-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

-

PRE-ORDER SHIPS IN SCALE TODAY!

The beloved Ships in Scale Magazine is back and charting a new course for 2026!

Discover new skills, new techniques, and new inspirations in every issue.

NOTE THAT OUR FIRST ISSUE WILL BE JAN/FEB 2026

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

N. S. Del Rosario / 1759 Felucca/ 1:36 building log

- Thread starter Manatas

- Start date

- Watchers 21

-

- Tags

- ancre felucca 1759

Very good work on the beams and hatch carlings. Not easy to make all of them with the correct curve

Well done !!!

Well done !!!

Very nice mill work going from your own milled lumber to the finished turned and detailed mast. Well done. Rich ((PT-2)Very good work on the beams and hatch carlings. Not easy to make all of them with the correct curve

Well done !!!

- Joined

- Apr 20, 2020

- Messages

- 6,259

- Points

- 738

Dear ManatasStory of making masts:

View attachment 249026View attachment 249028View attachment 249029View attachment 249030View attachment 249031View attachment 249032View attachment 249033View attachment 249034View attachment 249035View attachment 249036View attachment 249037

now looking for best ways to make mast wedges..

Just today I got to know your amazing blog for building this beautiful model. I must say that I was very impressed by your highest quality and most accurate work. I will continue to follow with great curiosity

You know, I would like to see the sheaves cut into the lower part of masts for raising and lowering them at sea. One false move and you have a very heavy arrow dropping and piercing the hull, possibly clear through and then they may have to cut away the ropes dragging it along. Yours are well made and placed. Rich (PT-2)Story of making masts:

View attachment 249026View attachment 249028View attachment 249029View attachment 249030View attachment 249031View attachment 249032View attachment 249033View attachment 249034View attachment 249035View attachment 249036View attachment 249037

now looking for best ways to make mast wedges..

