You've gotta love those old school electrical parts. They sure don't make them like they used to. Everything is held together with screws, and you can fix it easily. Today's equivalent is just some sort of cheap plastic snapped and permanently glued together. If it breaks, you have to order a different part online.OK, ladies and gentleman, If I can call you that....

First up today is repair of the motor power cord. So first step was to remove the black tape to see damage, then inspect wire to actual damage which looks like a not so friendly rat or squirrel might have nibbled on.

I think I had show the power cord and damage in another posting so here is repairs.

I stripped back insulation on cord till I got to damages spot, which exposed about 4" of wire. Then I measured what I needed from original ends for installation.

Next up was to cut and strip the wires and solder the new ends for installation in the switch housing.

View attachment 534375

then it was time to reinstall the cover and check how it fit and went together, all was well at this point with repairs.

... Last but not least was a quick test run and all was well.

-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

-

PRE-ORDER SHIPS IN SCALE TODAY!

The beloved Ships in Scale Magazine is back and charting a new course for 2026!

Discover new skills, new techniques, and new inspirations in every issue.

NOTE THAT OUR FIRST ISSUE WILL BE JAN/FEB 2026

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unimat Hobby Lathe Restoration

- Thread starter Kurt Konrath

- Start date

- Watchers 16

UNIMAT produced a riser block to significantly give more swing.

I see that Kurt has the table saw accessory, and while I don't have one and can't be absolutely certain, I'll add that I believe the headstock riser block must be used with the table saw accessory so that the table is raised high enough for the back end of the table to clear the motor when the table is mounted on the lathe.

UNIMAT produced a riser block to significantly give more swing.

View attachment 534419View attachment 534420

Yes, EMCO did make a headstock riser block for the Unimat SL/DB. This is reportedly used with the table saw accessory to raise the table high enough for the table to clear the motor when mounted on the lathe. (The square cross-slide milling table may require it for the same reason, but I've never tried that, so I can say so for sure.) There has been discussions on the Unimat forums regarding the availability of a tailstock riser and, until your posting above, nobody has ever been able to confirm the existence of a Unimat factory part tailstock riser. I've never seen one in the manuals or advertisements. It's been something of an ongoing mystery why. It appears I may be looking at one. Certainly, the chuck and the tailstock dead center are at the same height, and it appears your machine has a tailstock riser in place. If so, can you offer any explanation. Was there ever a "unicorn" Unimat tailstock riser? Is yours a shop-built part? Can you post a "all sides" pictures of yours?

Thanks much!

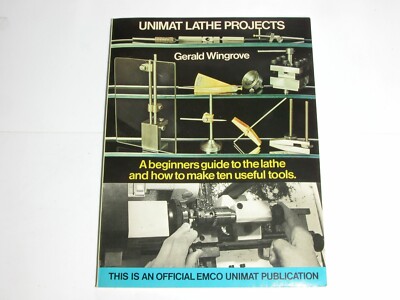

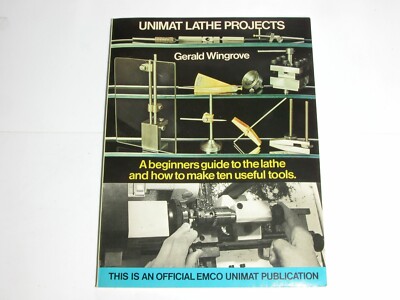

I don't recall whether I mentioned it before, but the late Gerald Wingrove's book, The Techniques of Ship Modeling, should be on every Unimat owner's bookshelf. Wingrove, probably one of the greatest all-around miniaturists of the last fifty years, made extensive use of the Unimat SL/DB. His Techniques of Ship Modeling generally addresses all manner of scratch-building techniques for ship modeling, including setting up a workshop space, Wingrove had at one time a "representative" position with Unimat and wrote several Unimat publications on the care and use of the Unimat SL/DB lathe. Although not a Unimat publication, Techniques is chock full of details on the use of the Unimat SL/DB lathe is ship modeling and addresses several very useful shop-made accessories, such as a pattern copying jig for turning identical duplicate parts. See: https://www.amazon.com/Techniques-Ship-Modelling-Gerald-Wingrove/dp/B002K4SS6M

- Joined

- Apr 21, 2018

- Messages

- 868

- Points

- 353

The Wingrove UNIMAT Primer....I don't recall whether I mentioned it before, but the late Gerald Wingrove's book, The Techniques of Ship Modeling, should be on every Unimat owner's bookshelf. Wingrove, probably one of the greatest all-around miniaturists of the last fifty years, made extensive use of the Unimat SL/DB. His Techniques of Ship Modeling generally addresses all manner of scratch-building techniques for ship modeling, including setting up a workshop space, Wingrove had at one time a "representative" position with Unimat and wrote several Unimat publications on the care and use of the Unimat SL/DB lathe. Although not a Unimat publication, Techniques is chock full of details on the use of the Unimat SL/DB lathe is ship modeling and addresses several very useful shop-made accessories, such as a pattern copying jig for turning identical duplicate parts. See: https://www.amazon.com/Techniques-Ship-Modelling-Gerald-Wingrove/dp/B002K4SS6M

Unimat Lathe Projects by Gerald Wingrove | eBay UK

A beginners guide to the lathe and how to make 10 useful tools by Gerald Wingrove, new.

www.ebay.co.uk

The Wingrove UNIMAT Primer....

