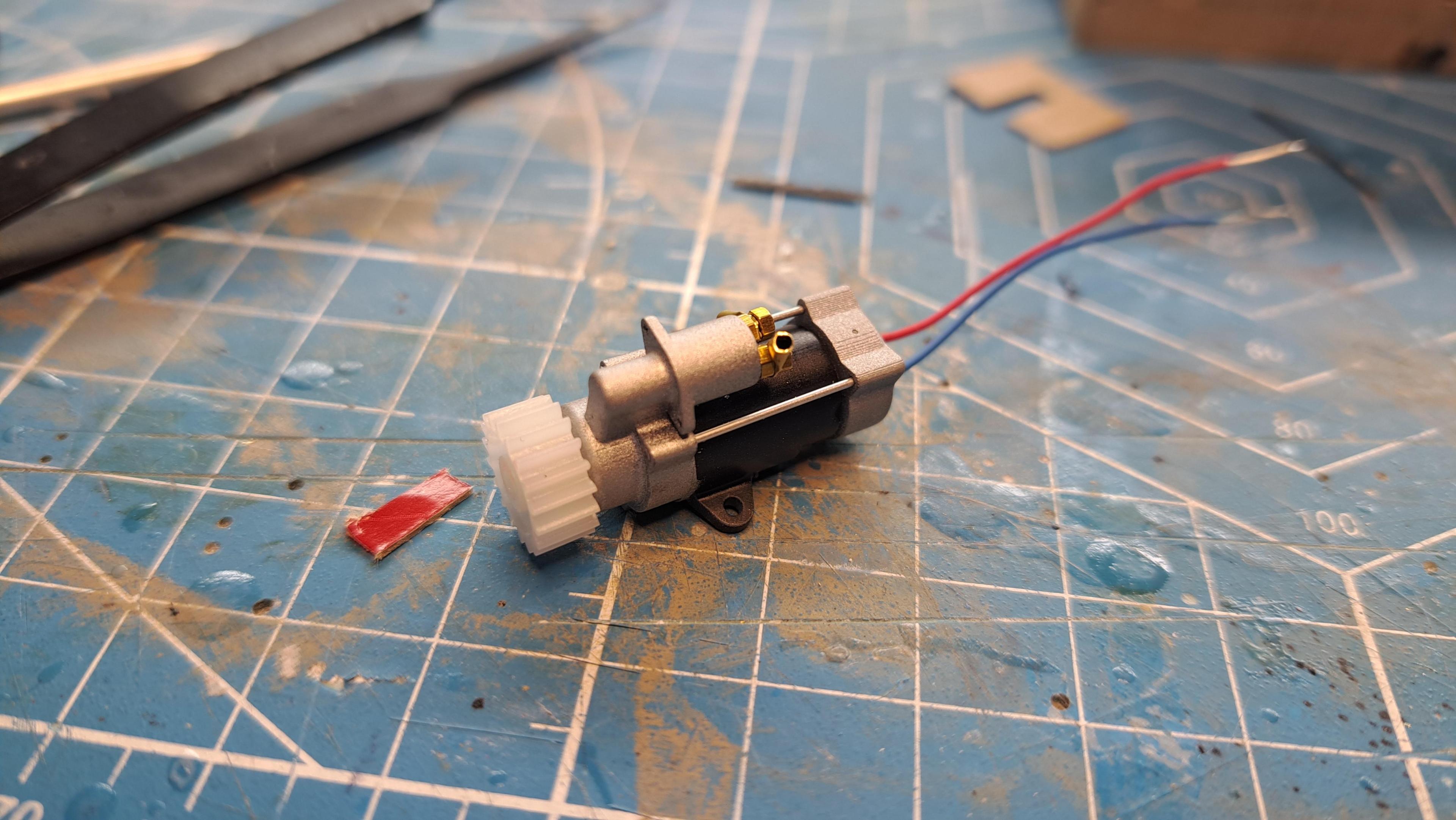

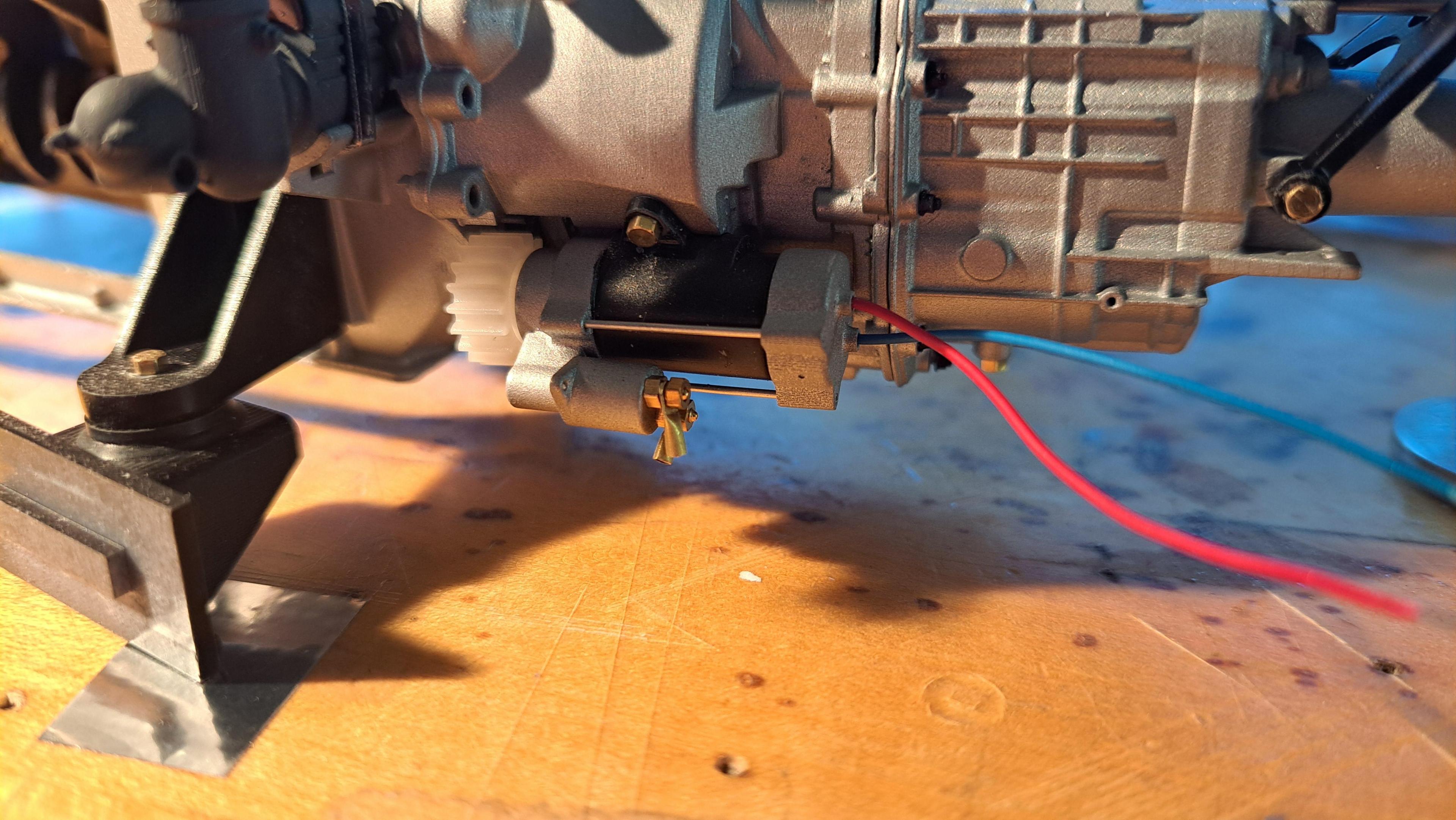

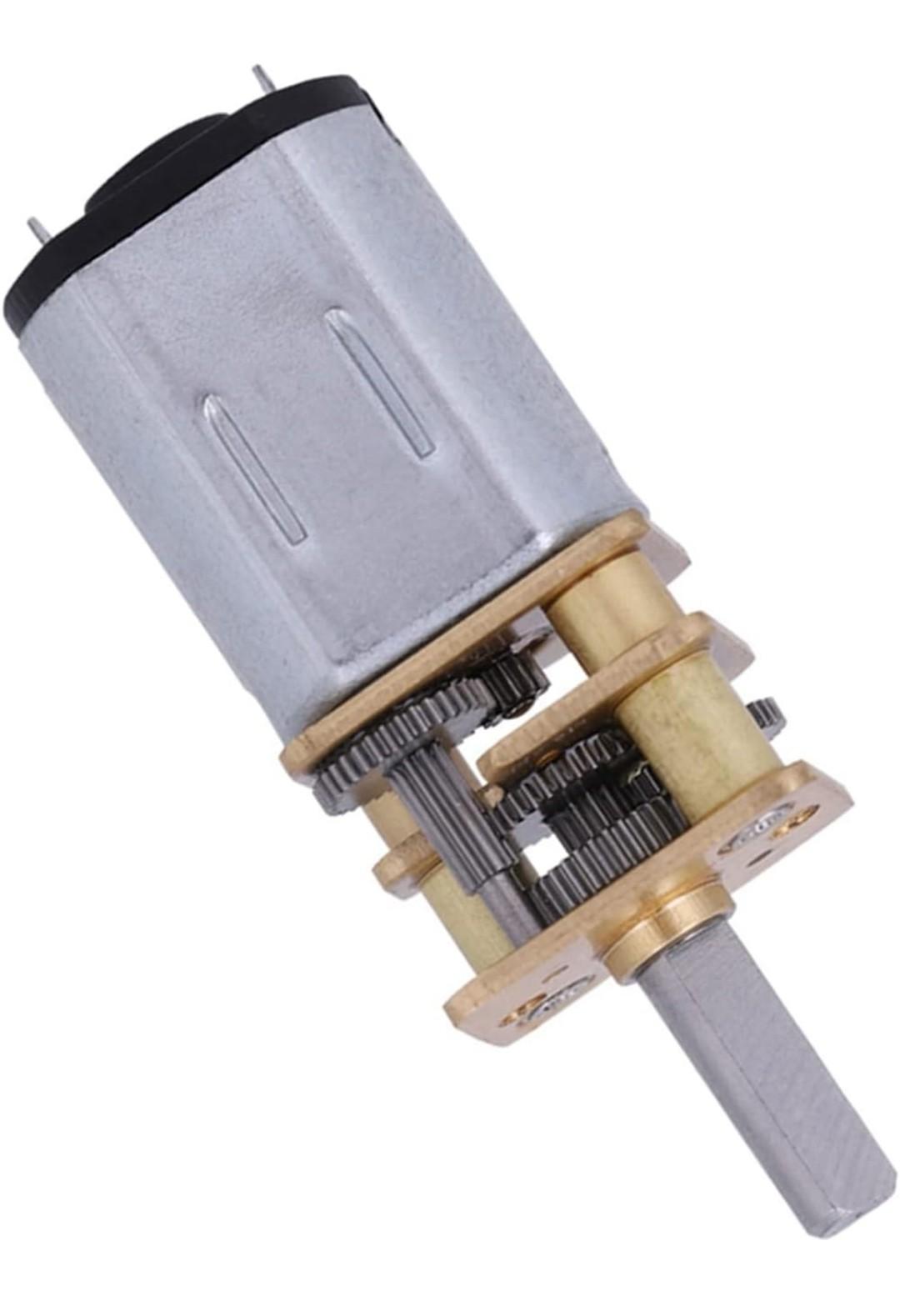

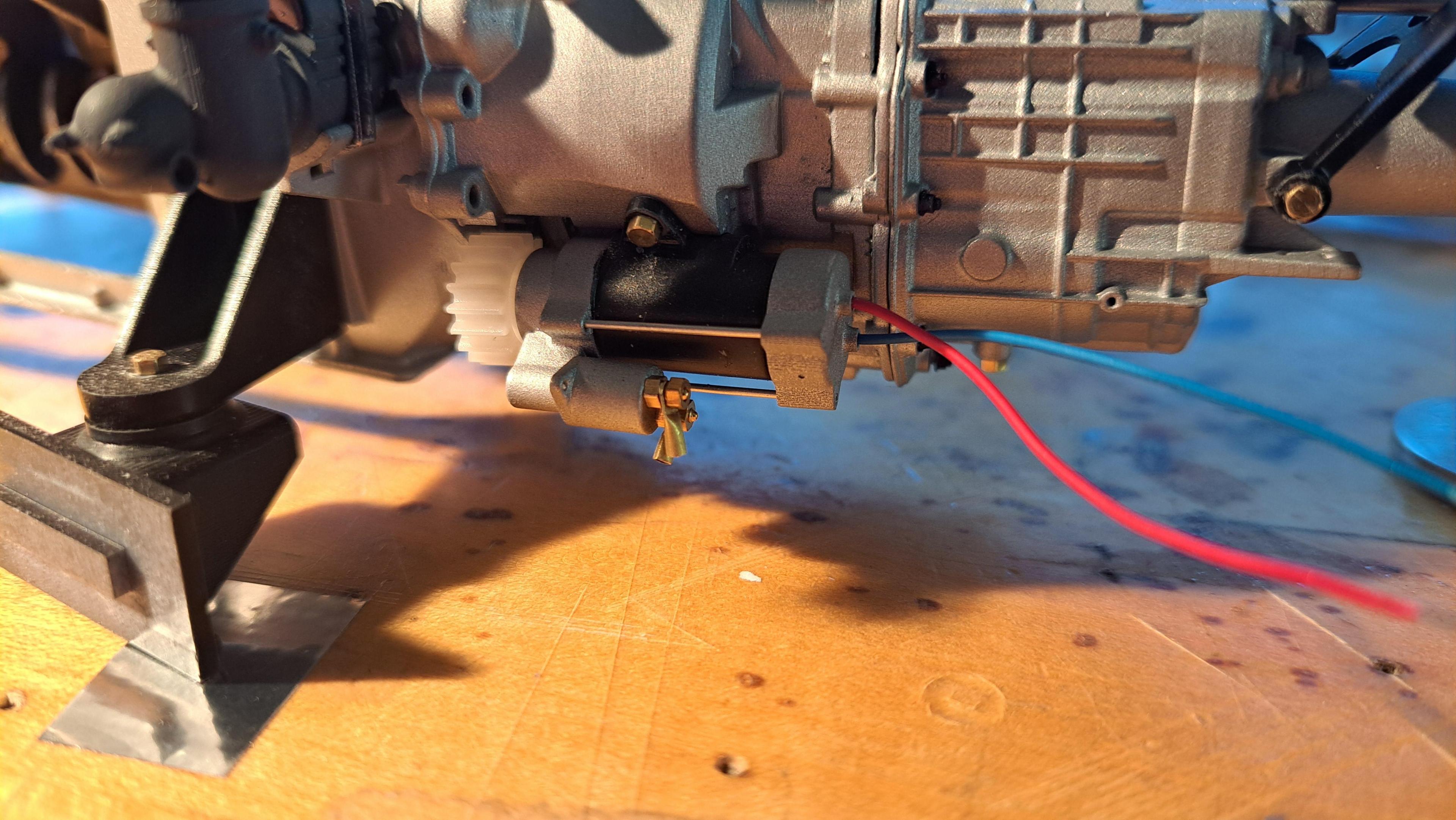

I received the 6mm dia gearmotors in 2 different ratios but unfortunately, they won't do. One simply doesn't have enough torq. As for the other, it could do but it's border line on torq and I find the rpm to slow. It's to bad because the assembly was quite nice with the gearmotor hidden inside the starter housing. I'll install the starter but it will only be for show.

