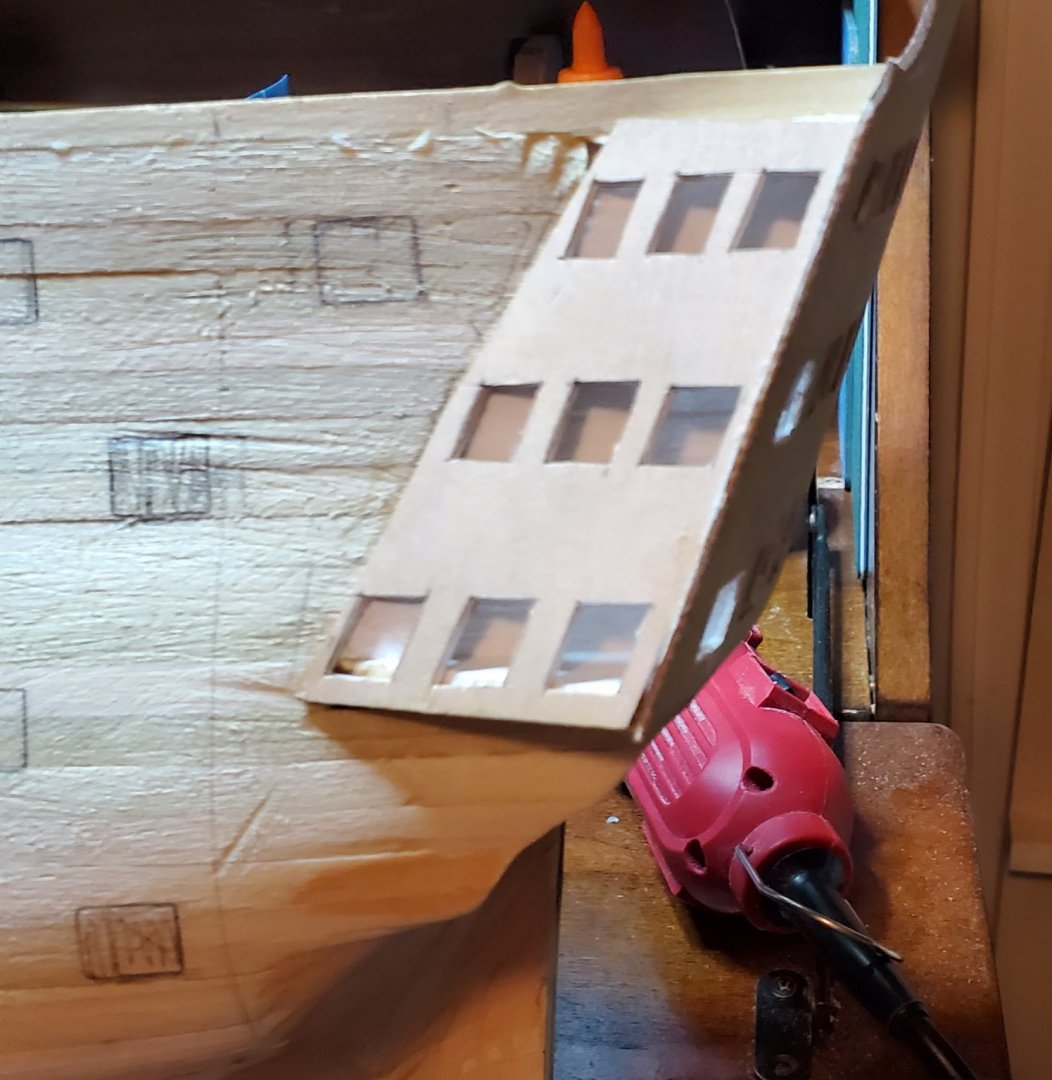

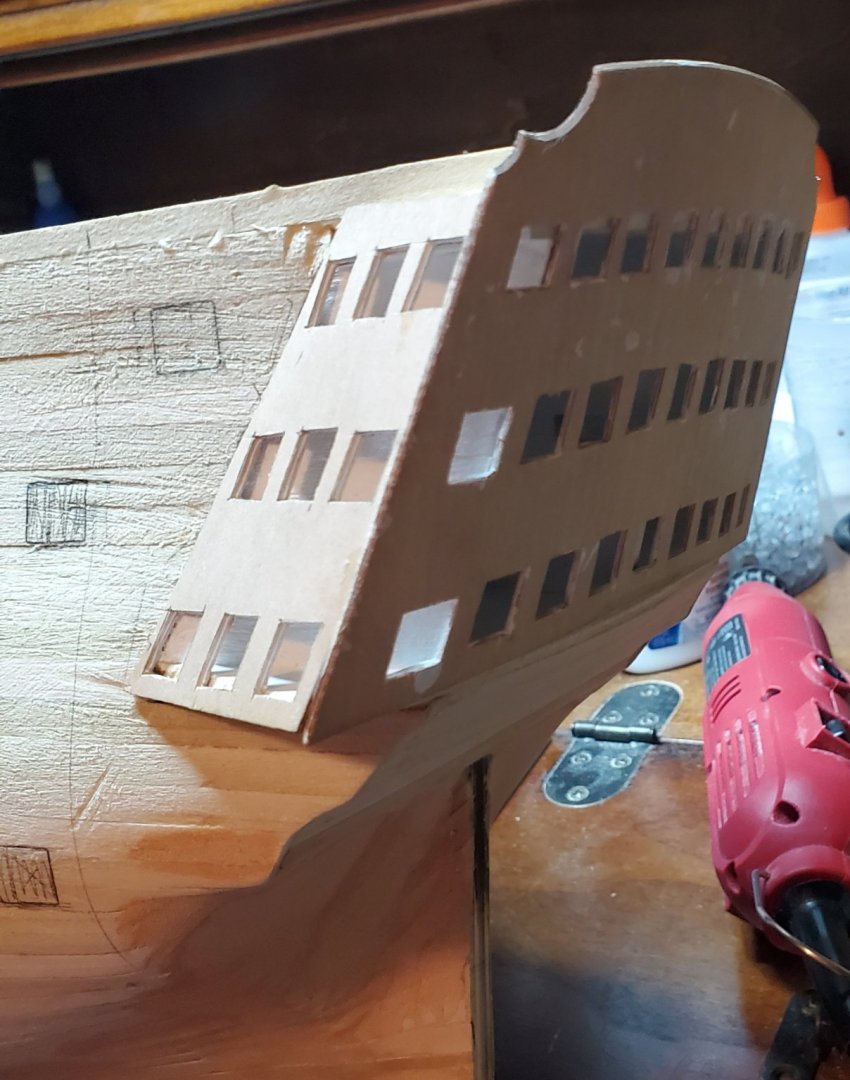

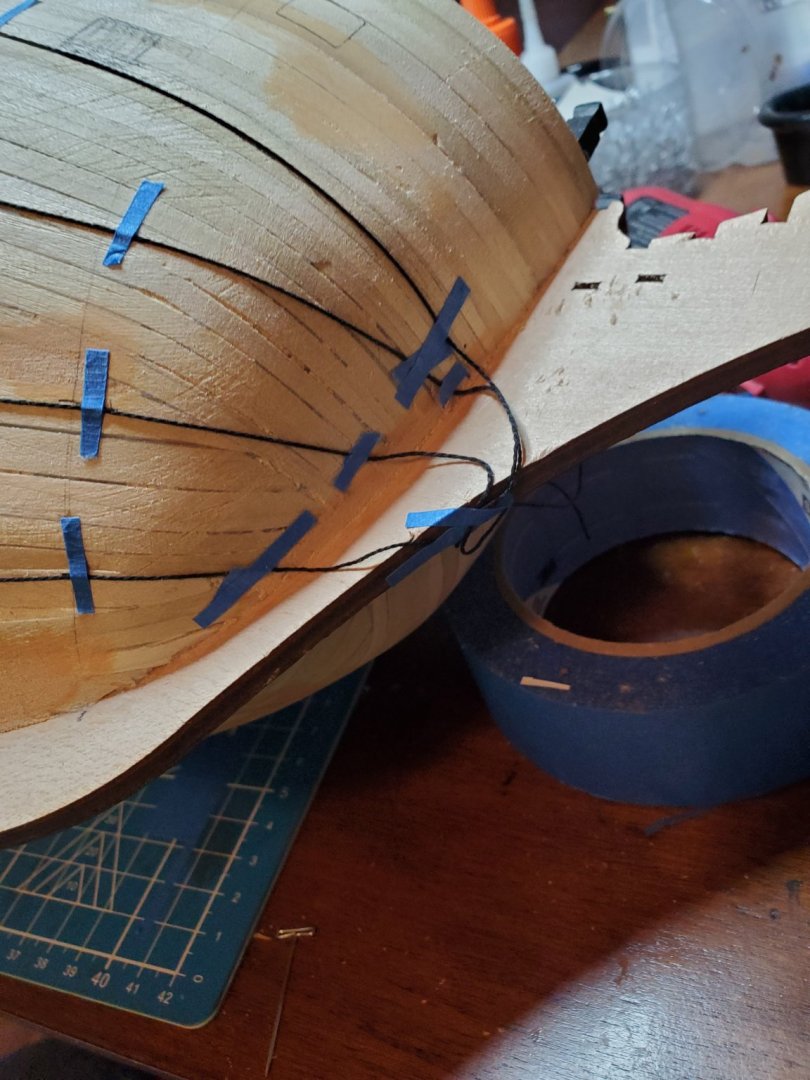

I hate this cheap lousy wood for the second planking in this kit. The first planking wood ( lime wood) was much better. It was very well finished and consistent. The walnut for second planking is all slightly different widths and very rough on the edges. .....With that out of the way ..... I got about half of each side done and it is rough going. I have to constantly try to adjust the width by sanding a little on the edges and try to make the bands finish close to width. I have noticed the thickness is varying slightly on the boards. ( I regret now not replacing all the wood, but it is stupid to pay five hundred dollars for a kit and have to replace almost every thing).