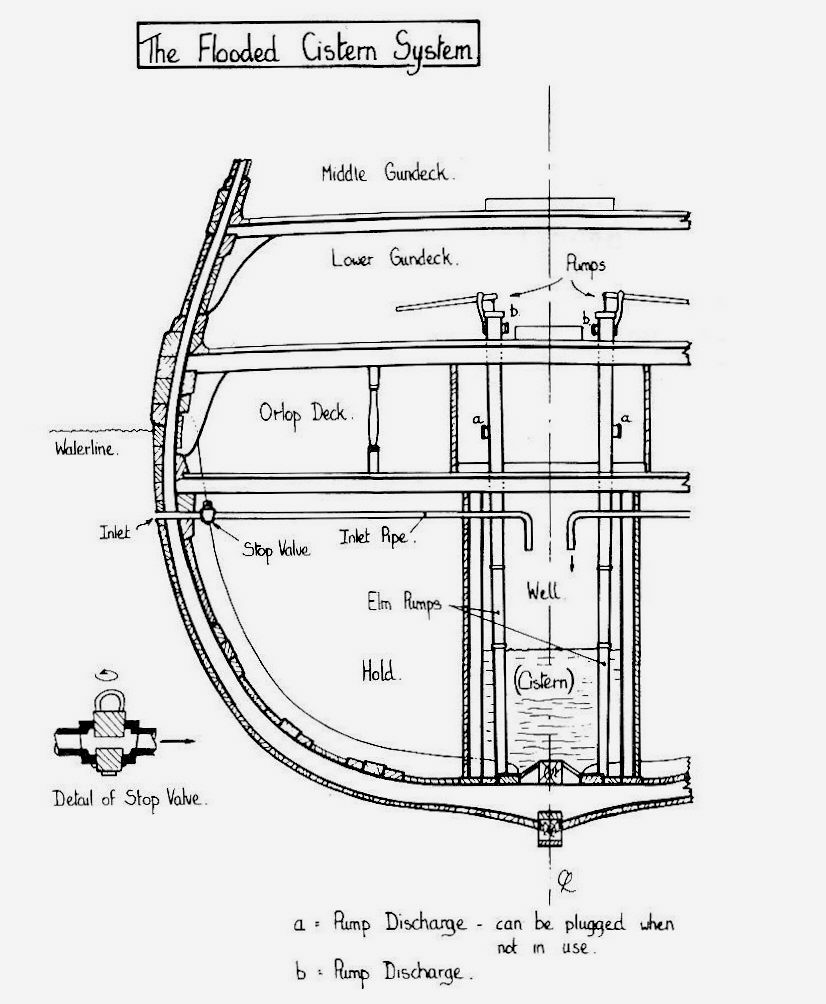

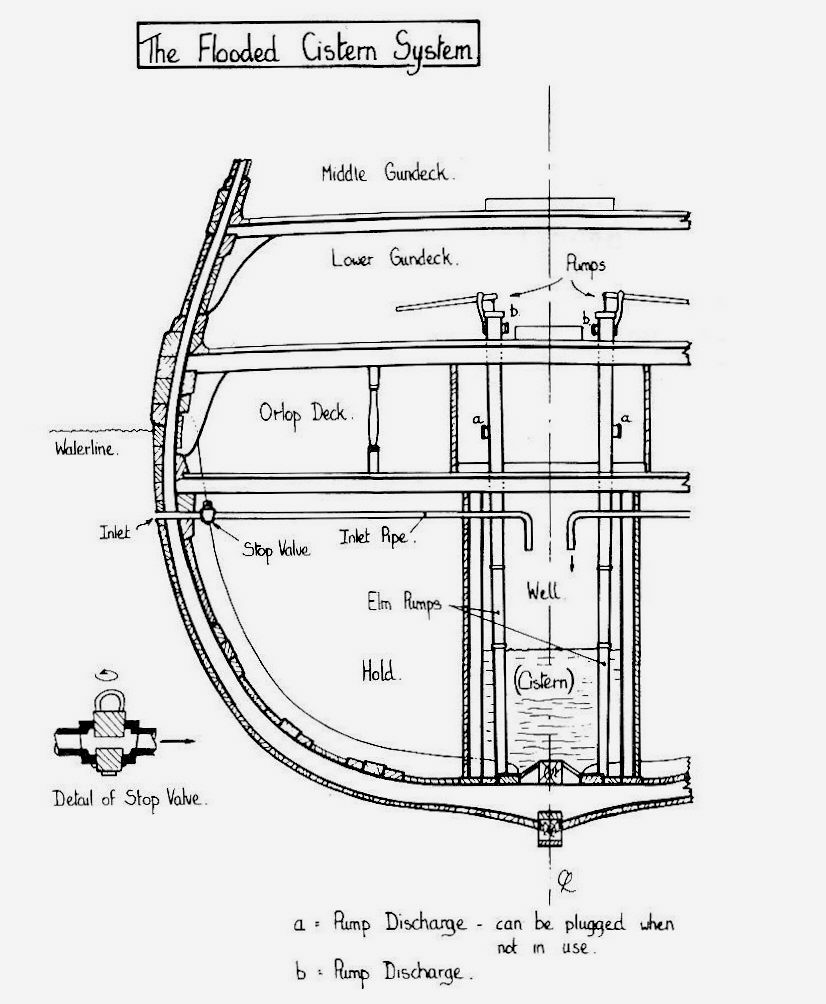

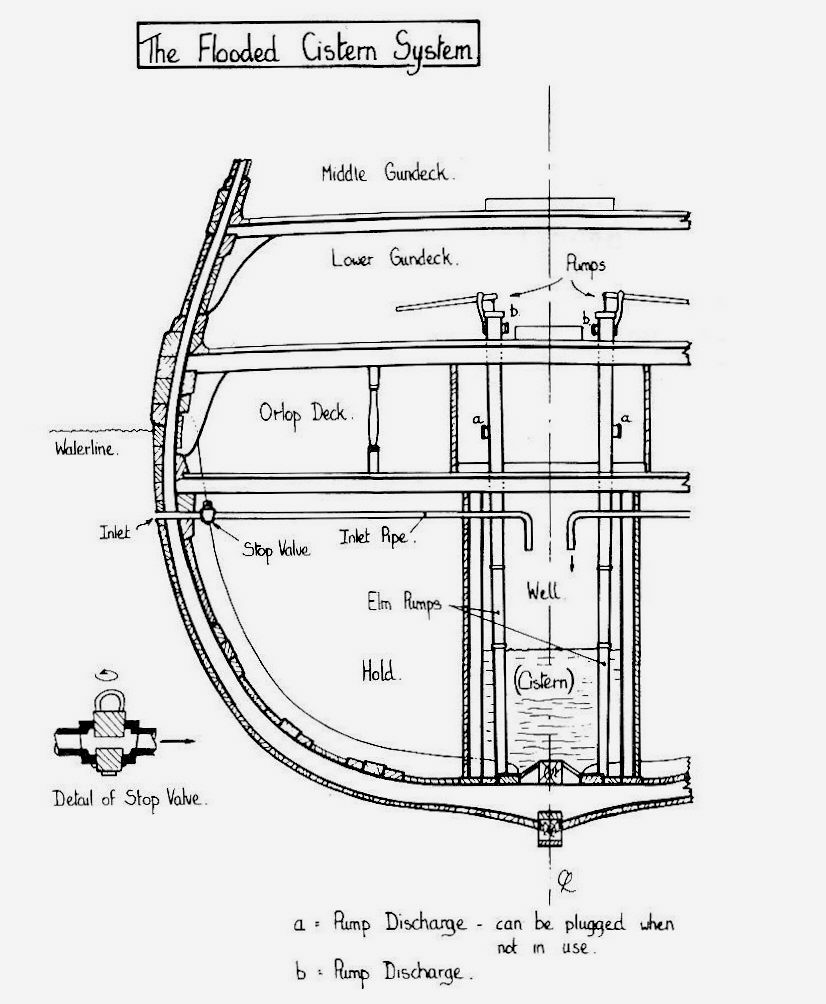

Very nice small work for very realistic pump handles. What type of pump are these associated with?Before deck planking it was necessary to make bilge pumps, so this thread about making them. View attachment 258782View attachment 258783View attachment 258784View attachment 258785View attachment 258786View attachment 258788View attachment 258789View attachment 258790

Rich (PT-2)

Hello, Rich and Manatas. This particular pump is called Bilge or Elmtree pump because the tube was made from the Elm tree.Thanks Rich for a good word. I don't know much about types of pumps, just made them according plans and a little bit of my imagination.

Check out this very interesting document, it is a great read to expand the knowledge, IMHO. BTW, the image you provided, taken from this book.

Attachments

Thanks Jimsky, very helpful information and good direction to obtain this bookHello, Rich and Manatas. This particular pump is called Bilge or Elm pumps because the tube was made from the Elm tree.

Check out this very interesting document, it is a great read to expand the knowledge, IMHO. BTW, the image you provided, taken from this book.

You have very good thesis here. I recognize some of the top signers as the leading nautical and underwater archealogical researchers and academicians of many decades. You have excellent drawings to build and understand the pump. Rich (PT-2)Hello, Rich and Manatas. This particular pump is called Bilge or Elm pumps because the tube was made from the Elm tree.

Check out this very interesting document, it is a great read to expand the knowledge, IMHO. BTW, the image you provided, taken from this book.

Many Thanks for this thesis - interesting read

Need help! Best would be somehow visually to explain for me how should I do thickness crossing on waterways when thickness of deck planks are different? As I can find in other sources and monograph examples everybody is doing planks at the same thickness, even in photos on original monograph I cant see difference of planks thickness. But plans and measurement information tells that thickness must be different. I just dont cnow how should be done bevieling on waterways in those places. Thanks in advance.

