Finally - the head!

In observing Druxey’s excellent carved works for his Speedwell project, these past few days, it dawned on me that definition of the brow and position of the nose were the key determinants for getting started.

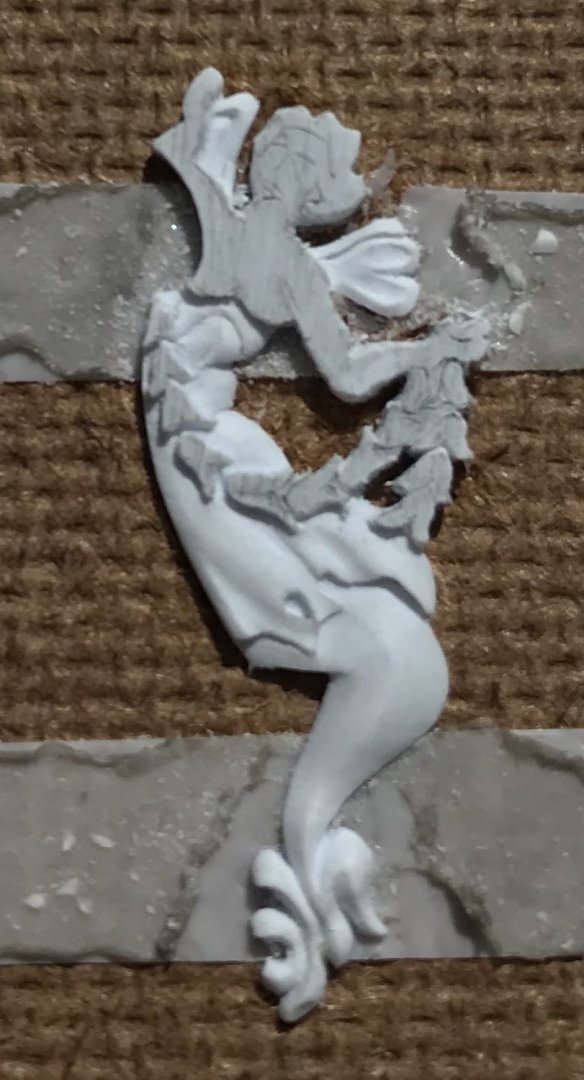

I began by digging down around the hairline, first with score cuts of the EXACTO, followed by pairing slices of the BEEBE. The idea is to approach at a steep enough angle that you creep towards the previously scribed brow line. Keep in mind that this head is just about the size of a pencil eraser head:

Once the hairline had been cut deeply enough, and I was satisfied with the rough slope of the forehead, I cut to the line beneath the left brow and down the nose line, setting it in relief. Again, in-between light scoring cuts, I use the BEEBE - this time with a scraping motion - to clear waste and to begin contouring the face around the eye socket.

It bears mentioning that I never intended to represent the roundness of the eye, itself.

I then cut beneath the right brow, scraped waste and began contouring the cheek area with scraping cuts.

At this stage, I started to worry that I was sculpting the MerAngel of Death, and that maybe I should have her holding a scythe, because her facial features began to seem skeletal.

When the carving becomes discouraging, like this, the best thing to do is take a breath and evaluate.

After leaving it for an hour, I came back and determined that now was a good time to rough in the mouth because its presence would cue me toward how and where to shape the cheeks and chin:

As I’ve drawn it, the mouth is just a soft diamond shape. It is achieved with four angled, stab cuts of the EXACTO, that converge at the bottom of the cut. I, then, use the heal of the EXACTO to dig out the waste and extend the corners of the mouth.

Although, in the above picture, you can see that I also began to contour the nose, I think it is evident that the simple addition of the mouth animates the face.

From there, it was a simple, but deliberative process of defining recesses and hollows around the cheeks and chin until the face appeared more cherubic than Skellator.

There does come a point, though, where one has to stop before they risk un-doing all that they worked so hard to arrive at. I found that point, and so I shifted my focus to shaping the coif: defined parts of the hair, rounds and hollows. it doesn’t take much to suggest the movement and shape of hair.

