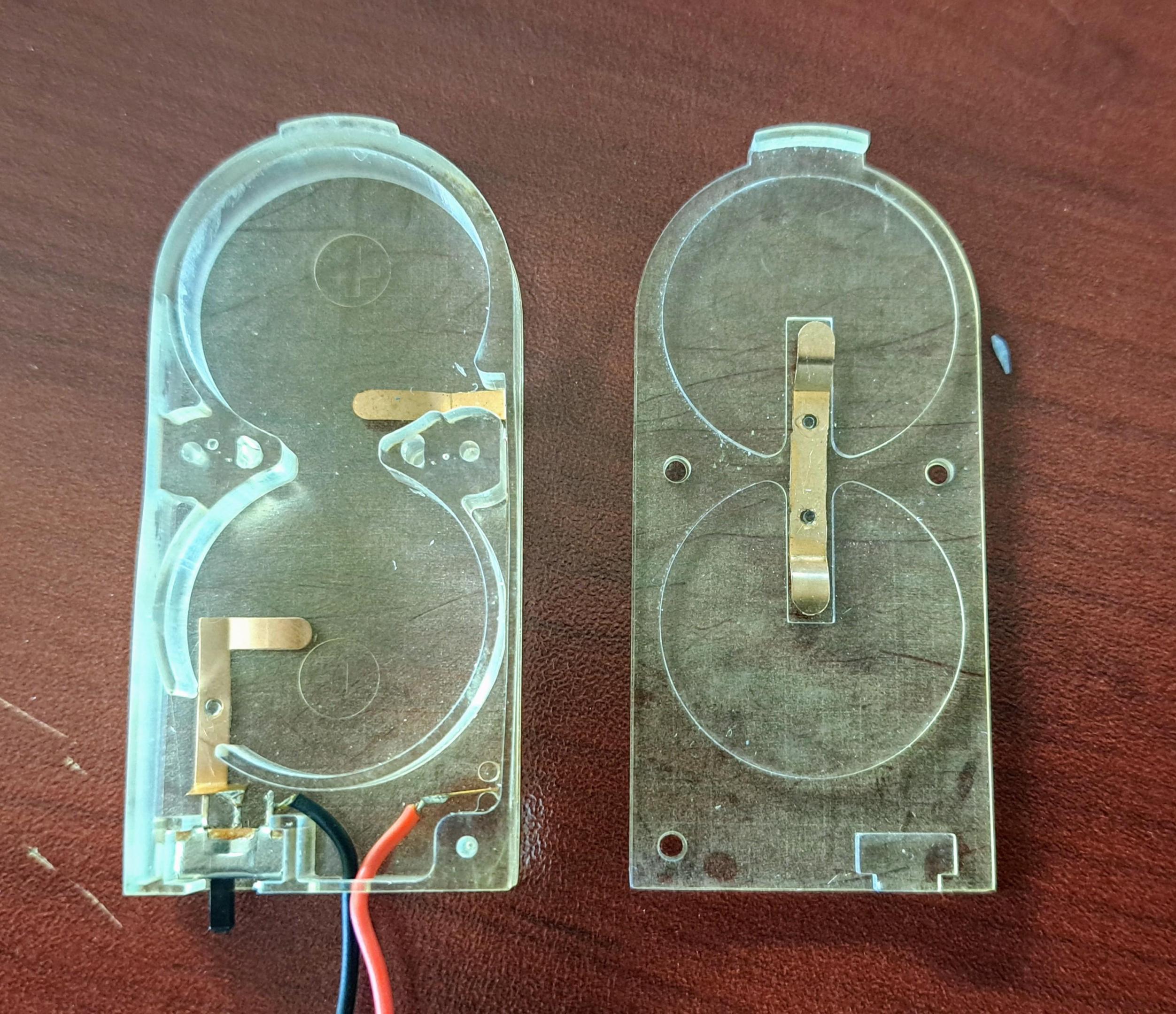

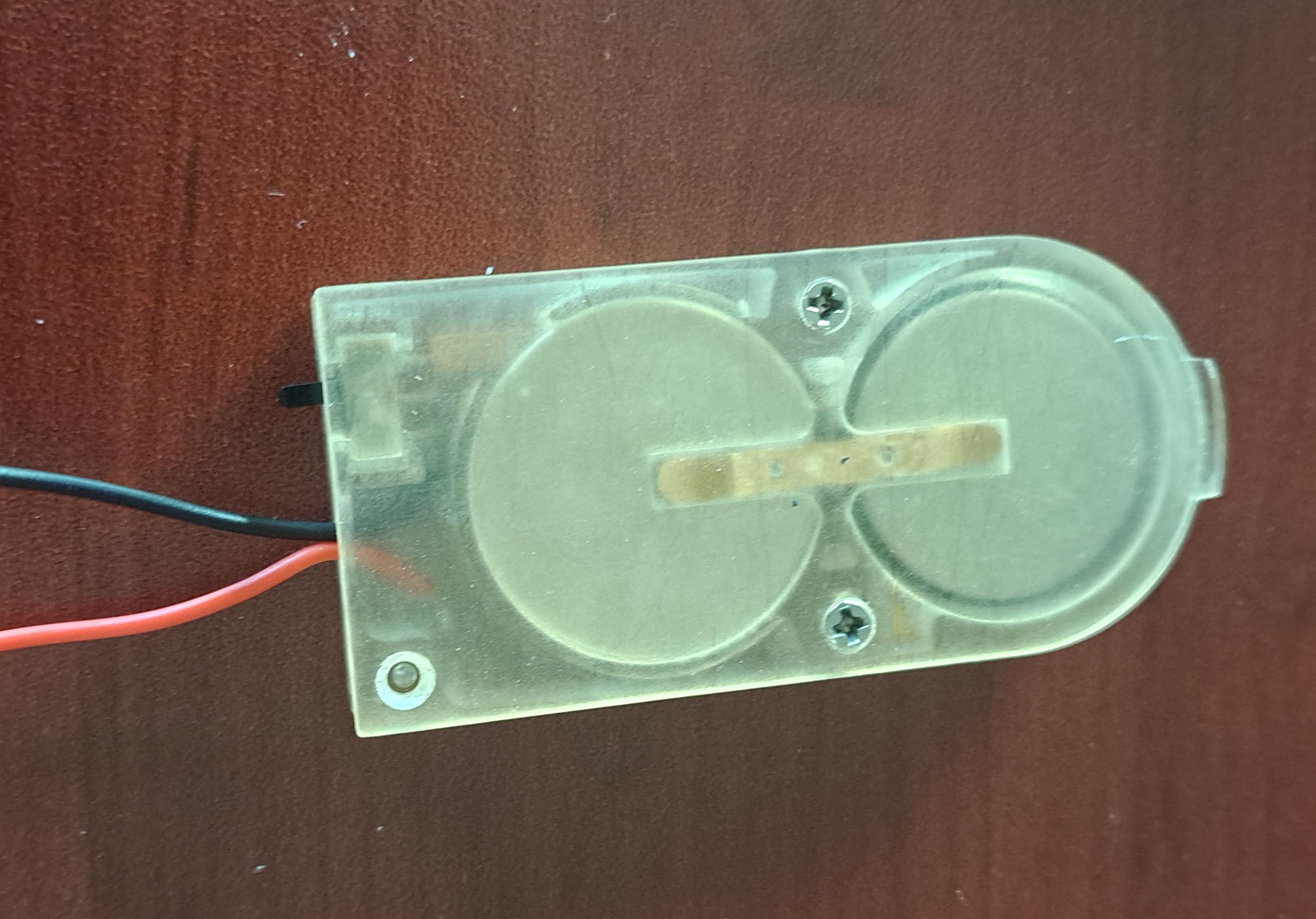

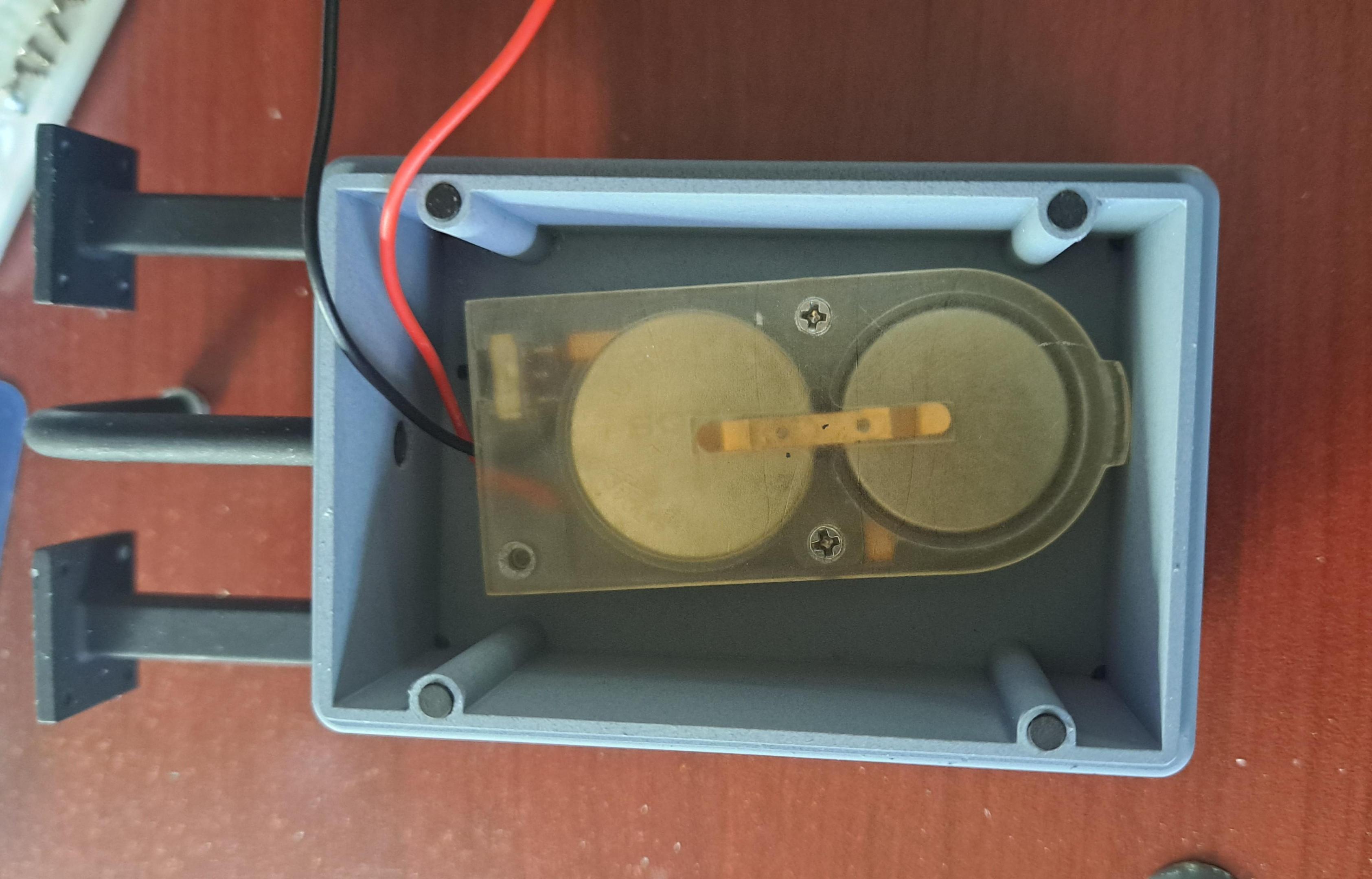

I started the final assembly of the display case, so far so good! I'm waiting for some .5mm dia electrical wire so while I'm waiting, i'm doing the control box wiring. I had a small CR 2032 button cell box but i'd rather use CR 2450 cells which are bigger. So using the inerts of the box I had, I designed a bigger one to suit the bigger cells.

