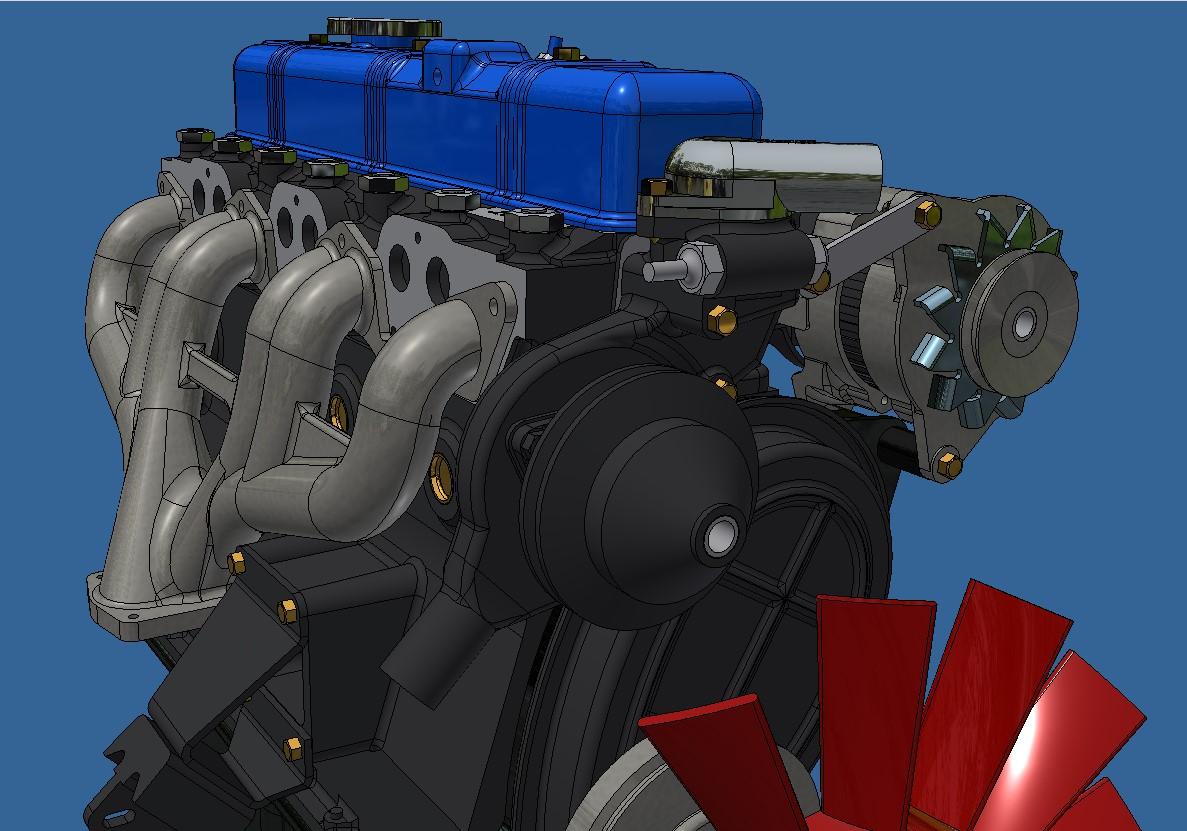

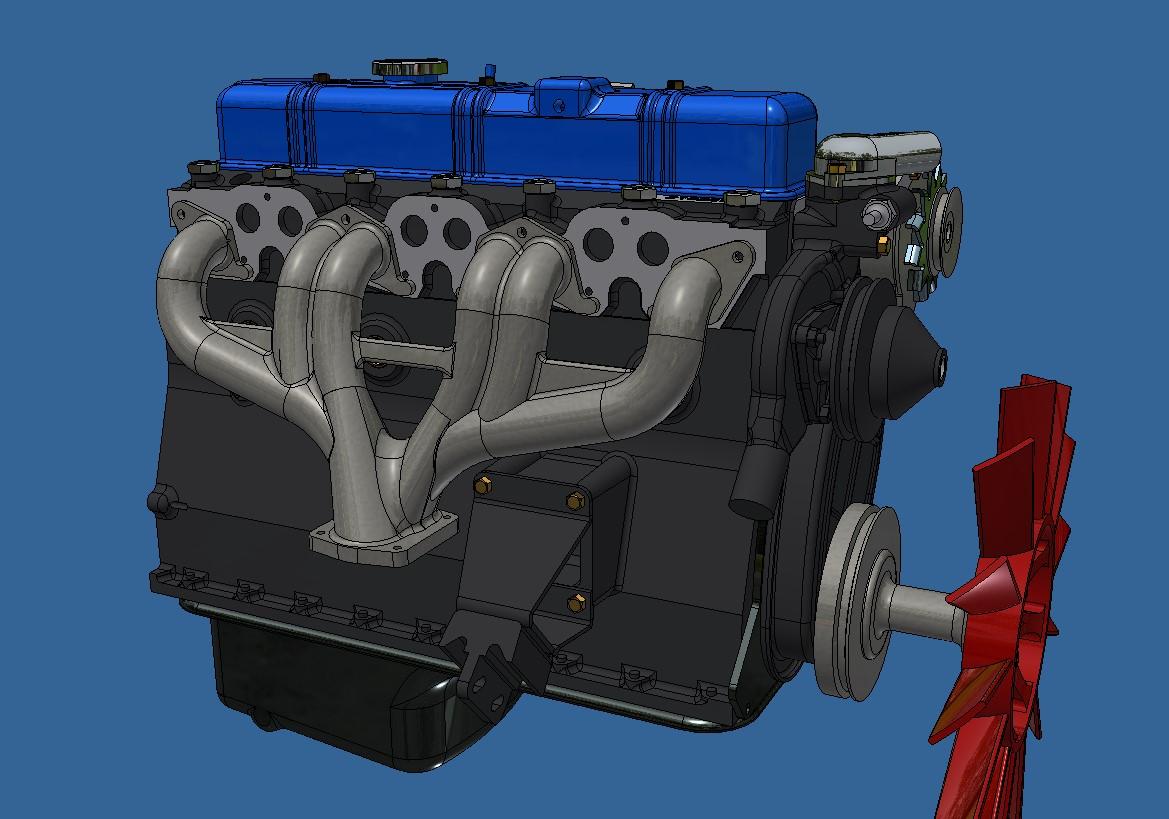

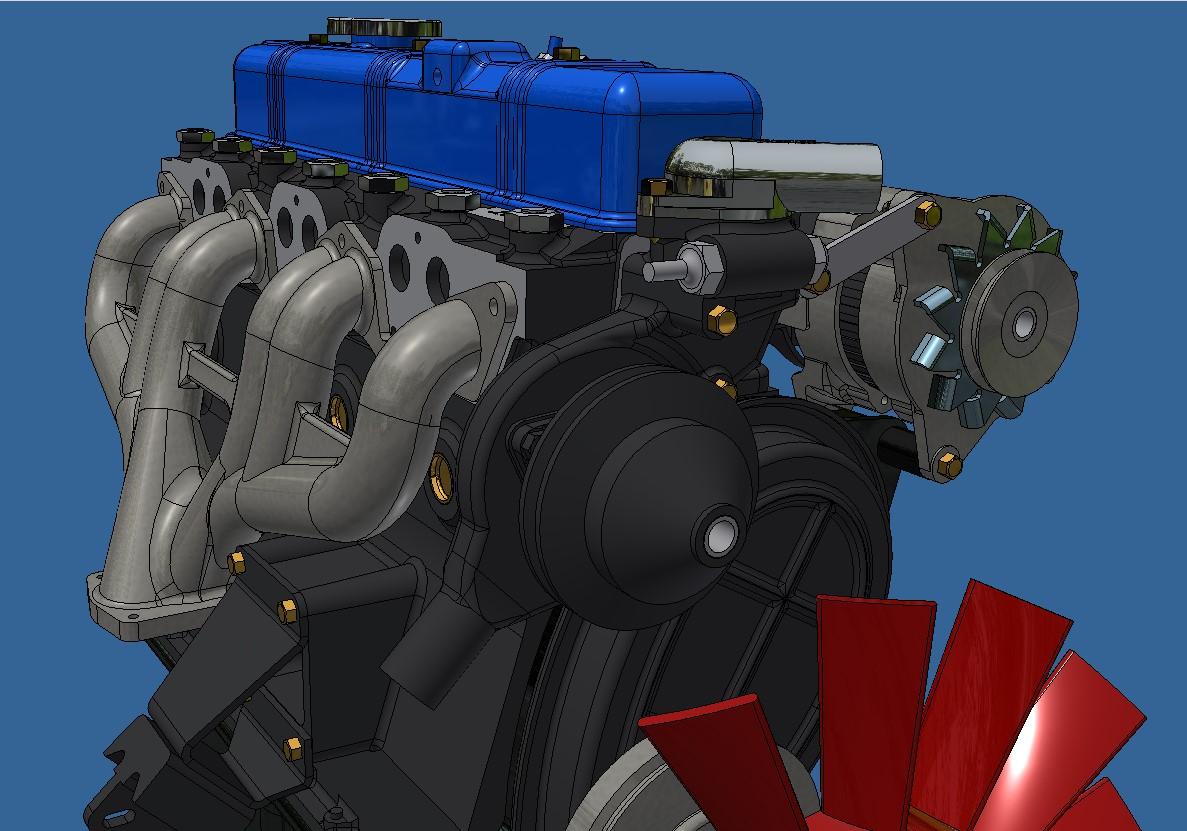

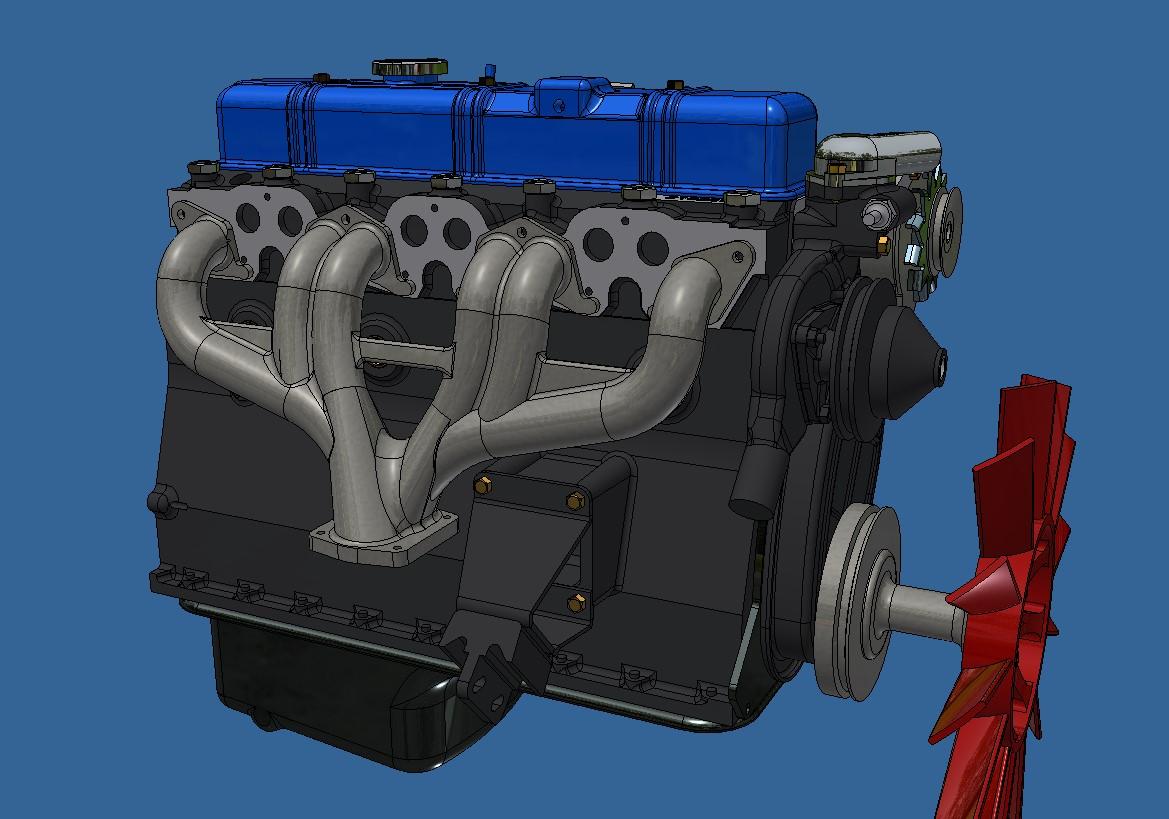

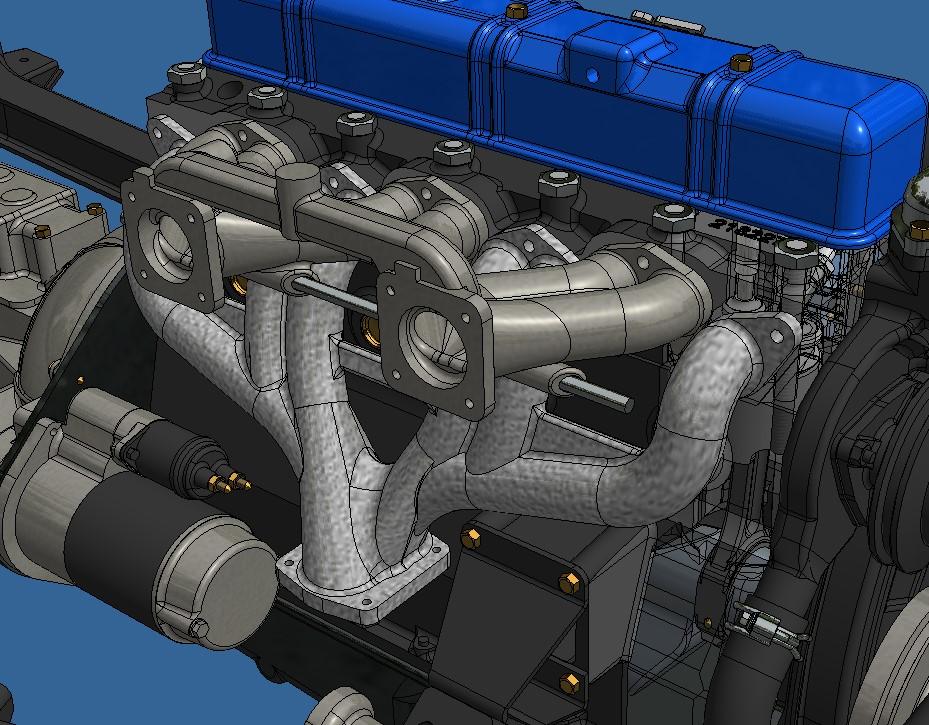

