It advances, slowly certainly, but surely:

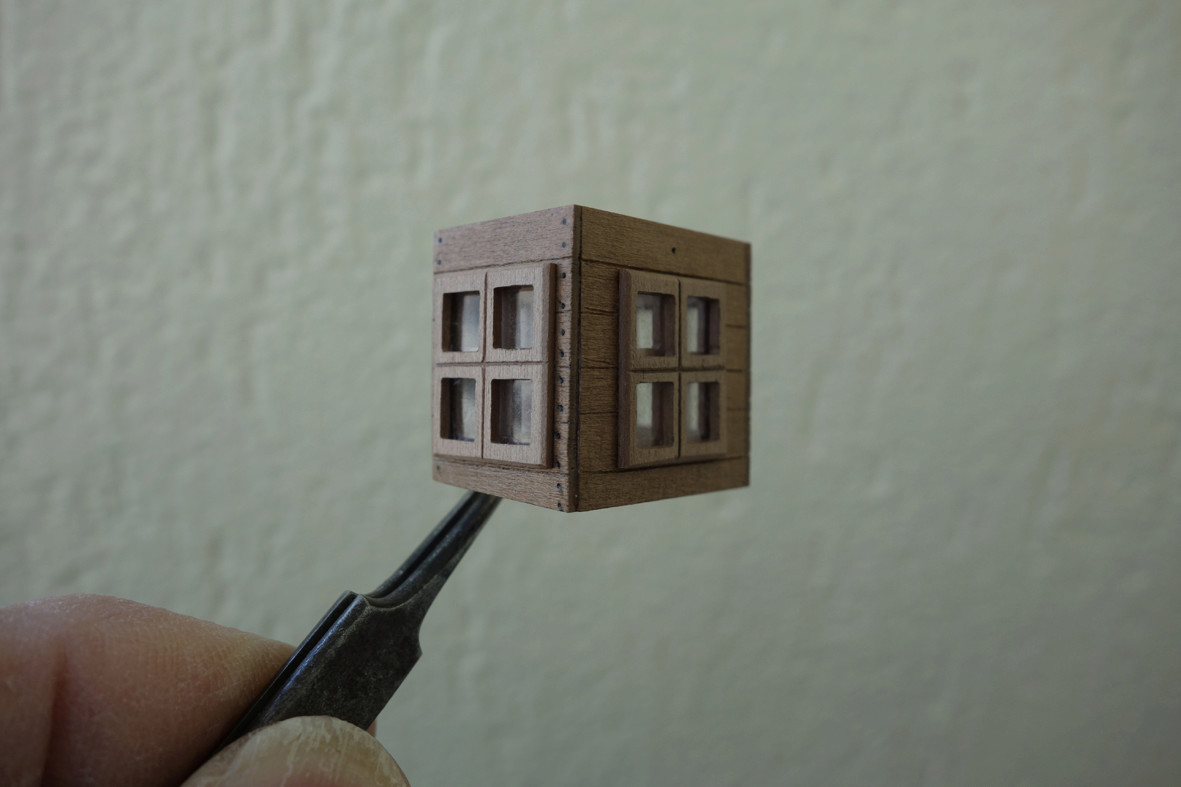

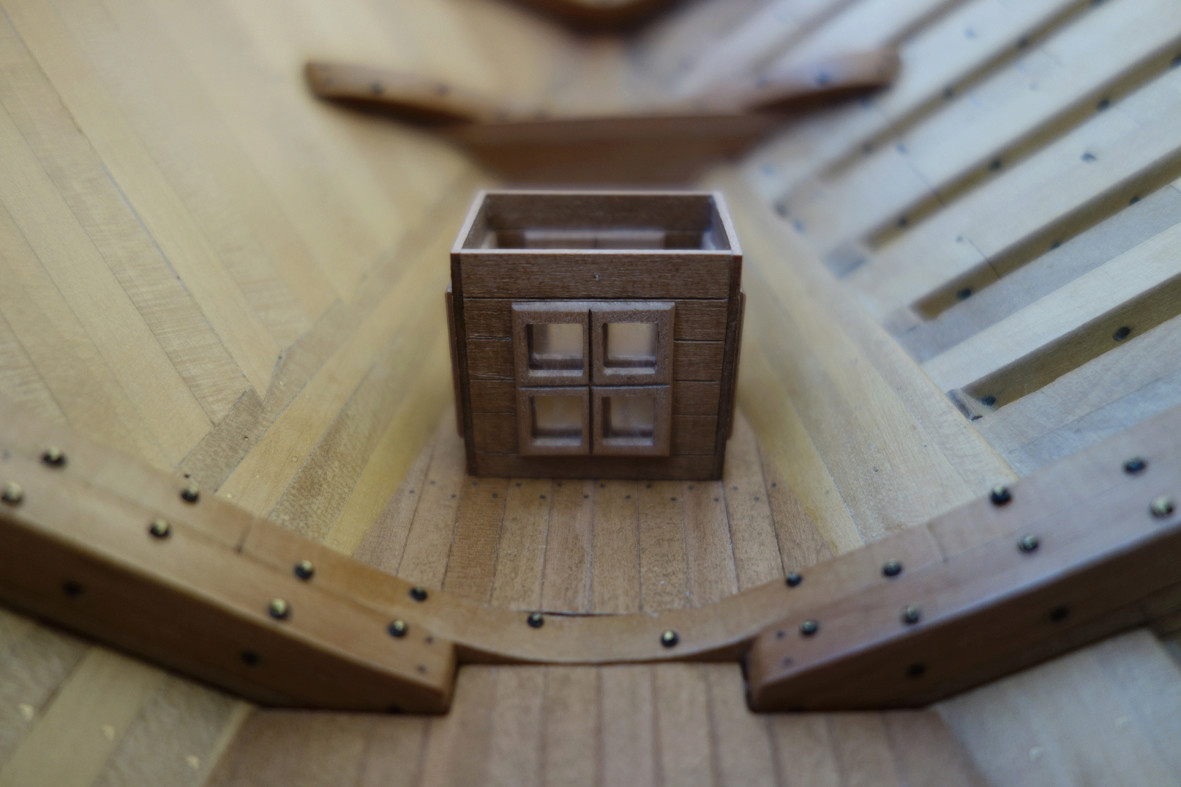

