Thank you Jim!

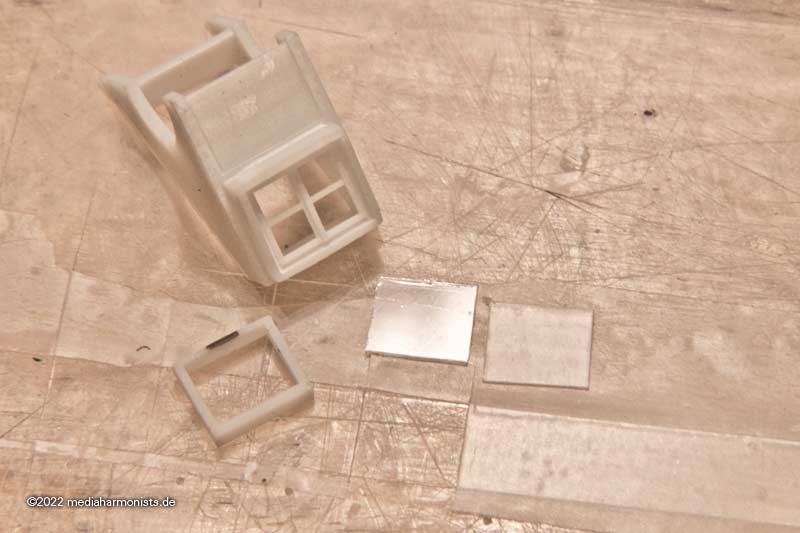

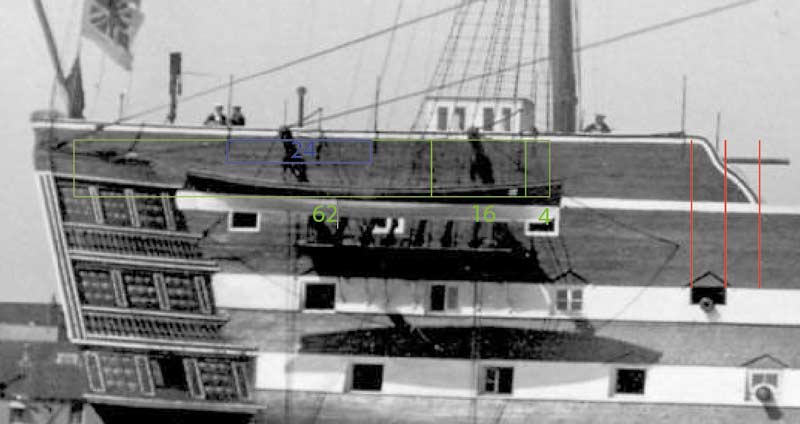

In the meantime, the white parts are also finished. And always these brain pictures. These were the two Trafalgar guns in the first attempt ...

