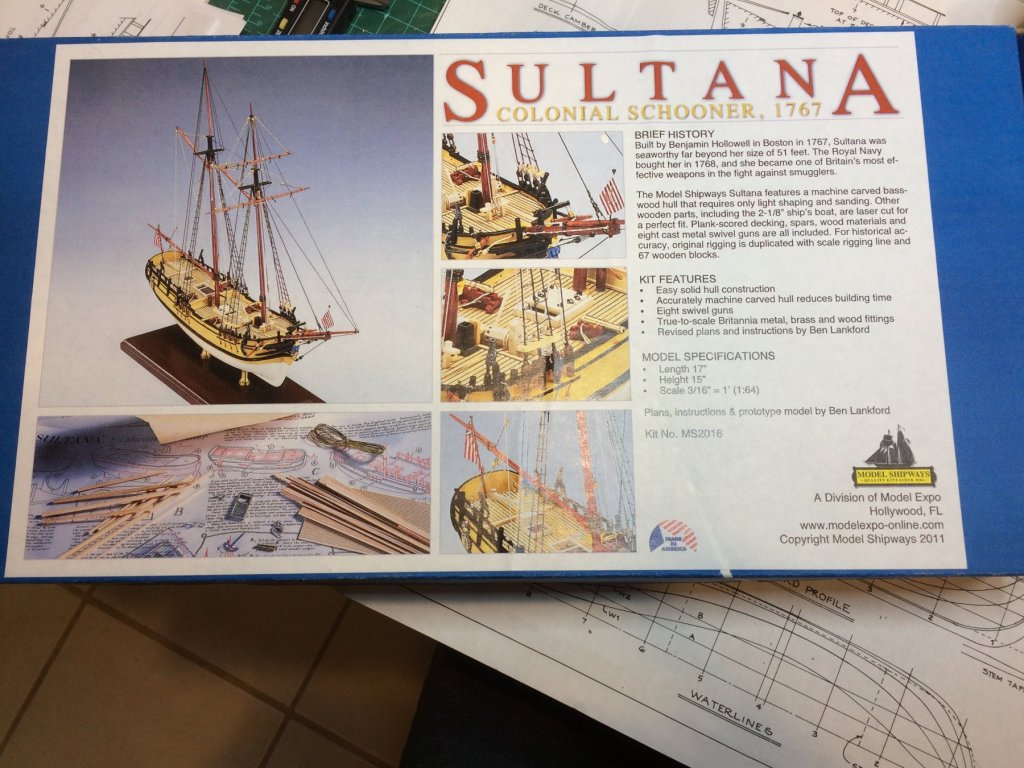

It is time to start a new build; actually it is time to continue with existing build i started some time ago while still residing in my rented apartment.

No room to do much but eager to get back to favorite hobby, i opened a box and started building it. Unfortunately at some point i realized that it is better to drop it back in the box and wait for better times, actually to get to the new place... After some time, my new shipyard was ready and it is time to start it again. So back to the shipyard after completion of Greek Birema, opened already opened box and started new ship building journey.

I will be following Chuck Passaro's building practicum for Sultana. I think it is covering very interesting approach to build and very useful for people wishing to get back to this hobby.

So lets start...