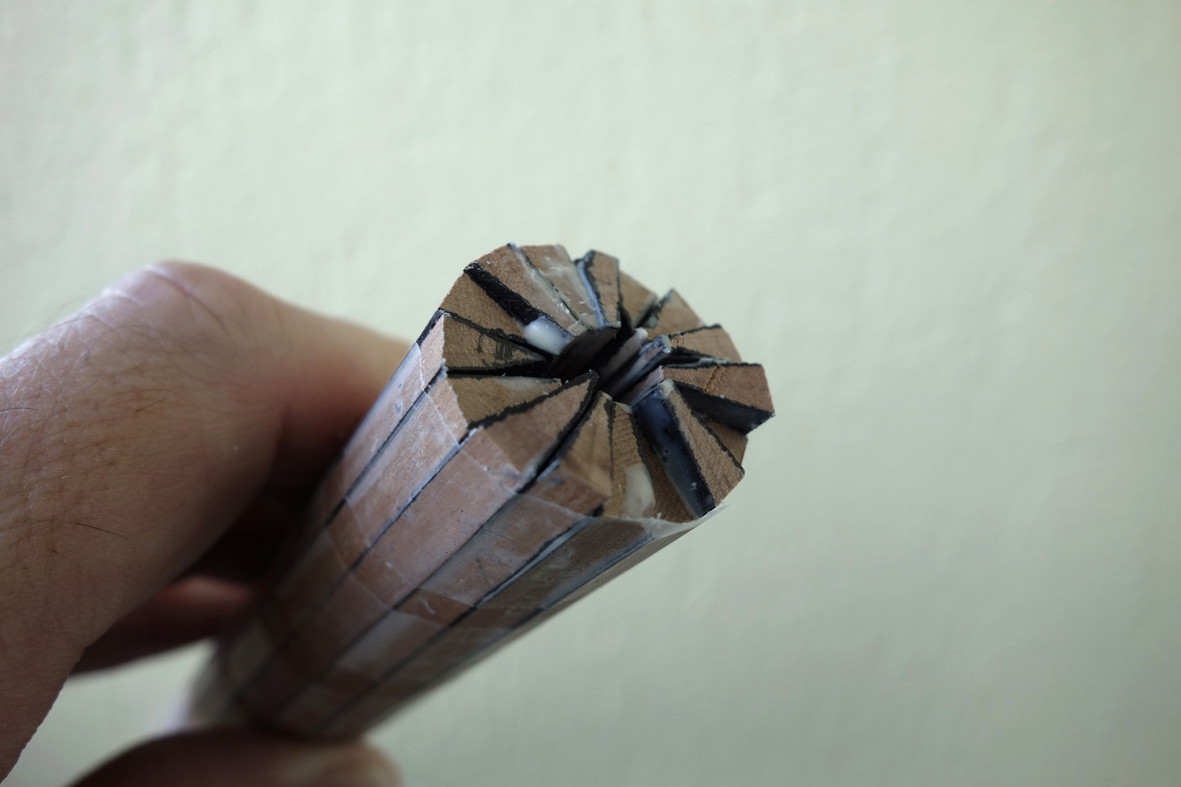

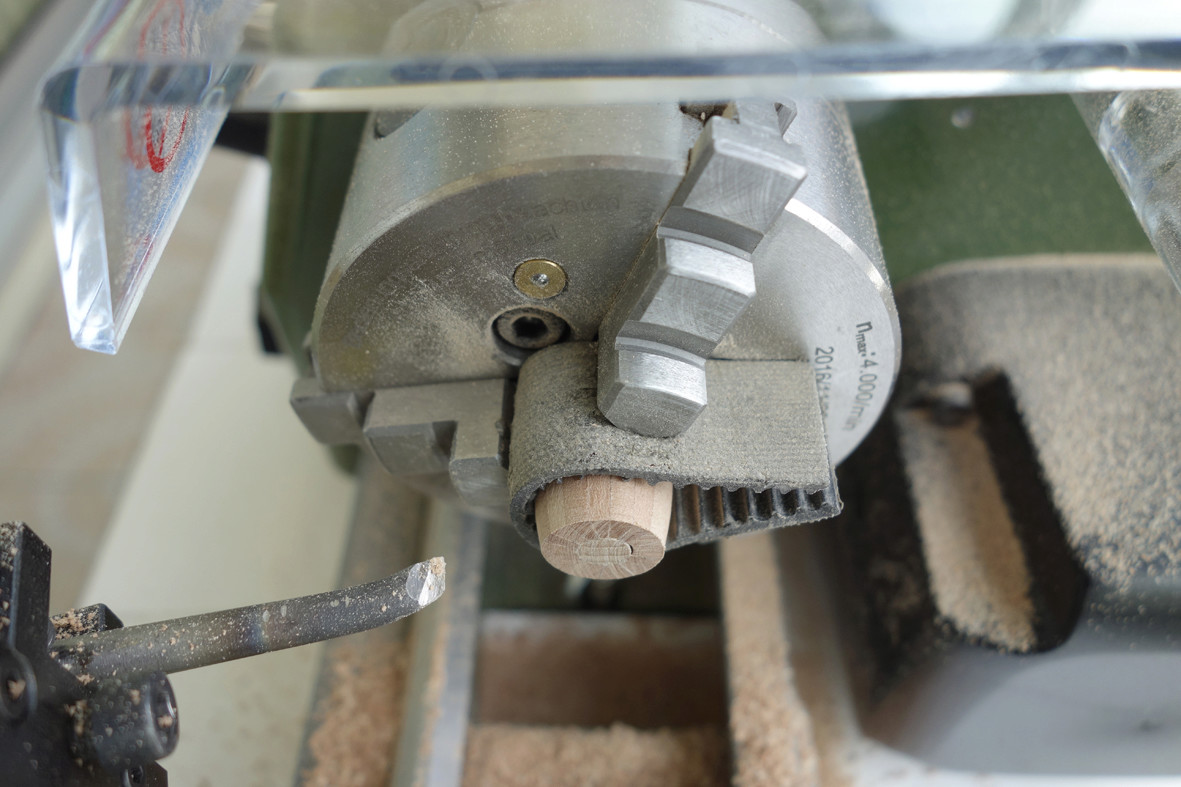

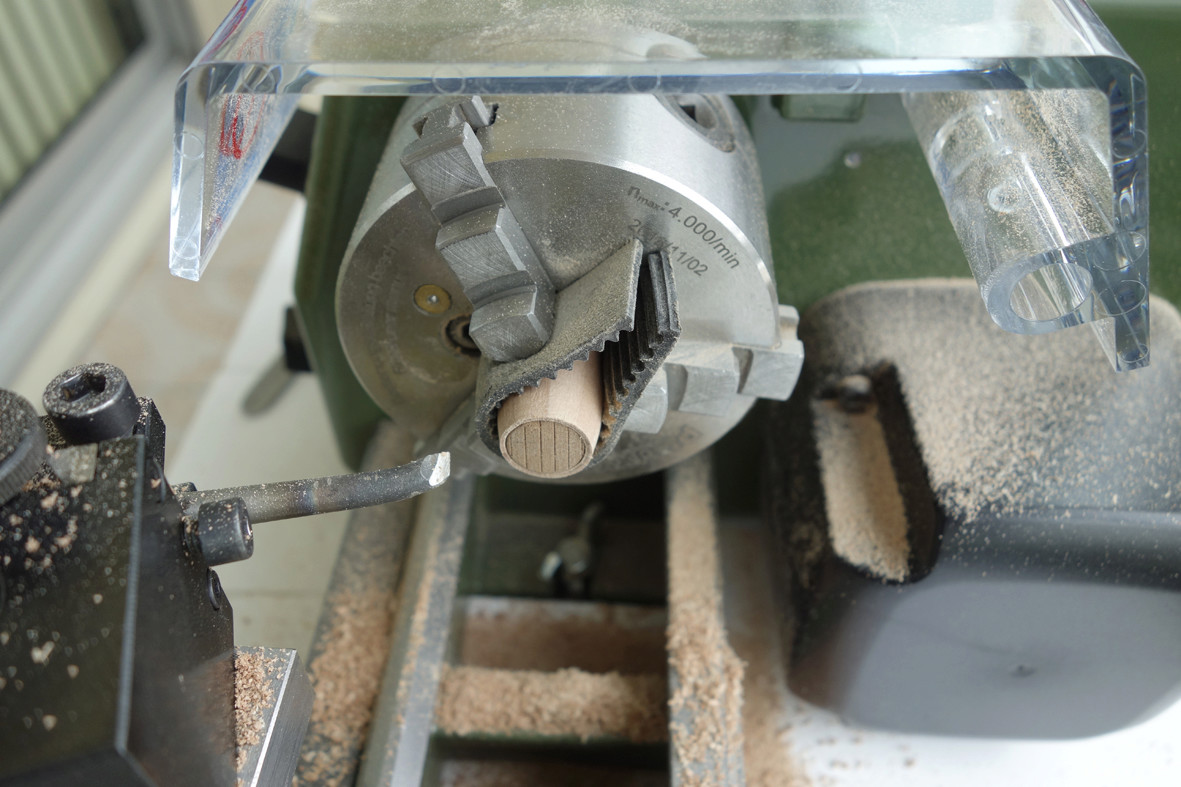