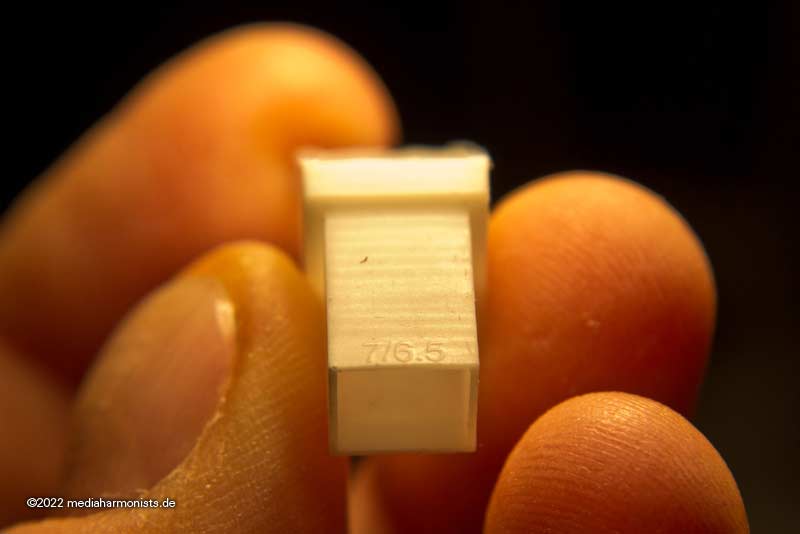

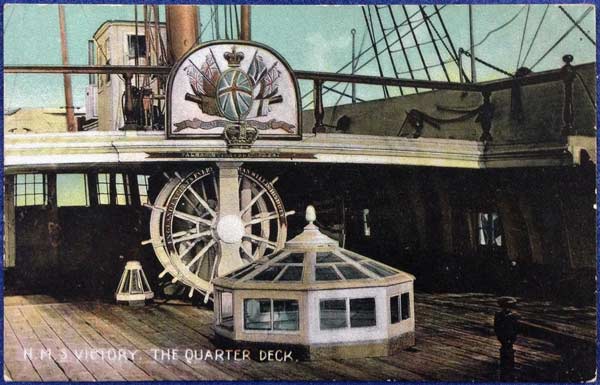

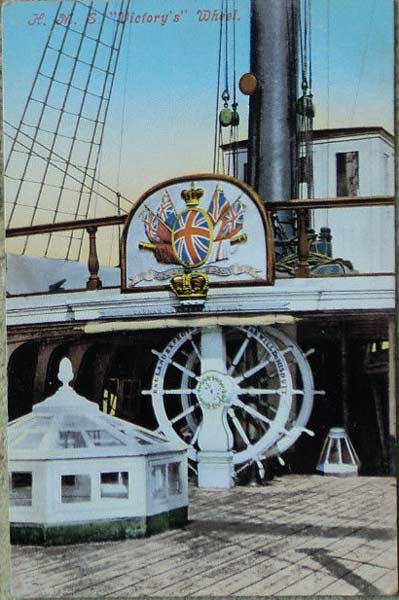

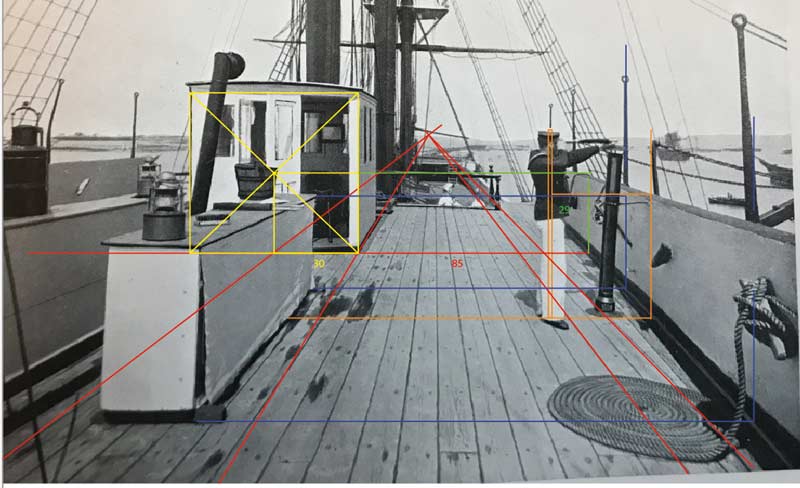

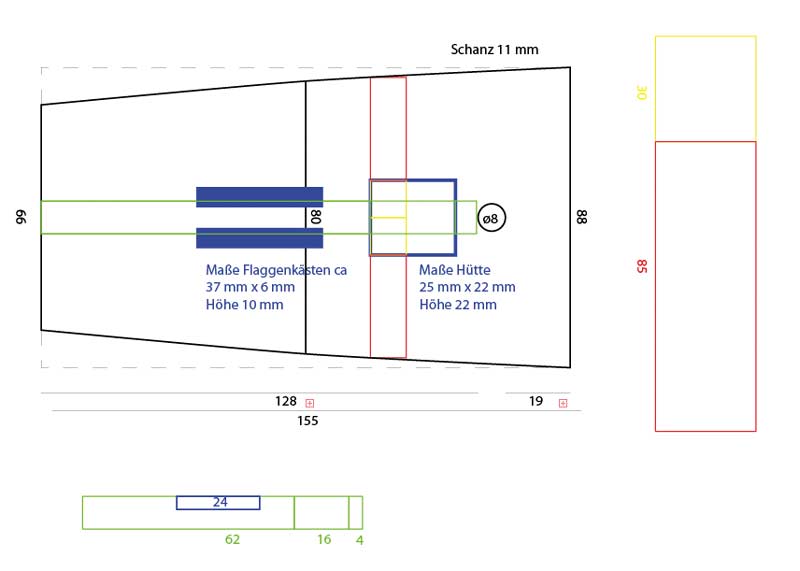

... but when I checked the window dimensions again ...