Here are a few pictures of the display case so far

and the battery box

The black one is for the small cells, the clear one I printed

And inside the control panel

Here are a few pictures of the display case so far

and the battery box

The black one is for the small cells, the clear one I printed

And inside the control panel

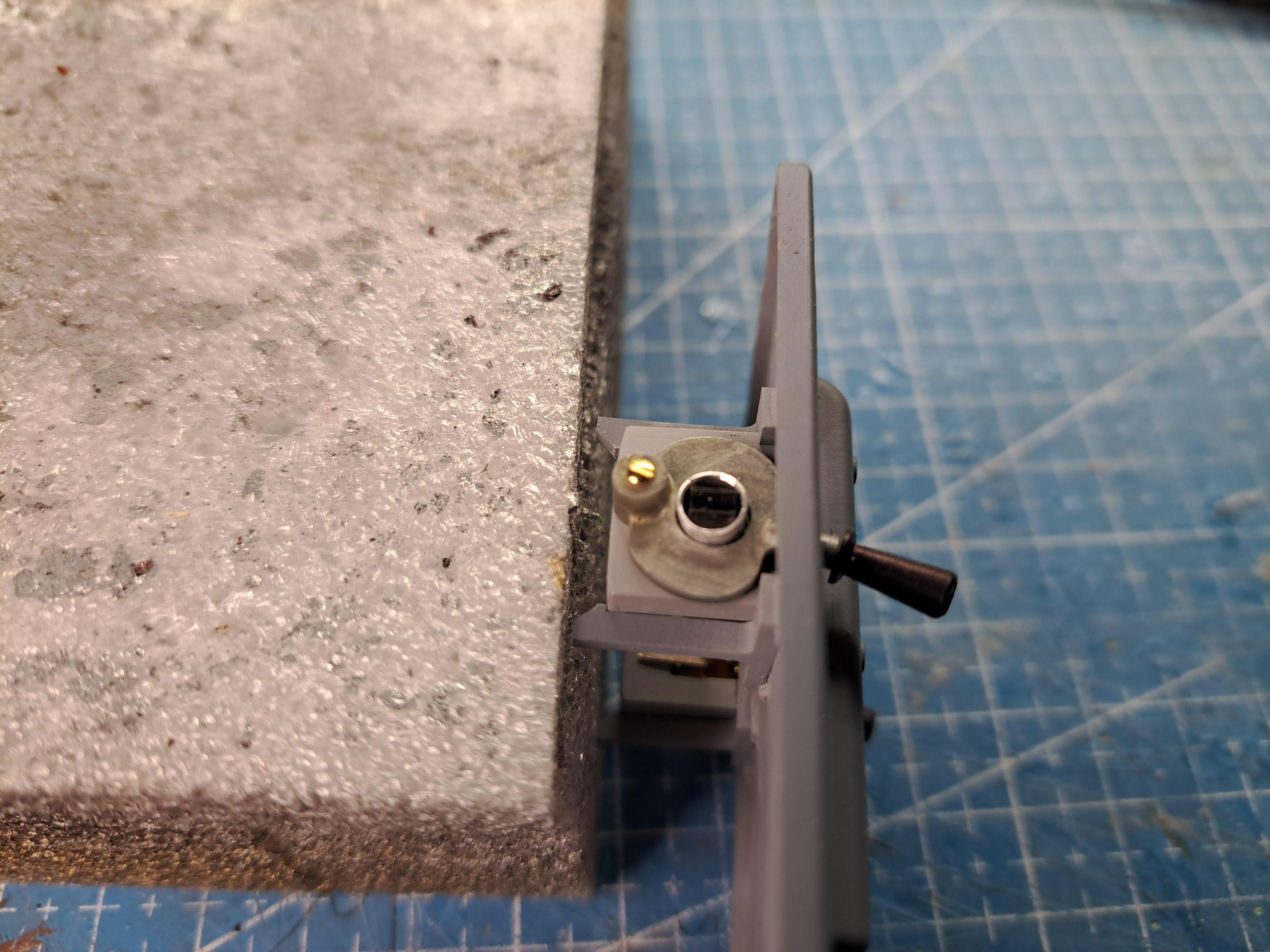

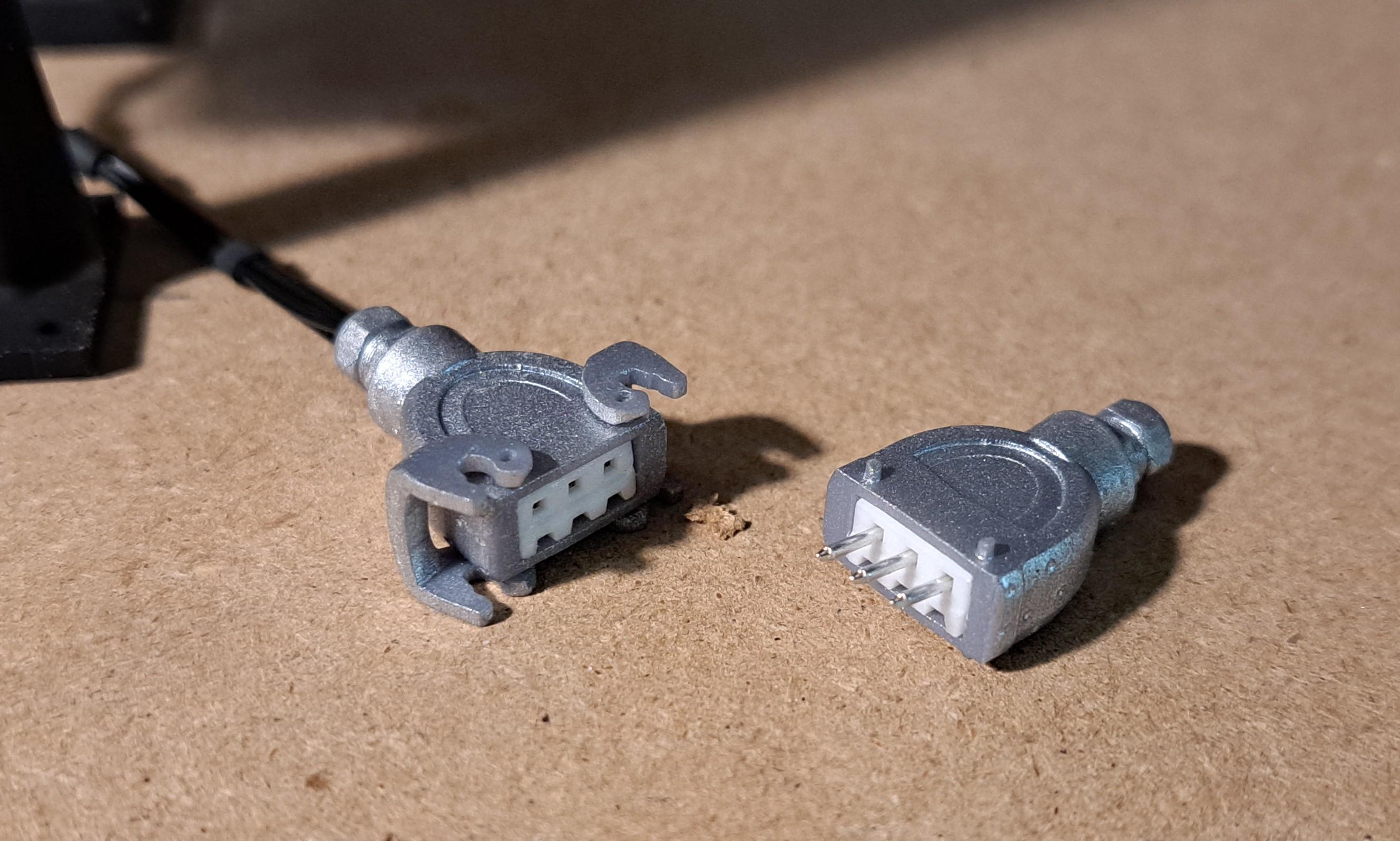

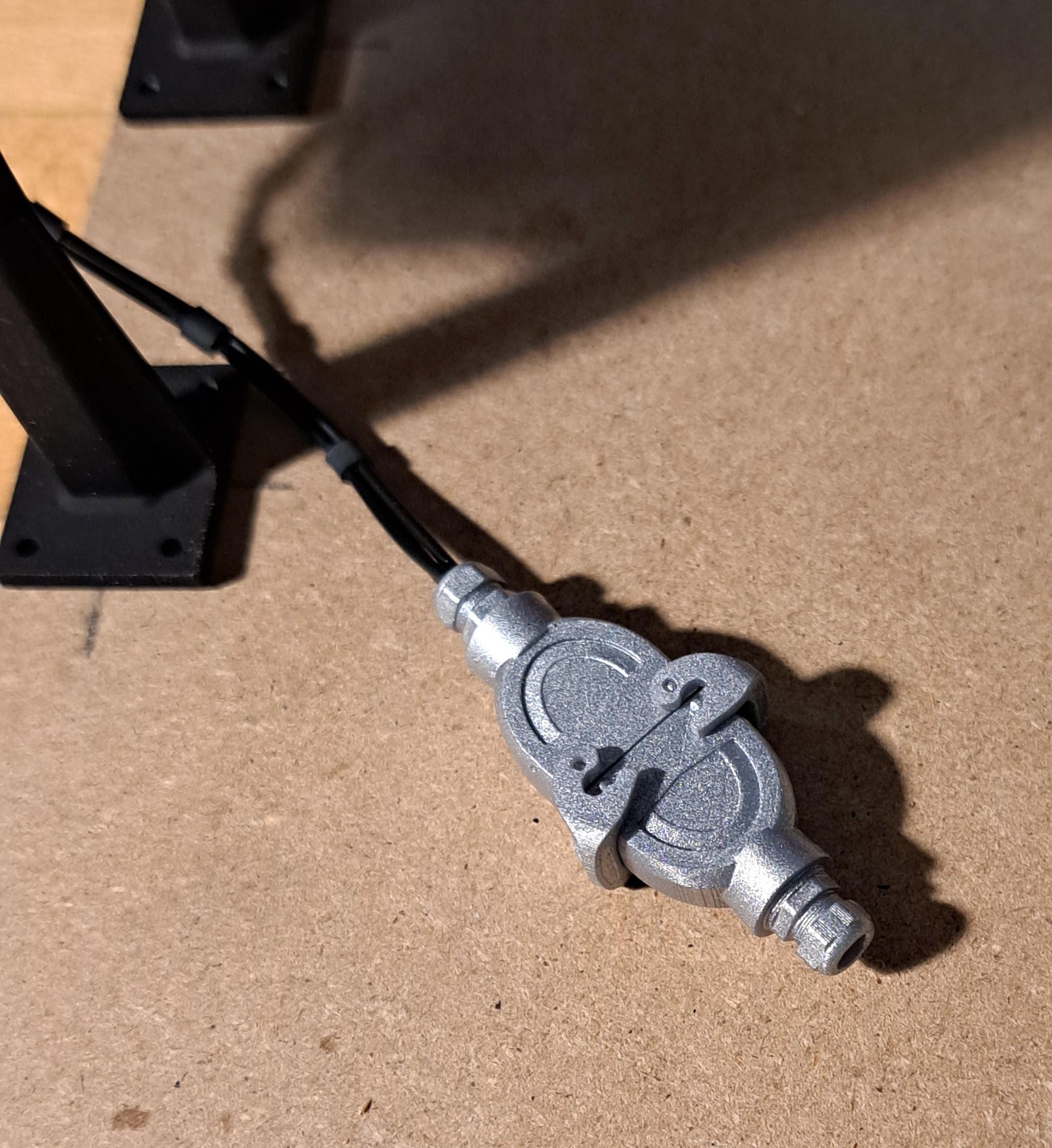

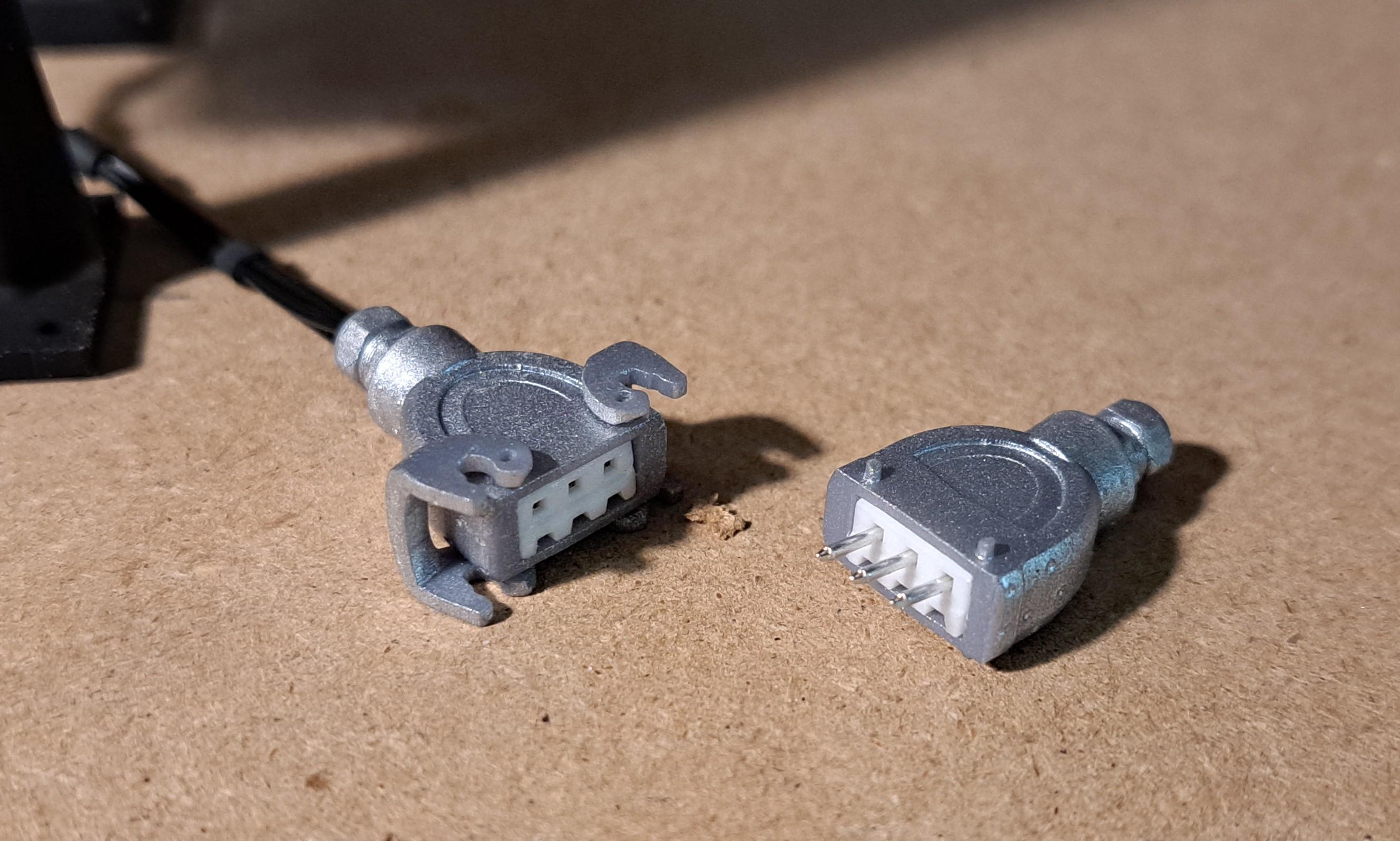

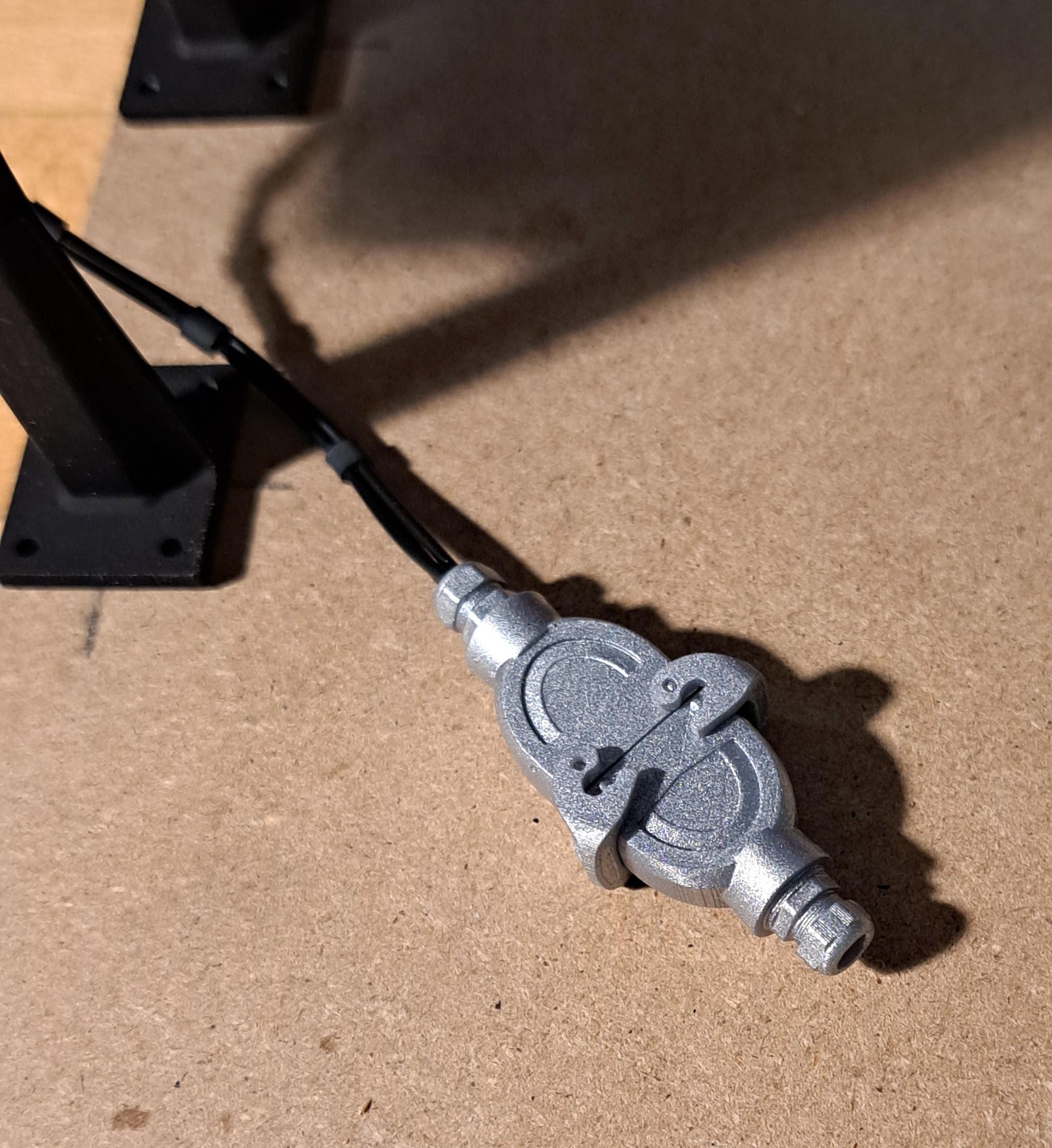

Did a bit more work on the electrical cabinet. The model will be hooked up to this cabinet but I want to be able to unhook it if I need to remove the model from the display case. So I modeled and printed a miniature multi pin connector complete with locking latchs. I've used these type of connectors many time on machines when it was necessary to separate one piece of equipement from another, exactly what I want to do here.