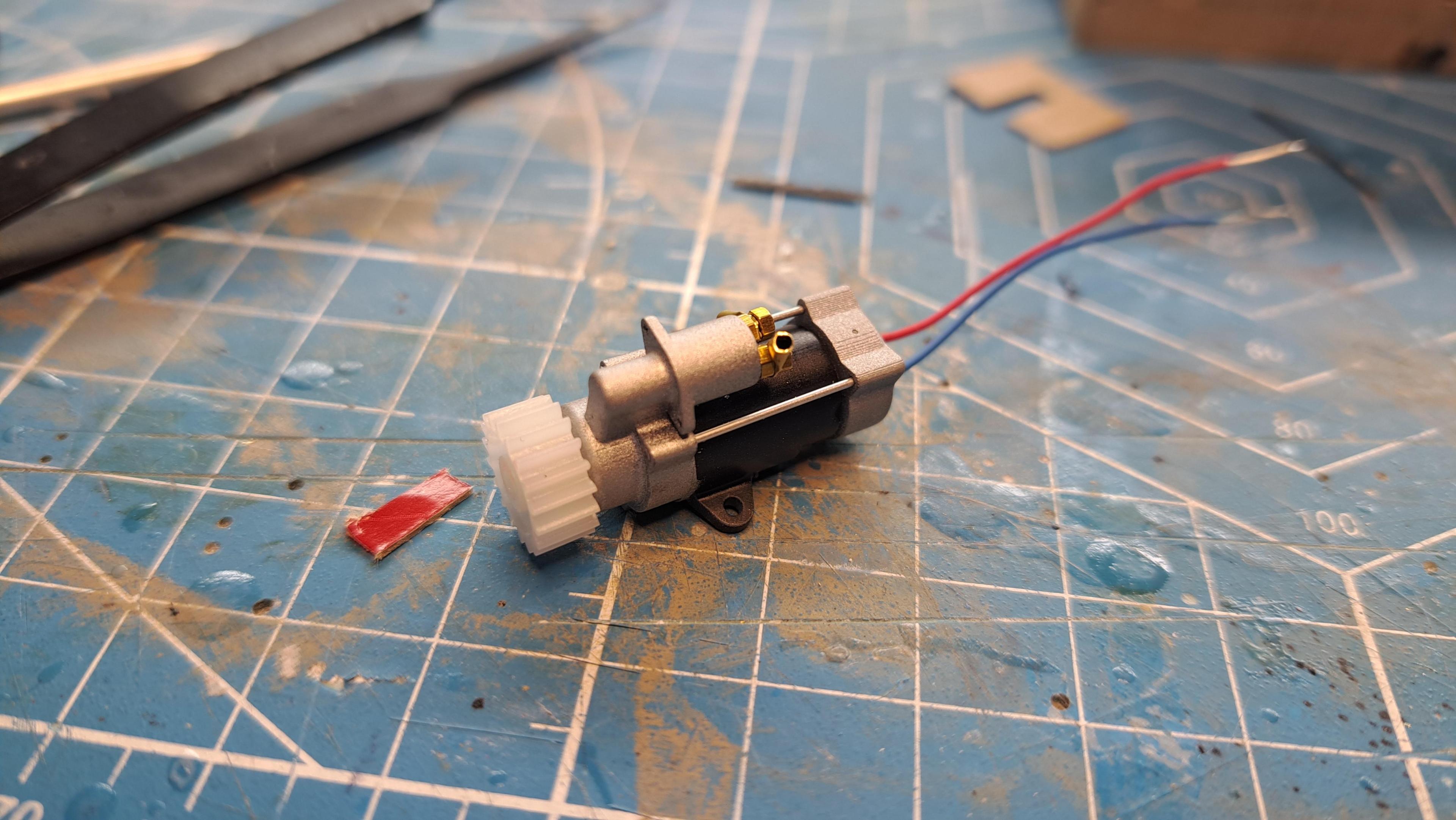

Here's the too small gearmotor/starter setup

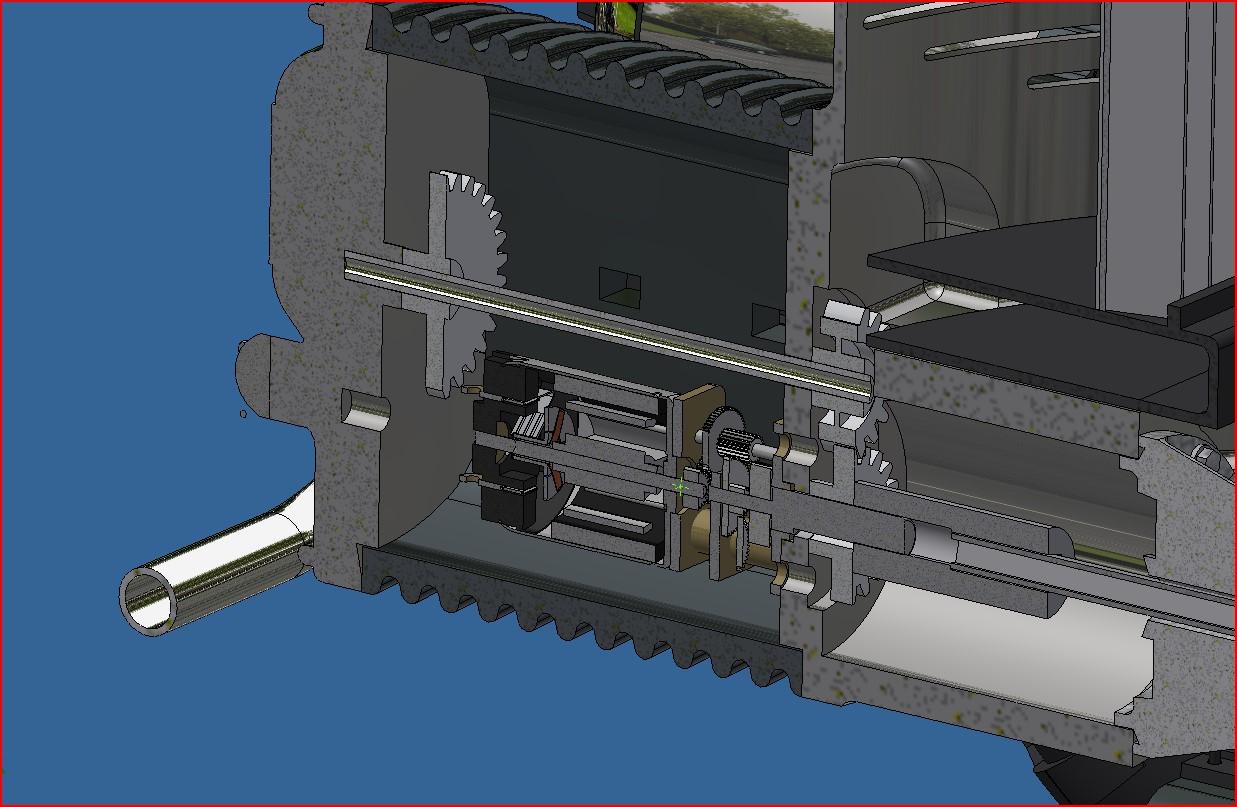

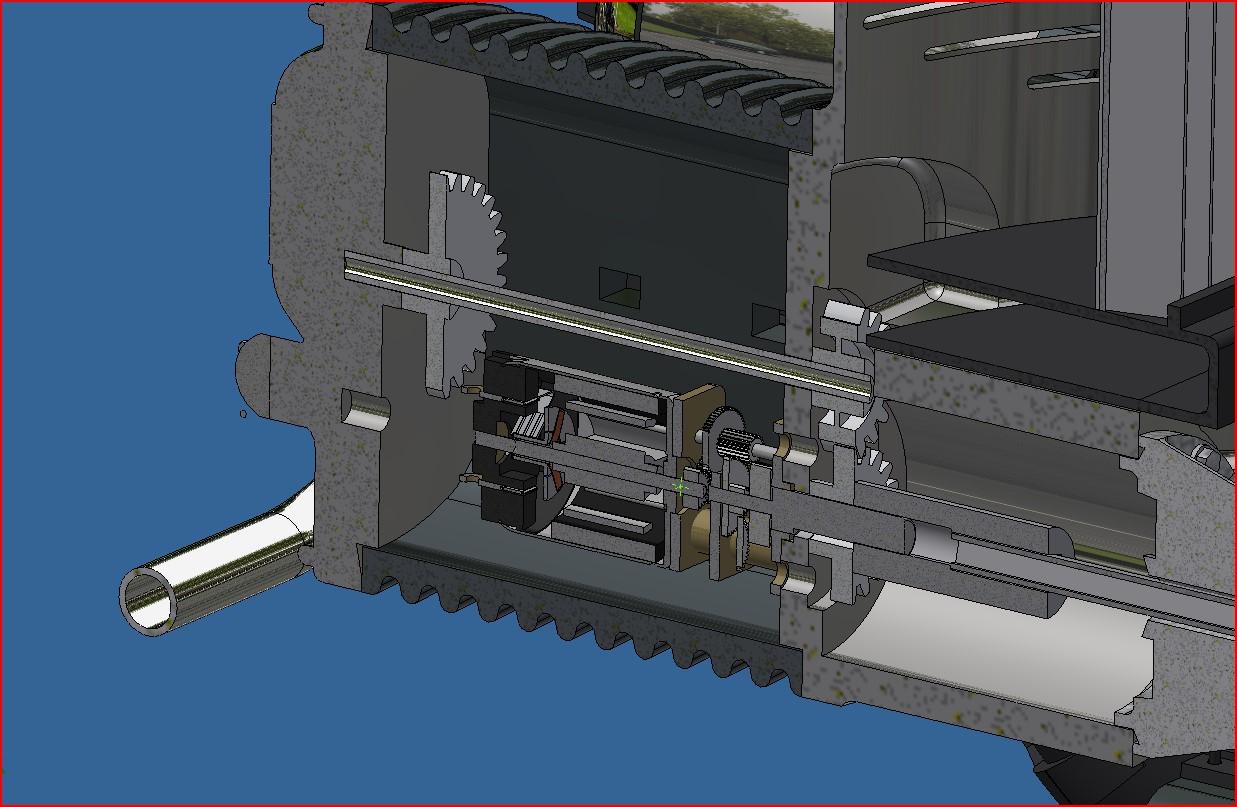

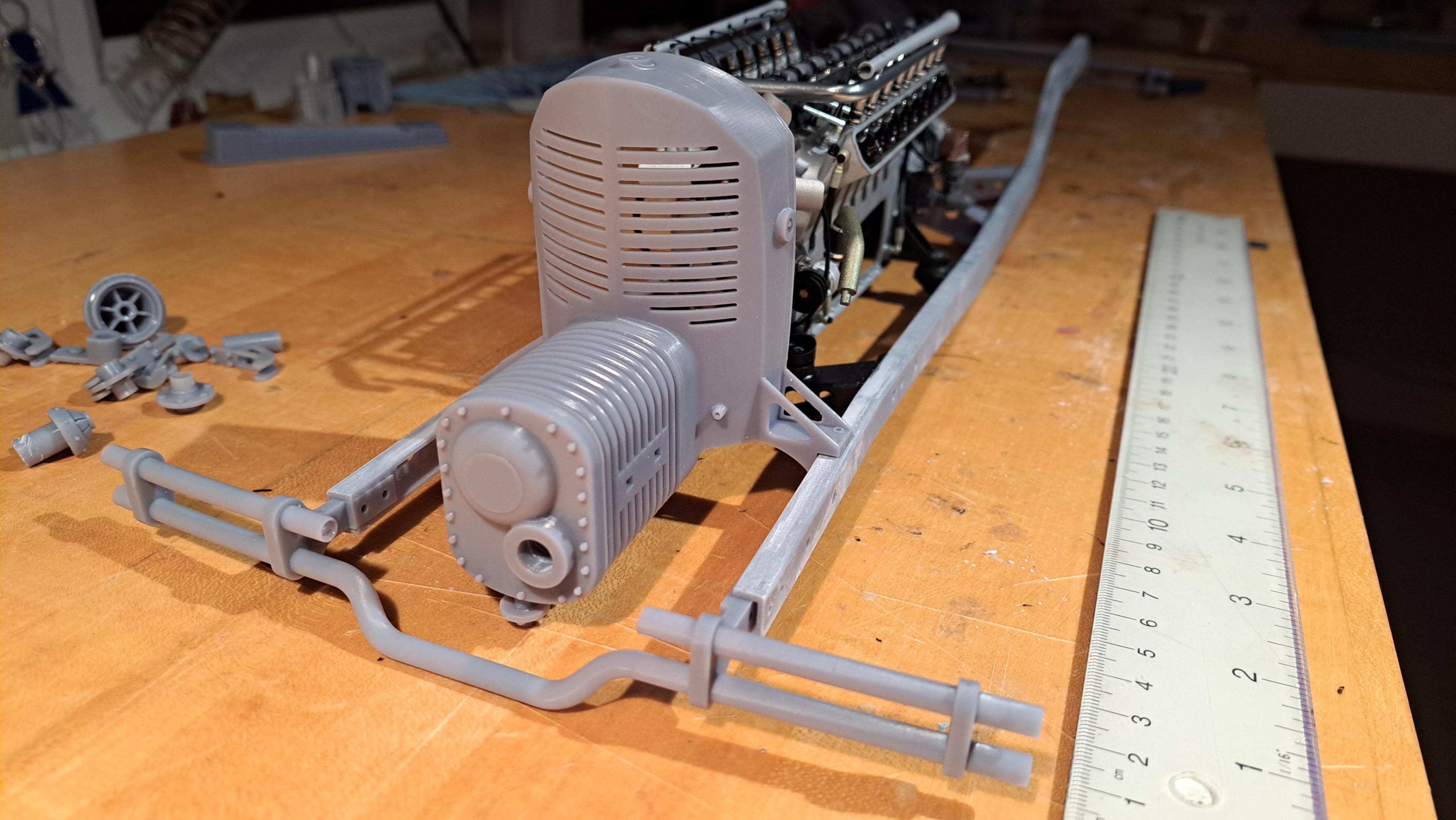

So I had to rethink how to drive the engine. I found another type of mini gearmotor, it has alot more torq but it's much bigger, too big to pass as a starter. Instead, the new motor will be hidden inside the blower and it will be inline with the crankshaft. I even figured out a way to drive the rotating thingy in the front of the blower using the same gears I had planned to use to drive it in the first place. I ordered 2 different torqs, hopefully one will do the job.

