Hello Everyone.

As promised masts - and first up the foremast. The foremast comprises of two dowels which are joined in a particular way. The bigger of the two is a 6mm dowel which is tapered at the top to 4mm, while the smaller one is a 4mm dowel which is tapered to 2mm at the top.

View attachment 312674

Both dowels are cut at an angle over a distance of 30mm, are then glued together and are finally tied with two wooldings which are tied in the following way as per the instruction manual:

View attachment 312675

View attachment 312676

I did not take pictures of this, but here you can see in the instruction manual how the dowels are cut.

View attachment 312677

You obviously have to exercise great care when creating the angled joints to make sure that they are flat and true, but other than that, this part did not present any trouble. The base of the mast still needs to be slightly tapered at an angle as well, but that I will only do before actual installation.

View attachment 312678

Now however, the fun and games start with the shaping of the mast cheeks and then the way that they get attached to the mast. The instruction manual shows a simple groove that is cut into the inside of the mast cheeks for the rope to pass through (Photograph below).

View attachment 312679

But when I enquired about this to make absolutely sure, our dearest

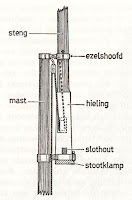

@Kolderstok Hans sends me the following drawing to show me how it should actually be done.

View attachment 312680

And then tells me that he is sure I will opt to do it this way (the most difficult way) by fitting actual sheaves to the inside of the mast cheeks.

And to make sure that I know exactly how to do it, he sends me the following literature:

View attachment 312682

View attachment 312681

Much obliged Hans! Thank you very much.

But he also sends me another book - all 600MB of it.

View attachment 312683

Oh boy ...

And to make sure that I know exactly how to do it, he sends me the following literature:

And to make sure that I know exactly how to do it, he sends me the following literature:

. That has been my delay (probable more likely procrastination) in attempting one- finding a dowel small enough and how to cut it thin enough- like you I am tool deficient. Cheers Grant

. That has been my delay (probable more likely procrastination) in attempting one- finding a dowel small enough and how to cut it thin enough- like you I am tool deficient. Cheers Grant