By the way, I was also thinking about making my own lamp, but I think I'll test the sewing machine lamp and if it's not so good, I'll make a custom one based on it. The price is good, even if I have to remake it later. There are better options, but they're х10 more expensive.The LED ring light is quite large I agree. I looked around but was not able to find a smaller ring light that would fit onto the bottom of the mill body (36mm diameter). I don't know if the sewing light would fit but if it does, it looks a nice cheap option. I tried using some small LED spot lights on flexible stalks to light the work area but I found that the lights just got in the way and cast shadows so you really need to light directly above the cutter. If I find time I might make a custom LED light myself as a little project.

-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

-

PRE-ORDER SHIPS IN SCALE TODAY!

The beloved Ships in Scale Magazine is back and charting a new course for 2026!

Discover new skills, new techniques, and new inspirations in every issue.

NOTE THAT OUR FIRST ISSUE WILL BE JAN/FEB 2026

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Proxxon MF 70 | Upgrade Tools Jigs Workspace | Making: grating ladder stair skylight pin carriage pump windlass winch mast yard

https://www.ebay.com/itm/1650286812...CKmDnkakS1A6Y5UBV3+0Ho+pLHLjHOXInoYlP3AzSb5K6 gJhySYLgbcZHIG4uw99cNT20AwpEuEmxU3ERMIgMhEDhRRIU%2FUAZmg4Bl5sOxDSo4TtUGRbqKMoFaHUvwwPJSVl38YjGFMyjG4Lv4iAVKAzQxLmqz3fb%2FWPQjgB2Vobsjk6EnMdh38kWy7RIifrn8M6aKZRDhwIRFAgEL0fS0LwaM%2F00uXZYmw%3D%7Ctkp%3ABk9SR-6hnuf2Zg&keyword=proxxon+mf+70&sacat=0&relatedSearch=true

I dug up a cheap, small, LED goose neck desk lamp, seems to do the job without getting in the way. Old school + LED brother. I'm sure it will be plenty dusty and greasy soon enough.The LED ring light is quite large I agree. I looked around but was not able to find a smaller ring light that would fit onto the bottom of the mill body (36mm diameter). I don't know if the sewing light would fit but if it does, it looks a nice cheap option. I tried using some small LED spot lights on flexible stalks to light the work area but I found that the lights just got in the way and cast shadows so you really need to light directly above the cutter. If I find time I might make a custom LED light myself as a little project.

@piter56 @glennb17 @GIG1810

Thanks, friends. These are good options.

This link shows, in three parts, how to make a grating like this step-by-step.

The difficulty with this lattice is that not only is there a cut-out in the side sections, but also that the longitudinal and transverse slats are not the same thickness. Some are 1 mm, while others are 0.8 mm.

Thanks, friends. These are good options.

This link shows, in three parts, how to make a grating like this step-by-step.

The difficulty with this lattice is that not only is there a cut-out in the side sections, but also that the longitudinal and transverse slats are not the same thickness. Some are 1 mm, while others are 0.8 mm.

HMS Alert [1777] 1:48 POF by serikoff. (Two hulls: skeleton and fully rigged)

This is some truly beautiful work, Sergey! You have a rare gift! True story

shipsofscale.com

I show you step-by-step instructions in the link in the post above. It's milled along an arc, then sanded, in short.I apologize for my density, but how to get the curvature in the hatch?

In the link below, I show step-by-step how I built this Skylight (companionway to the captain's quarters) for my cutter on a Proxxon MF 70 in two parts.

But the technology is applicable to any similar design on any similar ship.

But the technology is applicable to any similar design on any similar ship.

HMS Alert [1777] 1:48 POF by serikoff. (Two hulls: skeleton and fully rigged)

Okey. So that explains your precision with the drilling... but to practice on patients? yuck... ROTF