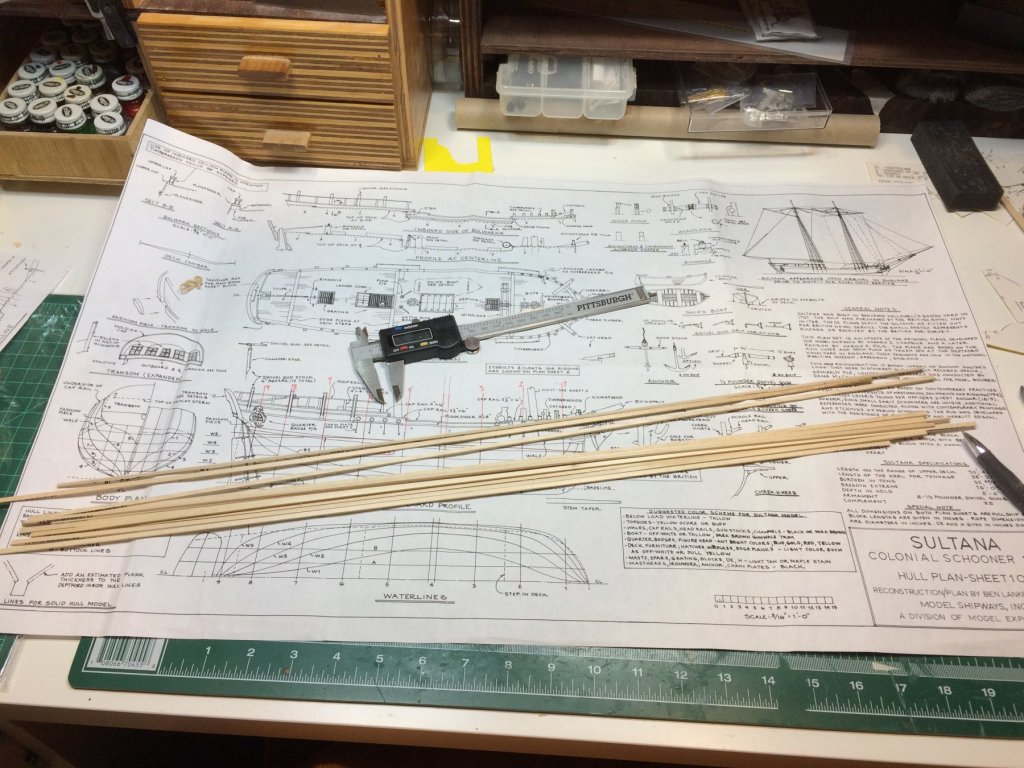

This is a solid hull model, that need some adjustment during building process. First is to remove existing bulwarks that will be replaced with double planking. In the box we have some amount of planking material i will be replacing with basswood that i have in my shop. I will be cutting it on my mini table saw.

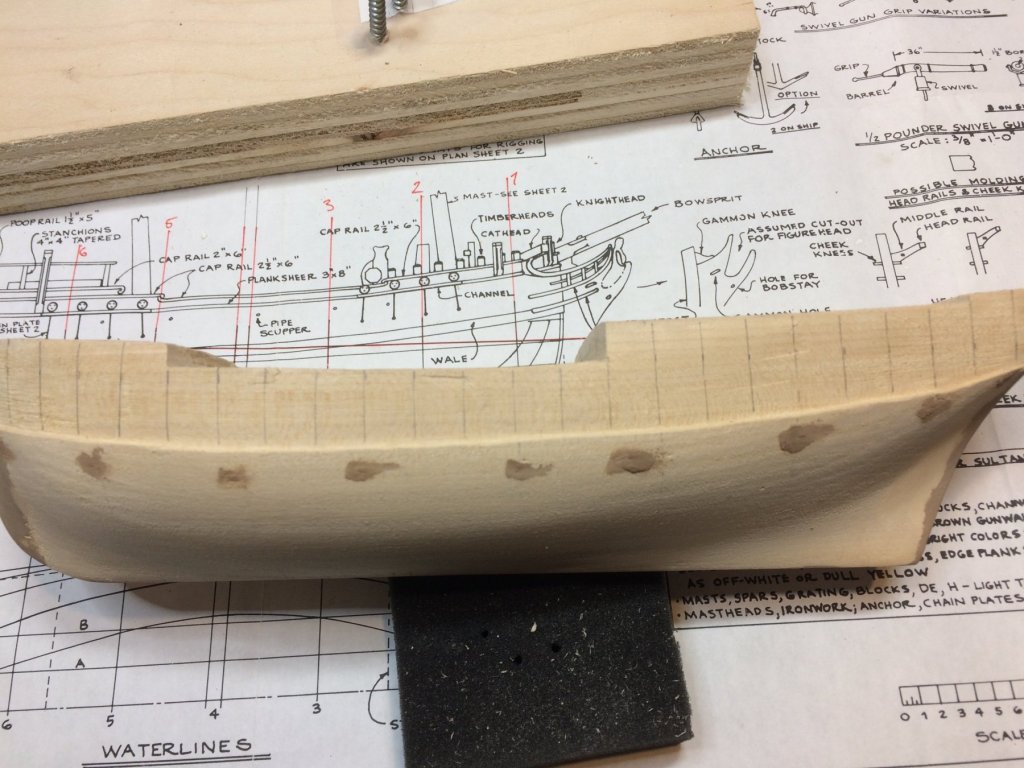

Here is hull with removed bulwarks, at the deck level hull was sanded and some wood filler added to correct the hull shape.

Ok, that is for now; see you all soon..

Happy modeling..

No room to do much but eager to get back to favorite hobby, i opened a box and started building it. Unfortunately at some point i realized that it is better to drop it back in the box and wait for better times, actually to get to the new place... After some time, my new shipyard was ready and it is time to start it again. So back to the shipyard after completion of Greek Birema, opened already opened box and started new ship building journey.

I will be following Chuck Passaro's building practicum for Sultana. I think it is covering very interesting approach to build and very useful for people wishing to get back to this hobby.

So lets start...

This is a solid hull model, that need some adjustment during building process. First is to remove existing bulwarks that will be replaced with double planking. In the box we have some amount of planking material i will be replacing with basswood that i have in my shop. I will be cutting it on my mini table saw.

Here is hull with removed bulwarks, at the deck level hull was sanded and some wood filler added to correct the hull shape.

Ok, that is for now; see you all soon..

Happy modeling..