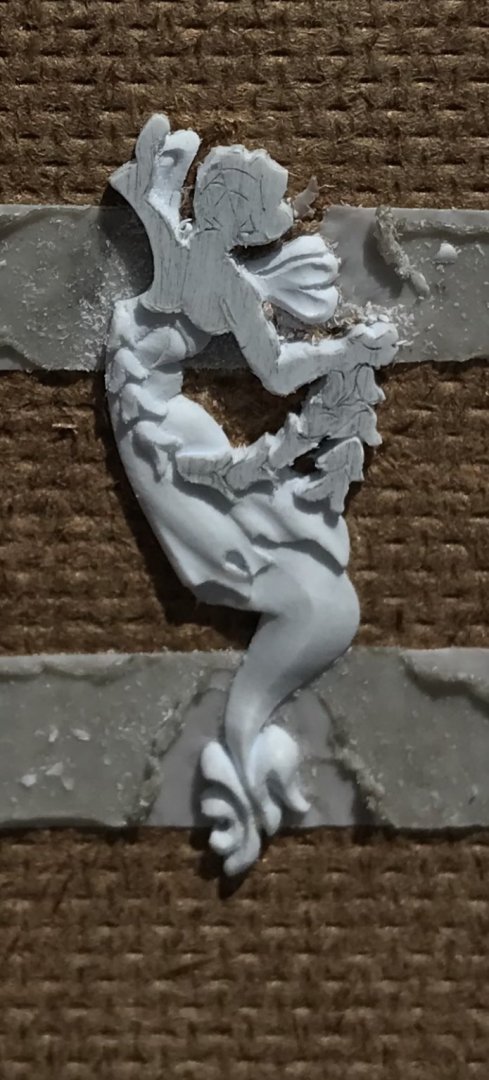

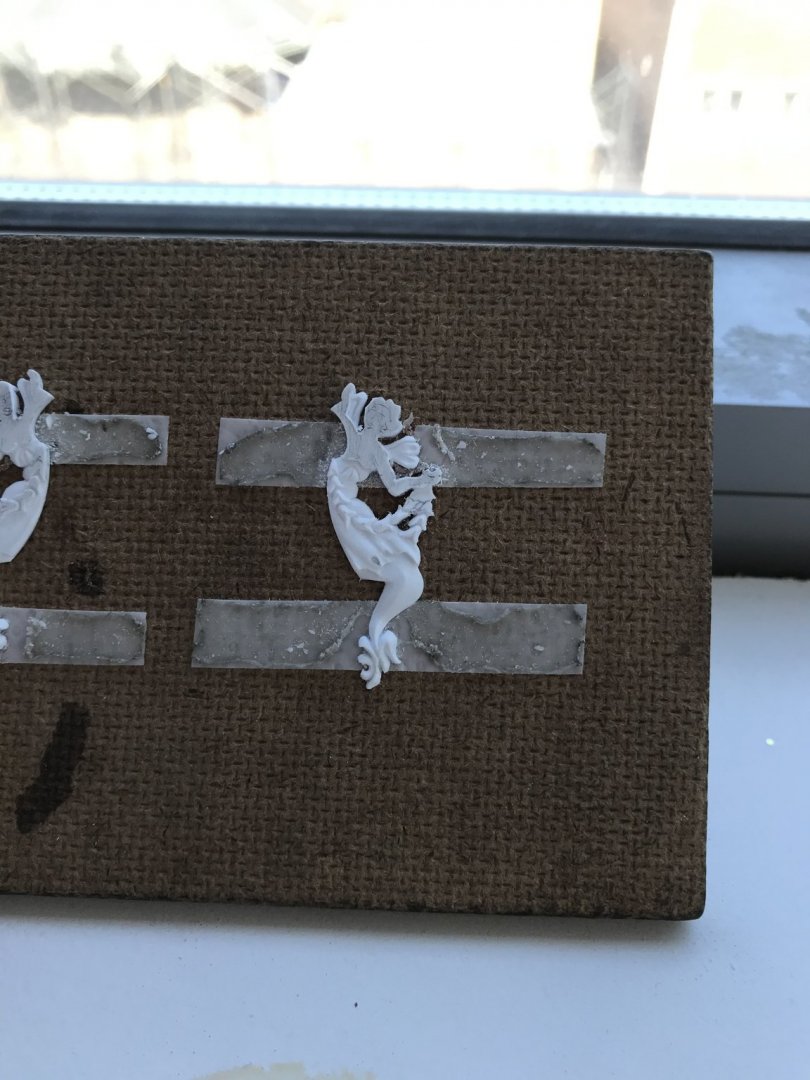

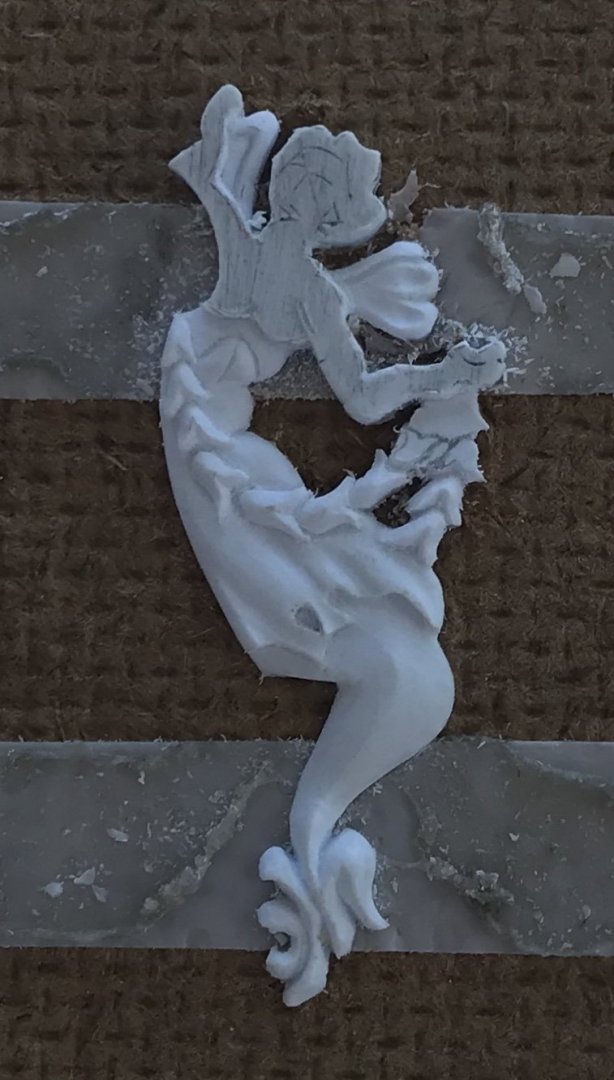

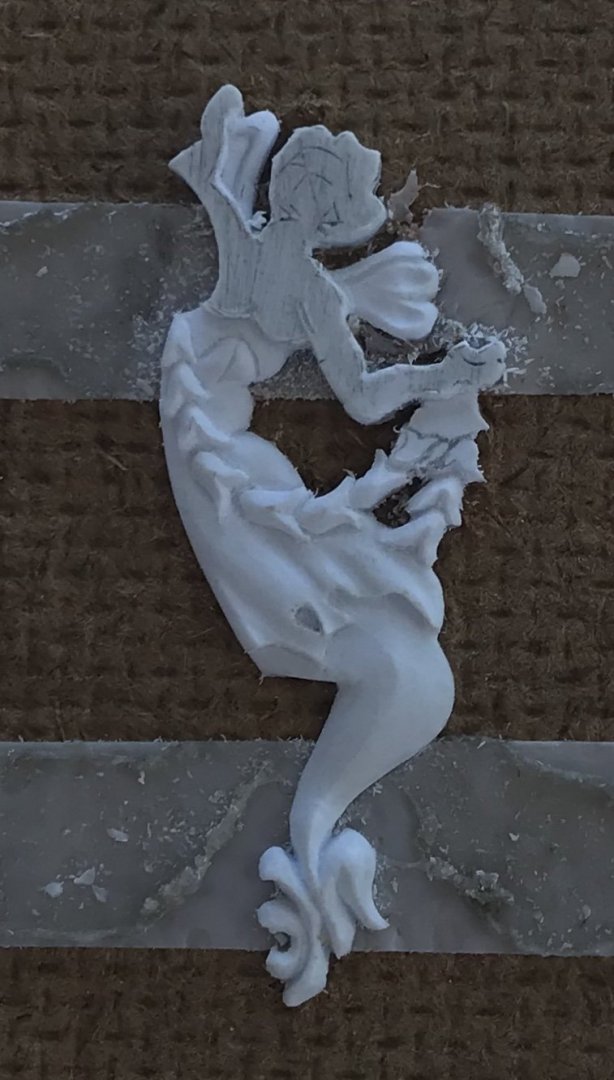

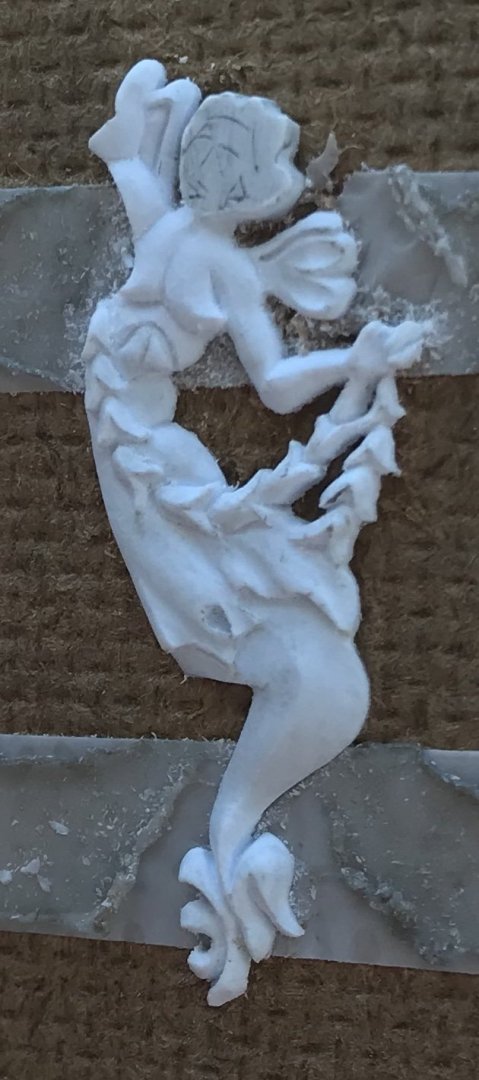

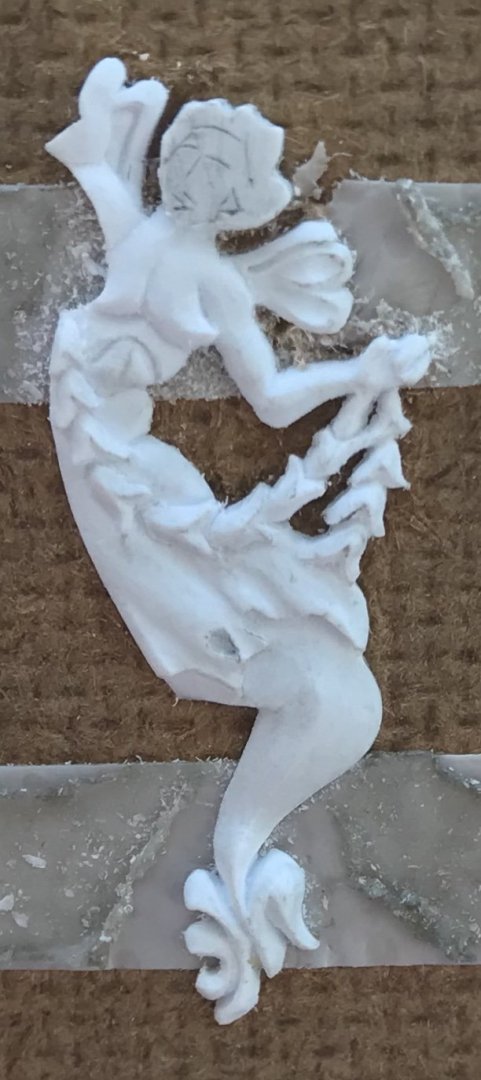

The completed figure:

I’m not 100% satisfied with the nose, but I have at least five more faces, like this, to carve for the ship, so I think I will get better at it, as I go.

Although the difference is very, very slight, you may notice that the bust profile has changed a little. A friend