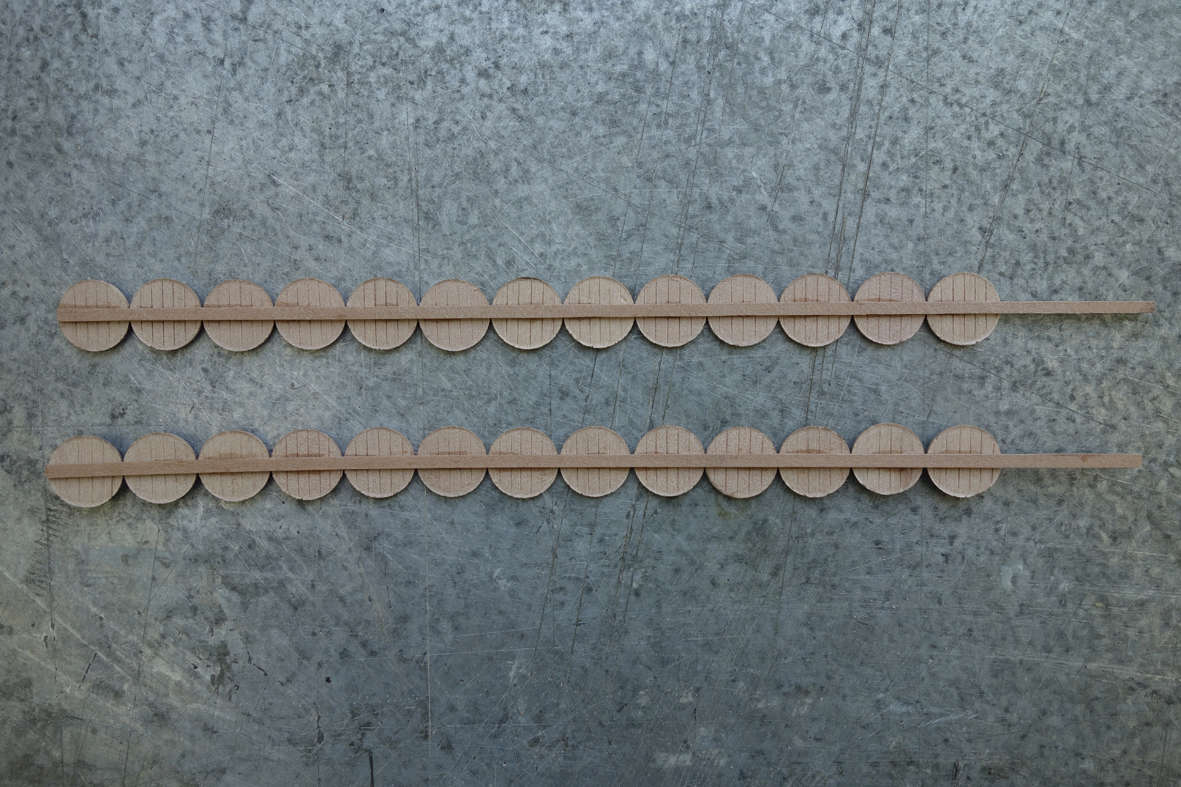

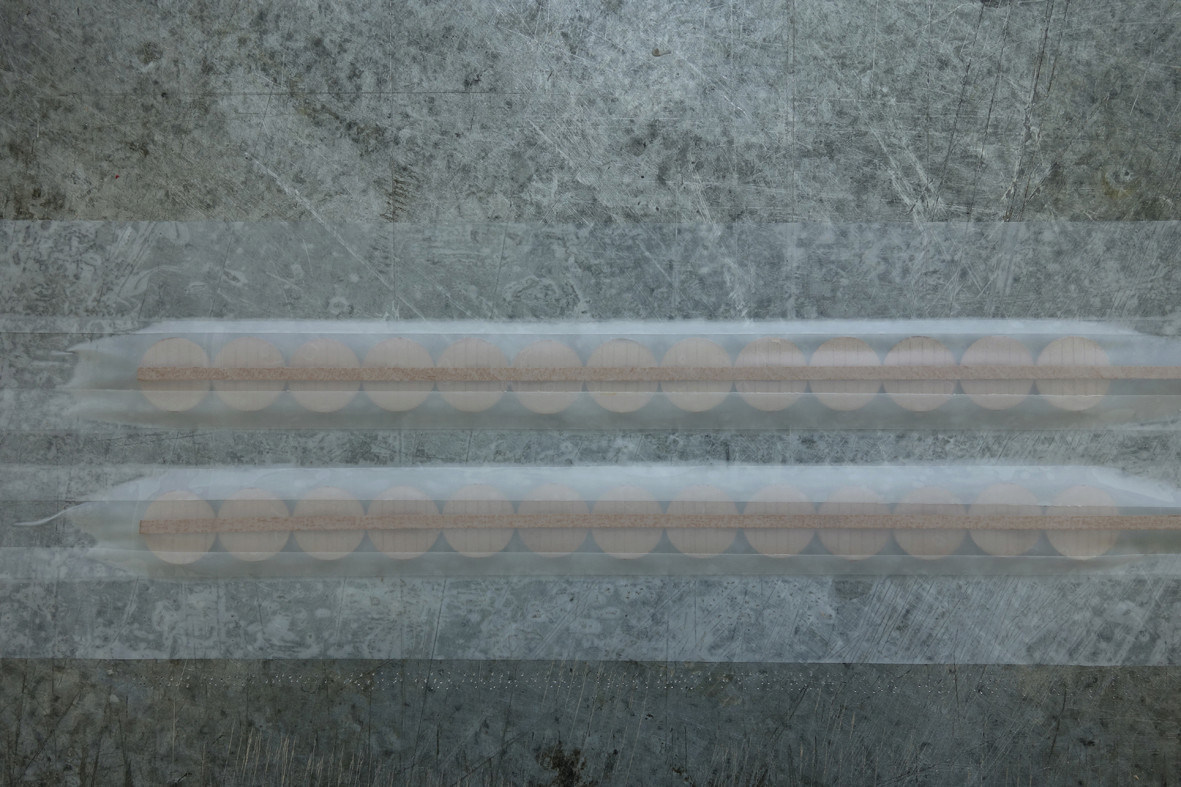

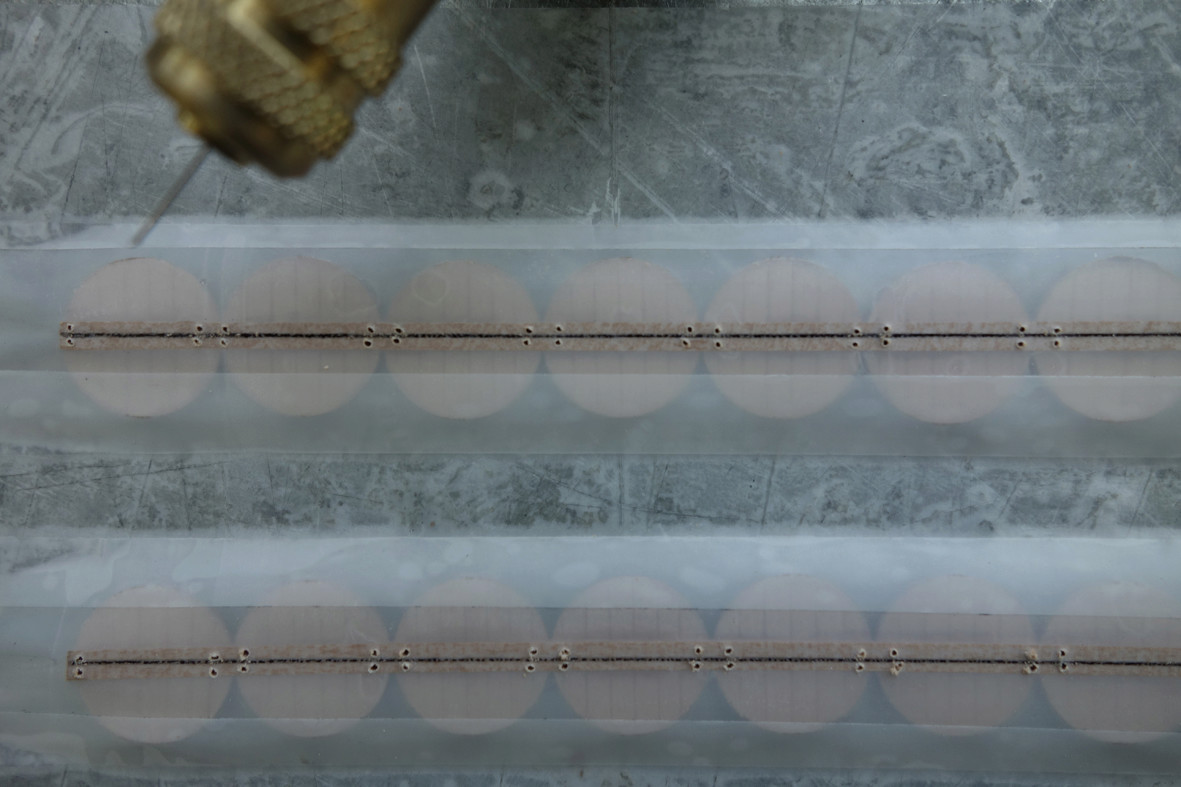

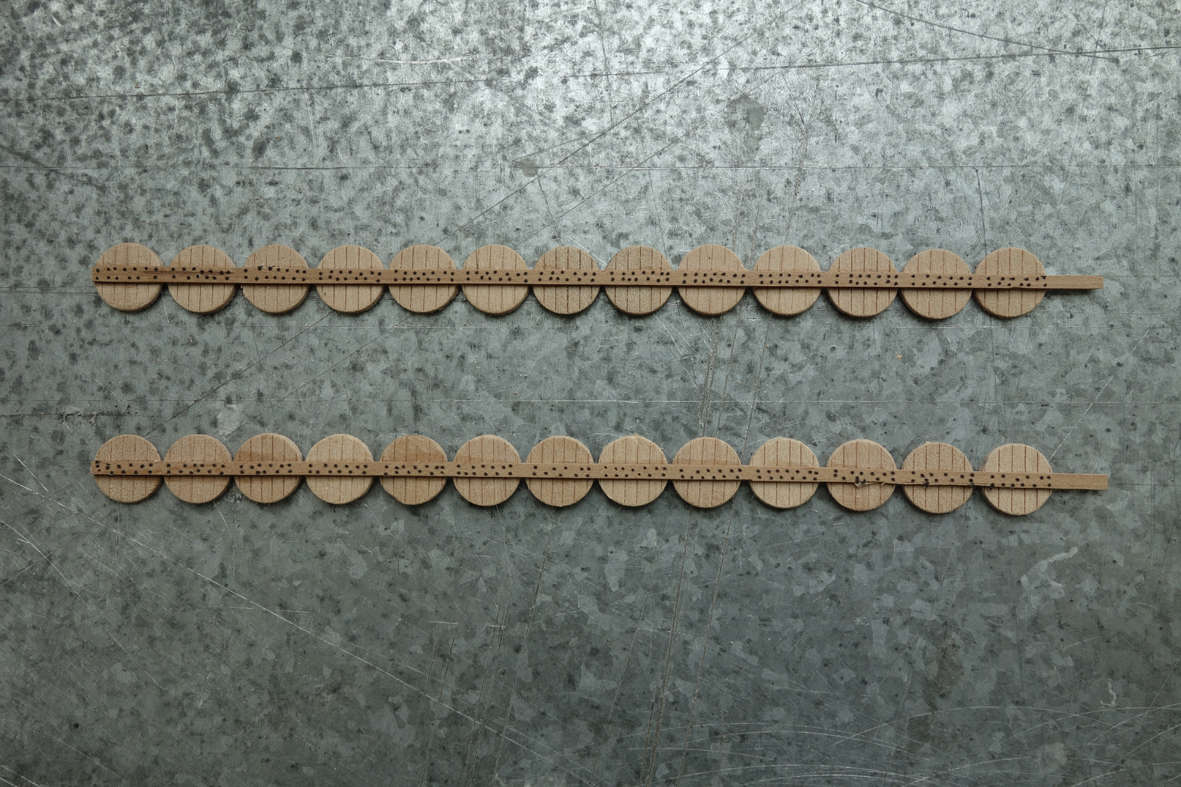

After about thirteen hours of work, spread over two days, about 25 broken blades, here are all the pieces cut and arranged:

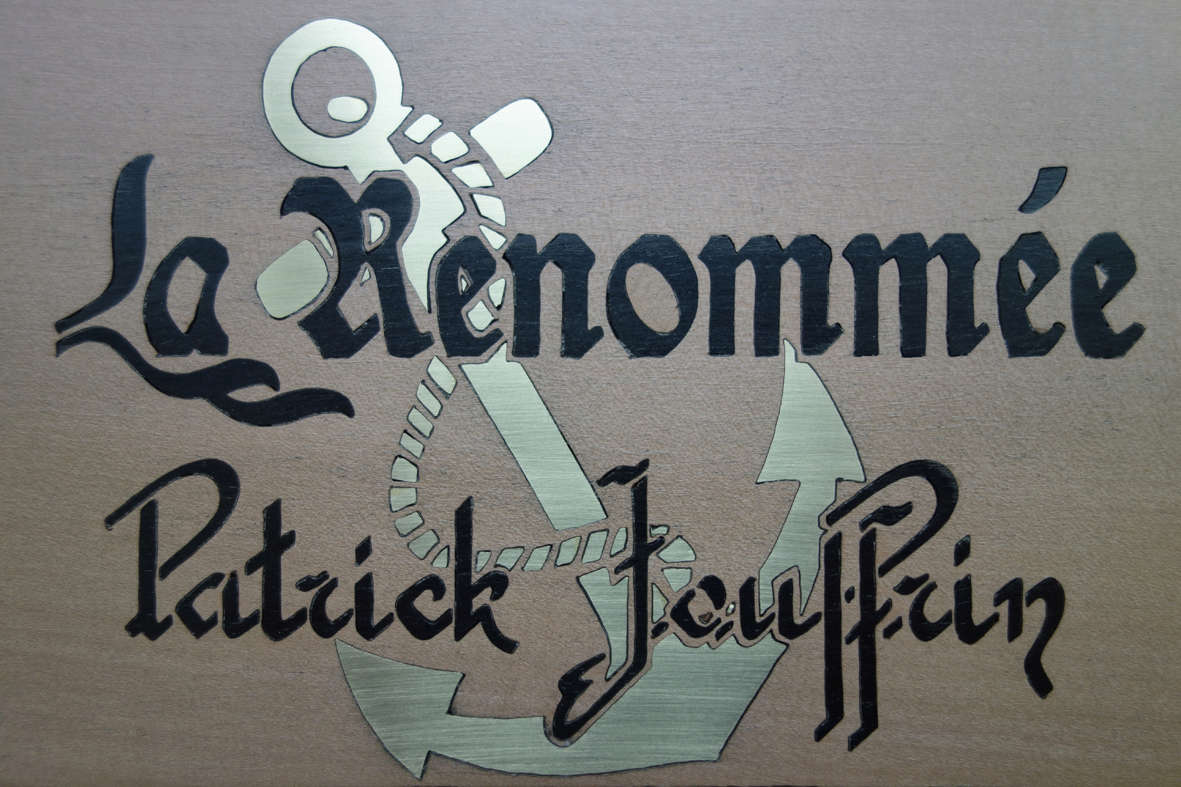

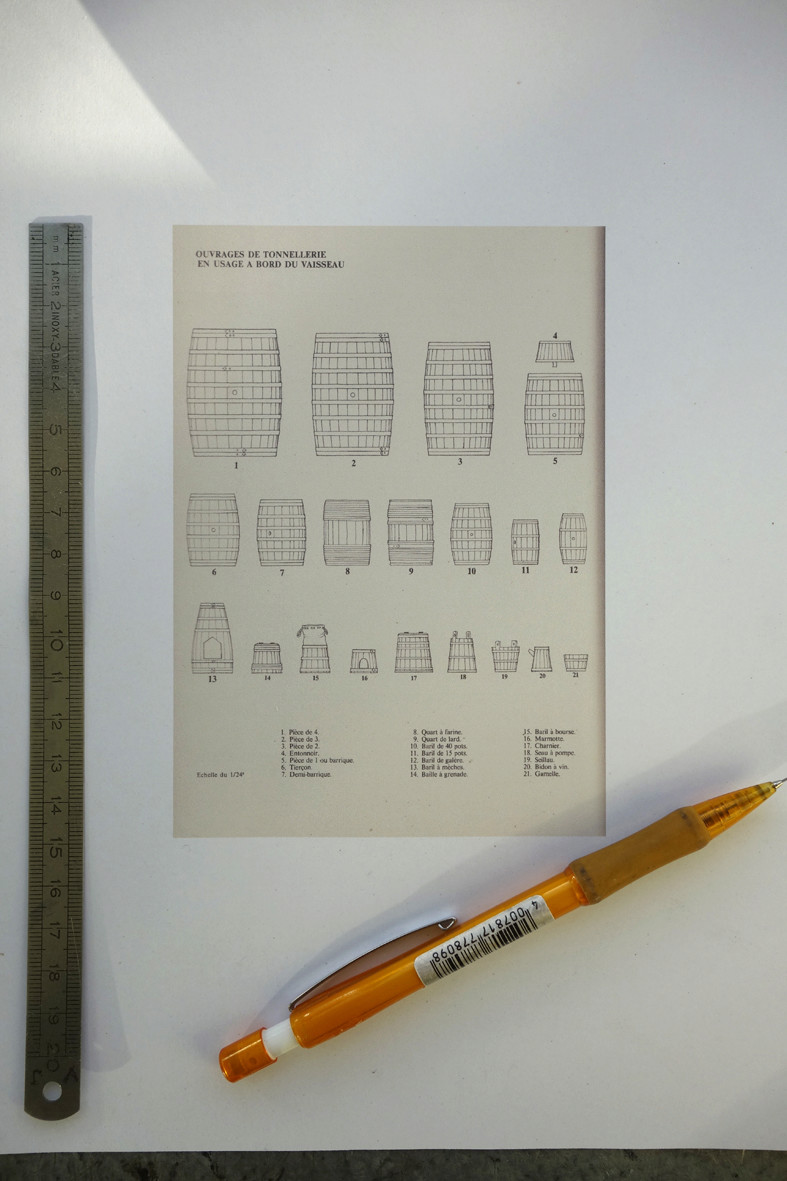

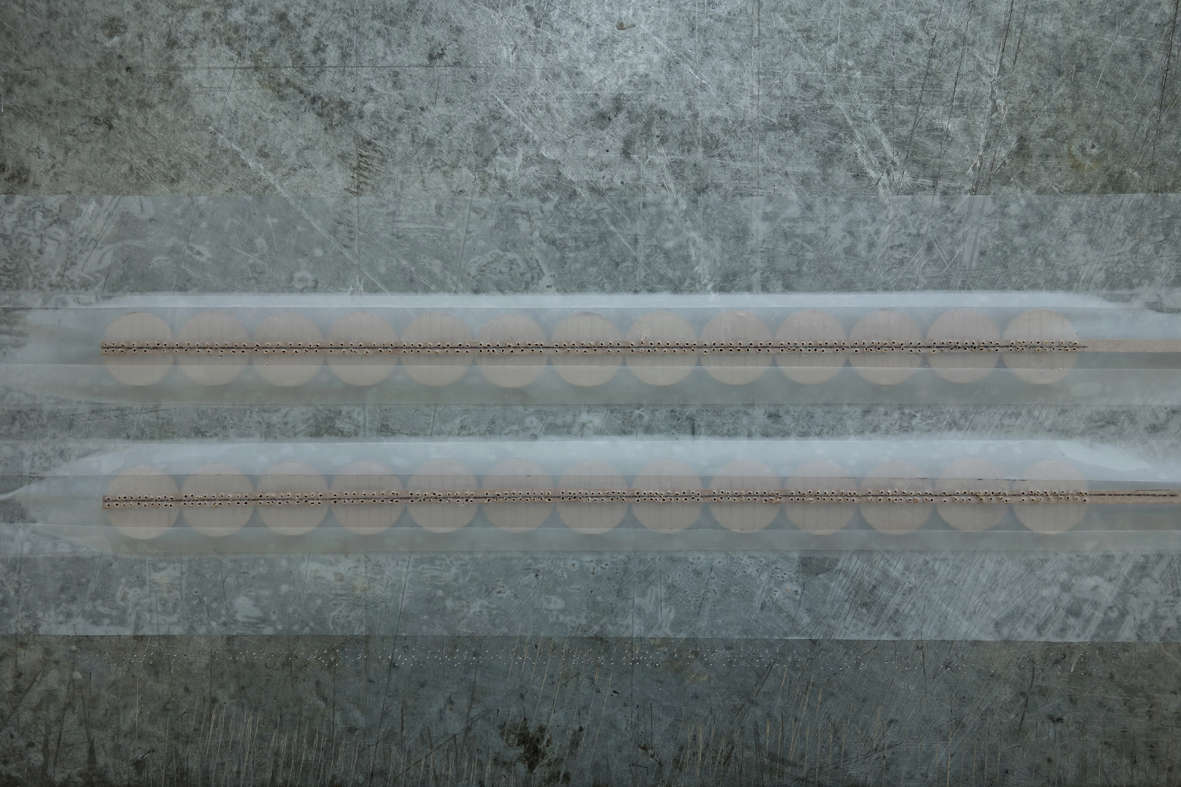

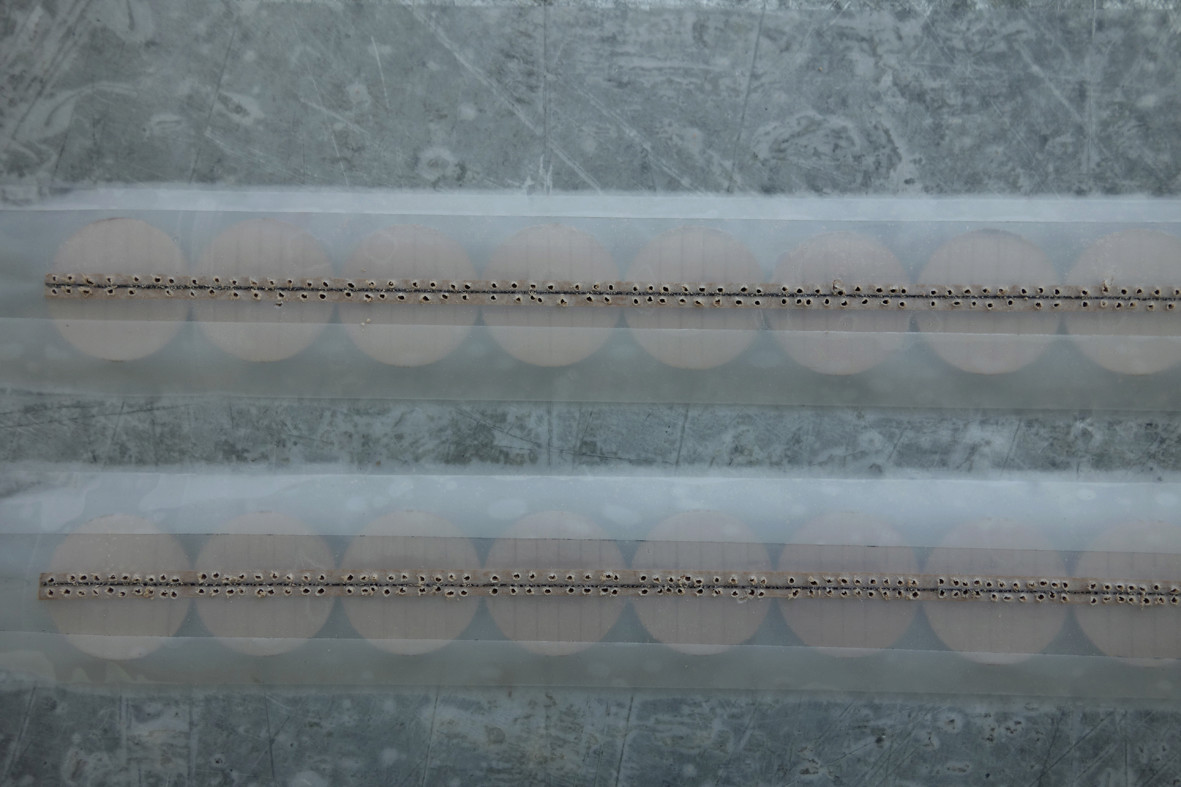