All connections to the battery box and switchs are done

Here's the cable connector on the cabinet

And the multi pin connector

All connections to the battery box and switchs are done

Here's the cable connector on the cabinet

And the multi pin connector

Completed the wire harness on the model and everything work as planned

View attachment 20240408_083236.mp4

View attachment 20240408_084511.mp4

View attachment 20240408_083236.mp4

View attachment 20240408_084511.mp4

The case is pretty much finished, l'm still waiting for my .5mm electrical wire order to come in to do the lighting.

So while I'm waiting, I went back to the model itself. Like I said before, the only thing left in the body.

Here's a list of what as to be done

1- reprint a new body with full walls and all missing features (hinge cut-outs, holes to locate mesh screen, visers and soft top frame)

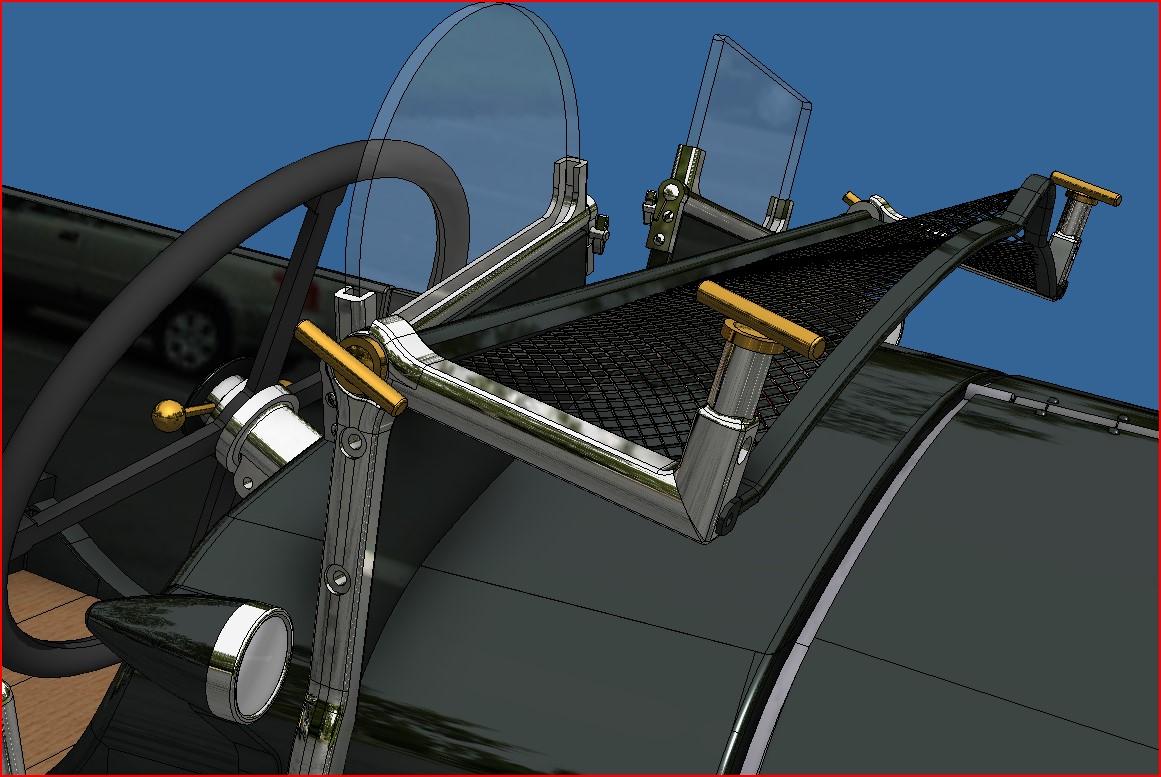

2- design mesh screen and visor mount

3- design soft top frame

4- wrap body with rexine like material (I've done a few test and i think I have a good material)

5- make leather coverded seats

6- make all interior panel and fittings

7- make dashboard

8- make wood floor boards

....

So as you can see, I'm closer to the end but still have lots to do. On May 10th, lt will make 1 year since I started this project, and I see at least another 3 months to complete.

Here are a few pictures of what as been done so far.

I did some wrapping test using the kit's body. I tried a very thin black leather on the passager side and a 4 way sstretch glossy fabric on the drivers side. Althougt the leather is nice and very easy to work with, I find that the glossy fabric better mimics the rexine.

