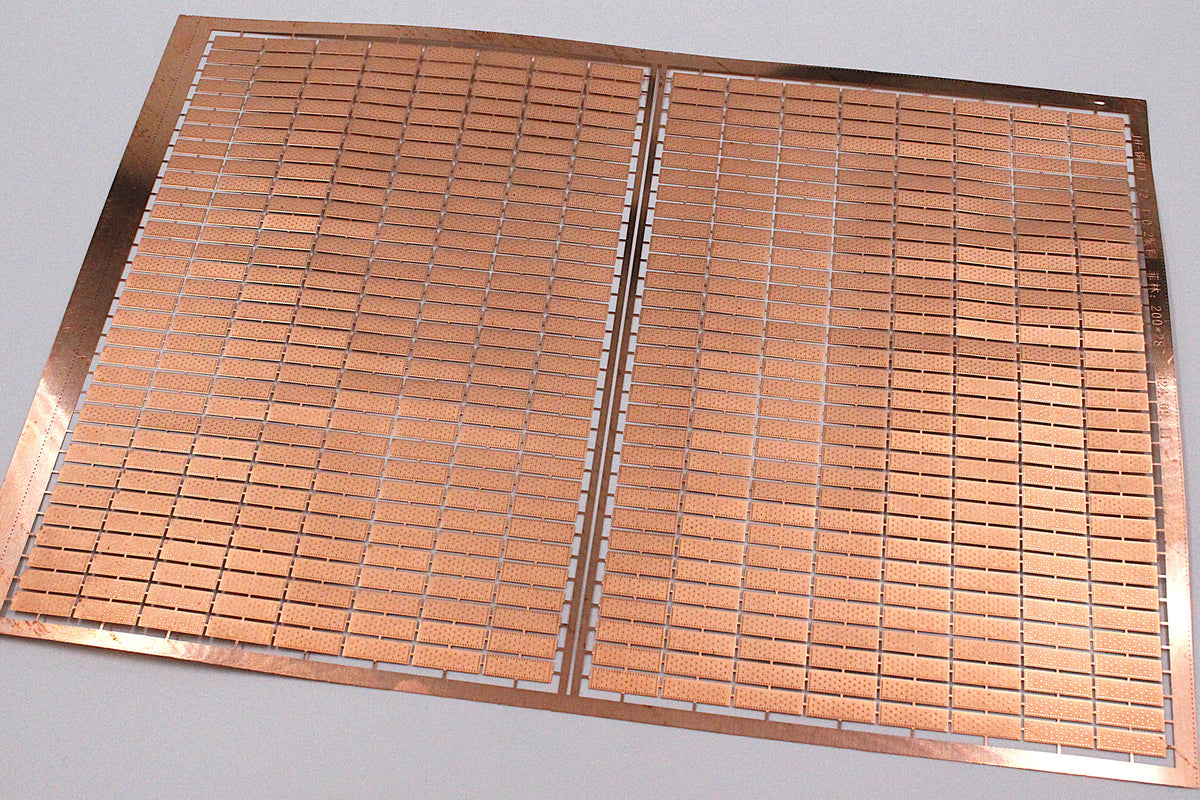

Today, I finally reached the waterline. From the keel to the waterline (WL), there are 29 rows of copper plating. To prevent glue from seeping onto the paint above the plates, I use electrical tape, which I align precisely along the waterline.

As planned, I started plating from the keel upward, ensuring the rows remained perfectly horizontal to the keel. Upon reaching the waterline, I switched to plating horizontally along the waterline, ensuring the rows align with it. This way, the lower rows naturally taper into these, rather than the other way around.

At the stern, I'll taper the rows to a point, while at the bow, two rows will follow the waterline.

A few words about "tapering" (the rows that narrow to a point): Since the copper plating simulates nails, the upper edge of the plates (where the nail imprints are close together) must always be preserved to maintain this appearance. I first mark the cut line, then, if the section is above the waterline, I cover it with electrical tape before attaching the row. Once the top row is in place, I can proceed with the lower ones.

After securing the plates, I completed a full row that tapers to nothing for the first time.

On one side, the progress so far looks like this:

For the other side (I work on both sides simultaneously in portions), I start at the waterline and work downward to meet the lower rows, carefully mirroring the pattern from the first side. Even if something doesn’t align perfectly, I can blend the rows seamlessly because these sections will be lower. And, as expected, slight discrepancies appeared—an excess of about 1.5 mm. I’ll have to find a way to cover this, but since it’s a small area, it should remain unnoticeable.

Another issue has emerged: when removing the protective electrical tape, small fragments of paint come off with it. I’ll likely need to touch up the lower wales to fix these imperfections.

The holidays are coming up, which means I’ll have more time to work on the ship. I’m eager to finally finish the copper plating. Honestly… this might be the last time I do it (if I build another model). It’s such a specialized and tedious task!

I would also like to take this opportunity to wish everyone a happy holiday season—whether you celebrate New Year, Christmas, or any other holiday. I wish you all health, kindness, and PEACE! I never thought I’d find myself genuinely wishing for peace, but here we are. Take care of yourselves and your loved ones!

As planned, I started plating from the keel upward, ensuring the rows remained perfectly horizontal to the keel. Upon reaching the waterline, I switched to plating horizontally along the waterline, ensuring the rows align with it. This way, the lower rows naturally taper into these, rather than the other way around.

At the stern, I'll taper the rows to a point, while at the bow, two rows will follow the waterline.

A few words about "tapering" (the rows that narrow to a point): Since the copper plating simulates nails, the upper edge of the plates (where the nail imprints are close together) must always be preserved to maintain this appearance. I first mark the cut line, then, if the section is above the waterline, I cover it with electrical tape before attaching the row. Once the top row is in place, I can proceed with the lower ones.

After securing the plates, I completed a full row that tapers to nothing for the first time.

On one side, the progress so far looks like this:

For the other side (I work on both sides simultaneously in portions), I start at the waterline and work downward to meet the lower rows, carefully mirroring the pattern from the first side. Even if something doesn’t align perfectly, I can blend the rows seamlessly because these sections will be lower. And, as expected, slight discrepancies appeared—an excess of about 1.5 mm. I’ll have to find a way to cover this, but since it’s a small area, it should remain unnoticeable.

Another issue has emerged: when removing the protective electrical tape, small fragments of paint come off with it. I’ll likely need to touch up the lower wales to fix these imperfections.

The holidays are coming up, which means I’ll have more time to work on the ship. I’m eager to finally finish the copper plating. Honestly… this might be the last time I do it (if I build another model). It’s such a specialized and tedious task!

I would also like to take this opportunity to wish everyone a happy holiday season—whether you celebrate New Year, Christmas, or any other holiday. I wish you all health, kindness, and PEACE! I never thought I’d find myself genuinely wishing for peace, but here we are. Take care of yourselves and your loved ones!