- Joined

- Dec 15, 2023

- Messages

- 111

- Points

- 103

A few months ago I had a request to design and build a prototype of Semi Kit of this Ship for a client in the UK.

How did I get this job? I worked on this ships restoration in 2010/11 and was tasked with taking all the measurements, scan data and photos of her without planking at times and building a digital model of her exterior and structure to exact as built specifications, the result is like an Anatomy of the ship book.

All the plans that exist today are educated guesses based on crude measurements due to the period or based of earlier plans , so a lot of inherited mistakes have crept into the plans, I have studied all the plans I know of and then tried to wipe all that and start with what is known and verified from the ship, and its really an eye opener as to how much crucial info is off.

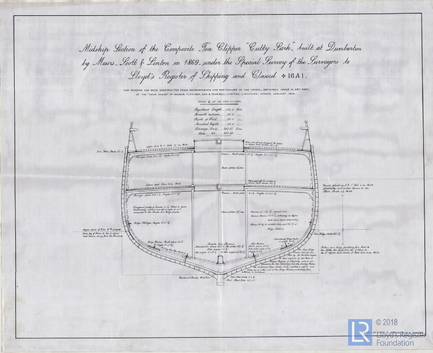

The Cutty Sarks hull was laser scanned in 2009 to provide the architects who designed her current enclosure with a firm guide as to her hull form, and when this is rebuilt using naval Architects techniques and lofted in Nurbs software and faired the error is only very small about 10mm at most full size, the only lines plan that has the midship correct for example is C Jordans midship 1922, but even his sheer line is off aft.

The sagging and collapse of Cutty Sarks hull has been factored into this as it was during the restoration.

I could do a whole post on which plans have what issues and back it up with photographic evidence on every count but I am not prepared to do this publicly.

The official Plans from the Cutty Sark .Org are also approximate even by there own admission, they are based on recollections and previous plans.

What surprised me the most is I have owned C Nepean Longridges book most of my life and viewed it as the bible but after working on the ship and measuring it first hand it's far from it, I am perplexed how some of the measurements are so far out, I can only assume some of the things he measured have been replaced to different scantlings from when she was afloat as a training ship.

In saying all of this how many modellers really care about absolute accuracy? and just want to have fun, I personally could not go and spend over $1000 on a kit that has out of scale planking, wrong lines and even the waterline in the wrong place, the AL kit is the worst, it's not on in my opinion.

I am going to do some plans based off the scan and you will be able to see for yourselves. I am just sectioning the scan, no interpretation is required, it's absolute

I am wanting to know if anyone out there is interested in this kit as I plan to do a small run of this.

I will start this blog with images of the CAD model and showing it overlaid over a version of the scan mesh

But first the size of the model and the height relative to a standard sized room

A couple of shots of the cad model and scan overlaid.

And lines compared to the sections of the laser scan.

How did I get this job? I worked on this ships restoration in 2010/11 and was tasked with taking all the measurements, scan data and photos of her without planking at times and building a digital model of her exterior and structure to exact as built specifications, the result is like an Anatomy of the ship book.

All the plans that exist today are educated guesses based on crude measurements due to the period or based of earlier plans , so a lot of inherited mistakes have crept into the plans, I have studied all the plans I know of and then tried to wipe all that and start with what is known and verified from the ship, and its really an eye opener as to how much crucial info is off.

The Cutty Sarks hull was laser scanned in 2009 to provide the architects who designed her current enclosure with a firm guide as to her hull form, and when this is rebuilt using naval Architects techniques and lofted in Nurbs software and faired the error is only very small about 10mm at most full size, the only lines plan that has the midship correct for example is C Jordans midship 1922, but even his sheer line is off aft.

The sagging and collapse of Cutty Sarks hull has been factored into this as it was during the restoration.

I could do a whole post on which plans have what issues and back it up with photographic evidence on every count but I am not prepared to do this publicly.

The official Plans from the Cutty Sark .Org are also approximate even by there own admission, they are based on recollections and previous plans.

What surprised me the most is I have owned C Nepean Longridges book most of my life and viewed it as the bible but after working on the ship and measuring it first hand it's far from it, I am perplexed how some of the measurements are so far out, I can only assume some of the things he measured have been replaced to different scantlings from when she was afloat as a training ship.

In saying all of this how many modellers really care about absolute accuracy? and just want to have fun, I personally could not go and spend over $1000 on a kit that has out of scale planking, wrong lines and even the waterline in the wrong place, the AL kit is the worst, it's not on in my opinion.

I am going to do some plans based off the scan and you will be able to see for yourselves. I am just sectioning the scan, no interpretation is required, it's absolute

I am wanting to know if anyone out there is interested in this kit as I plan to do a small run of this.

I will start this blog with images of the CAD model and showing it overlaid over a version of the scan mesh

But first the size of the model and the height relative to a standard sized room

A couple of shots of the cad model and scan overlaid.

And lines compared to the sections of the laser scan.