on the site PM’d me to offer a gentle critique. His thought was that, perhaps as I first shaped the one full breast, the end was a little too severe.

I agreed with him and attempted to soften the very end of the breast, and make it a little more natural looking. To some degree, the prior shaping of the breast limits modification, at this stage, but I do think this is a little bit better.

I want to say that I appreciate the courage it sometimes takes to offer constructive criticism - particularly when it involves matters of artistic interpretation, and most especially when it involves anatomy. We live in our bodies, full time, yet it has become increasingly difficult to talk about them without fear of offense. Anyway, I appreciated that.

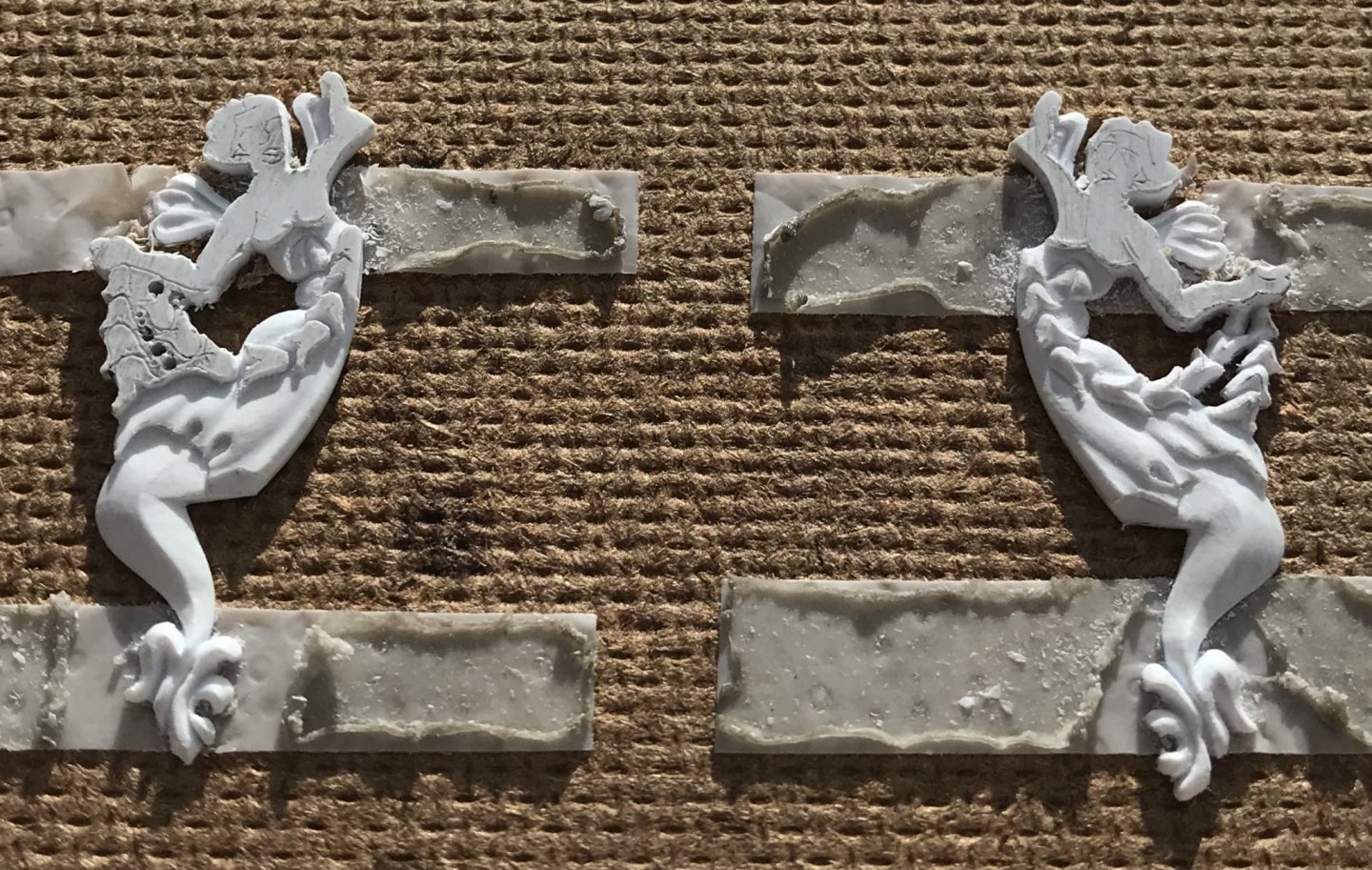

So, I will complete the second carving, and then I will immediately begin the other pair of MerAngels that flank the forward edge of the quarter gallery amortisment. I have figured out what I need to modify, on these figures, so that I don’t have to eliminate my aft-most octagonal port.