Very nice work. 1:36 is a nice large scale for such detailing. It will be quite a ship. Rich (PT-2)Before deck planking it was necessary to make bilge pumps, so this thread about making them. View attachment 258782View attachment 258783View attachment 258784View attachment 258785View attachment 258786View attachment 258788View attachment 258789View attachment 258790

Hi Manatas!

Stronger (thicker) deck planks are like the binding-strakes on larger ships. They give the ship greater rigidity. For simplicity, they are executed on many models as normal deck planks. They are not protrude from the top of the deck, simply because of the risk of tripping.

Binding-strake (8) in the book "The 74 gun ship", Volume 1, page 110.

On the "Ancre site" you can find numerous construction photos of the Del Rosario.

In the fotos, the top of the deck is always flat. Except for the bend through the deck beams.

Best regards

Thomas

Stronger (thicker) deck planks are like the binding-strakes on larger ships. They give the ship greater rigidity. For simplicity, they are executed on many models as normal deck planks. They are not protrude from the top of the deck, simply because of the risk of tripping.

Binding-strake (8) in the book "The 74 gun ship", Volume 1, page 110.

On the "Ancre site" you can find numerous construction photos of the Del Rosario.

In the fotos, the top of the deck is always flat. Except for the bend through the deck beams.

Best regards

Thomas

Last edited:

Thanks Thomas for showing me where I can find more photos than in monographie book, I wonder how they didnt mentioned in the book this kind of info. But, in this case, I see that everybody and even F. Fissore making deck flat, but as I understand by plan - "Stronger" plank are set in the cut out in the deck beam, then middel panks are at the same level on top, but side planks are thinner and makes different height, just cant undestand how they should end and merge with waterway... Or my plans understanding is bad and I need to make every planks flat?Hi Manatas!

Stronger (thicker) deck planks are set into the cutouts in the deck beams (similar to the carlings). They are not protrude from the top of the deck, simply because of the risk of tripping.

On the "Ancre site" you can find numerous construction photos of the Del Rosario.

View attachment 265045

In the fotos, the top of the deck is always flat. Except for the bend through the deck beams.

Best regards

Thomas

Example from wood scraps:

1: Deck beams. Above it two thin and one thicker deck plank. The deck is flat on top.

This is achieved by cutting out the thicker deck plank at the bottom between the deck beams. Then it also looks like the cross-section drawing of the construction plan.

Best regards

Thomas

1: Deck beams. Above it two thin and one thicker deck plank. The deck is flat on top.

This is achieved by cutting out the thicker deck plank at the bottom between the deck beams. Then it also looks like the cross-section drawing of the construction plan.

Best regards

Thomas

Hallo Thomas,Example from wood scraps:

View attachment 265072

1: Deck beams. Above it two thin and one thicker deck plank. The deck is flat on top.

View attachment 265073

This is achieved by cutting out the thicker deck plank at the bottom between the deck beams. Then it also looks like the cross-section drawing of the construction plan.

Best regards

Thomas

many thanks for the work with the example, but unfortunately on the Rosario the deck was not build like on a french warship, she had really a step on the top of the deck

So I think that there will be no other way than to adjust the difference in height of the 0,5mm over a certain length of the waterway along the lower plank (marked with red)

Yes Uwek, I thought the same, but I was so unsure that didn't make myself to do that and was afraid is that possible that it will be small "corner" between deck plank and waterway where floor heights will be different in a very beginning of plank.

I can understand your thoughts completely, but I have no other idea of how it could be done differently.Yes Uwek, I thought the same, but I was so unsure that didn't make myself to do that and was afraid is that possible that it will be small "corner" between deck plank and waterway where floor heights will be different in a very beginning of plank.

On the photos of the build included in the ancre booklet this detail is not really visible.......