When I started this project, one of my goals was to have working brakes. To achieve this, I needed working brake segments. So I drew them up and printed them with the only printer I had at the time (a filament printer). So I had my brake segments which eventually gave me working brakes. The thing is, I now have a resin printer. Sooo, me being me, I had to redo them. Here are a few pictures.

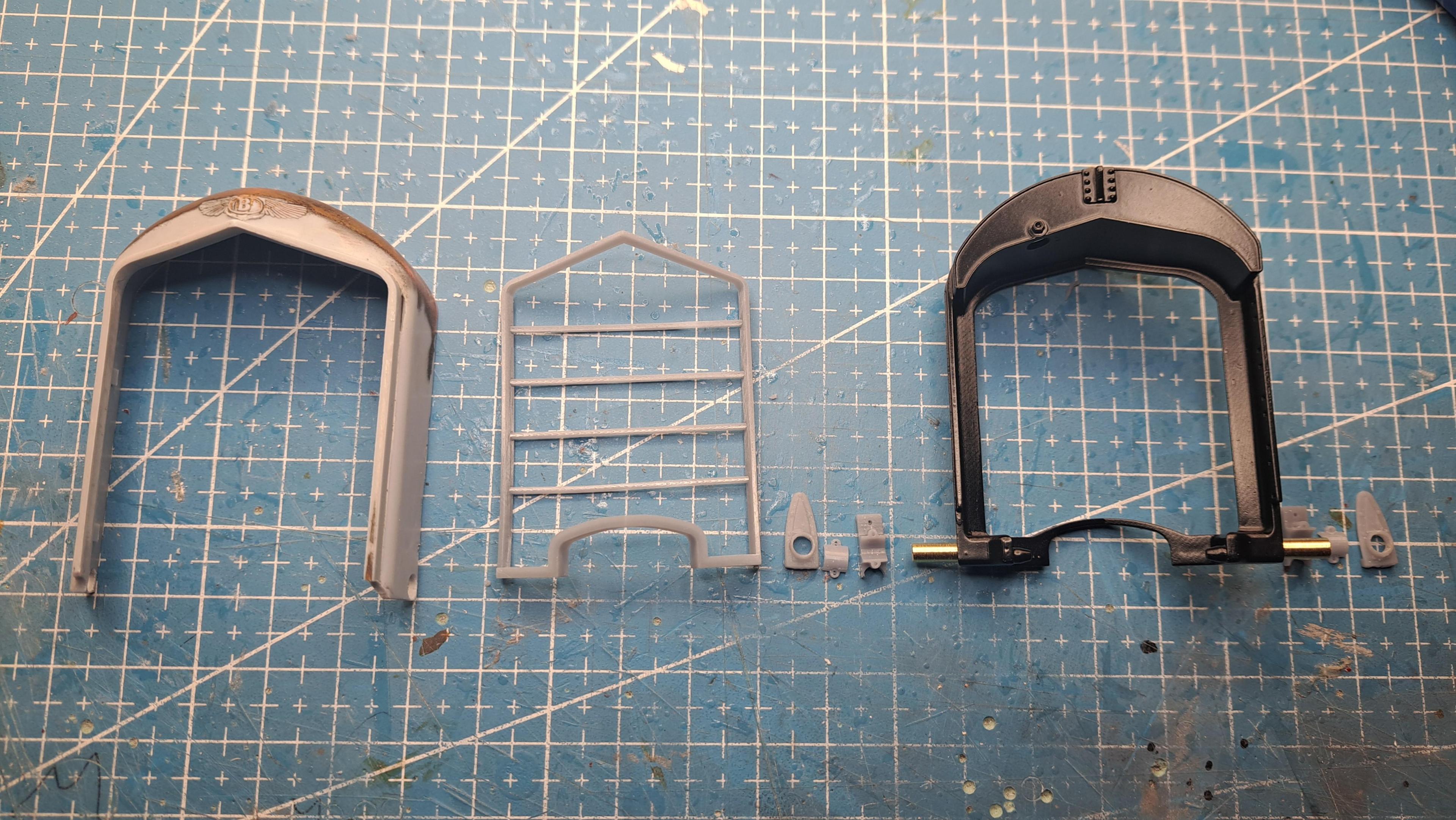

First, here's what the kit proposes

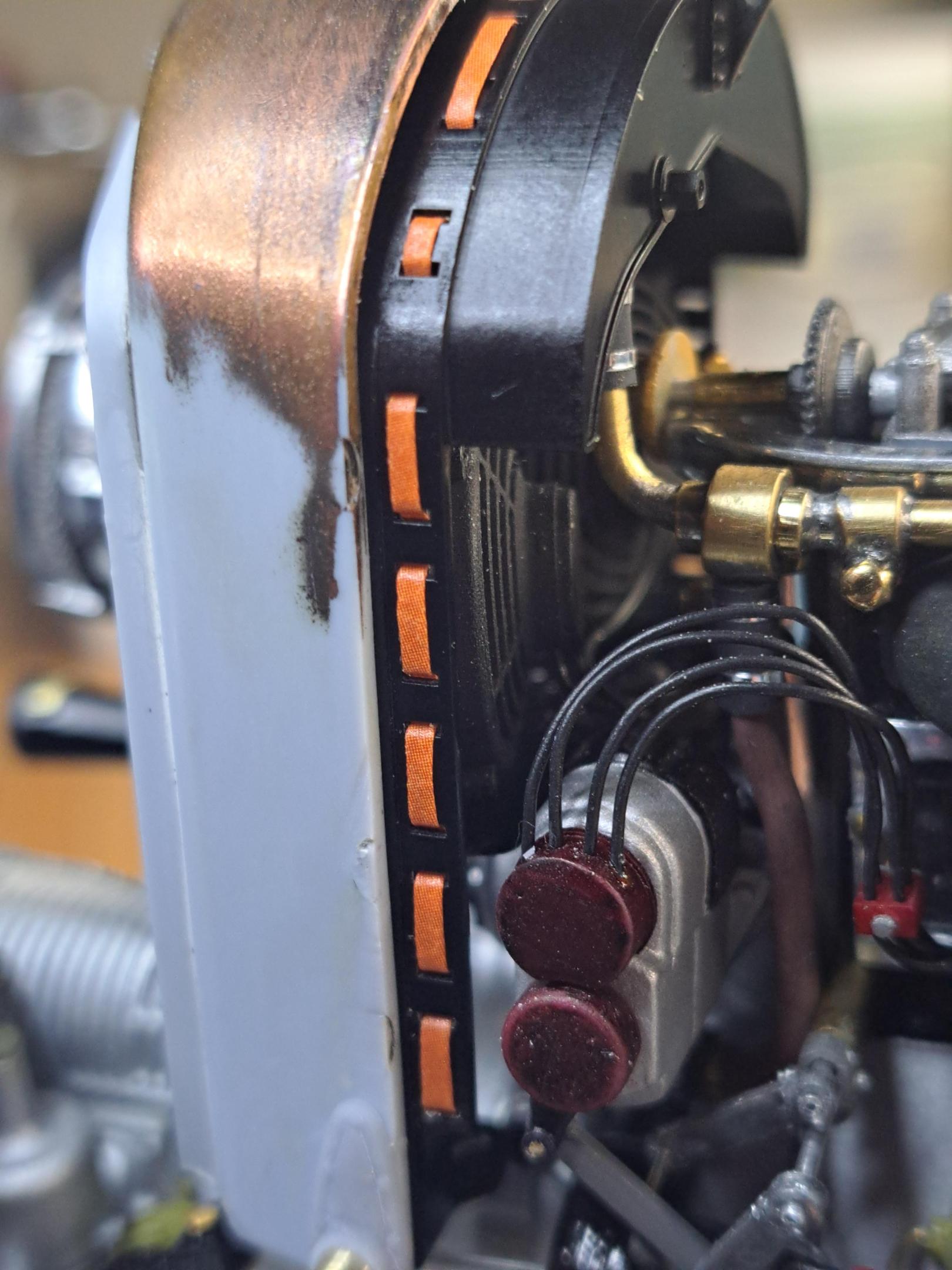

These are the segments I printed first

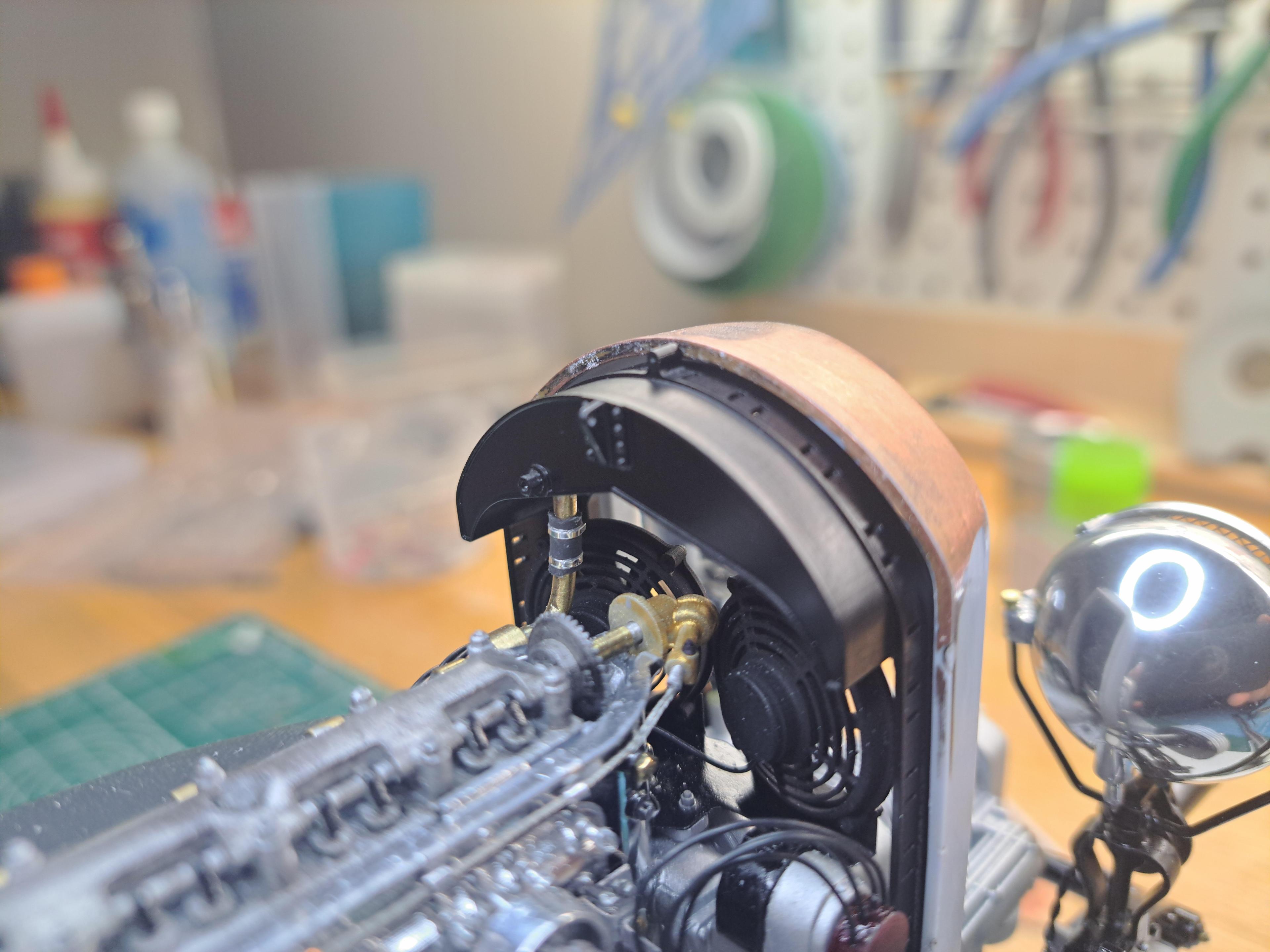