It is best to launch right into more figures because the mode of seeing and thinking that it requires is now active in my mind. If I really have the stamina left, after that, I may even carve the pair of bow angels. It may be better to wait on them, though, to see exactly how all of the elements of the head come together.

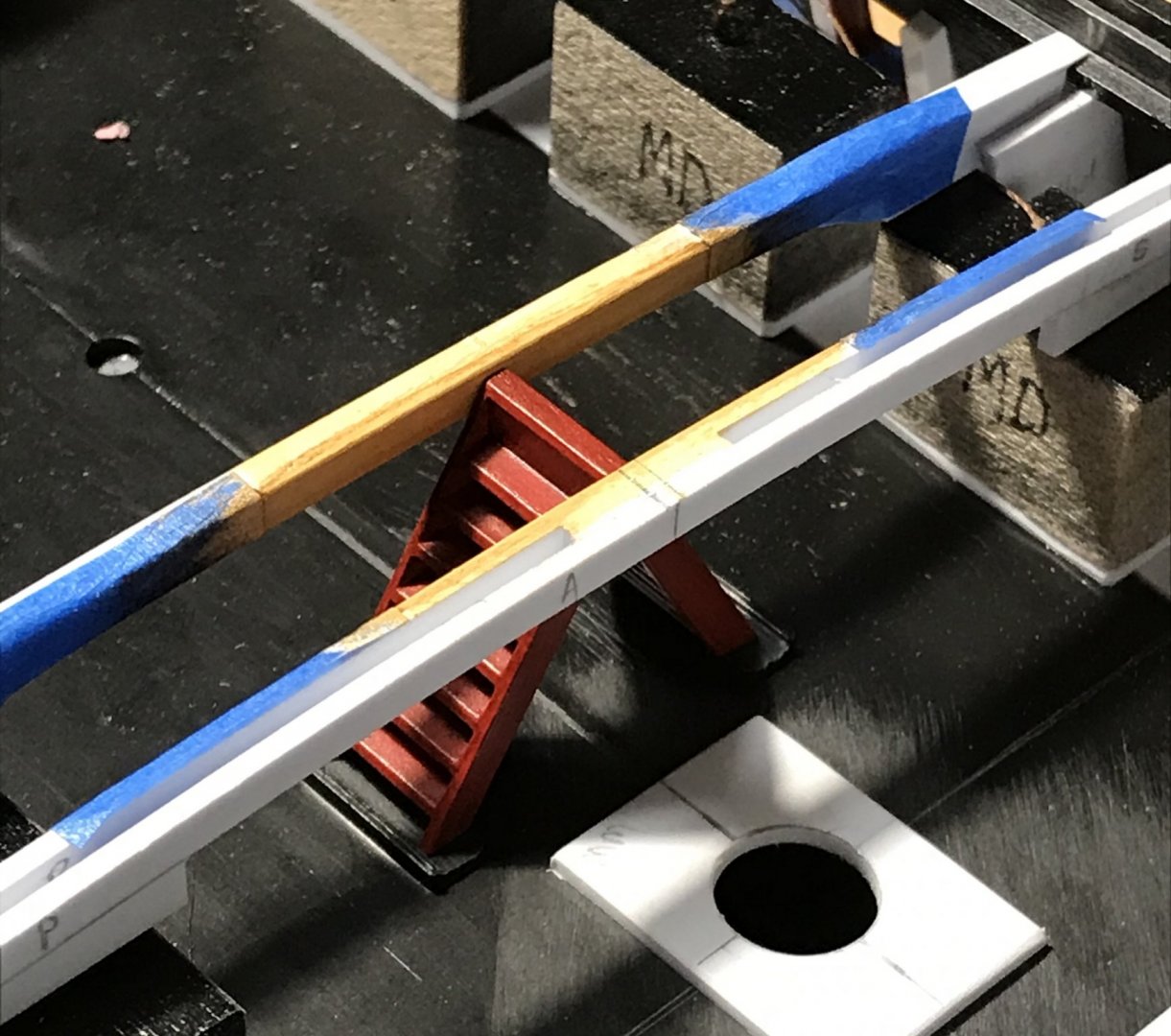

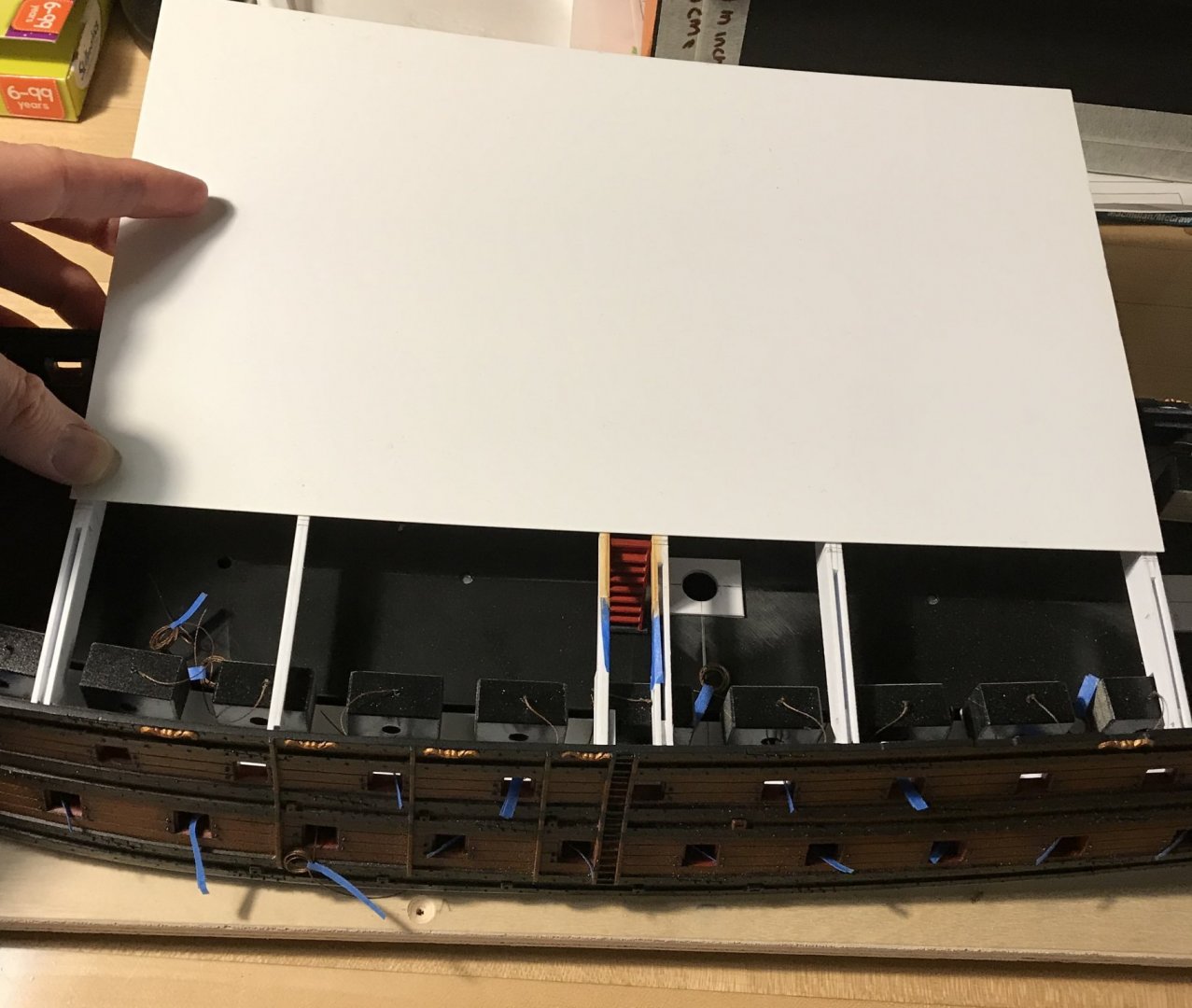

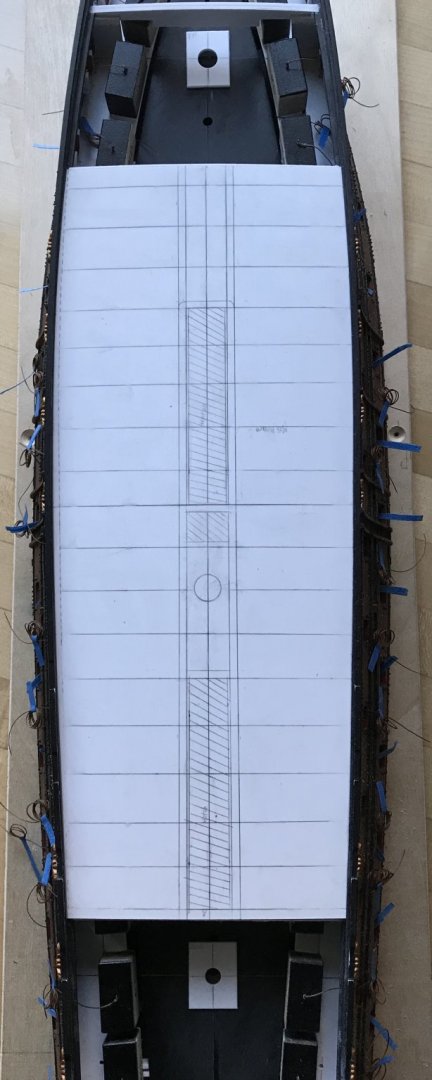

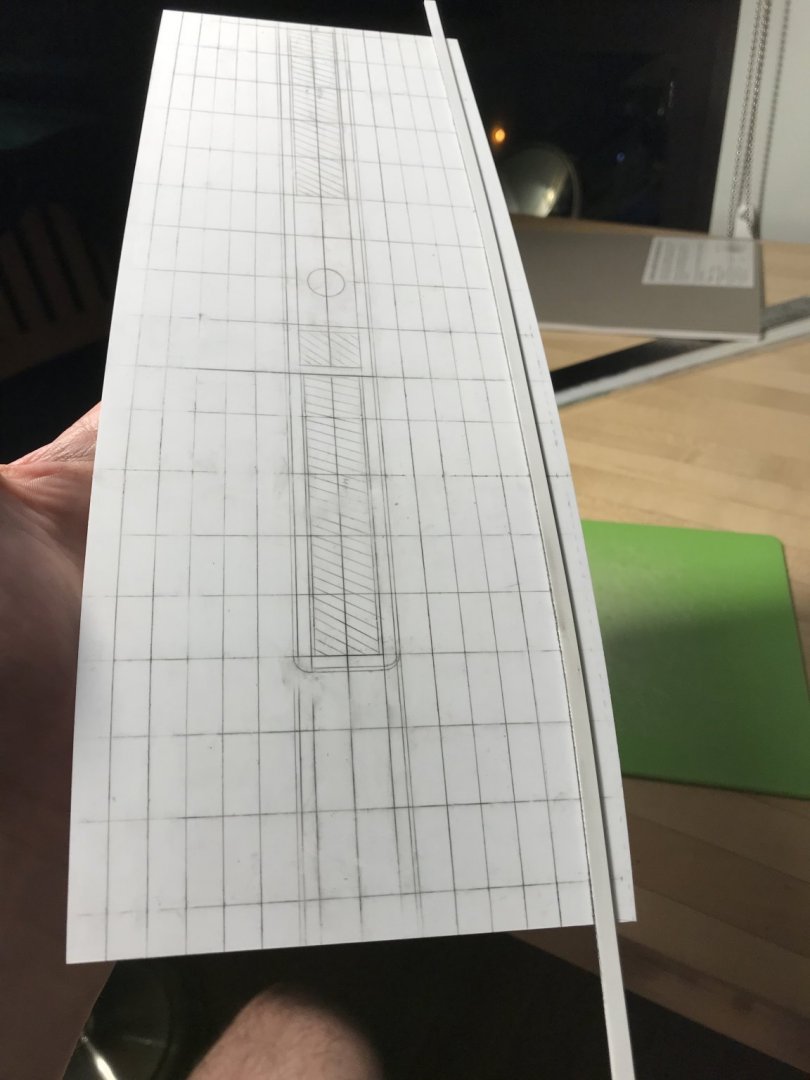

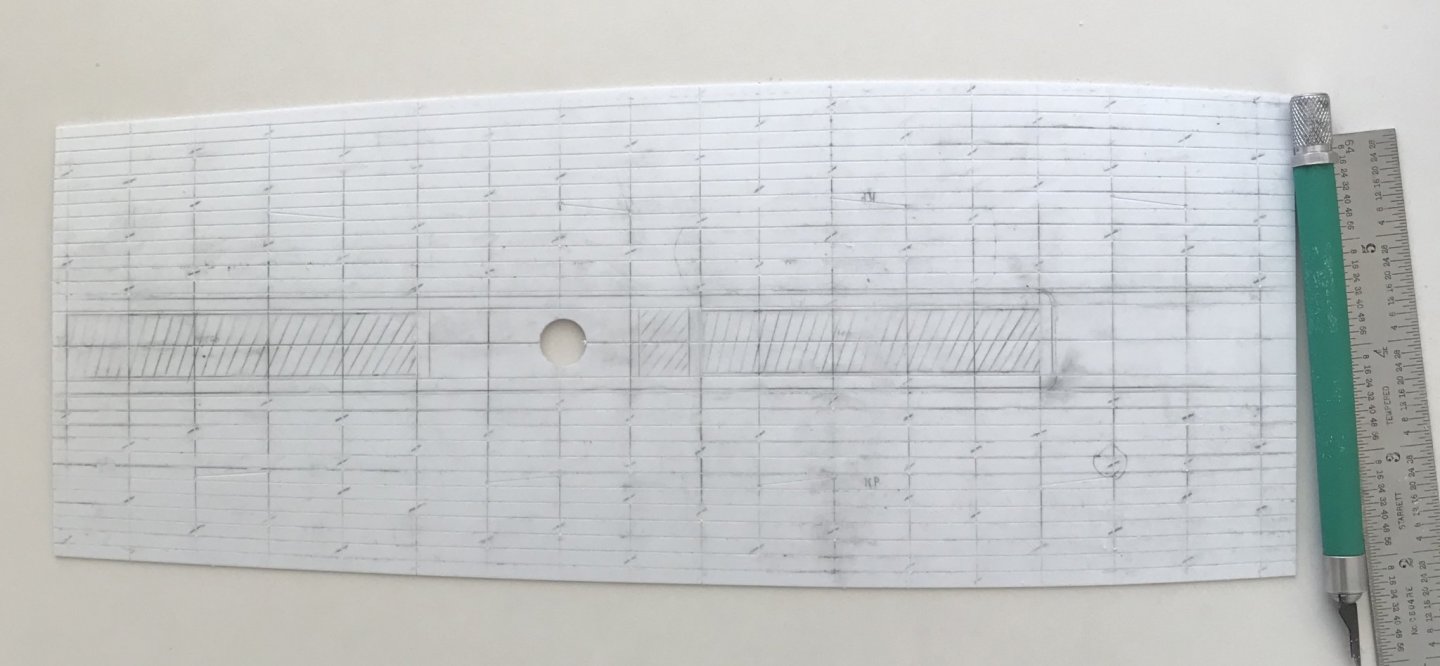