Here's what the new design looks like

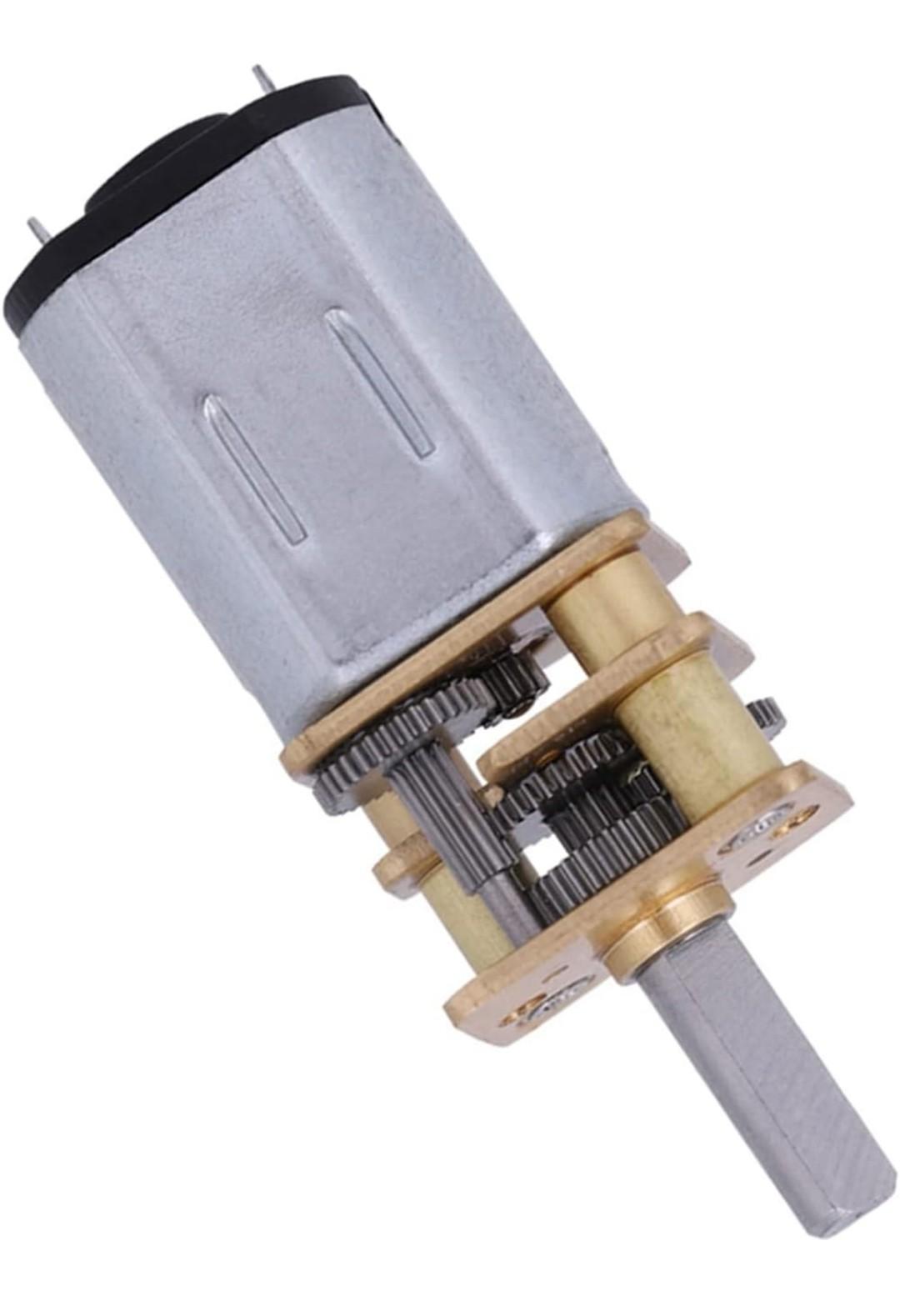

And here's the new gearmotor type

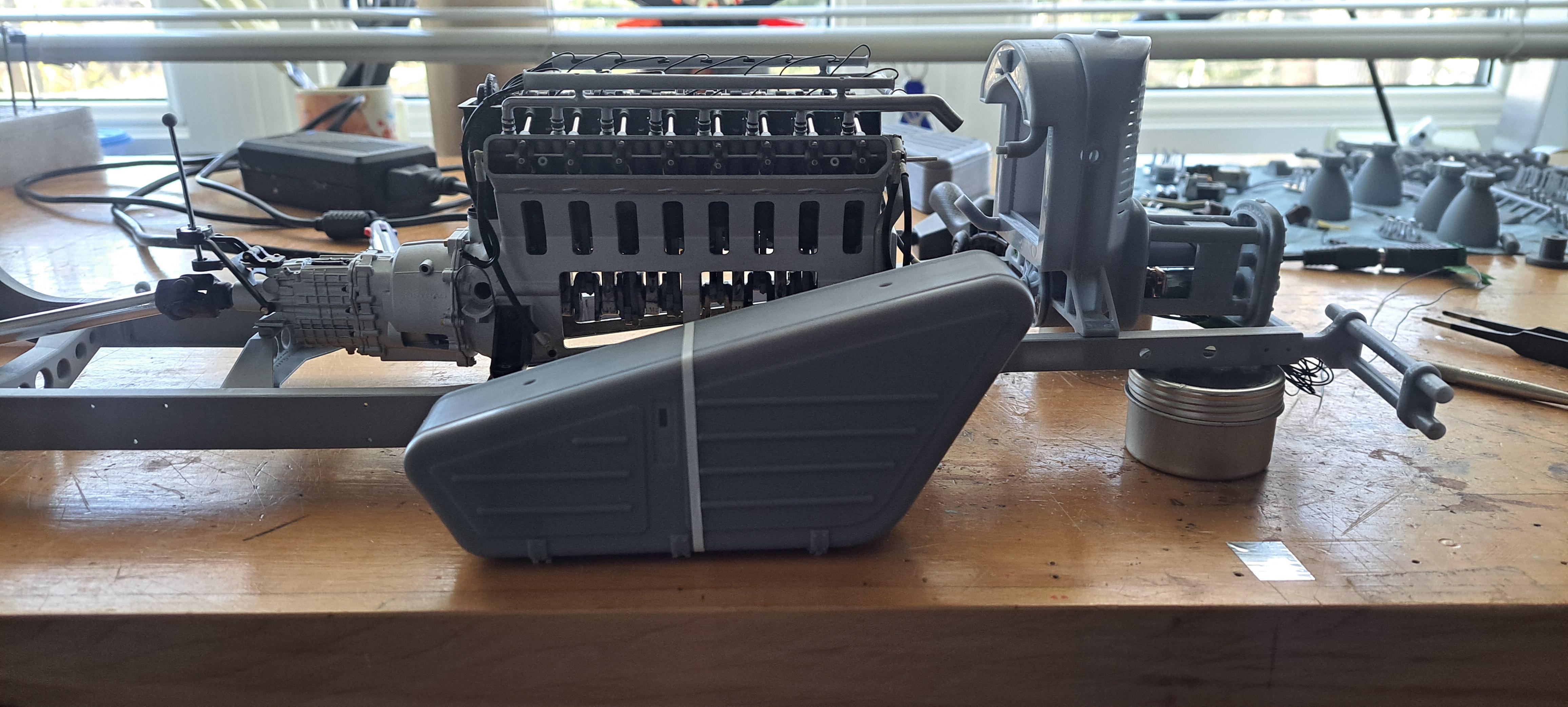

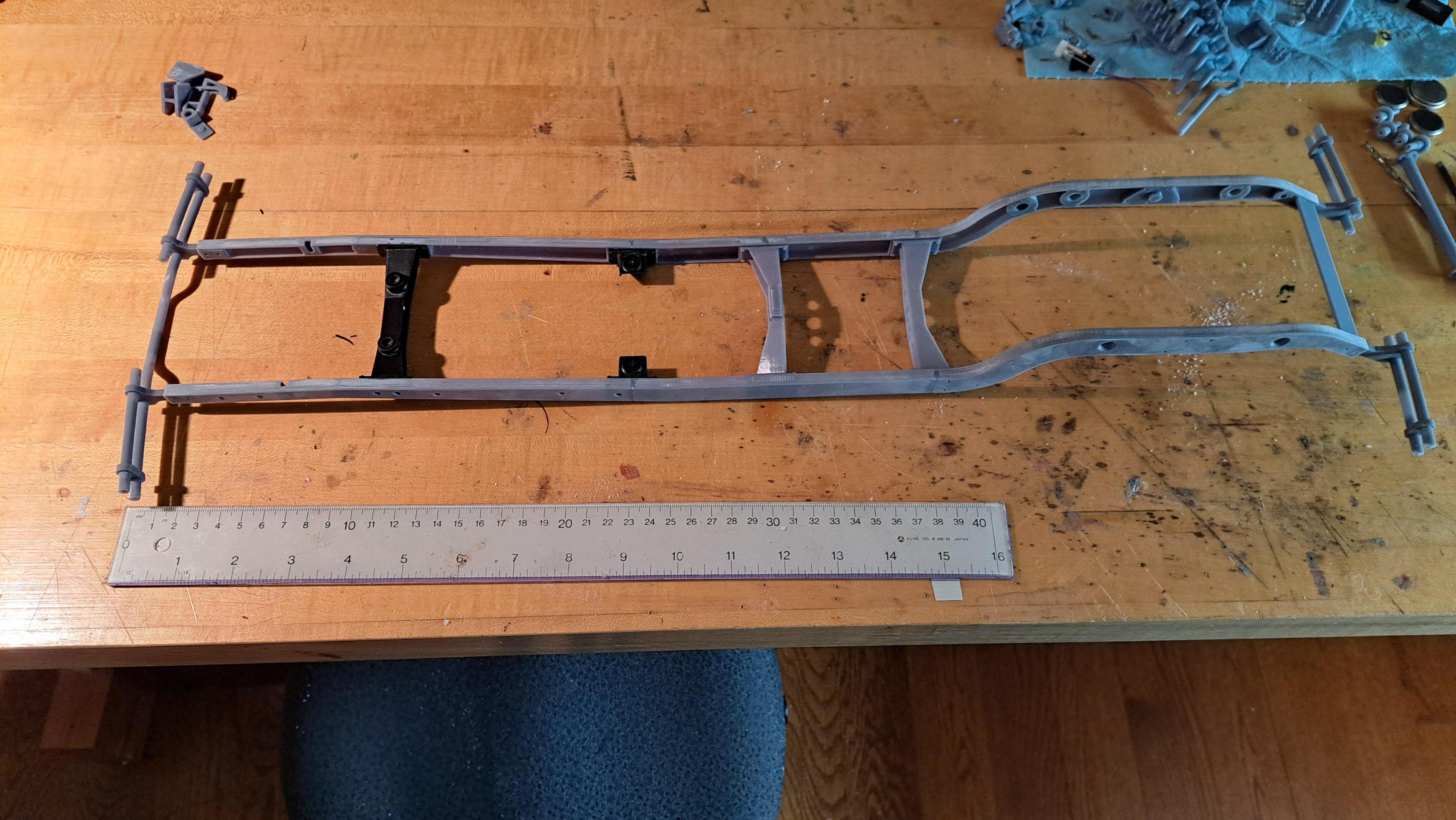

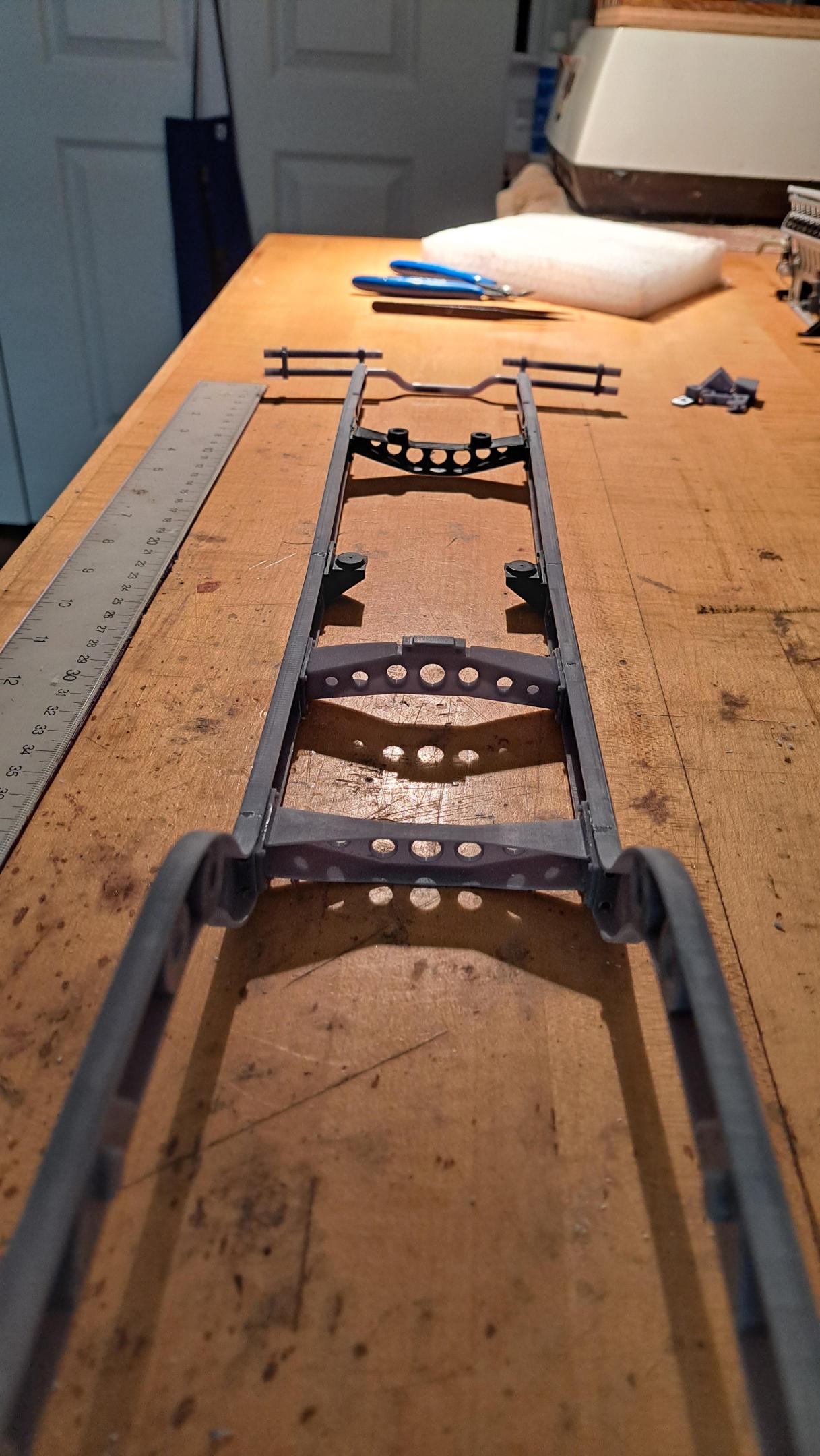