Leather

Glossy fabric

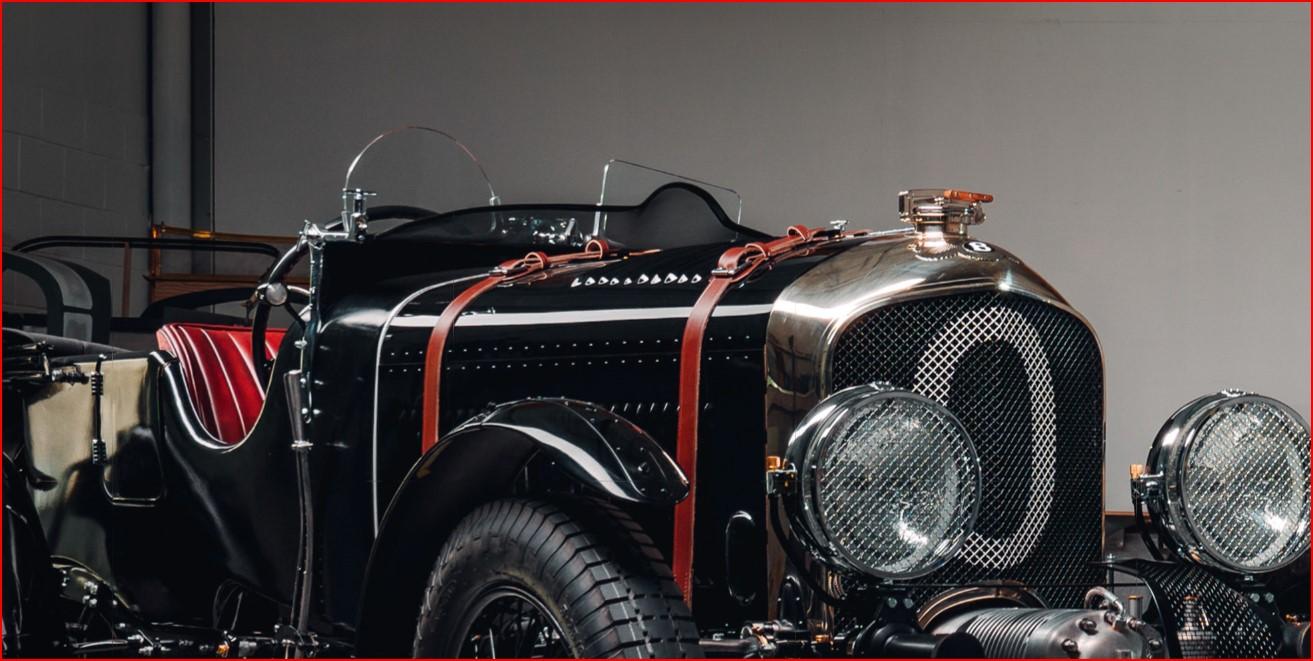

actual rexine coverded body

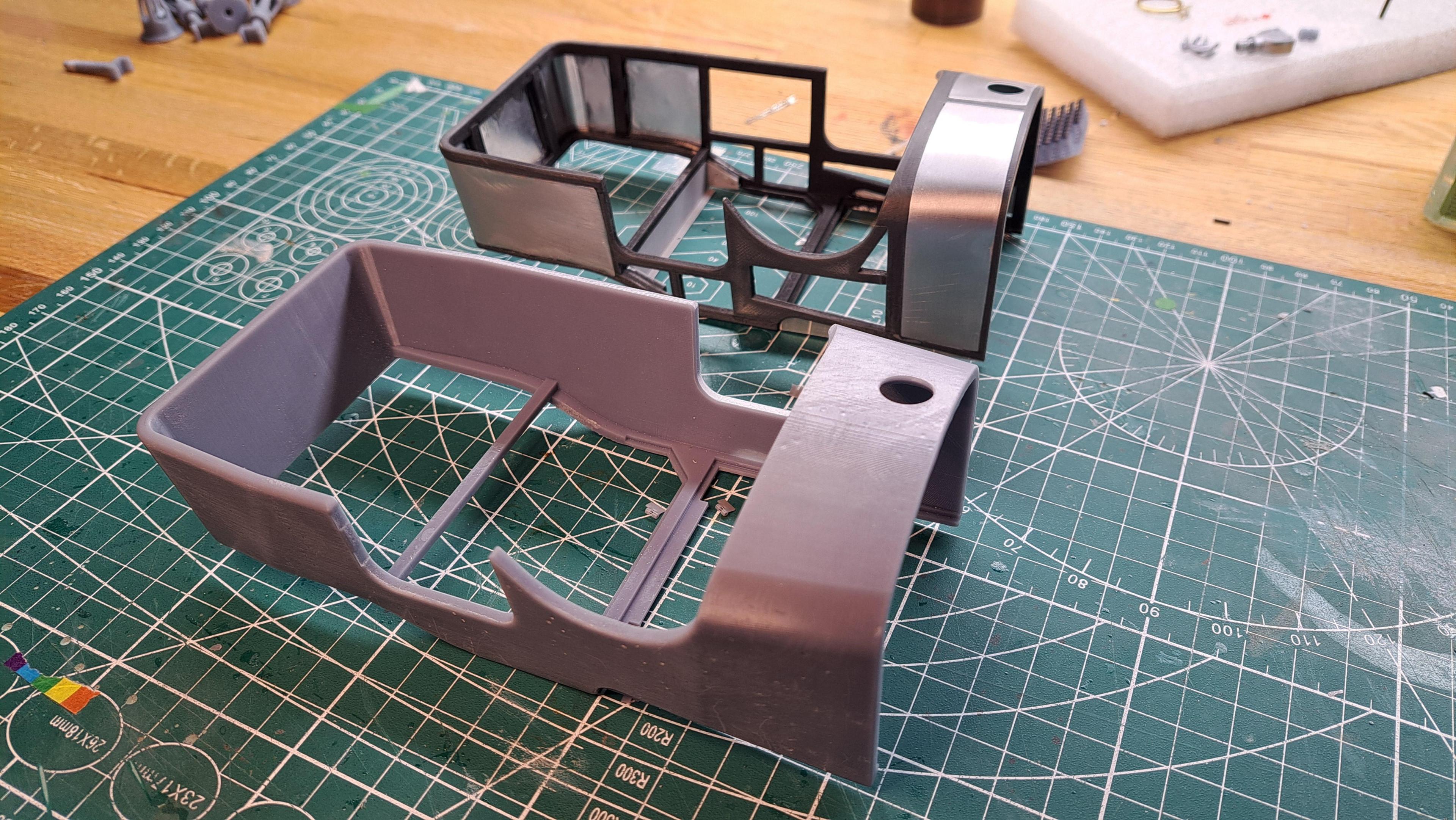

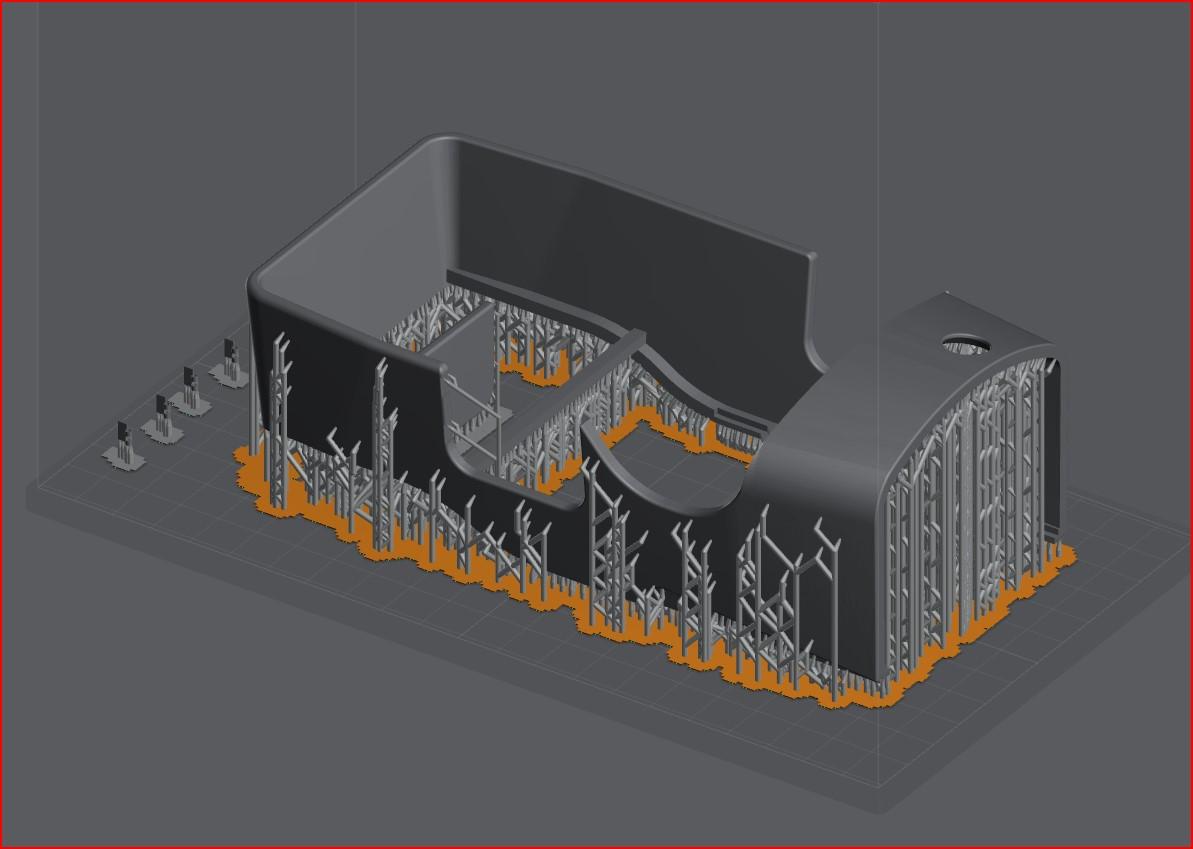

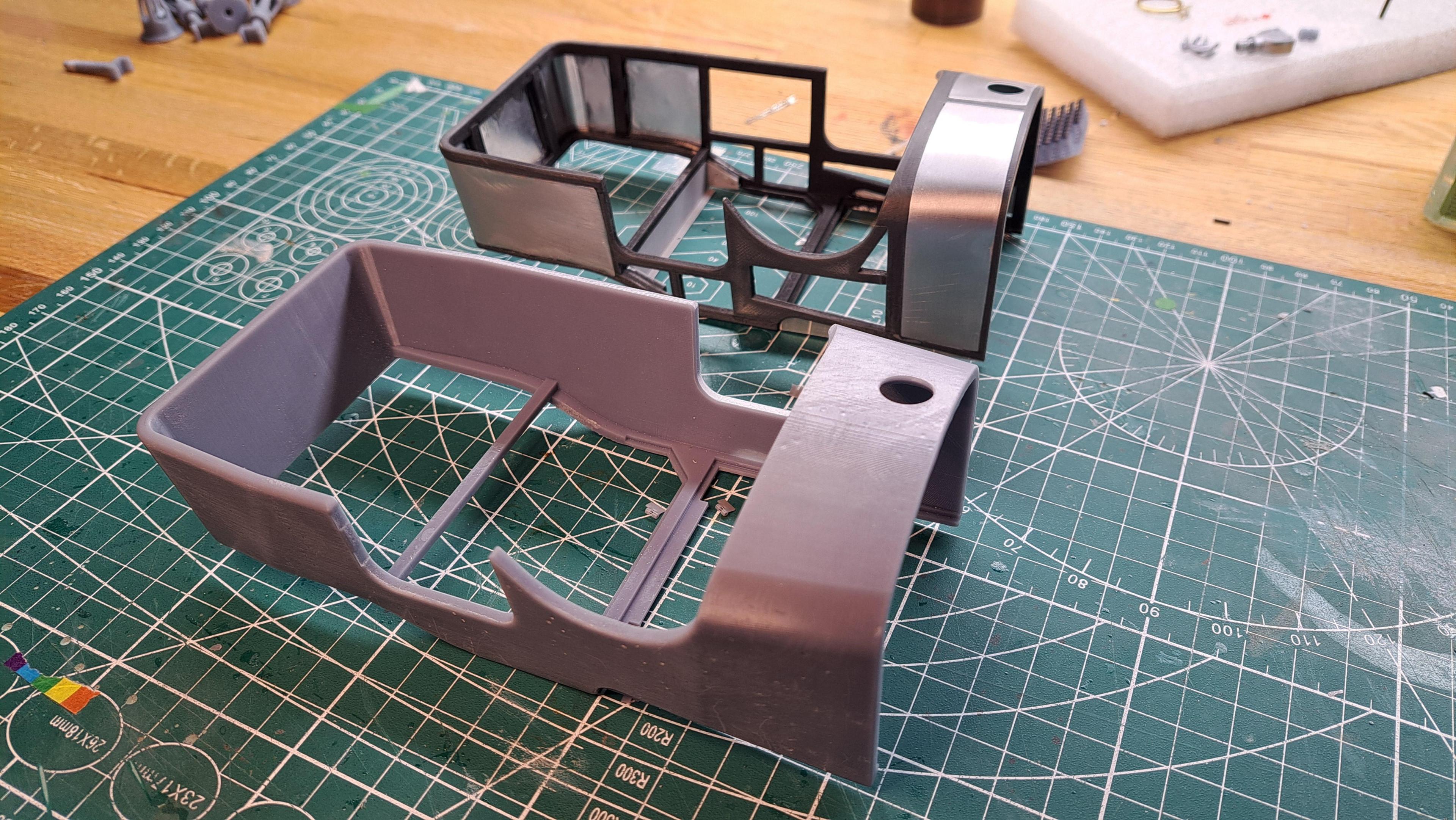

I've test printed a new body. It has exactly the same shape and size as my other