Tiny and very good looking. Now the kit for the boat

JL

Not yet...

|

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering. |

|

|

The beloved Ships in Scale Magazine is back and charting a new course for 2026! Discover new skills, new techniques, and new inspirations in every issue. NOTE THAT OUR FIRST ISSUE WILL BE JAN/FEB 2026 |

|

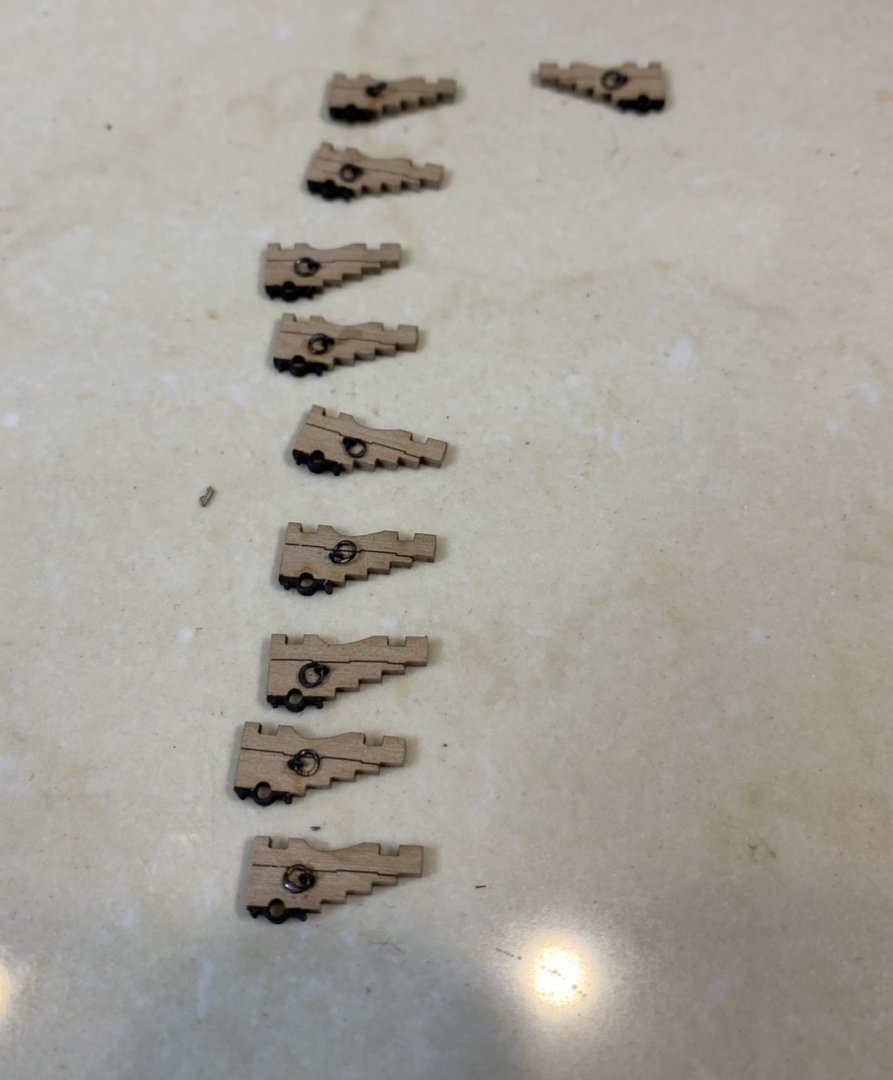

Tiny and very good looking. Now the kit for the boat

JL

I am very impressed with your close up photography. What camera are you using and I am assuming you are using MACRO mode ?

Many thanks for showing us the method of soldering rings!