... crap, the panes only have two parts. Three parts were at the guns in the upper deck.

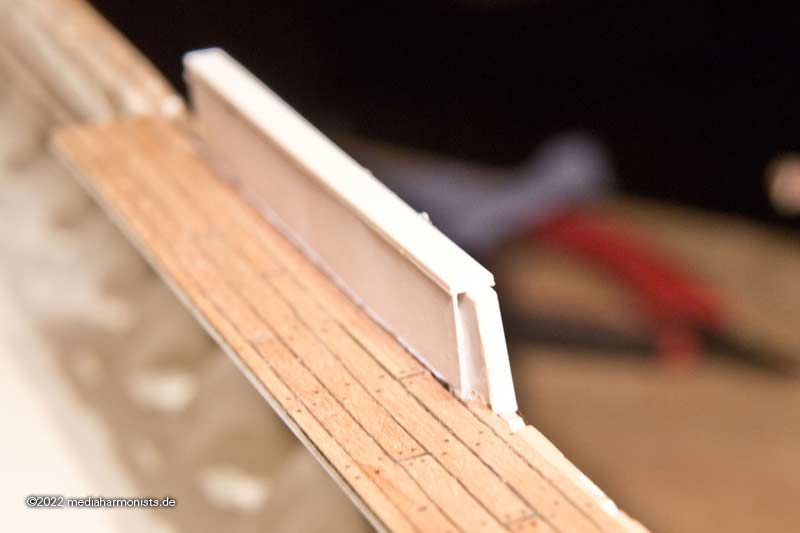

Then glued in the frame as before ...

... filler pieces glued in for better support ...

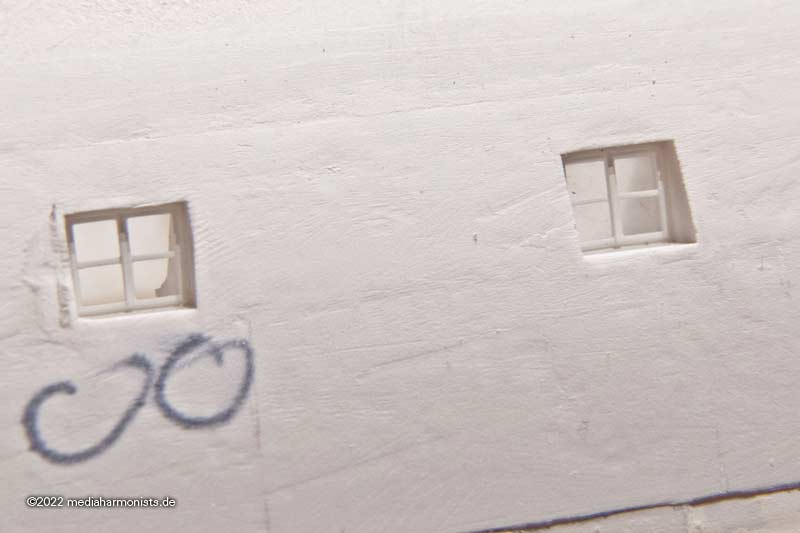

... and filled with putty

This deck is also only inlaid, because I will have to to take it out again and work on the inside later to put the window panes into the frames. For this I will trim back the carriages. That's why I made the new triangular cut-outs on the frontside of the carriage.