shipsofscale.com

- Joined

- Sep 23, 2021

- Messages

- 281

- Points

- 168

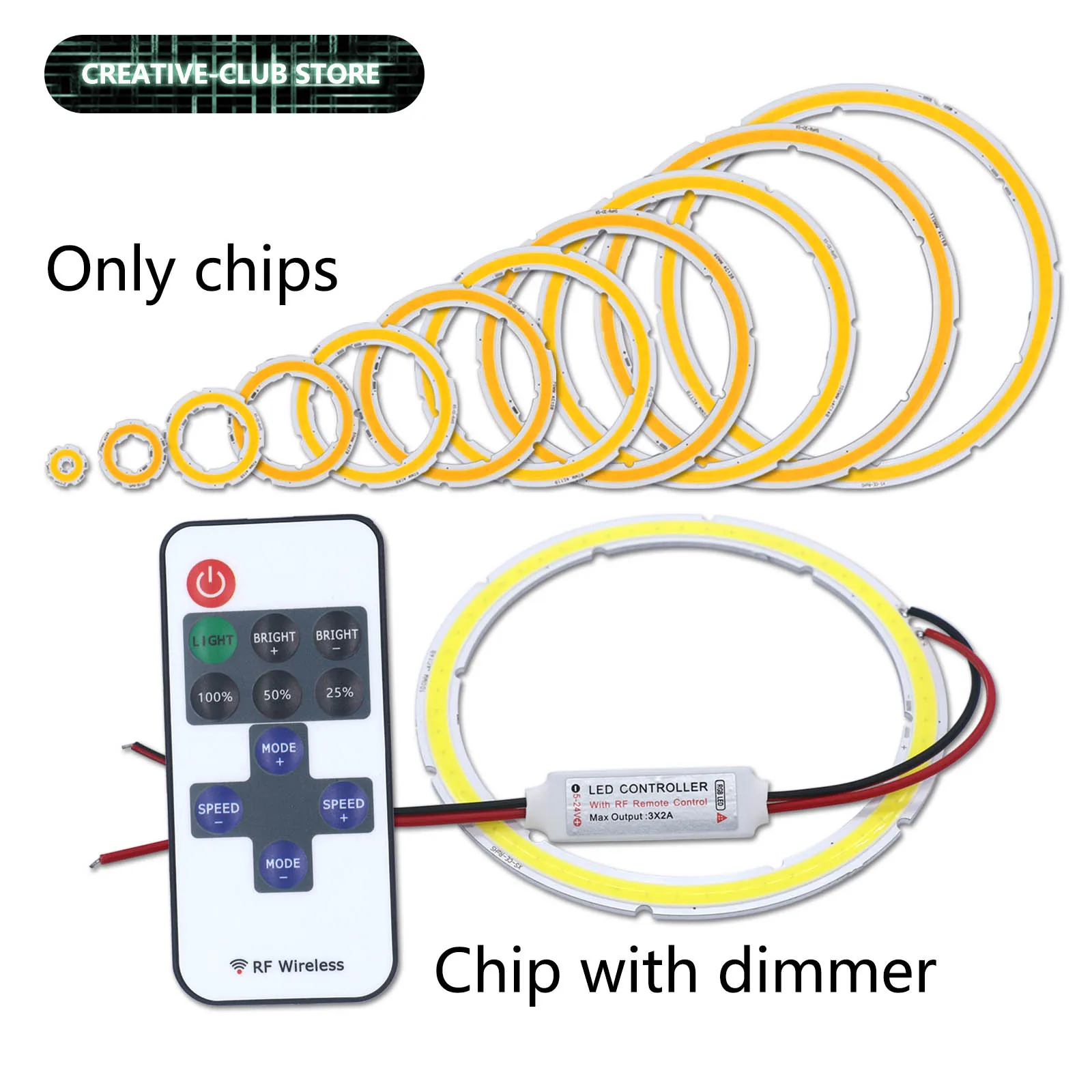

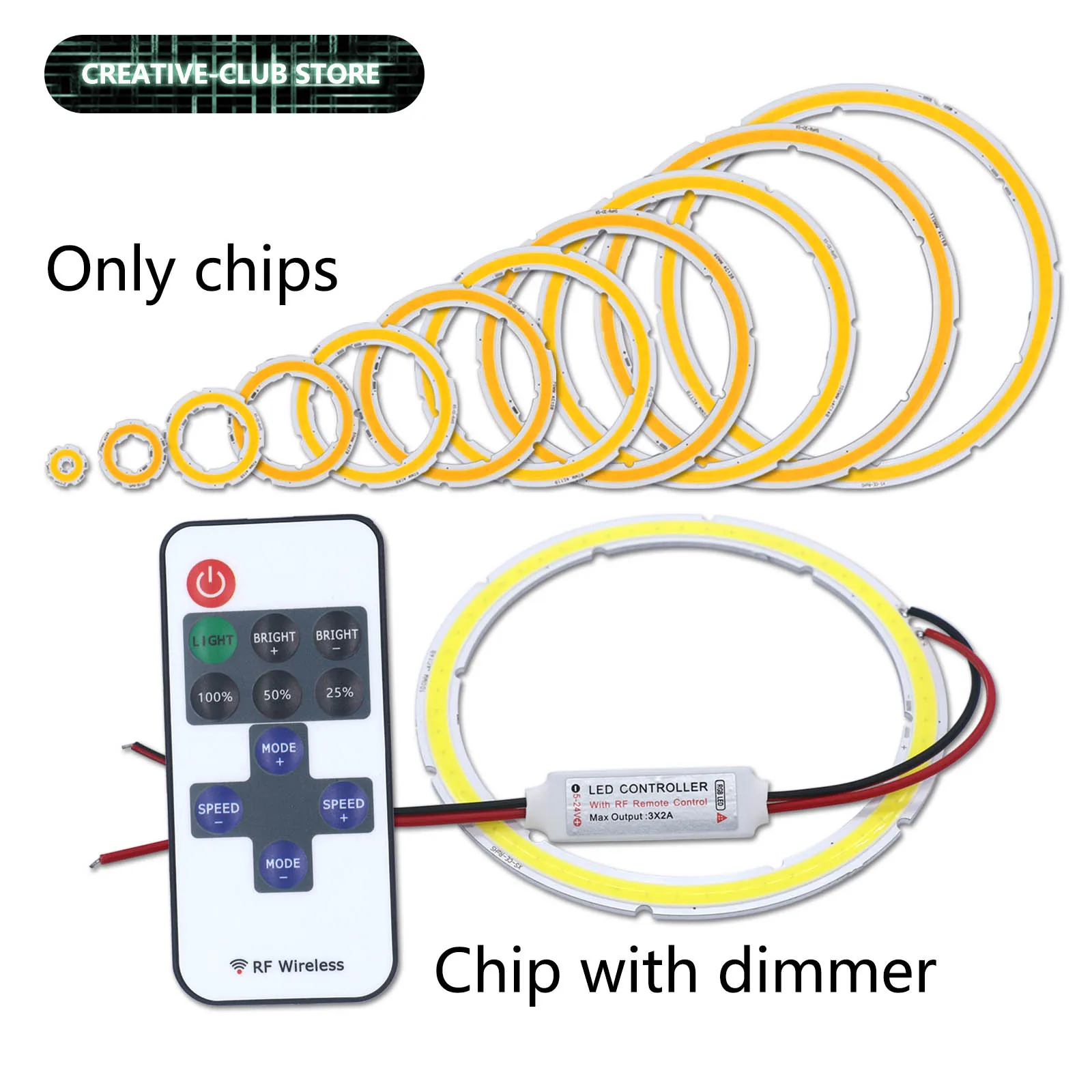

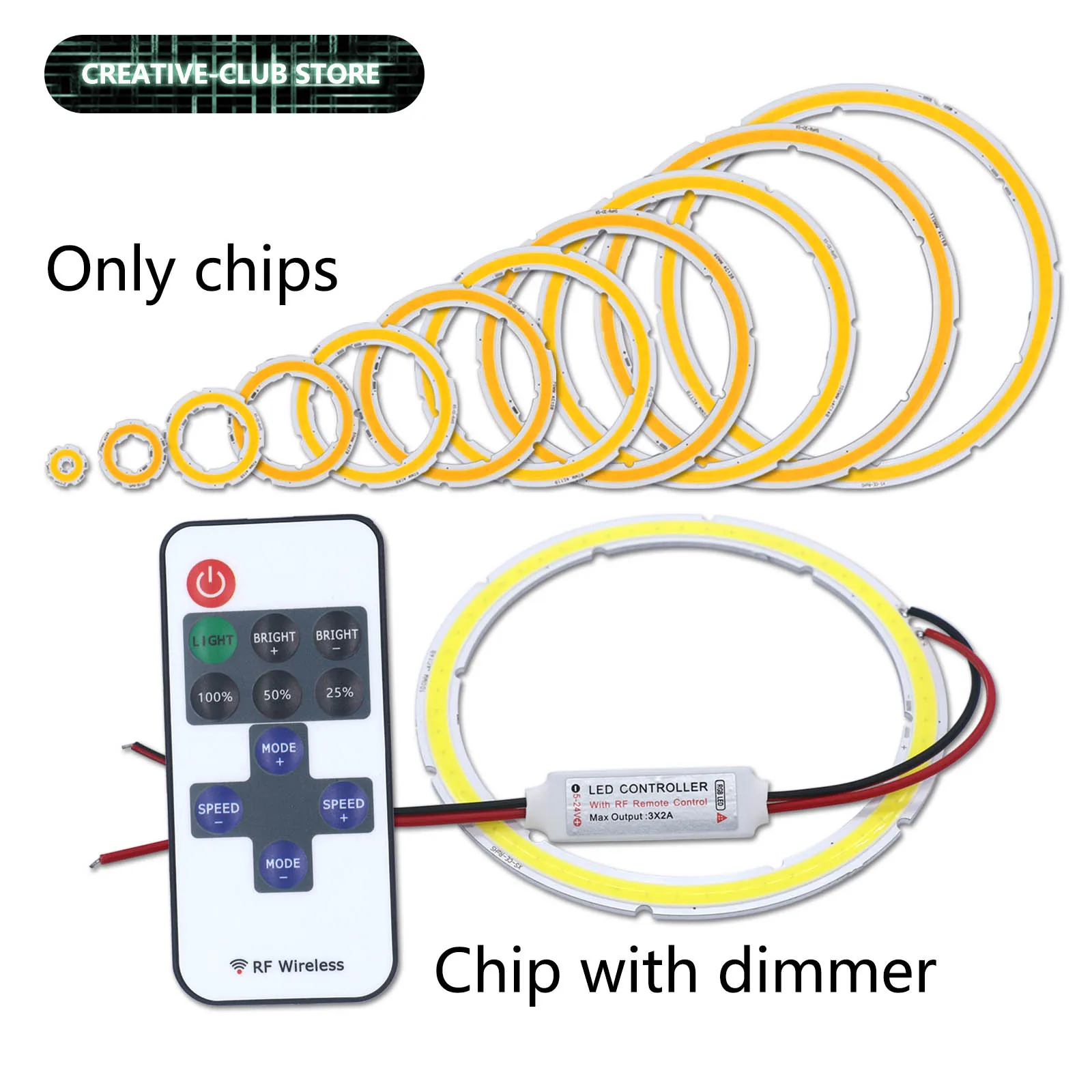

Just a quick update regarding the light. Nobody sells the Proxxon light in the UK and shipping from a European supplier made them too expensive. I looked again and found these Angel-Eye lights on AliExpress which are perfect. I bought the 40mm OD version which is 12V and works on the dimmer that I already have. Paid £1.60 for the light! Very thin and compact and I used some double sided tape to stick the light onto the mill.

www.aliexpress.com

www.aliexpress.com

Annular Angel Eyes Led COB Chips Bulb Light Source Dimmable With Dimming Remote Control for Car Motorcycle Daytime Running Light - AliExpress 39

Smarter Shopping, Better Living! Aliexpress.com