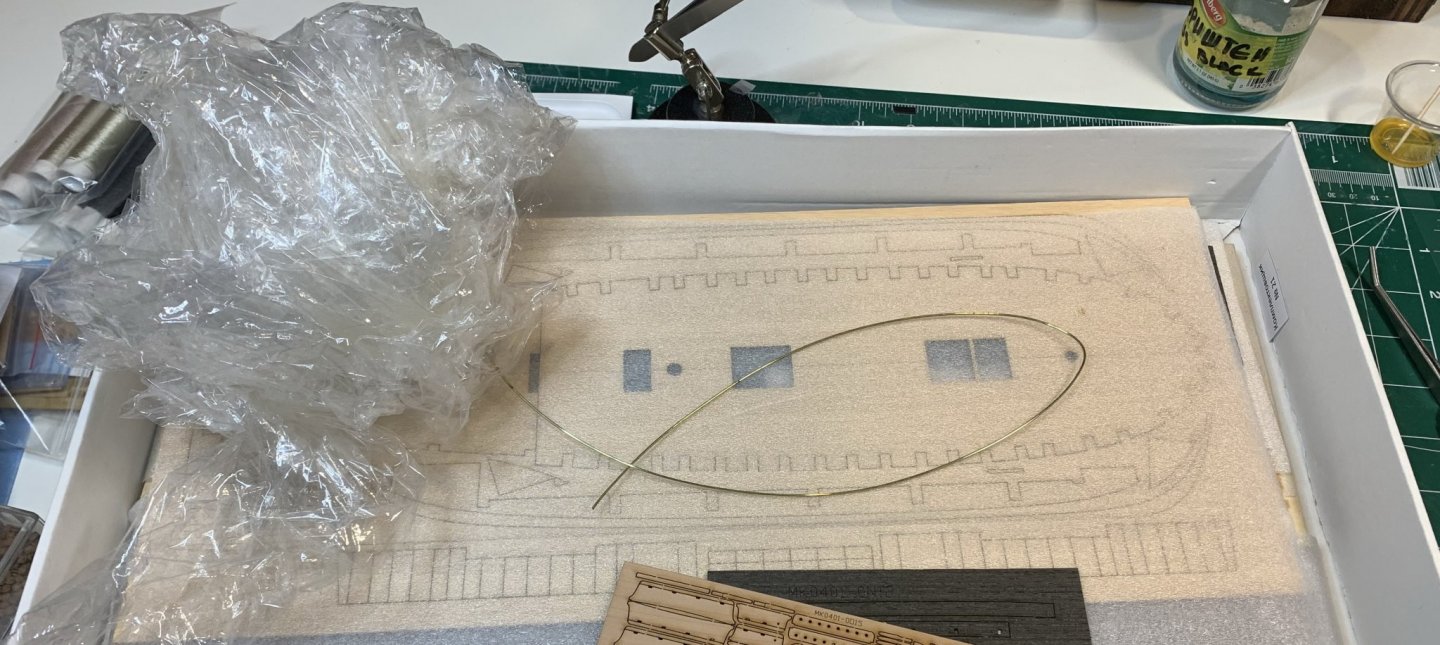

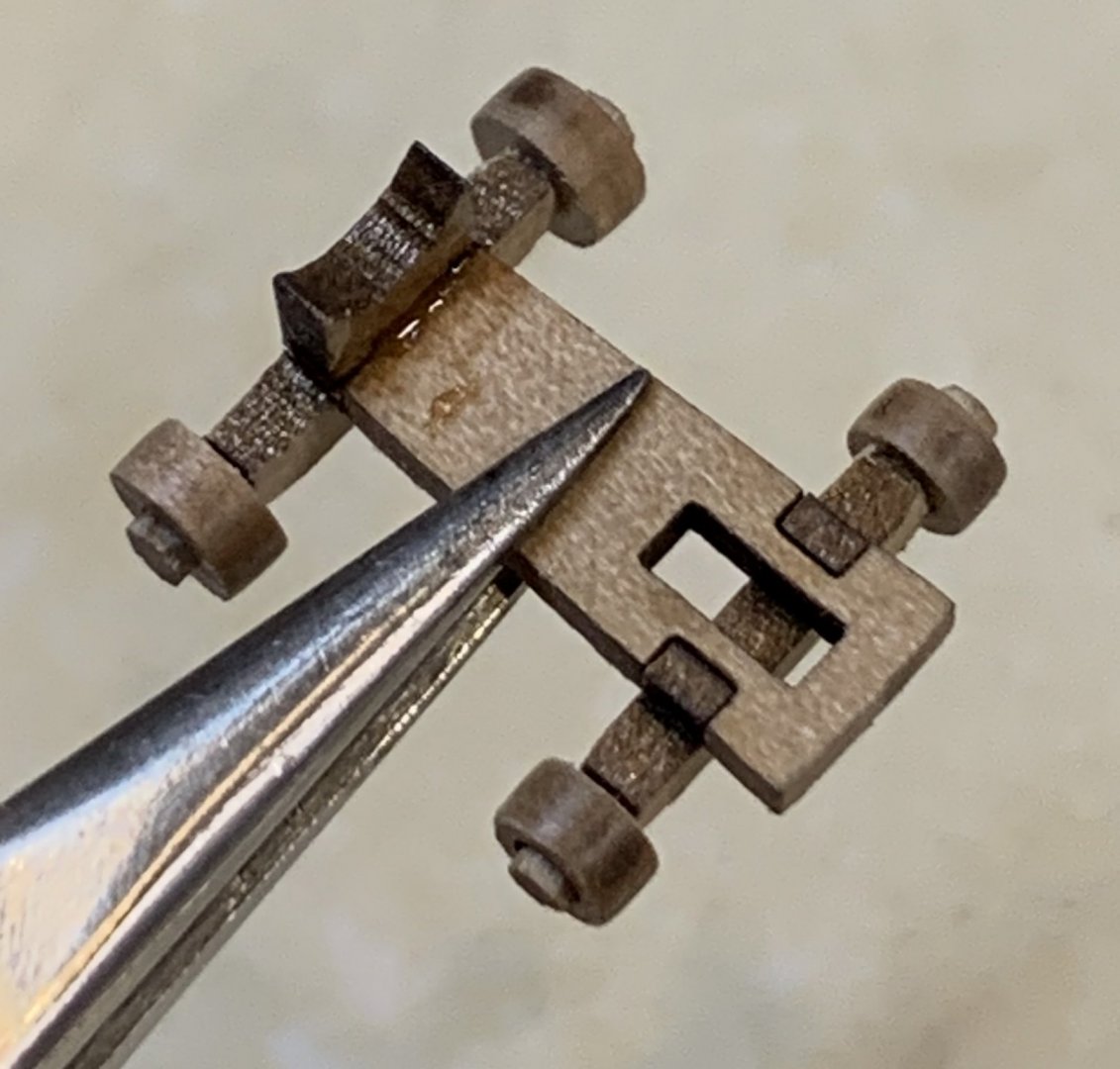

In no apparent reason, started to work on ship cannons. Searching thru the kit, i noticed how well kit parts were protected with plastic foliage..

12 ship guns....

First i remove all burrs that were visible on guns...

Then guns were dipped into blackening solvent, left for 20 seconds, removed and wiped. After that i polished all guns...

Two polished guns and one not..