printed body except it has full walls. It will make wrapping much easier. And once finished in and out, no one will see the differrnce.

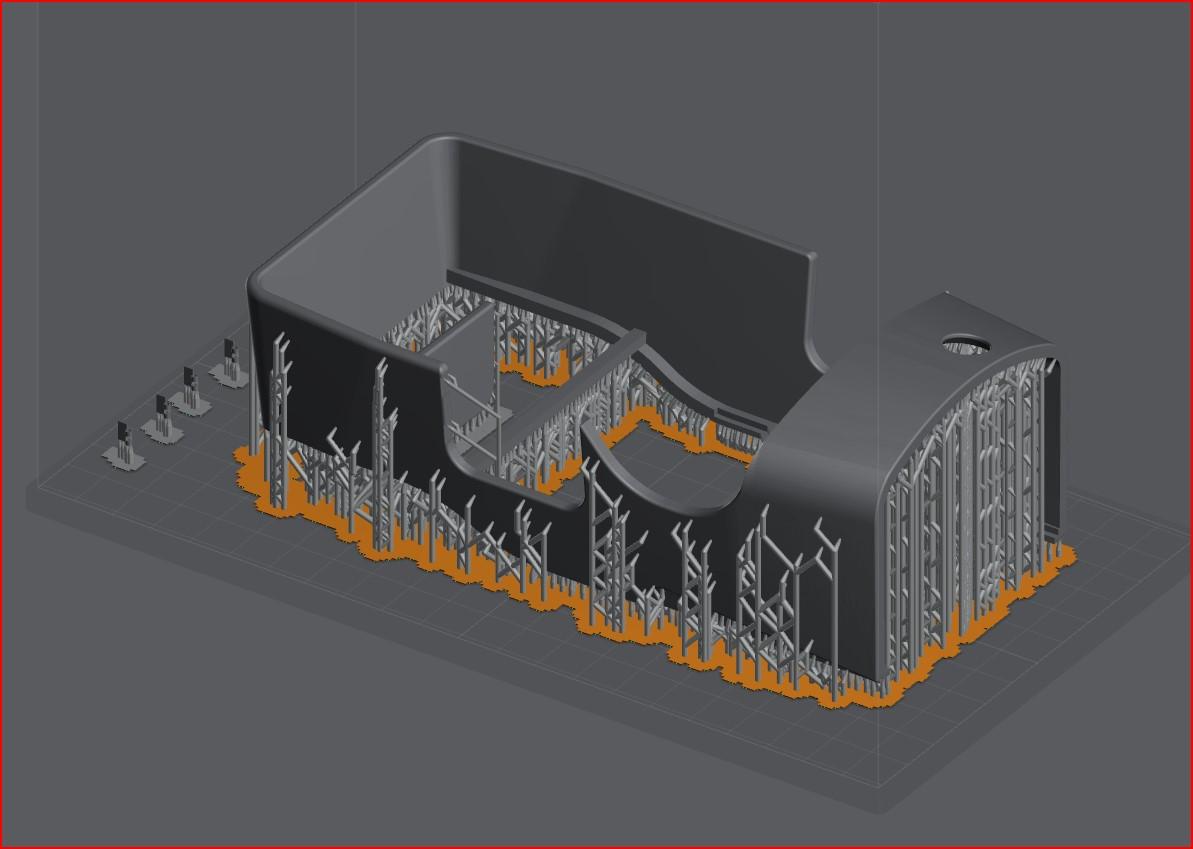

Body in slicer app

I started modeling the mesh screen mounting brackets

.jpg.4a61aa236935b41eed1a0e08249bbff9.jpg)