I can dismantle the "package". In the end, I will be able to make two plates. One in pear tree (with brass lettering):

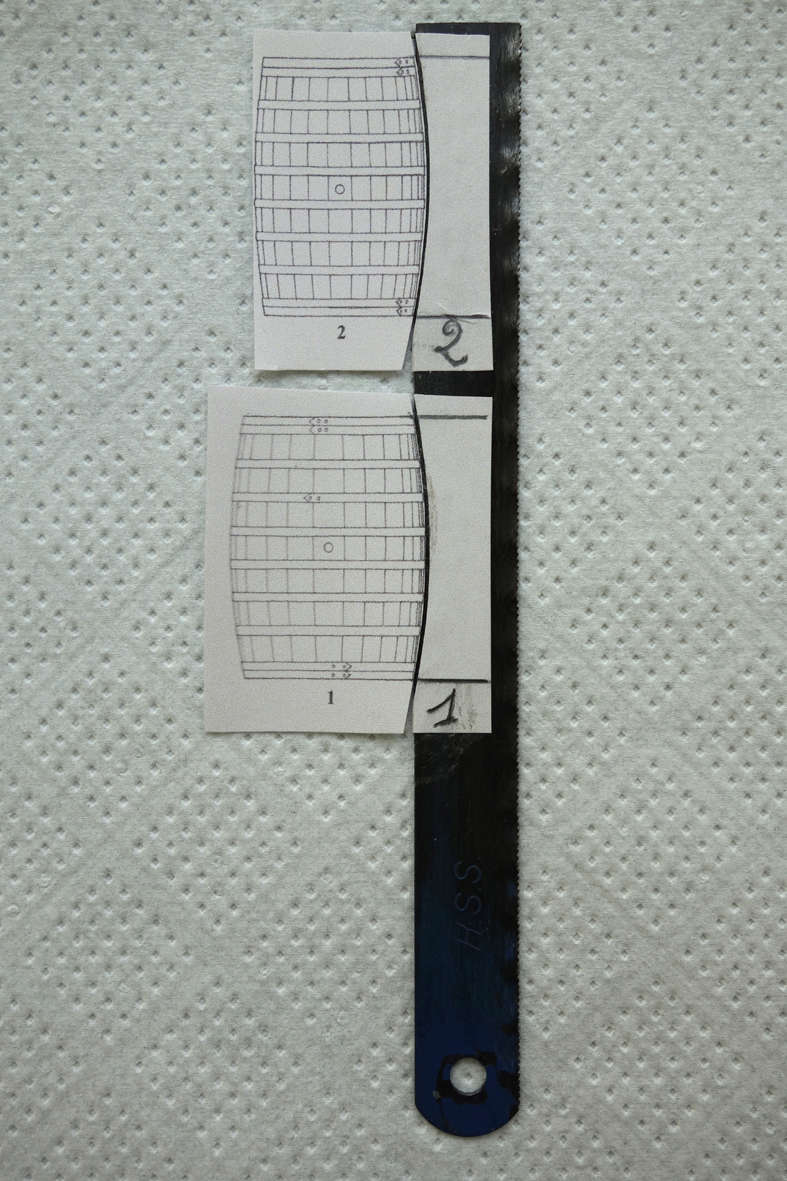

and one in brass (with an ebony lettering):