This is what I really wanted

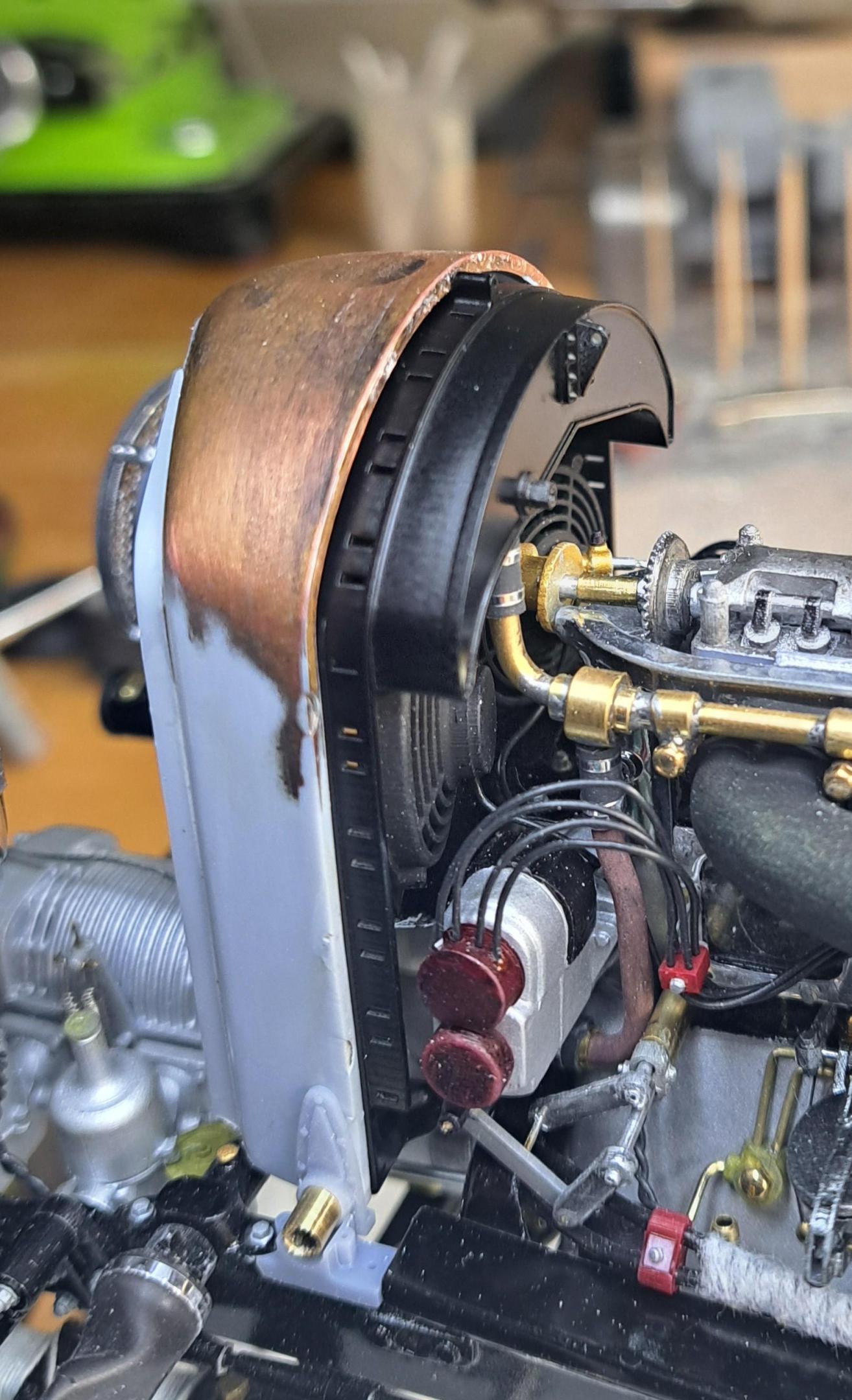

And this is what I now have. Still need to make the return spring.

it's really nice to be able to do praticaly any parts at will!!