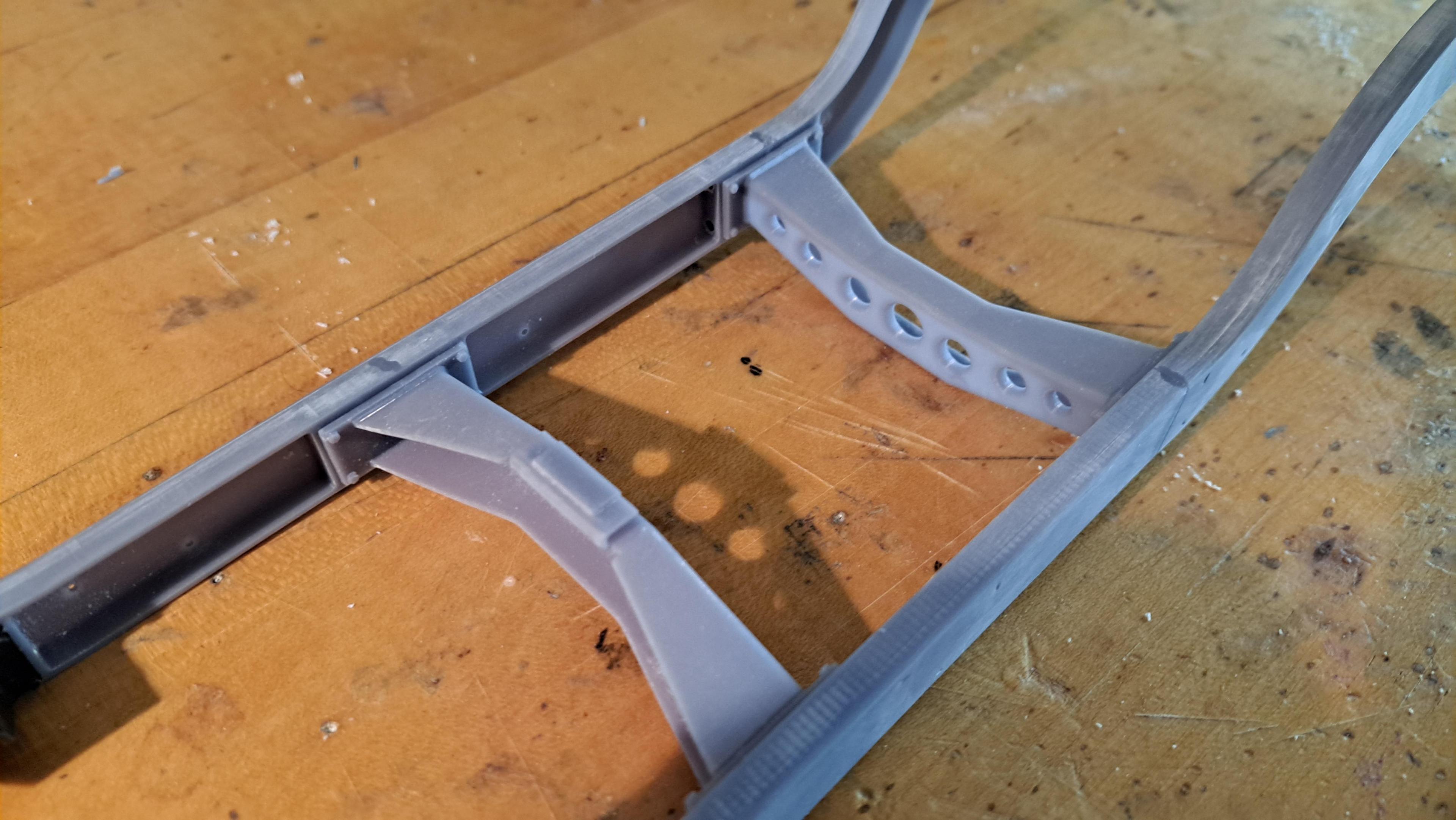

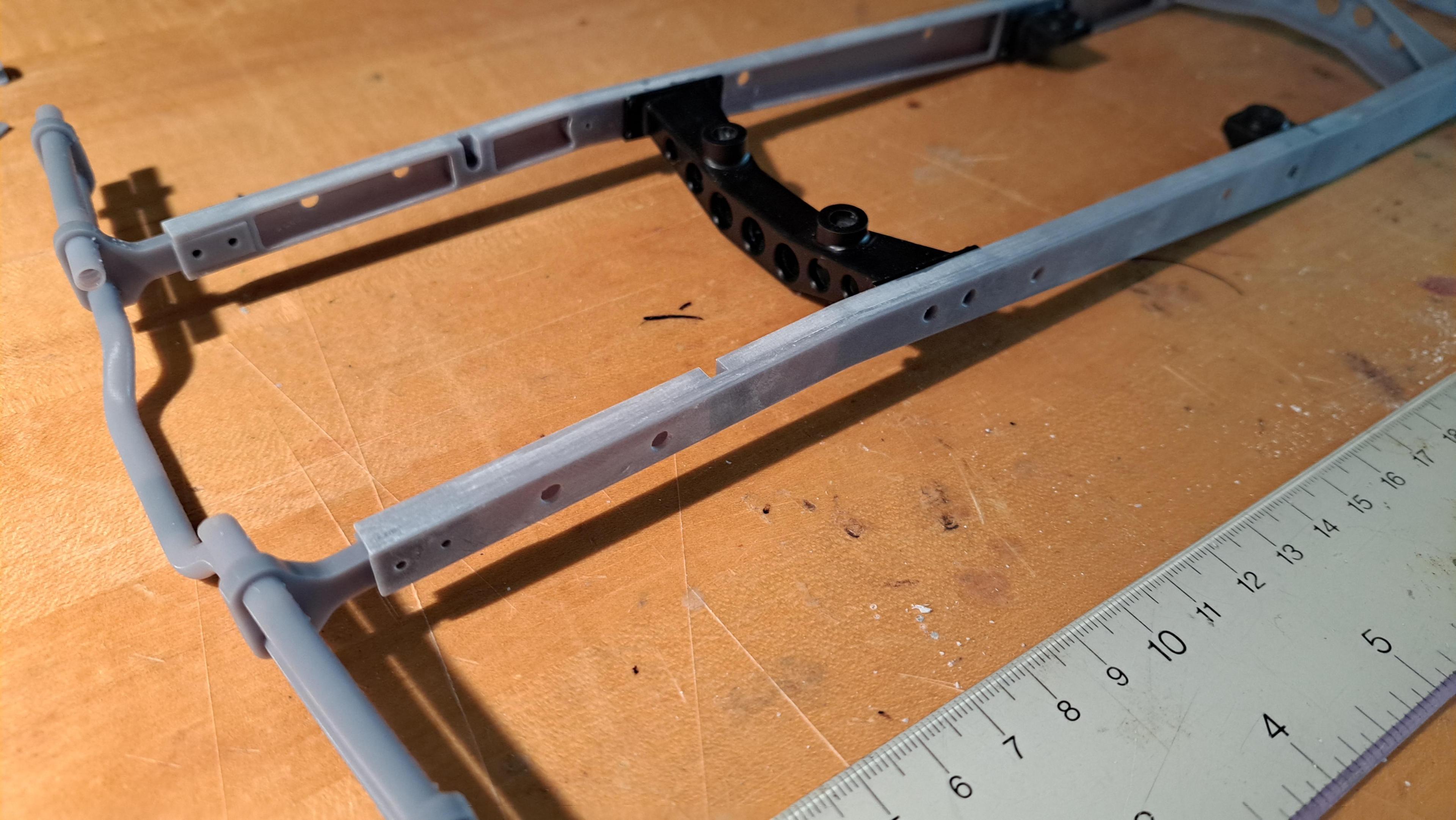

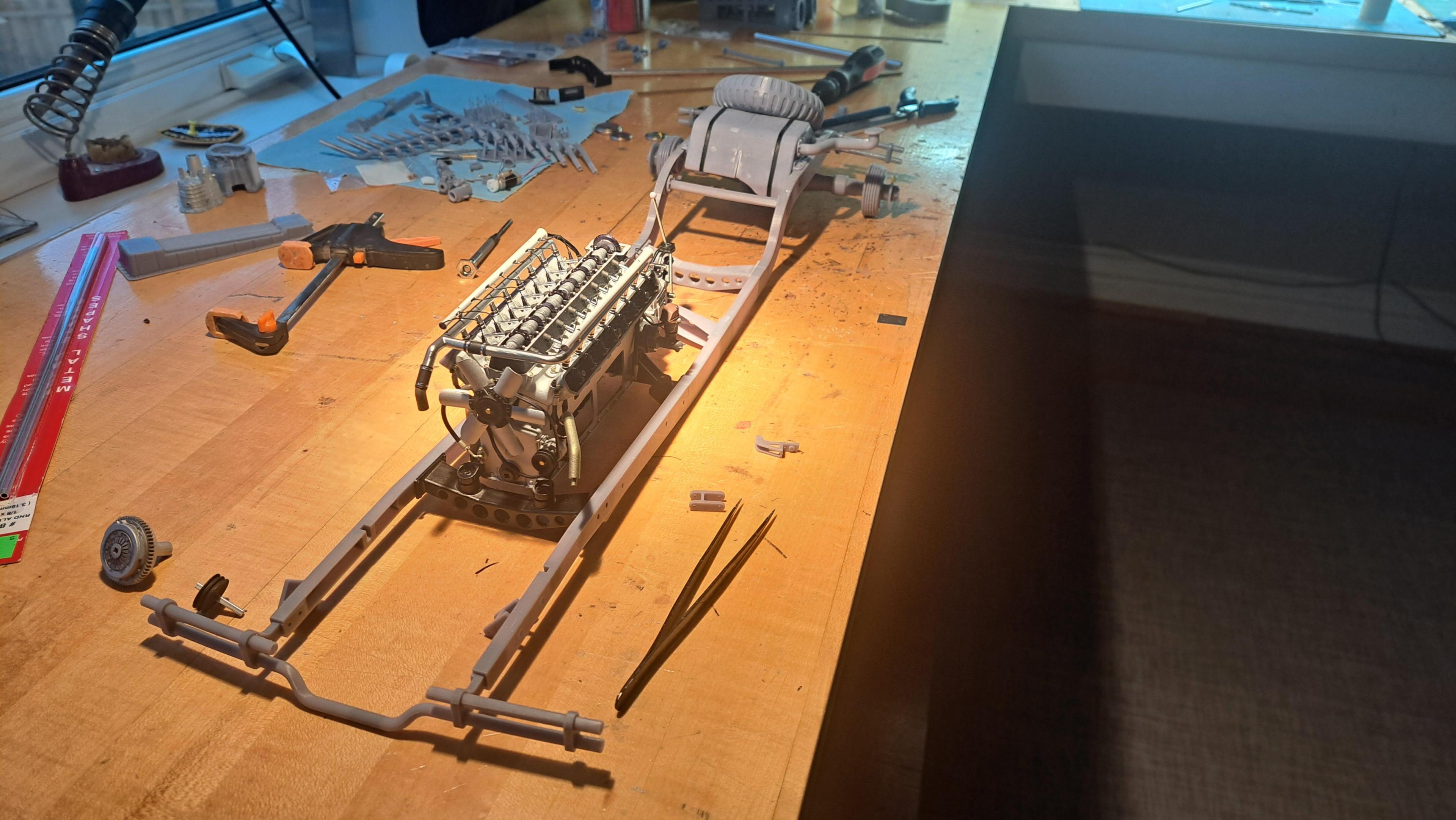

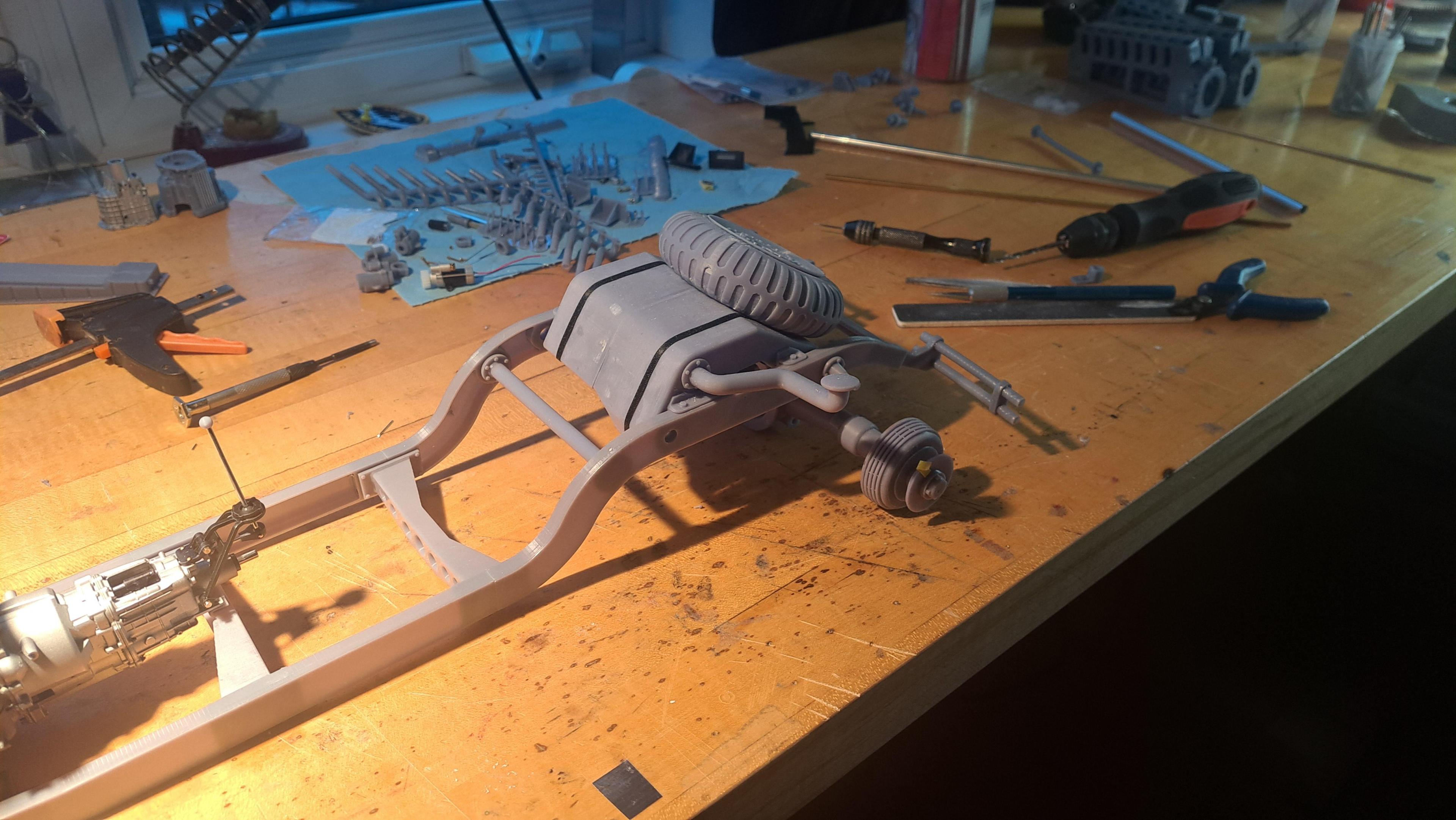

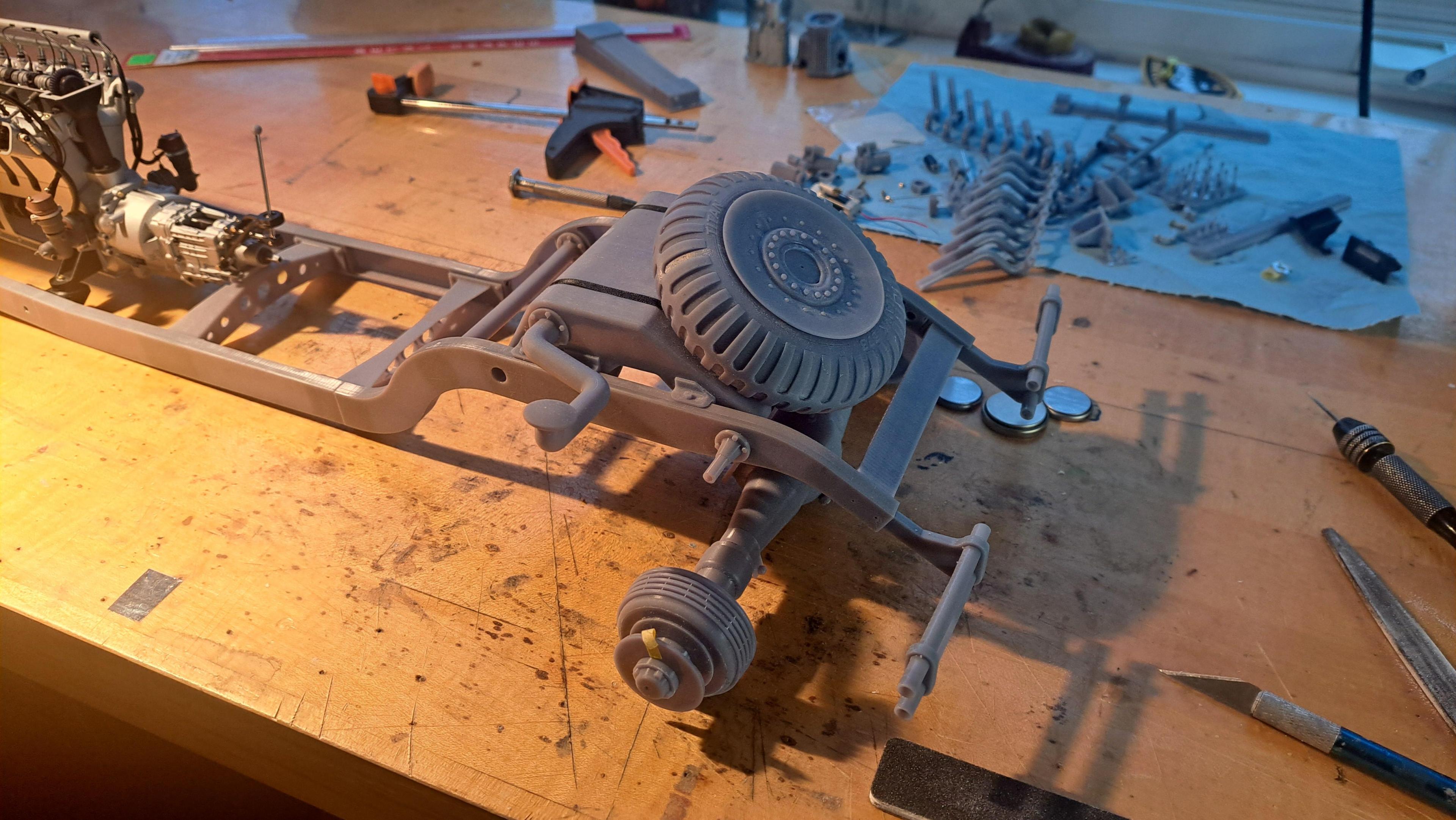

