Hello again!

I was surprised to discover that my initial fairing to the shape of the hull, for these lower finishing pieces, was only approximate.

I was sanding them along the curving arc of the lower main wales, but not accounting for their actual rake in the horizontal plane. It was also only possible, initially, to guess at what the connecting angle would be with the transitional moulding above.

When I first offered these up to the hull, after securing the section above, I found that there was significant daylight in the middle of the piece, and the top angle was all wrong.

It took a fair amount of careful contour sanding and re-checking, but eventually I got the pieces flush up to the hull, fore and aft, and a closed joint at top.

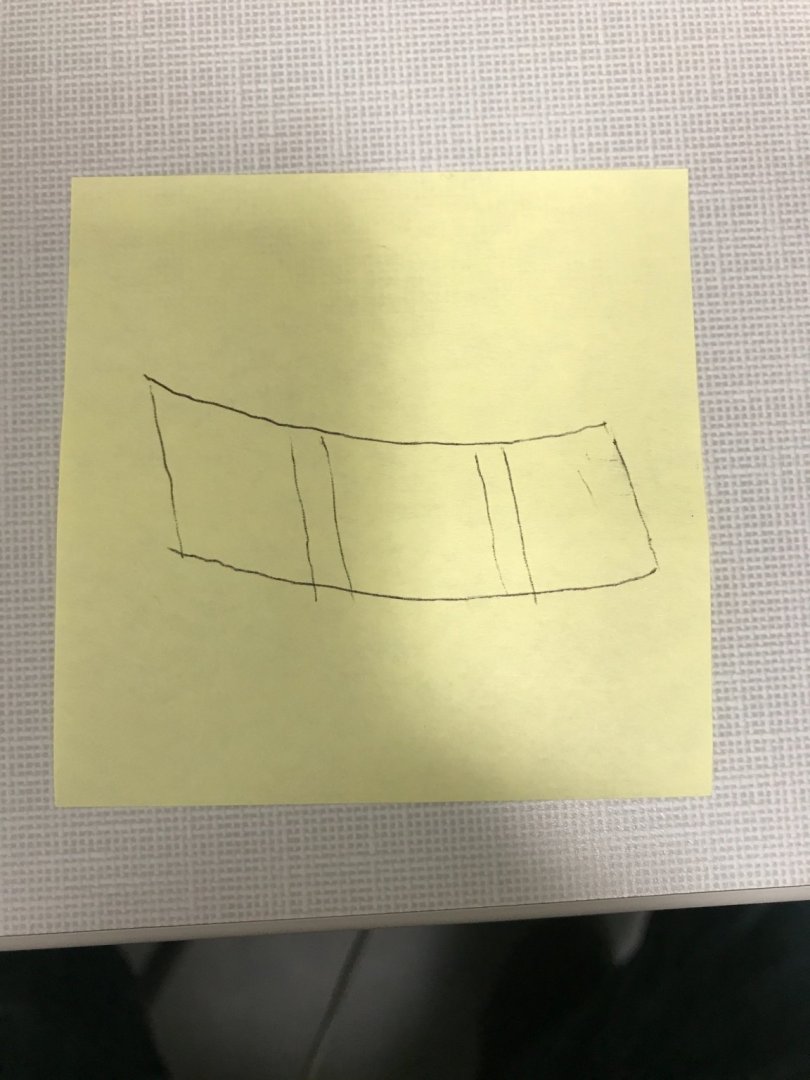

Here you can see the changing tumblehome as reflected upon these inner surfaces:

View attachment 200387

One mistake I made was painting these before final fitting. All of that handling burnished through much of the gold. I also found that, while ordinarily sure-handed, I kept dropping these delicate pointed things on the floor. Lots of swearing! My kids wrote a song in my honor for dad’s hobby-time: “Oh EFF!!, I dropped my model... Oh EFF!!, the paint is scuffed!”

Anyway, after fitting and retouching, I was finally able to secure them in place:

View attachment 200384

View attachment 200386

View attachment 200382

View attachment 200383View attachment 200383

View attachment 200381

Now, while I could not be happier with how this is progressing, I do sometimes think it is important to talk about some of the things this model IS NOT, even though it aspires to be them.

While I’m pretty sure that I have an accurate read on the shaping of the active seats of ease, I am less certain about the lower finishing.

In this port quarter drawing of La Royal Therese, one can see the seats of ease section pretty clearly:

View attachment 200393

There isn’t really a lower finishing beneath, so it fairs back pretty closely to the hull. Nevertheless, I think I’ve captured the shape and weight of this section pretty well.

Here is another example in Le Terrible:

View attachment 200392

I do wonder, though, whether I’ve left the aft end of the lower finishing as too full. While I think I have the general contours correct, a part of me thinks that the aft end should probably round back more closely to the hull. I am not going to change it, but it is something to keep in mind for anyone else attempting to model these early QGs from pictures, alone.

The other issue to note is the exaggerated overhang of my stern counter:

View attachment 200380

As I’ve discussed before, this is a byproduct of my approach for including the round-up of the transom; in a tapering arc, I pared back the transom edge of the hull, towards the waterline, so that my stern post would not be positioned too far aft into the stern counter. This is a difficult thing to explain, and my whole line of reasoning may have been flawed, there, but it was an educated guess, at the time.

The result was a very rakish stern counter, which I find aesthetically pleasing, but it is not strictly accurate for the period.

One look at Tanneron’s models of Le Brillant and L’Agreable confirm a flatter, more vertical counter:

View attachment 200397

View attachment 200396

View attachment 200395

Lemineur’s monograph for the SP re-enforces this notion. It is notable, also, how Le Brillant’s lower finishing is relatively less bombastic than mine, and fairs much more closely with the hull.

Anyway, making this model in the manner in which I am is sometimes a guessing game. One particular benefit of this QG is that it extends beyond the line of the transom, and obscures the exaggeration. I will have to make a pair of wrapping corbels that finish this detail of the model. Here are the pattern tracings I have made for this purpose:

View attachment 200378

Anyway, EFFIT! as this moderately old man is wont to say. Taken in its entirety, these small architectural variances should not be too glaring:

View attachment 200379

View attachment 200388

So, I’m just finishing up the low finial of the lower finishing. I will wait to paint these until after final fitting:

View attachment 200390

View attachment 200389

Once those are in place, I can concentrate on making the window section above.

Now that I know the North East Joint Clubs meeting is slated for October, I will try to get a certain amount of work done. I would like to get the upper bulwarks up and painted, the structure of the upper stern framed and planked, the quarter deck installed, and perhaps make a start on the galley stove.

Given my pace, so far, this is ambitious, but not altogether impossible. When I last showed the thing, two years ago, it was merely a collection of un-assembled parts. However far I get, it will be a vast improvement.

As ever, thank you for stopping by, and for your likes and comments. Happy Holidays!

View attachment 200385

Amazing work once again Marc,

I would think the shape of the stern is very subjective and without good accurate drawings these things are really only a best educated guess, an interpretation of someone else's art work.

Cheers,

Stephen.