First, here's what the kit proposes

These are the segments I printed first

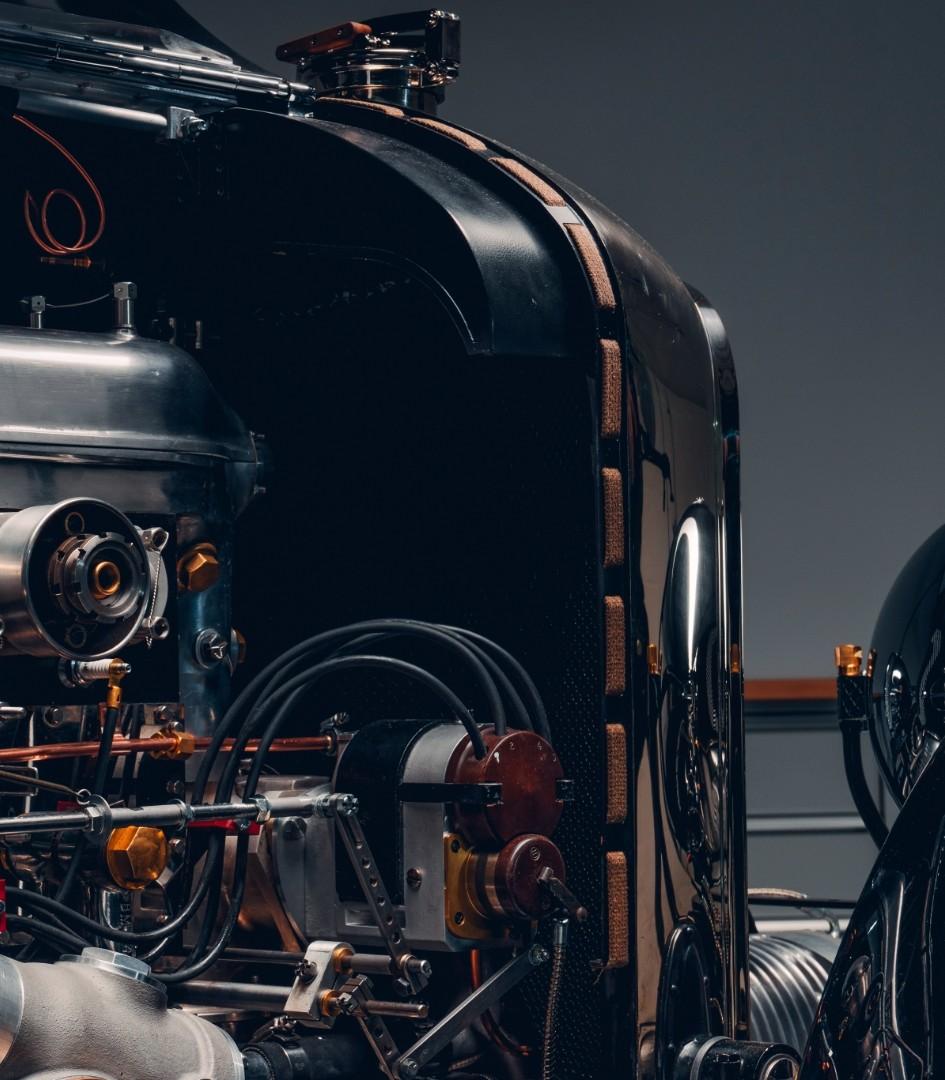

This is what I really wanted

And this is what I now have. Still need to make the return spring.

it's really nice to be able to do praticaly any parts at will!!