Thank you, this is a very interesting option and, most importantly, very inexpensive. You just need to wire it to any 12V power supply.Just a quick update regarding the light. Nobody sells the Proxxon light in the UK and shipping from a European supplier made them too expensive. I looked again and found these Angel-Eye lights on AliExpress which are perfect. I bought the 40mm OD version which is 12V and works on the dimmer that I already have. Paid £1.60 for the light! Very thin and compact and I used some double sided tape to stick the light onto the mill.

Annular Angel Eyes Led COB Chips Bulb Light Source Dimmable With Dimming Remote Control for Car Motorcycle Daytime Running Light - AliExpress 39

Smarter Shopping, Better Living! Aliexpress.comwww.aliexpress.com

- Joined

- Jan 5, 2026

- Messages

- 2

- Points

- 3

Have been admiring your work on HMS Alert - really impressive, and understand you have been using the Proxxon MF 70 for some of the work. I see that you have changed the bearings with significant improvement in the machine. Other users of the Proxxon have changed the collet and spindle to enable use of wider shanks. Have you done this on your machine as well? Or have you not found it necessary?

James

James

Thanks for the feedback. I haven't needed it yet. I'm currently using factory parts for everything I need, but that could change if necessary.Have been admiring your work on HMS Alert - really impressive, and understand you have been using the Proxxon MF 70 for some of the work. I see that you have changed the bearings with significant improvement in the machine. Other users of the Proxxon have changed the collet and spindle to enable use of wider shanks. Have you done this on your machine as well? Or have you not found it necessary?

James