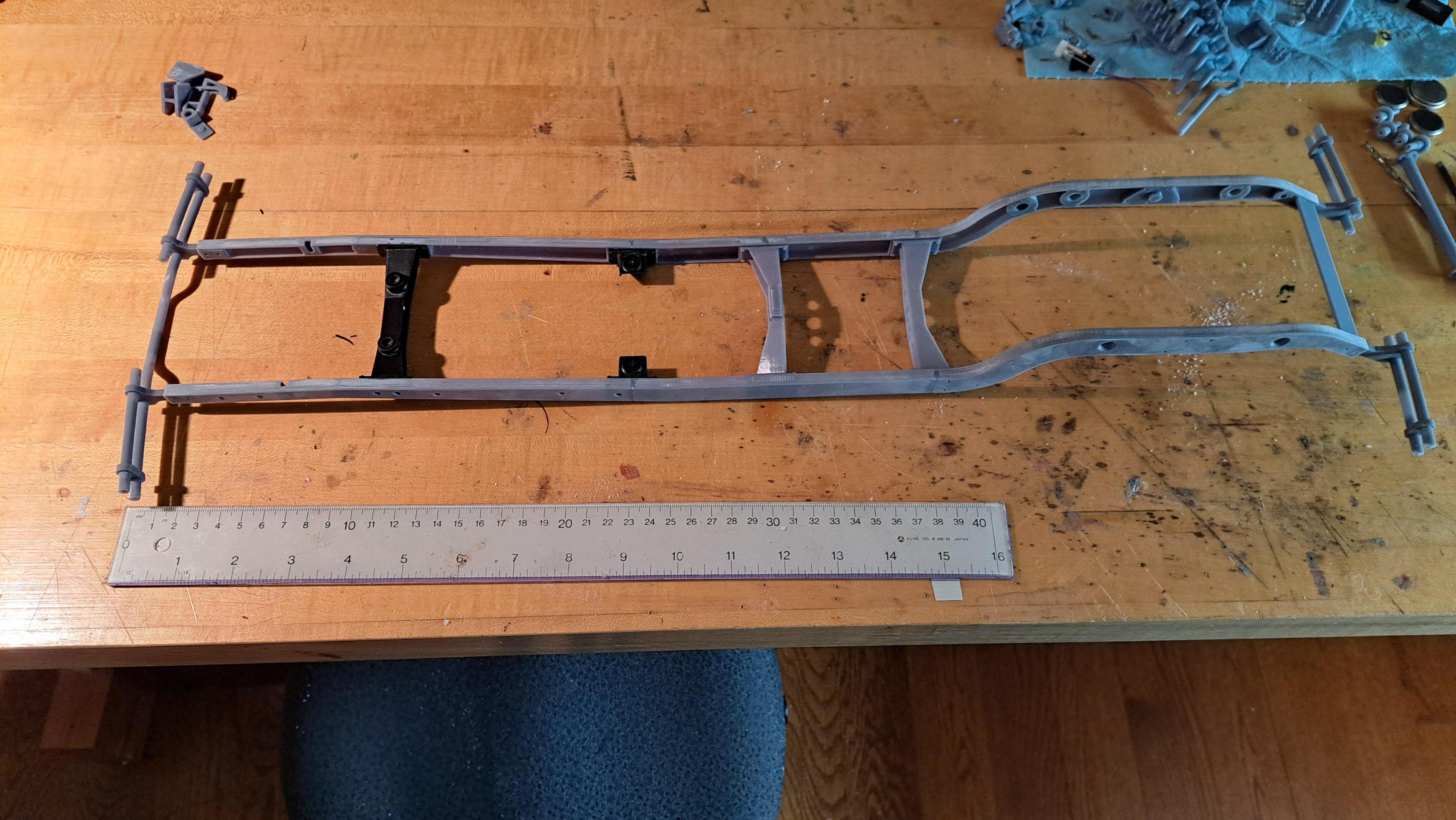

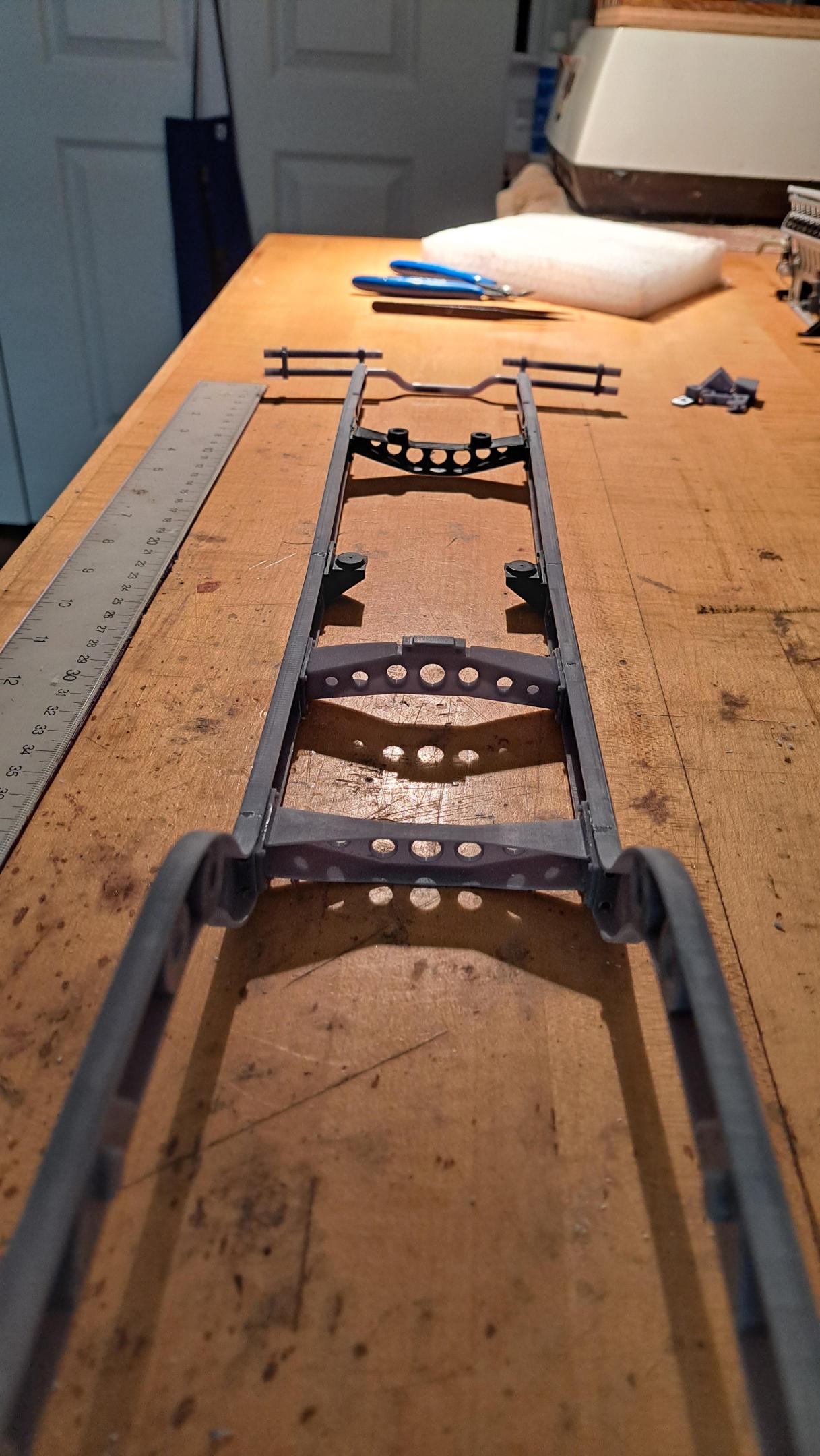

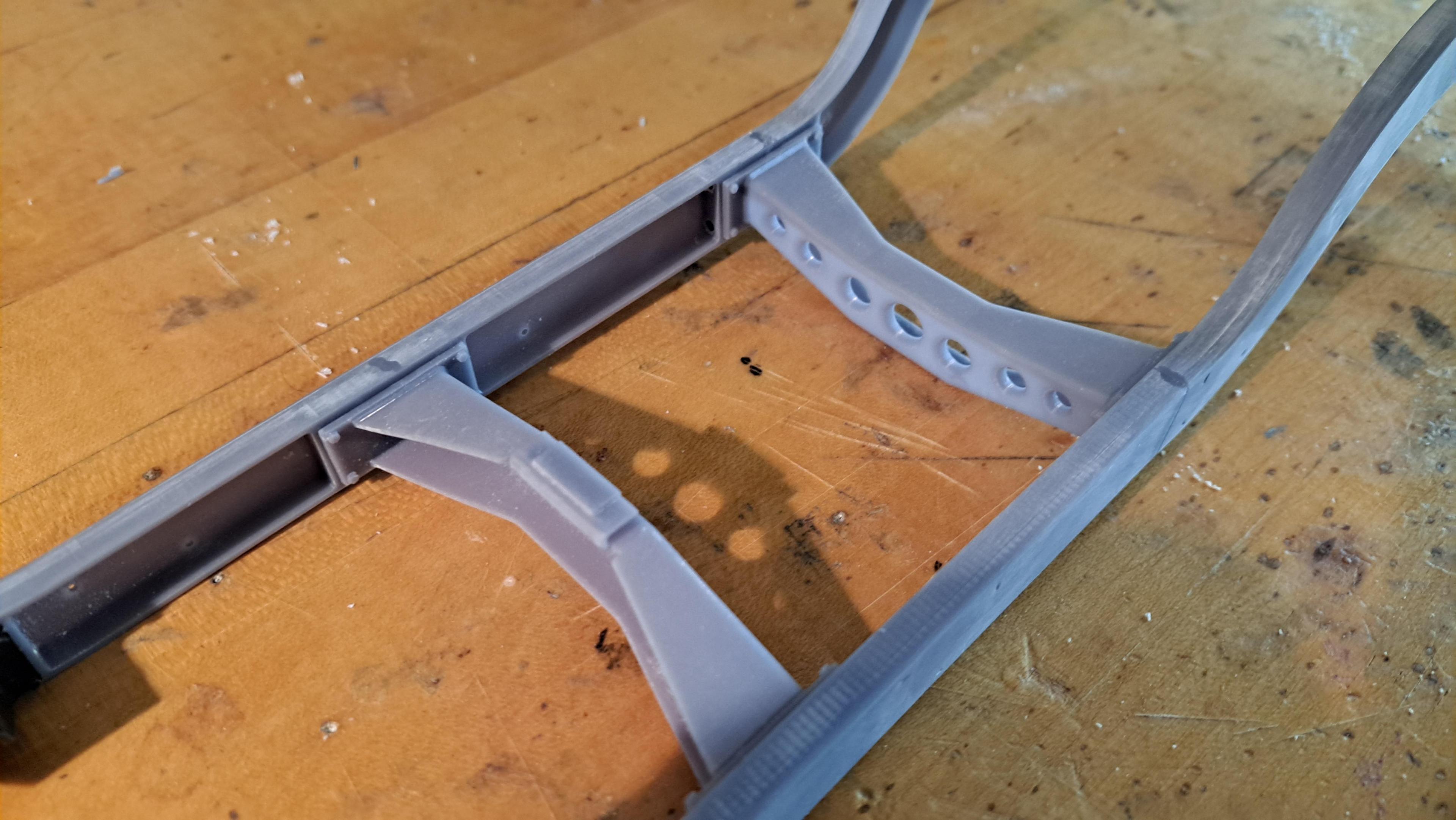

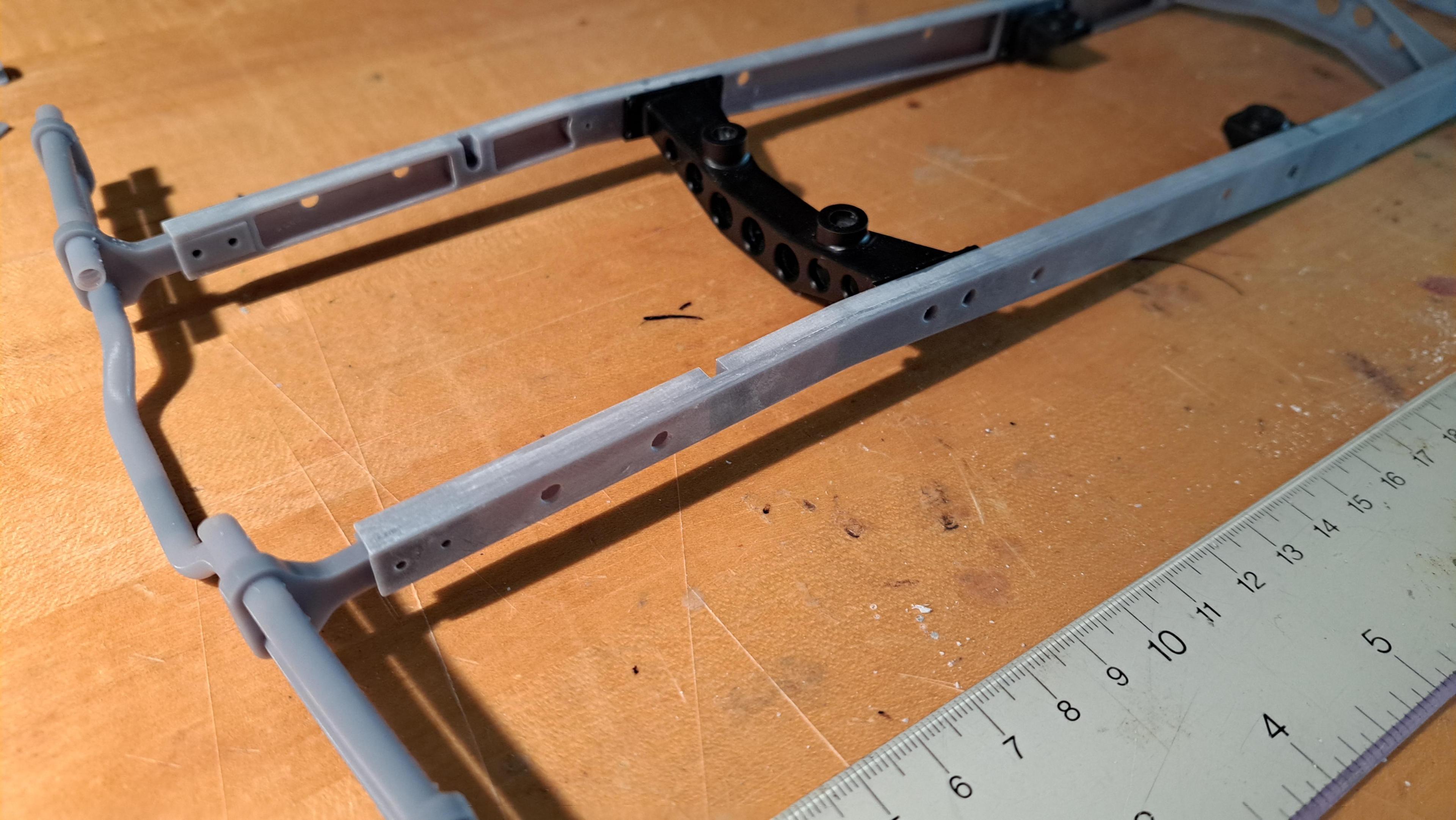

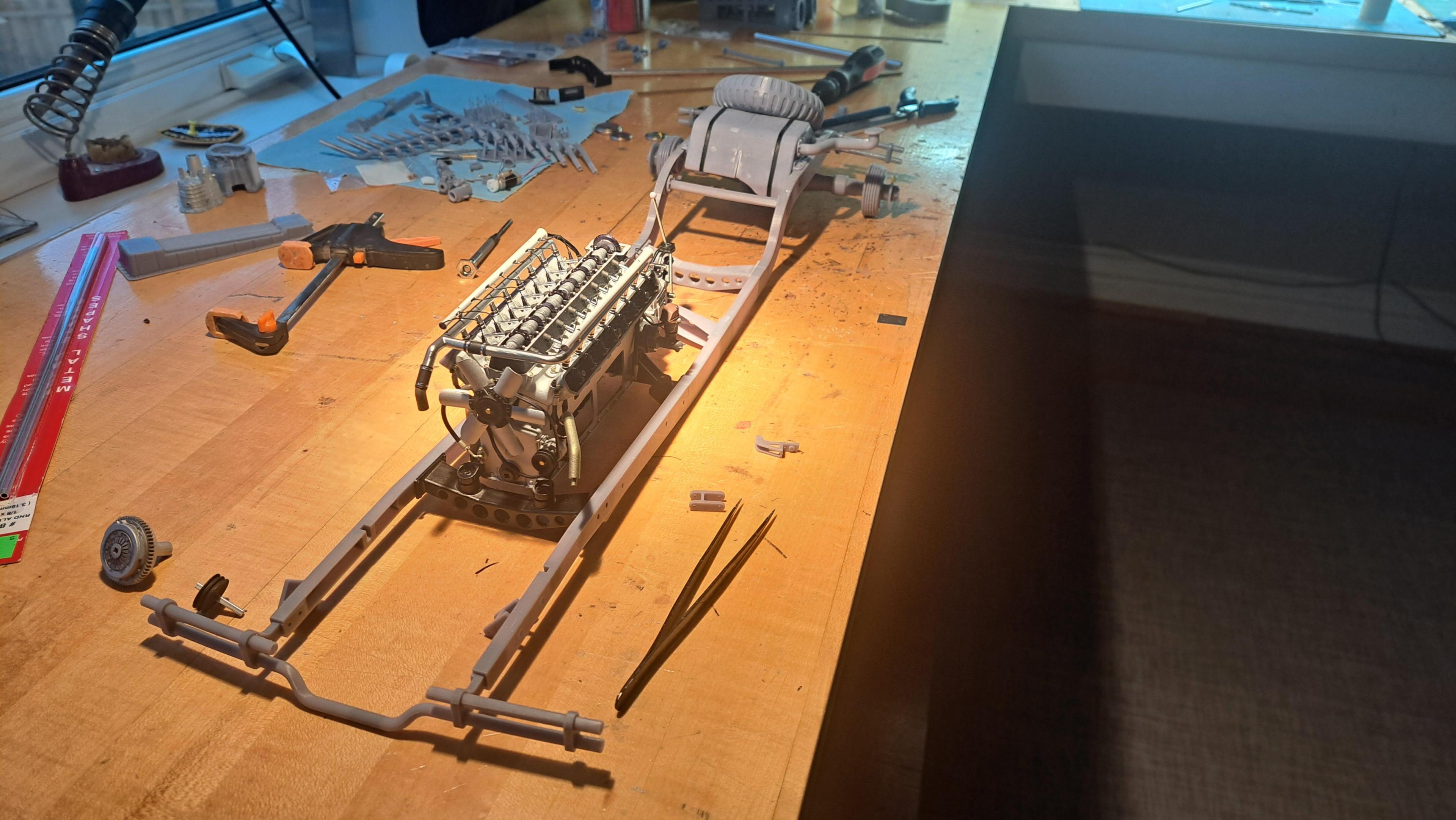

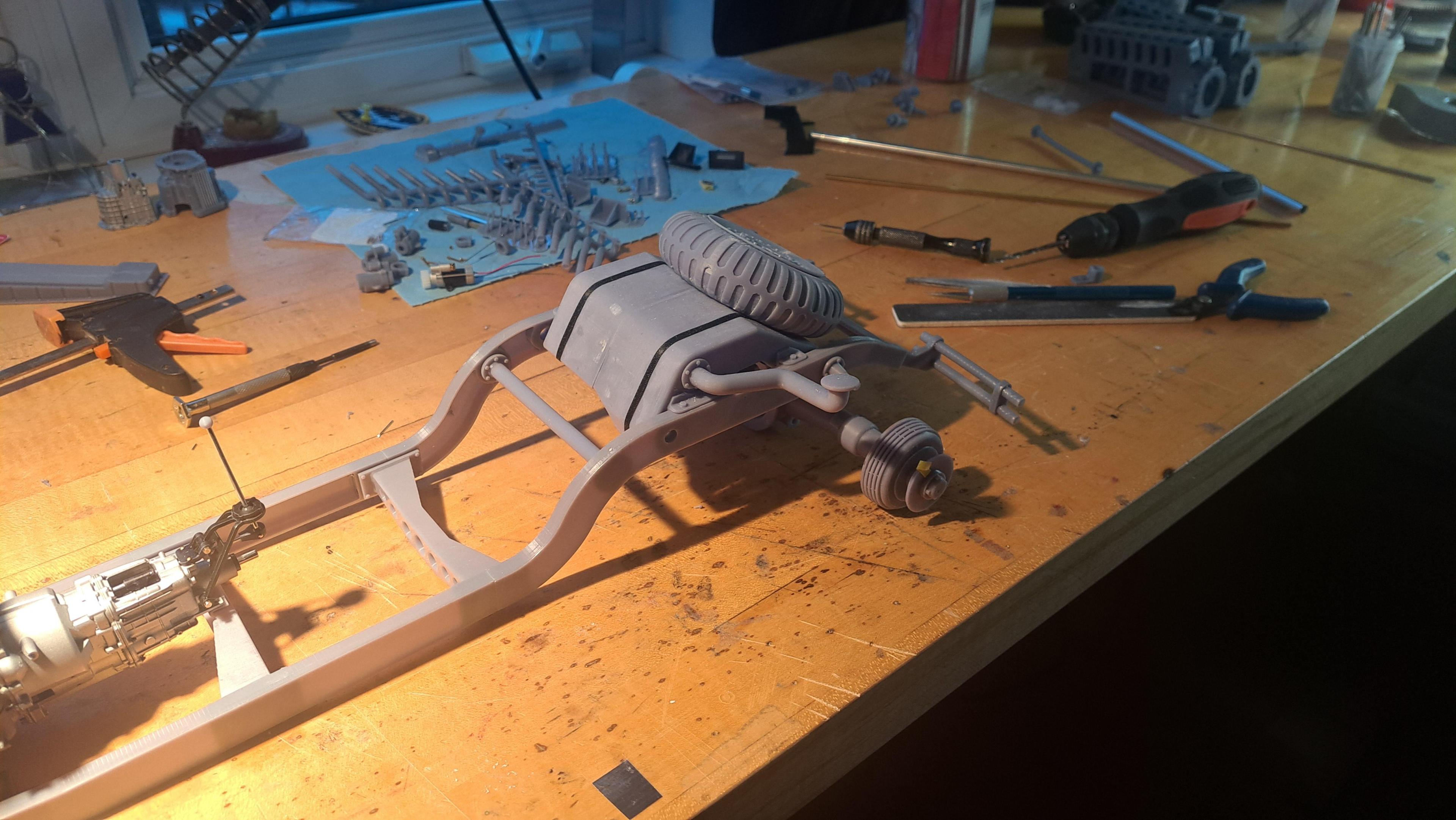