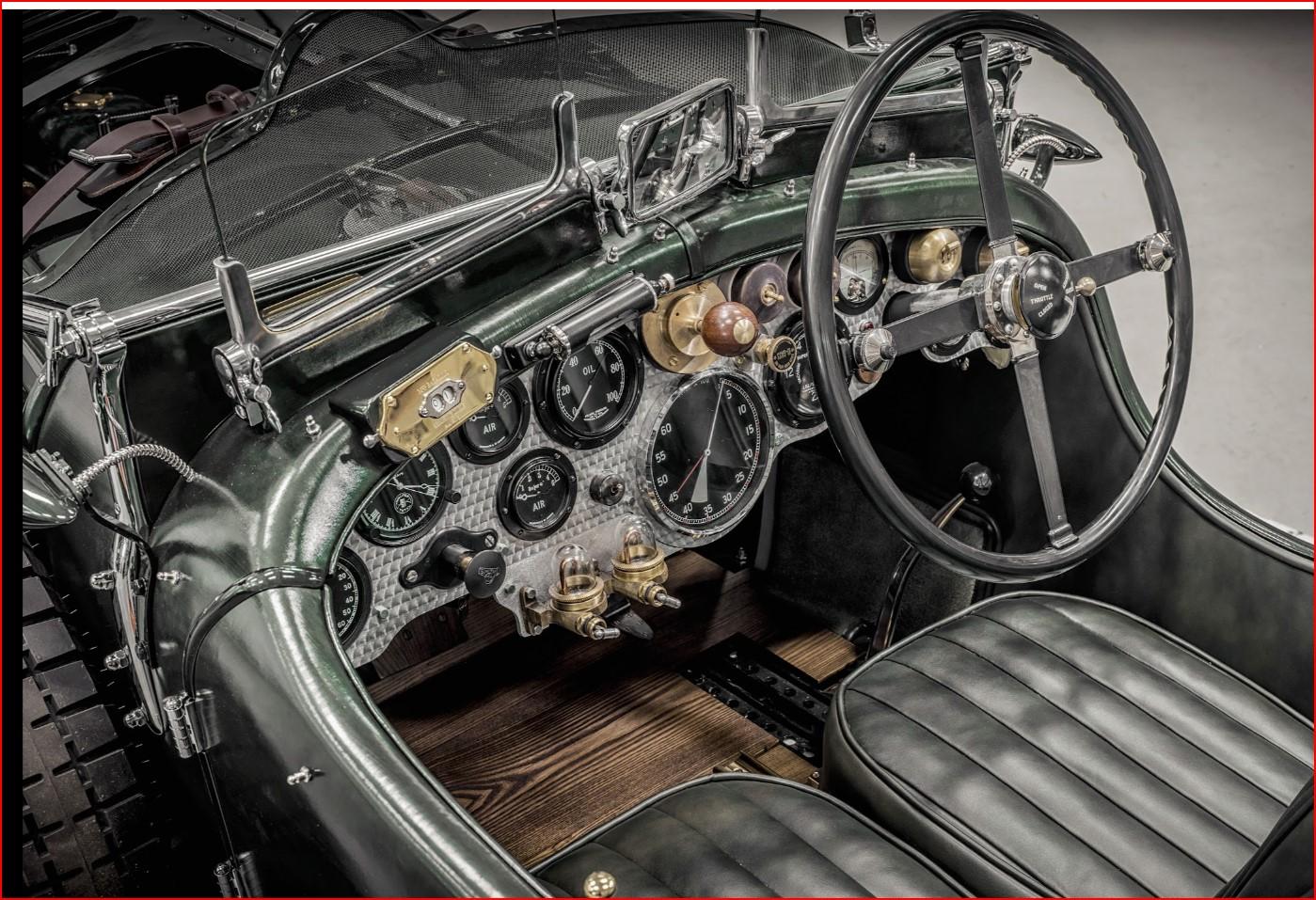

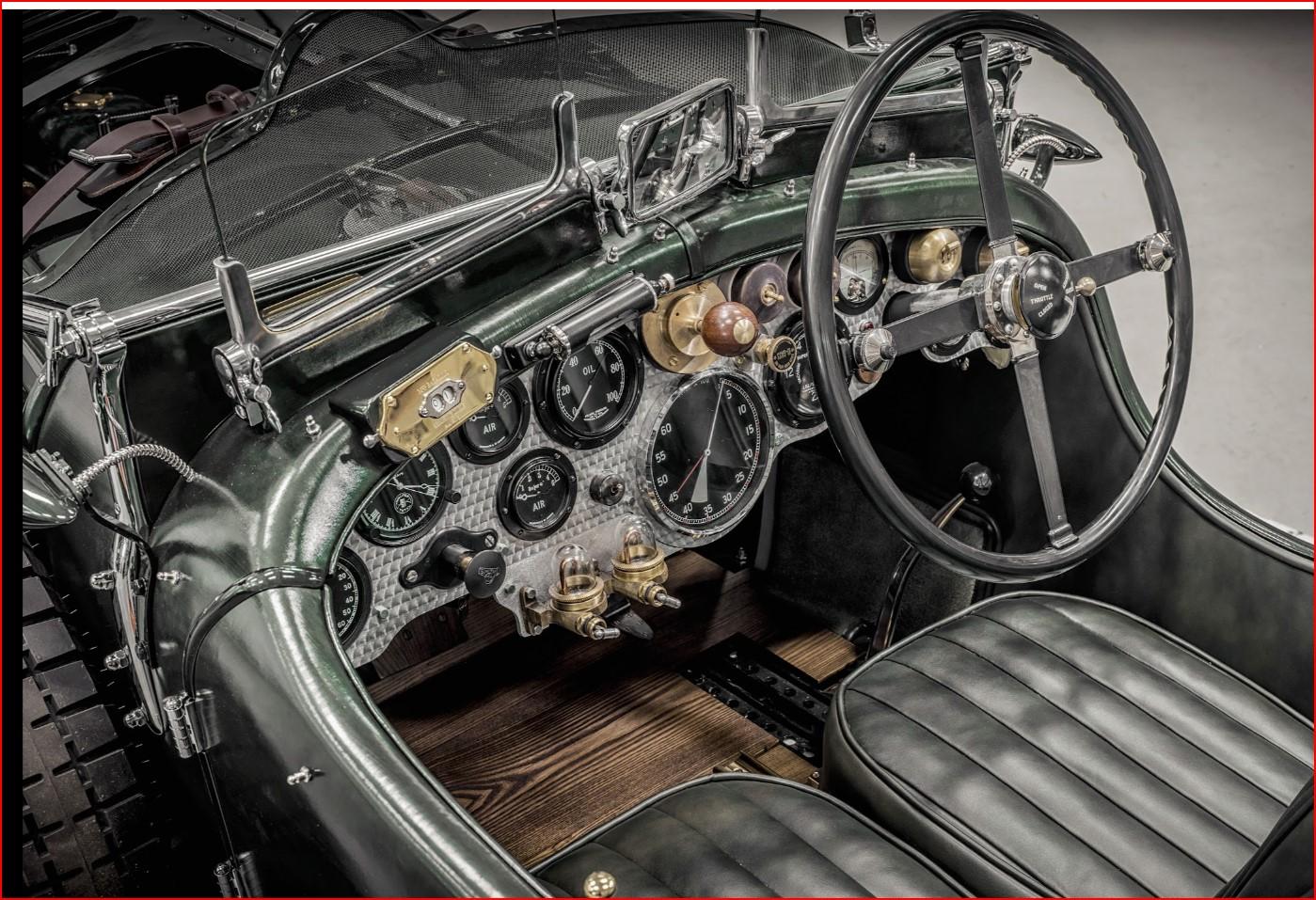

The real thing

So while I'm waiting, I went back to the model itself. Like I said before, the only thing left in the body.

Here's a list of what as to be done

1- reprint a new body with full walls and all missing features (hinge cut-outs, holes to locate mesh screen, visers and soft top frame)

2- design mesh screen and visor mount

3- design soft top frame

4- wrap body with rexine like material (I've done a few test and i think I have a good material)

5- make leather coverded seats

6- make all interior panel and fittings

7- make dashboard

8- make wood floor boards

....

So as you can see, I'm closer to the end but still have lots to do. On May 10th, lt will make 1 year since I started this project, and I see at least another 3 months to complete.

Here are a few pictures of what as been done so far.

I did some wrapping test using the kit's body. I tried a very thin black leather on the passager side and a 4 way sstretch glossy fabric on the drivers side. Althougt the leather is nice and very easy to work with, I find that the glossy fabric better mimics the rexine.

Leather

Glossy fabric

actual rexine coverded body

I've test printed a new body. It has exactly the same shape and size as my other printed body except it has full walls. It will make wrapping much easier. And once finished in and out, no one will see the differrnce.

Body in slicer app

I started modeling the mesh screen mounting brackets

.jpg.4a61aa236935b41eed1a0e08249bbff9.jpg)

The real thing

I'm using Lychee. I'm still convinced that my print quality could be better, it might ve due to the fact that I'm using a water wash resin and that I'm still fairly new to this.