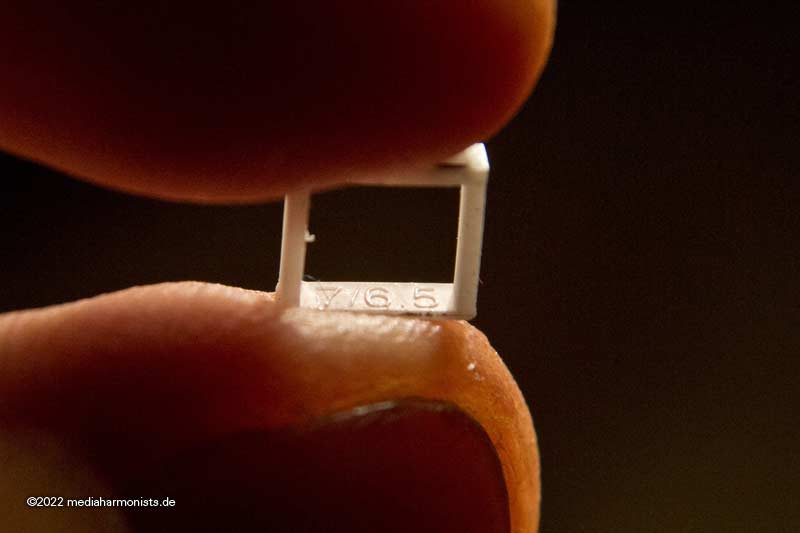

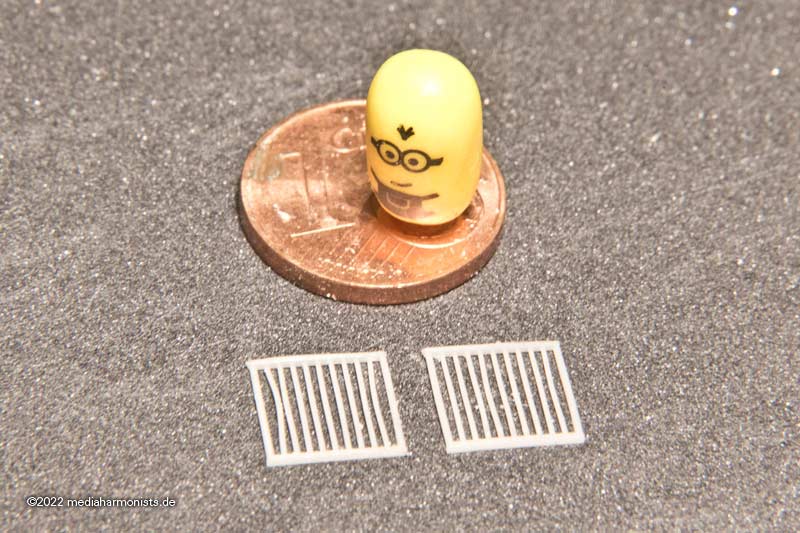

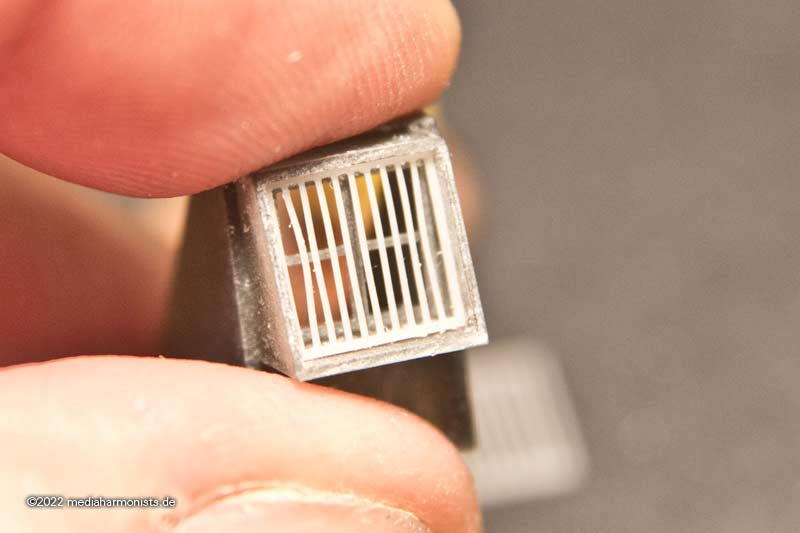

And I also did a test print. The foremost window in the lower deck had window bars. These are very fine.

And they are to be fitted into the already fixed frames. You can see, however, that they are so fine that slight distortions occur when printing - since no supports can be used. Since the frame has too little undersize for its hole, this is of course exacerbated.

And then again AAAAARGHH! With the dimensions of this bit, I got the first rectangular version and not the frames with a lower height that were used in the end ...

... ok, can be corrected with the next print, maybe the distortion will be better too.

XXXDAn