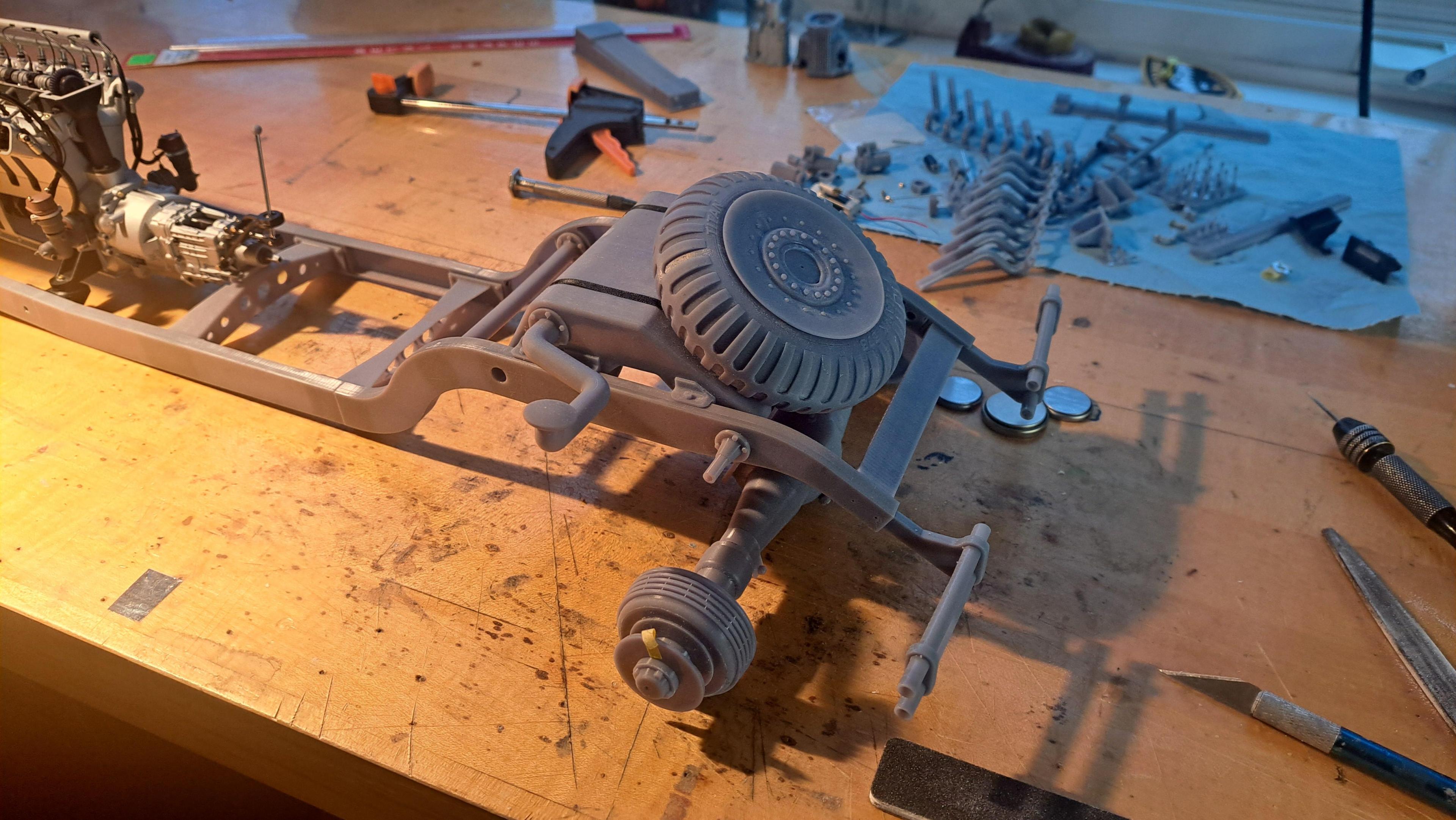

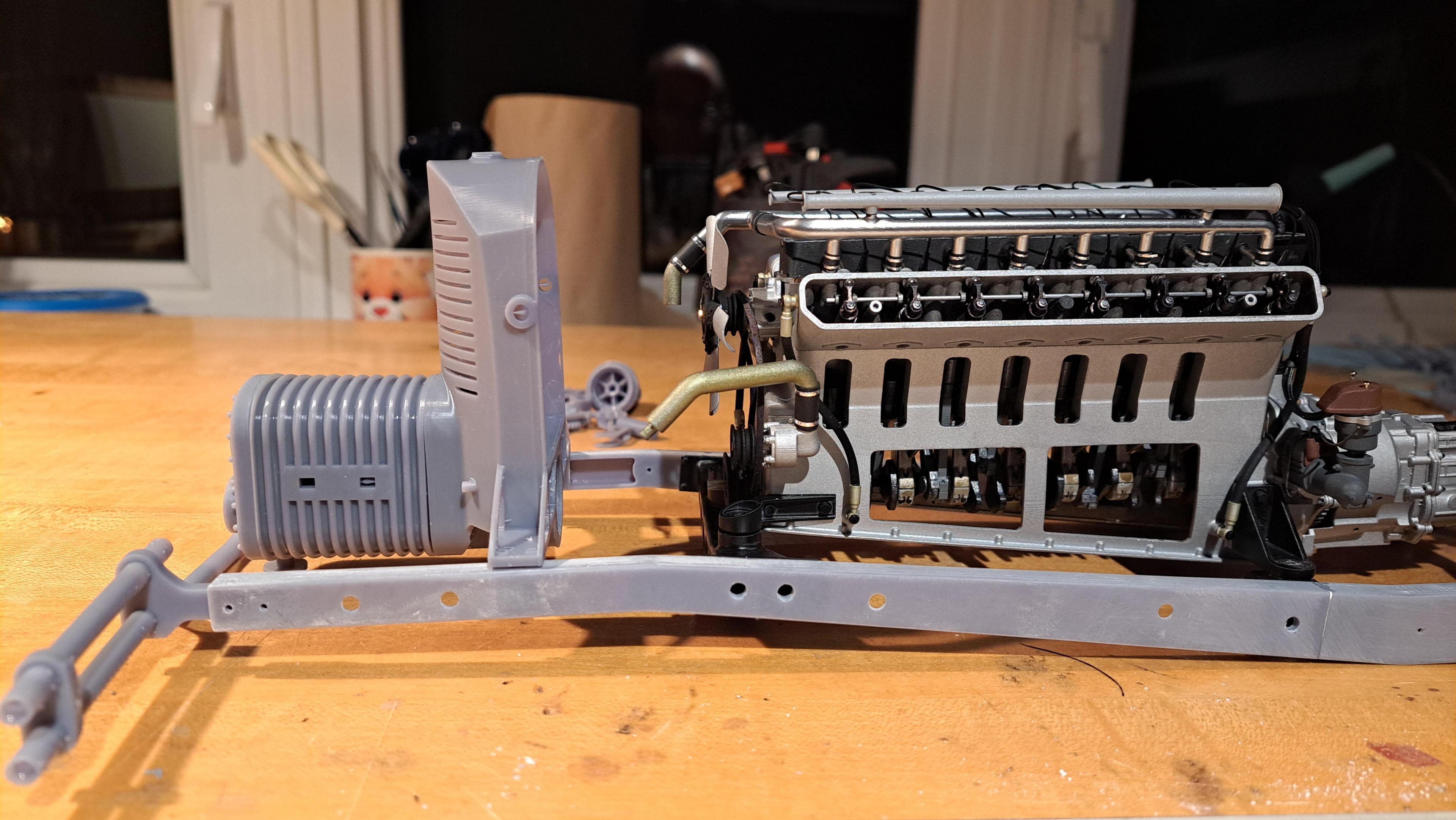

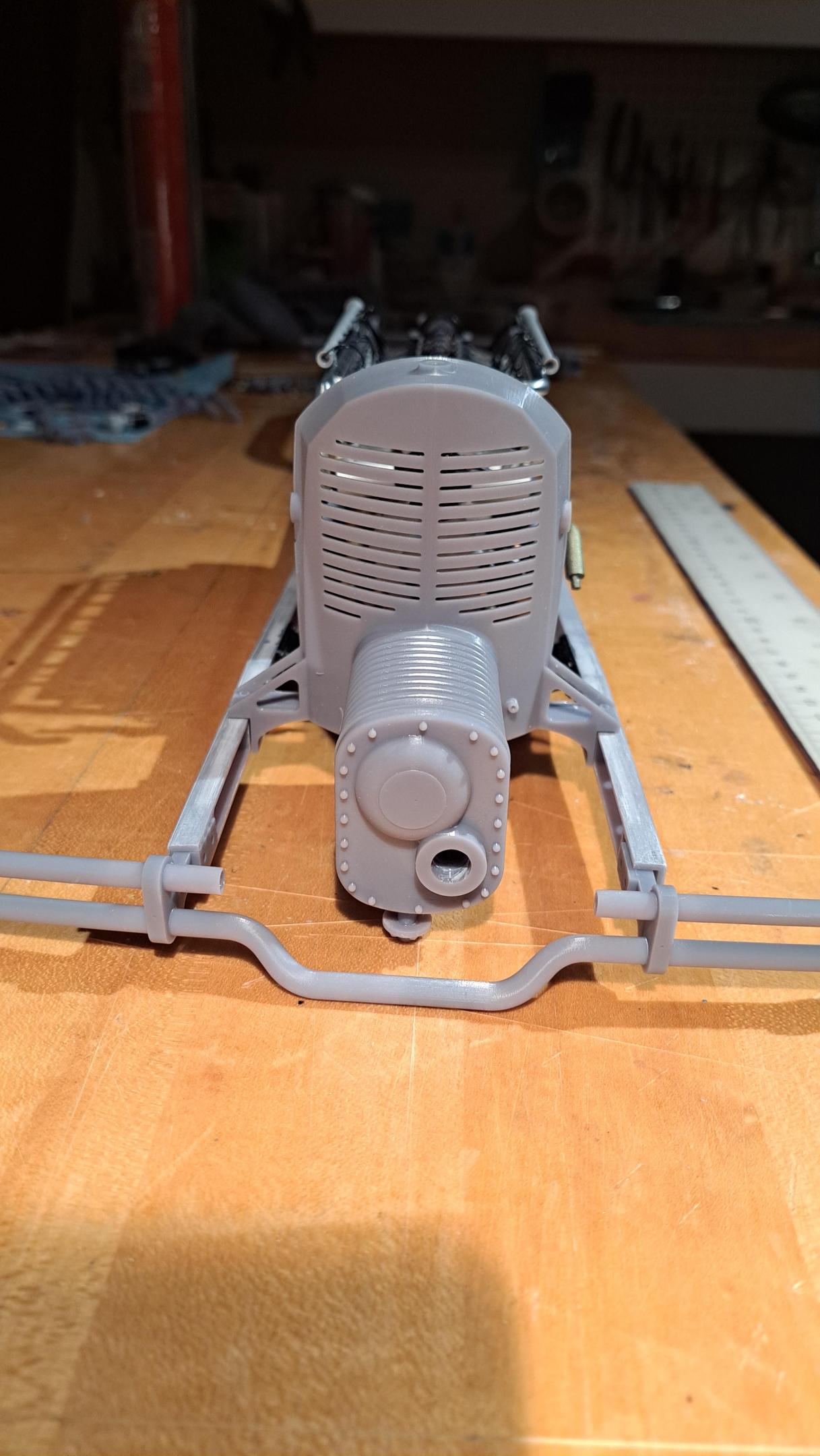

While waiting for the new motors to arrive, I started the frame. It's all printed and assembled, a lot easier and faster to print and assemble than the engine. I also test printed the radiator since the new gearmotor will be mounted in it. For a test print, it came out pretty good. At the risk of repeating myself, this model will be huge !