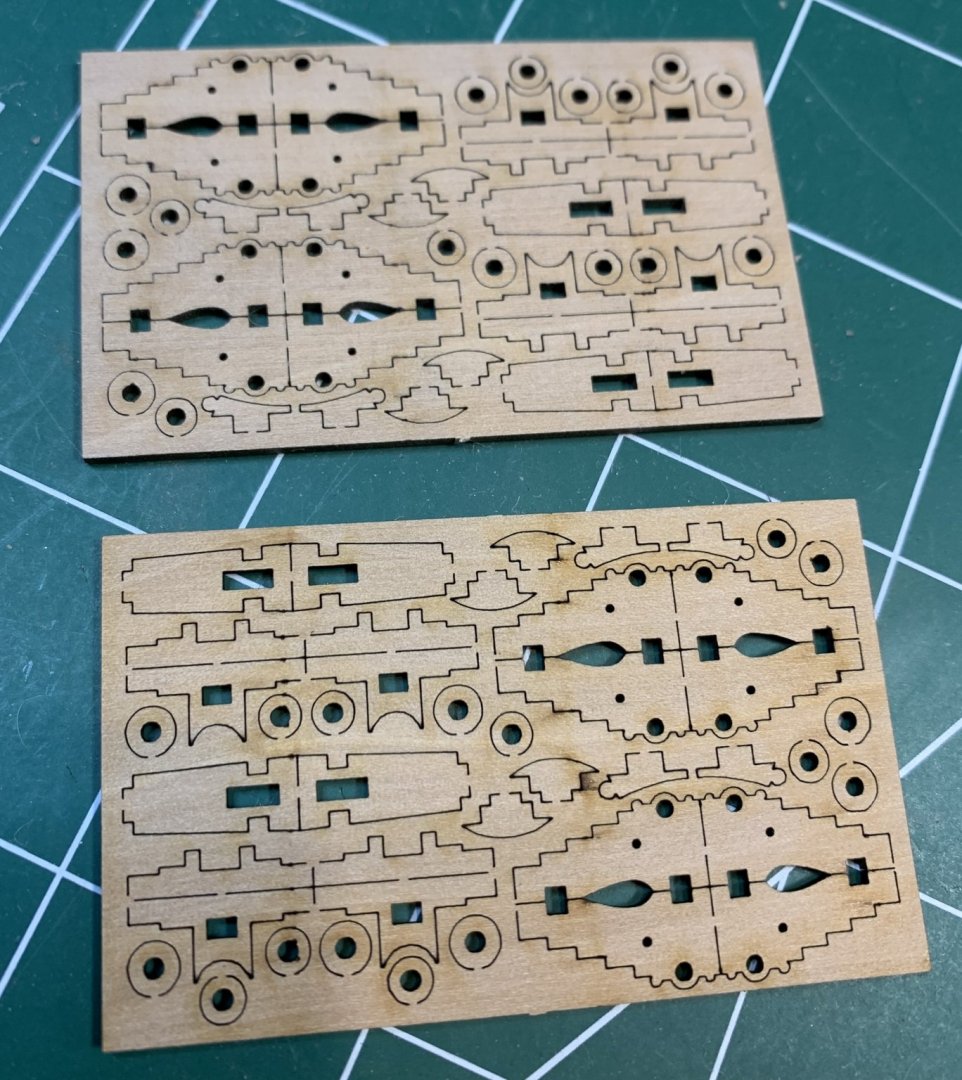

Light sanding was applied to all other gun parts to clean them out of laser cut burns or other damages..

The top one completed, the bottom is waiting its time.. It might need a bit more work but this will be done later.

The back wheels were removed from the sheets.

Setup to remove laser burns from wheels is very simple...

Two more to go...

On some cannons, muzzle opening required a bit of widening to make it a bit more realistic.

Happy modeling.

After blackening the gun barrels I give them an additional treatment with graphite powder between my fingers. It results in a very realistic appearance.

Janos

Good idea, never thought of it. ThanksAfter blackening the gun barrels I give them an additional treatment with graphite powder between my fingers. It results in a very realistic appearance.