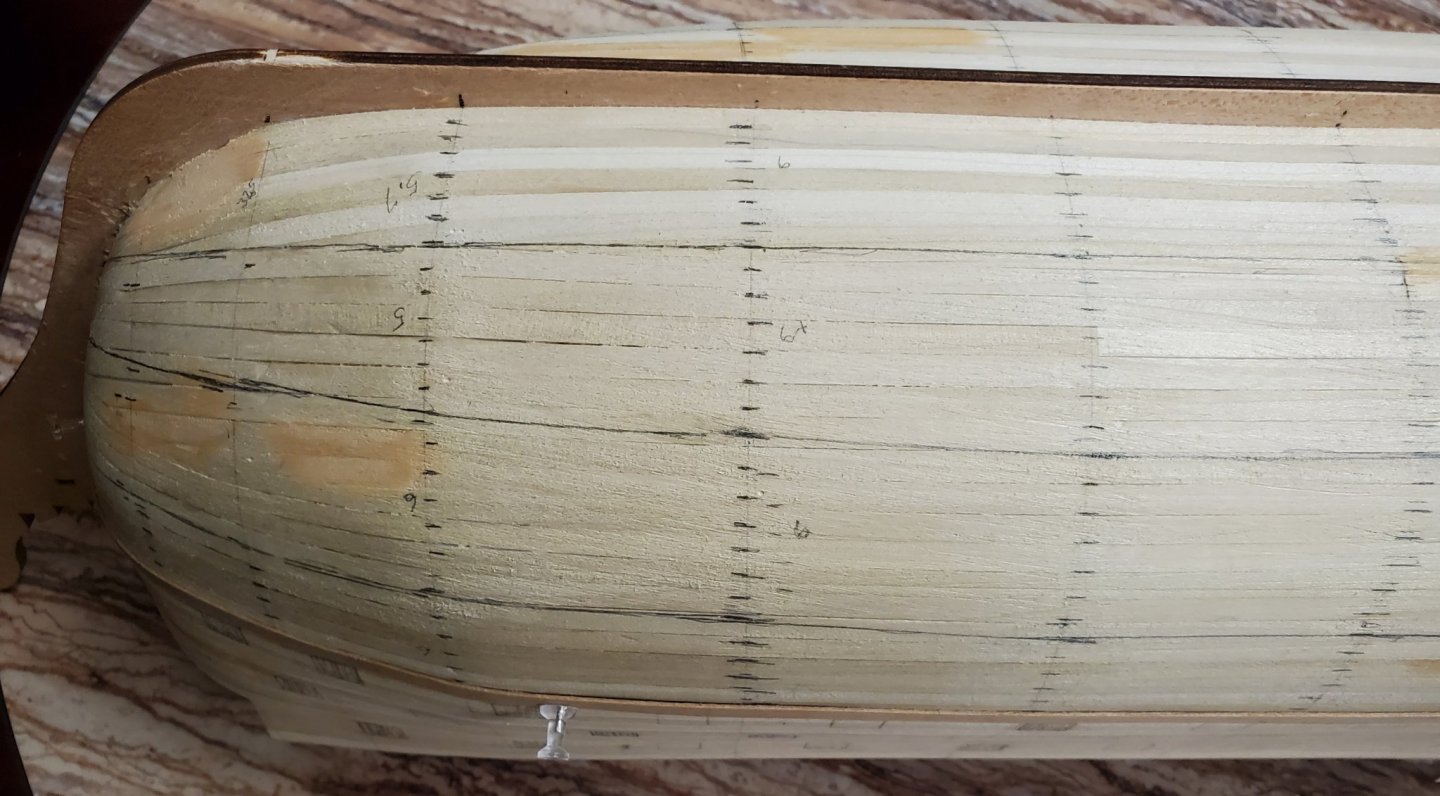

I did a preliminary sanding on one side and rubbed a dampened cloth on it to see how it will finish out before continuing.

I am not sure there is enough thickness to sand down to where it will need to be to satisfy me. This wood is only 1 mm thick. The curve on the bow is the worst area and the hardest to do. I don't think I can go back with new wood, as when I had to replace a couple of boards, I almost ruined the first layer planks trying to remove a plank. I would never get this stuff off..... so I shall continue and see what happens.

Mark Frazier