The assembled frame (that's an 18 in ruler next to it)

With the engine

and the gas tank I printed last summer

And with the radiator cowling and blower

I'm always impressed with what the printer puts out but like I said before, garbage in, garbage out. I guess I'm not giving it too much garbage !!

Here's the too small gearmotor/starter setup

So I had to rethink how to drive the engine. I found another type of mini gearmotor, it has alot more torq but it's much bigger, too big to pass as a starter. Instead, the new motor will be hidden inside the blower and it will be inline with the crankshaft. I even figured out a way to drive the rotating thingy in the front of the blower using the same gears I had planned to use to drive it in the first place. I ordered 2 different torqs, hopefully one will do the job.

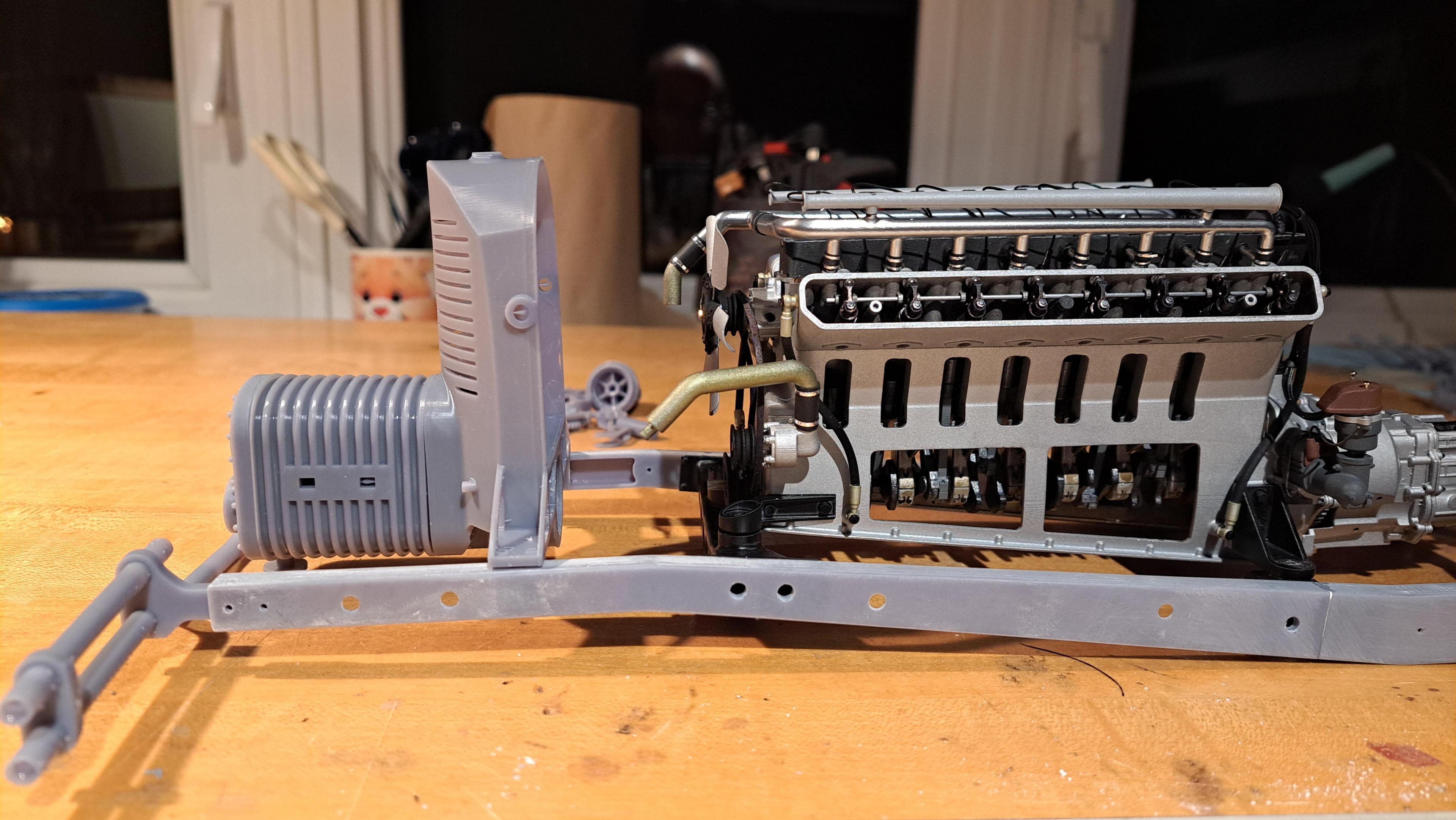

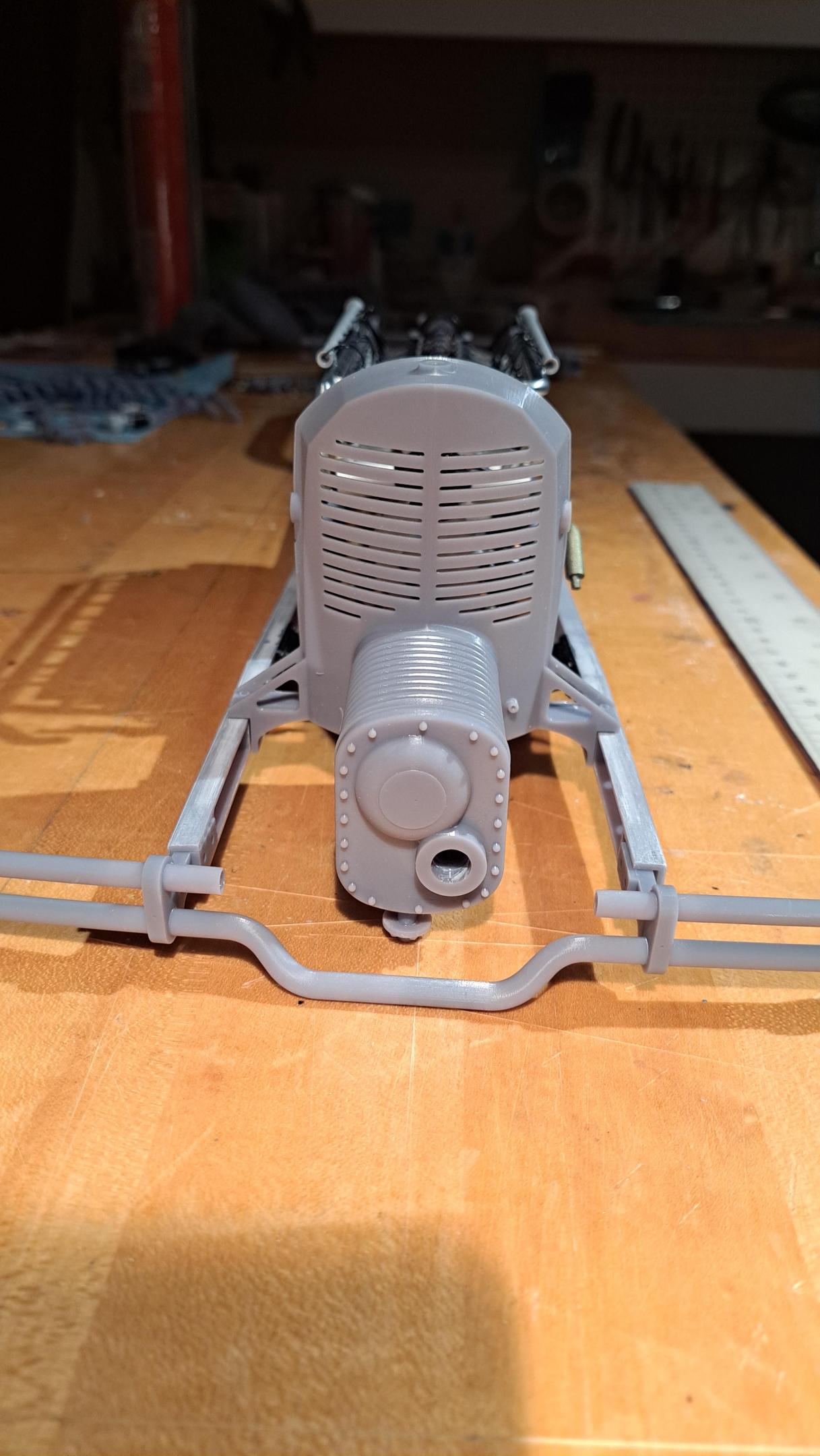

Here's what the new design looks like

And here's the new gearmotor type

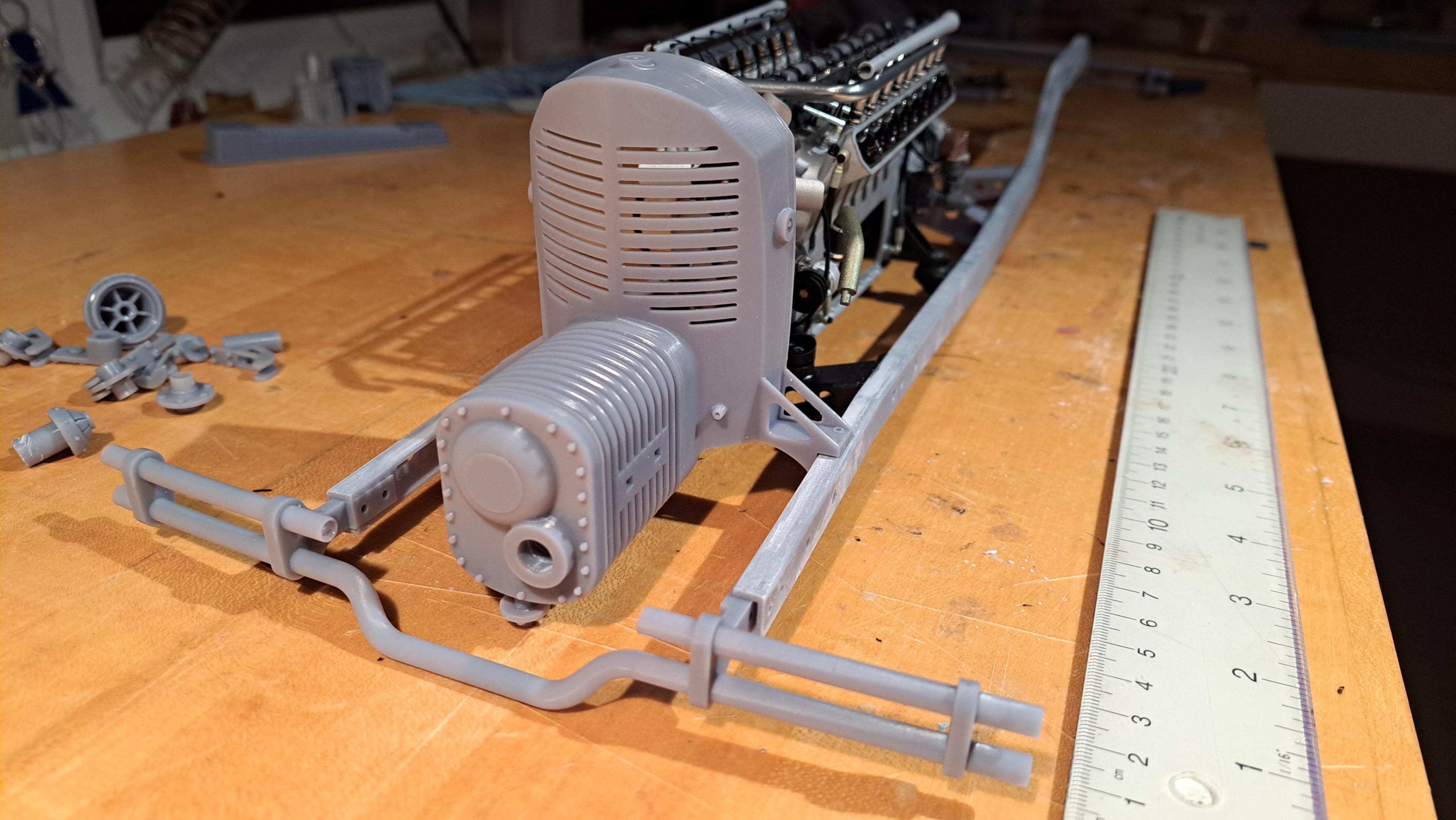

While waiting for the new motors to arrive, I started the frame. It's all printed and assembled, a lot easier and faster to print and assemble than the engine. I also test printed the radiator since the new gearmotor will be mounted in it. For a test print, it came out pretty good. At the risk of repeating myself, this model will be huge !

The assembled frame (that's an 18 in ruler next to it)

With the engine

and the gas tank I printed last summer

And with the radiator cowling and blower

I'm always impressed with what the printer puts out but like I said before, garbage in, garbage out. I guess I'm not giving it too much garbage !!