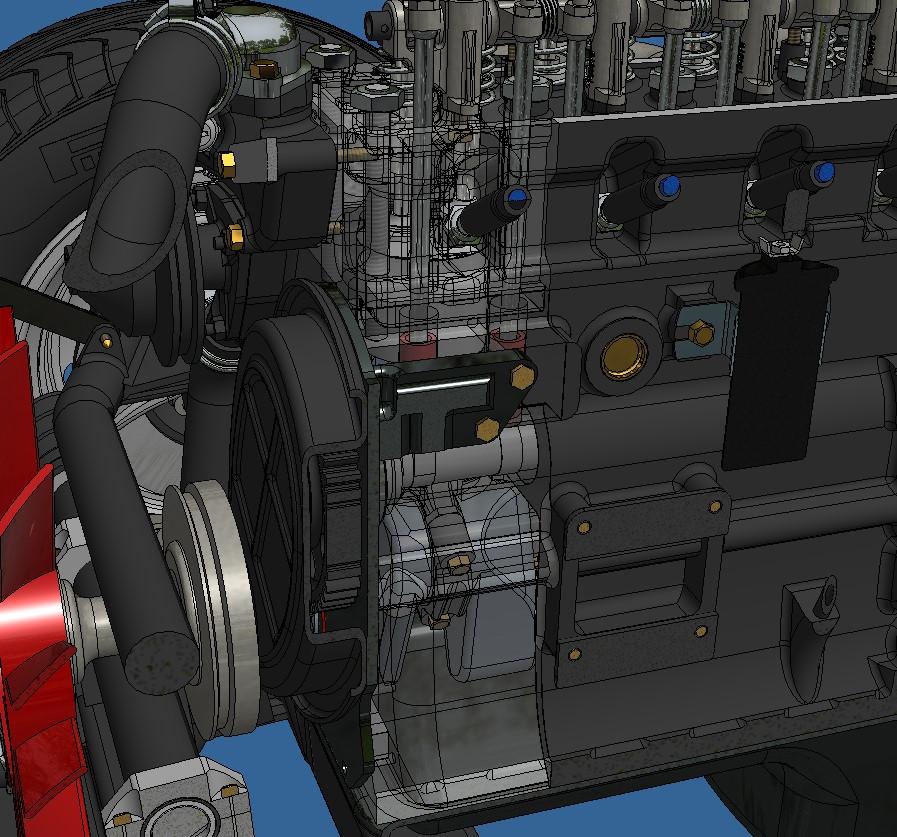

I'm almost done with the engine. I still need to do the intake manifold and the carburators, I'm keeping the carbs for last since they are quite complicated. The Stromberg carburators were one of the things a TR6 was known for so I want to get them as right as I can. Once all of this is done, I have to figure out how to showcase all these moving parts. The rocker cover and oil pan will be removable, that's a given. But i'd like to dive in deeper and look at the valves, pistons and conrods as they move. I might make a few cut-outs here and there, not to sure just how yet.