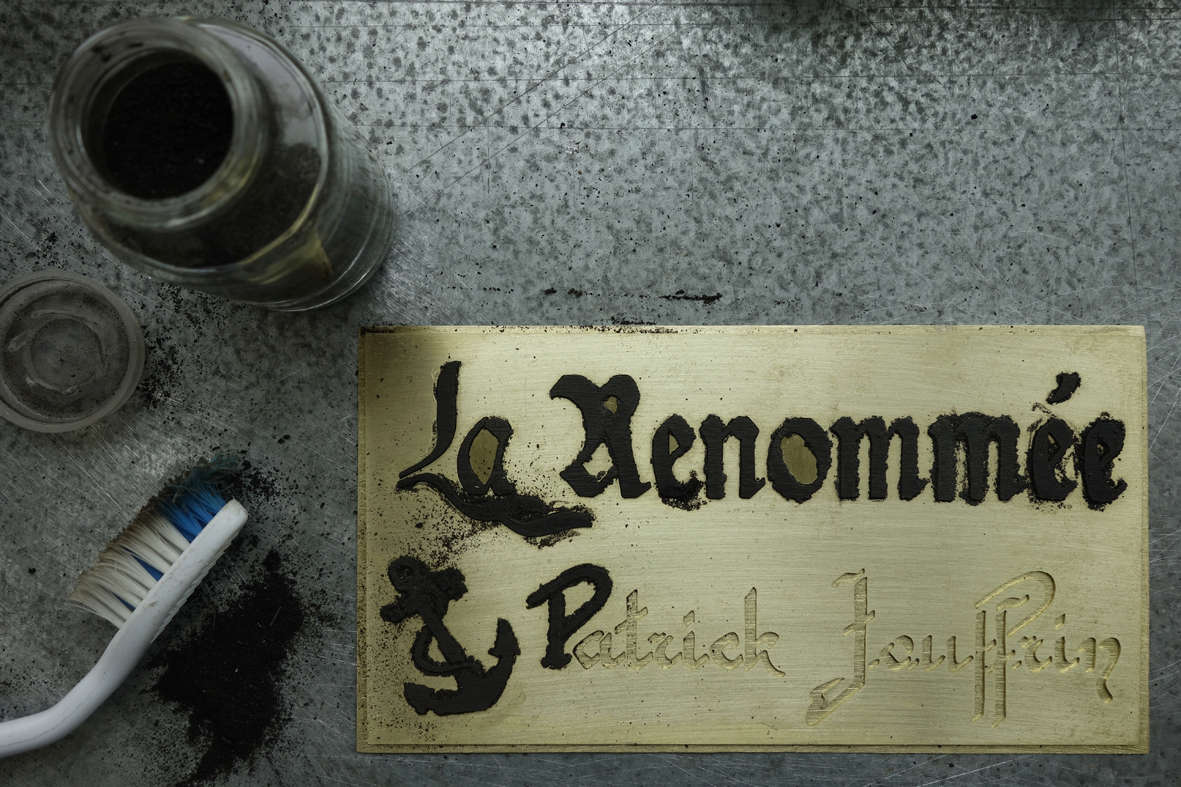

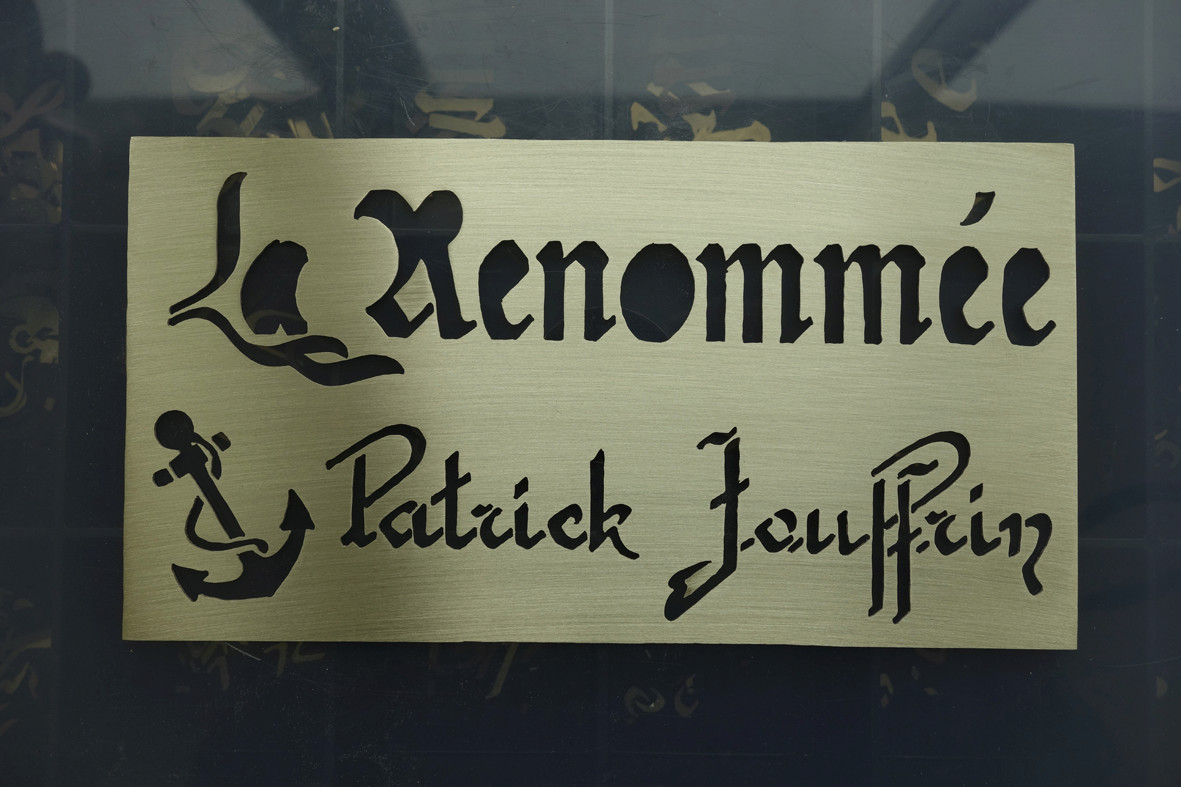

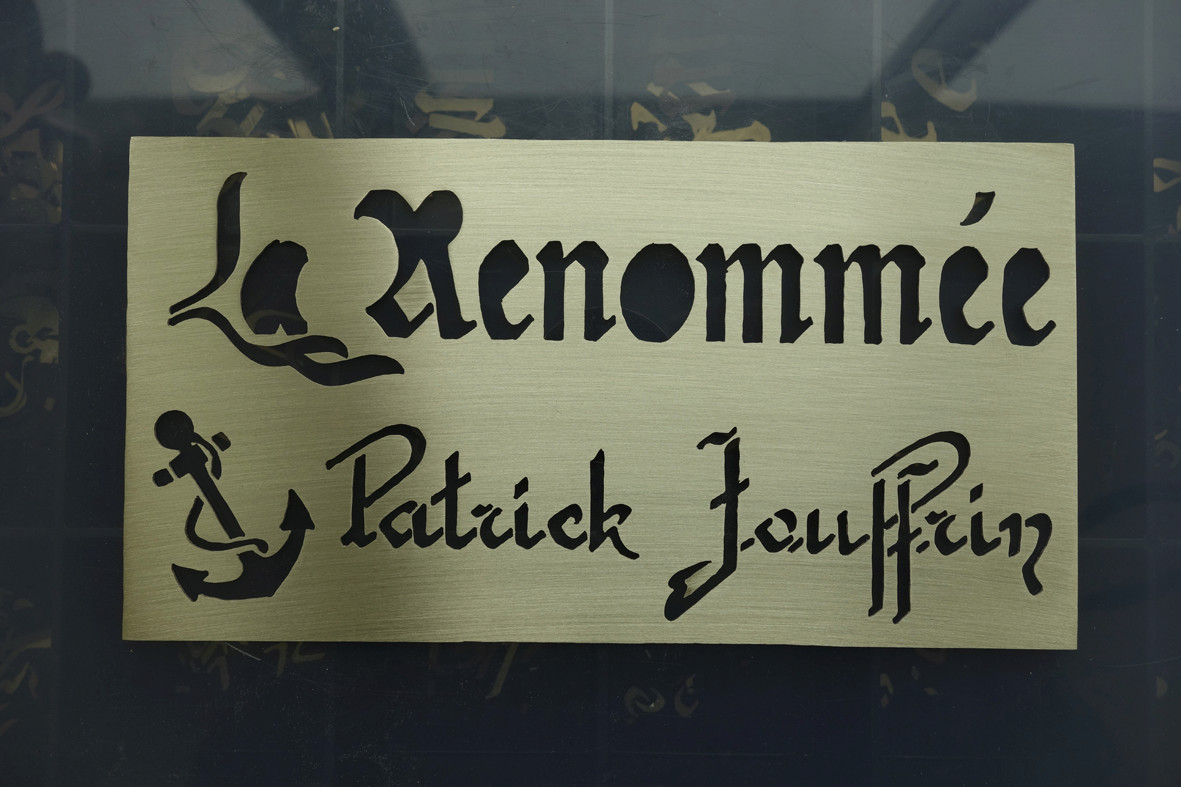

With the second brass plate I will make a small plaque to my name, as it is:

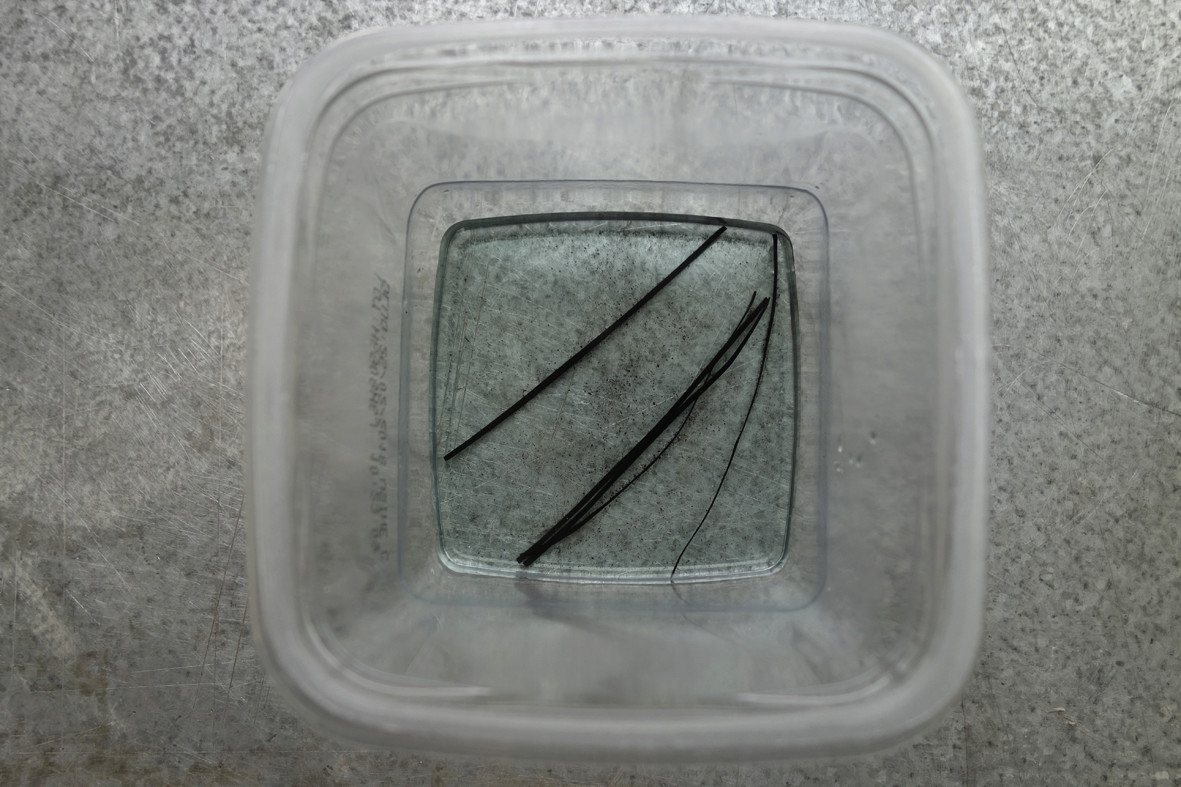

The ebony plate is unusable: it broke out in several places:

Before continuing, I rectify some small defects on the brass plate. Really almost insignificantly:

I stick my brass plate on a support - brass - also (Super-glue "GEL"):

After about thirteen hours of work, spread over two days, about 25 broken blades, here are all the pieces cut and arranged:

I can dismantle the "package". In the end, I will be able to make two plates. One in pear tree (with brass lettering):

and one in brass (with an ebony lettering):

With the second brass plate I will make a small plaque to my name, as it is:

The ebony plate is unusable: it broke out in several places:

Before continuing, I rectify some small defects on the brass plate. Really almost insignificantly:

I stick my brass plate on a support - brass - also (Super-glue "GEL"):