Janos

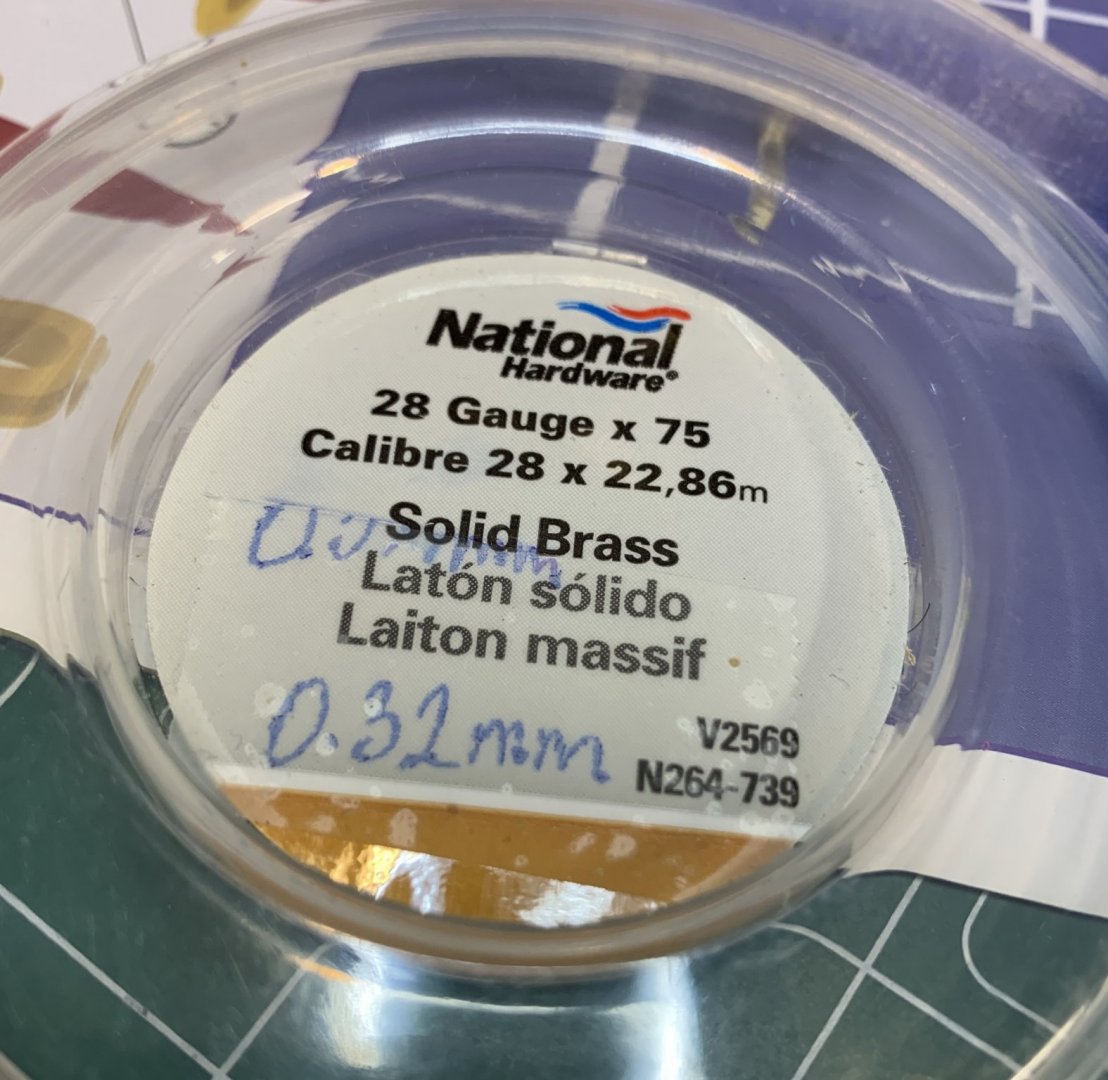

A miniature of what we call here a cranial saw. Well thought.For rounding up the ends of the square axles to accommodate the trucks I use a short piece of brass tube the inside diameter of which is equal to the requested outside diameter of the axle ending. I file a few 'teeth' into the first 1 mm of the tube. It does not have to be too precise, no worries about the proper cutting angles at all. Then the tube is fixed into the Proxxon drills chuck and here we go... Quick, easy and repetitive... you just have to take care of your fingers, keeping the axle while doing the rounding. For clean results I 'mark' the end position of the rounding with a knife blade before I start rounding the edges with the tube.

Janos

The guns and the carriage are looking very good - especially for this small scale of 1:72

For rounding up the ends of the square axles to accommodate the trucks I use a short piece of brass tube the inside diameter of which is equal to the requested outside diameter of the axle ending. I file a few 'teeth' into the first 1 mm of the tube. It does not have to be too precise, no worries about the proper cutting angles at all. Then the tube is fixed into the Proxxon drills chuck and here we go... Quick, easy and repetitive... you just have to take care of your fingers, keeping the axle while doing the rounding. For clean results I 'mark' the end position of the rounding with a knife blade before I start rounding the edges with the tube.

Janos