In other news, I have completed my main deck layout and begun engraving the plank seams. Now that I can see the entire layout, I really am not that bothered by the extra plank+, on the port side. I remembered that there’s a plank companionway, above the waist guns, that bridges the forecastle and quarter decks.

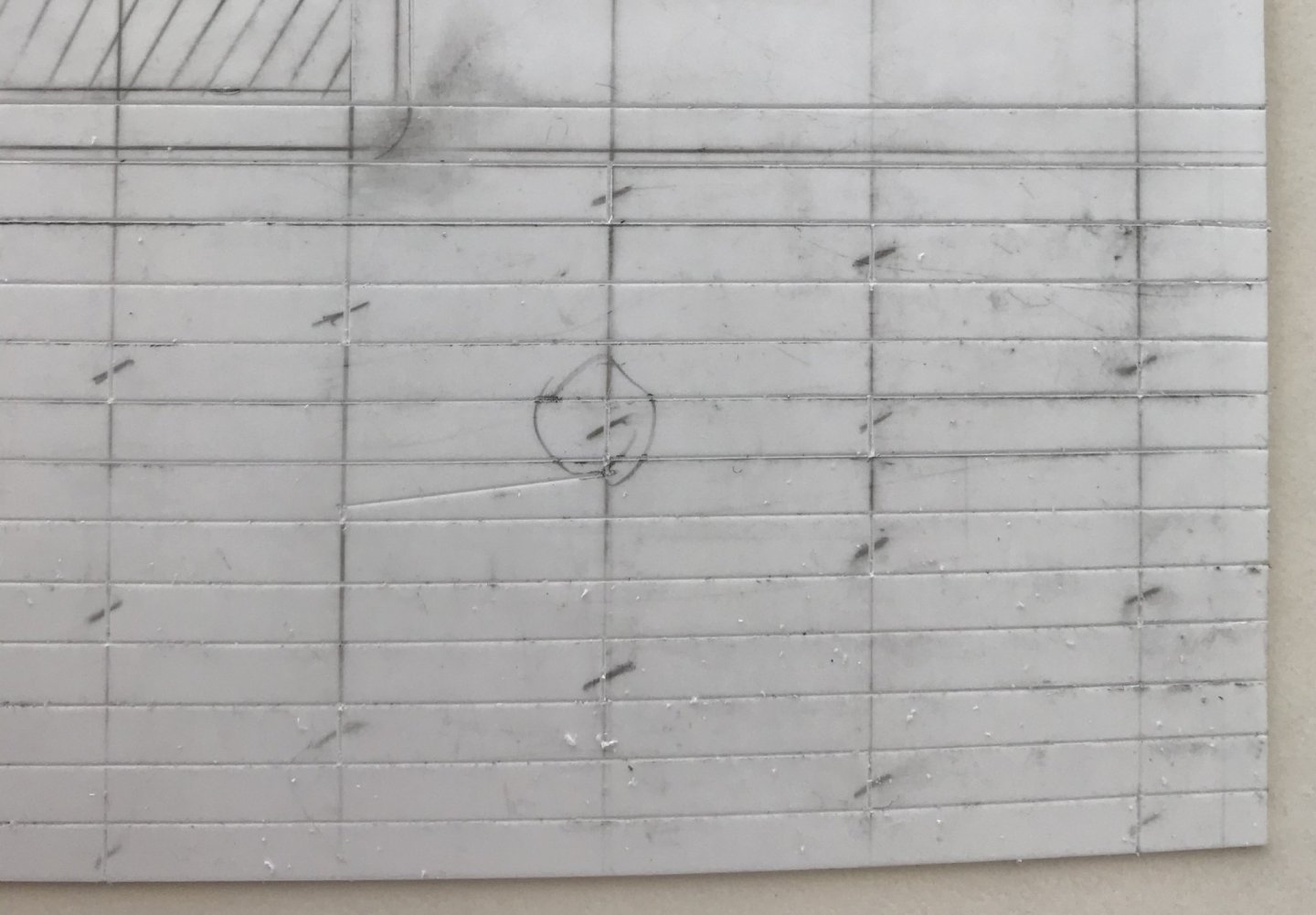

I also enlarged the main mast hole, in the main deck just enough so that I could plumb the mast perfectly. The mast plate, between the coamings, will be a tight fit and will secure the plumb position of the mast.

Onward and upward! Thanks for looking in.