Unimat Lathe Projects by Gerald Wingrove | eBay UK

A beginners guide to the lathe and how to make 10 useful tools by Gerald Wingrove, new.www.ebay.co.uk

Obscenely expensive, likely because it had a very small print run. Published in 1999, it addressed the Unimat 3 lathe, successor to the Unimat SL/DB lathe which itself was discontinued in 1990. It would appear the book was "dead on arrival." See USA eBay: https://www.amazon.com/product-revi...show_all_btm?ie=UTF8&reviewerType=all_reviews

- Joined

- Apr 21, 2018

- Messages

- 868

- Points

- 353

Bob, unfortunately I don't own one.Yes, EMCO did make a headstock riser block for the Unimat SL/DB. This is reportedly used with the table saw accessory to raise the table high enough for the table to clear the motor when mounted on the lathe. (The square cross-slide milling table may require it for the same reason, but I've never tried that, so I can say so for sure.) There has been discussions on the Unimat forums regarding the availability of a tailstock riser and, until your posting above, nobody has ever been able to confirm the existence of a Unimat factory part tailstock riser. I've never seen one in the manuals or advertisements. It's been something of an ongoing mystery why. It appears I may be looking at one. Certainly, the chuck and the tailstock dead center are at the same height, and it appears your machine has a tailstock riser in place. If so, can you offer any explanation. Was there ever a "unicorn" Unimat tailstock riser? Is yours a shop-built part? Can you post a "all sides" pictures of yours?

Thanks much!

All photo's I may use will be factory kit unless I mention otherwise.

I have photo's of a a vast library of their kit options; I don't own half as much as I'd like.

I could spend weeks downloading this material, but won't!

I am happy to share here what I can on specific requested items.

The ones I posted include the matching tail stock riser, so between center work can still be done.

The table saw photo includes the headstock riser.

They did a nifty little machine vice too.

Last edited:

- Joined

- Apr 21, 2018

- Messages

- 868

- Points

- 353

This I DO have a copy of!Obscenely expensive, likely because it had a very small print run. Published in 1999, it addressed the Unimat 3 lathe, successor to the Unimat SL/DB lathe which itself was discontinued in 1990. It would appear the book was "dead on arrival." See USA eBay: https://www.amazon.com/product-revi...show_all_btm?ie=UTF8&reviewerType=all_reviews

Though the cover shows the Mk 3, most of the contents were SL related.

At the time of publication the Mk3 was relatively new.

The Wngrove Techniques of Ship Modeling book is quite common and cheap to buy here.

Last edited:

Bob, unfortunately I don't own one.

All photo's I may use will be factory kit unless I mention otherwise.

I have photo's of a a vast library of their kit options; I don't own half as much as I'd like.

The ones I posted include the matching tail stock riser, so between center work can still be done.

The table saw photo includes the headstock riser.

They did a nifty little machine vice too.

I have the machinist's vise. Nicely made item.

If that's an EMCO photo, then they must have made a tailstock riser. It's got to be the rarest part of all. I've shopped eBay for Unimat parts for years, just to keep an eye on the market, if nothing else, and I've never, ever seen a tailstock riser. It's easy enough to make one, I suppose, but I've never seen one offered for sale.

Another project on my list!

- Joined

- Apr 21, 2018

- Messages

- 868

- Points

- 353

Bob, once again you have piqued my interest; upon re-visiting the riser photo's I posted, you may well be correct; those risers aren't the normal factory colour.I have the machinist's vise. Nicely made item.

If that's an EMCO photo, then they must have made a tailstock riser. It's got to be the rarest part of all. I've shopped eBay for Unimat parts for years, just to keep an eye on the market, if nothing else, and I've never, ever seen a tailstock riser. It's easy enough to make one, I suppose, but I've never seen one offered for sale.

Another project on my list!

I'll come back on that tomorrow.

Kurt has raised the profile of UNIMAT and laudably got favourable responses.

When I got my lathes and tried to encourage interest around 10 years ago, all I got was derision from folk telling me the UNIMAT was obsolete and way inferior to admittedly superior modern equivalents.

Kurt Konrath

Kurt Konrath

- Joined

- Apr 21, 2018

- Messages

- 868

- Points

- 353

Kurt, one of these would be useful... an alignment bar.Like me, old is not necessarily obsolete....

And I do have the head stock riser in the package I got with my Unimat.

Only issue with original is no hole for headstock alignment pin!

View attachment 534537

This is a copy of UNIMAT's own.

Kurt Konrath

Kurt Konrath

I have never seen that bar before, but one vendor of books and belts sells a version of that.

I have never seen that bar before, but one vendor of books and belts sells a version of that.

I've never seen an EMCO-made alignment bar, either. I have one from Little Machine Shop. It's quite handy if you are 1. going to be moving the headstock a lot or 2. want as accurate a cut as possible. The headstock locating pin (which is an item quite frequently lost) is probably just roughly aligned, due to wear or slippage, although I've never clocked mine. If you want as close to perfect alignment as possible, it's best to use an alignment bar, although the old razor blade held between two dead centers trick will yield a very close equivalent. $31 online. See: https://www.amazon.com/UNIMAT-lathe-alignment-bar-LatheCity/dp/B017FSXKI8

Only issue with original is no hole for headstock alignment pin!

As far as I know, they never made a riser for the tailstock, so there would be no reason to align the headstock exactly because there would be no reason to do so without a tailstock. The headstock riser came as part of the table saw attachment. .It raises the headstock, and hence the table saw table, so it will fit clear above the the motor.

It is quite possible that EMCO considered the use of headstock risers on both the headstock and tailstock for turning larger work to be inadvisable. As a workpiece diameter increases, the faster it turns and the greater leverage it places on the cutting tool. Those increases may have exceeded the designed parameters of the machine and they didn't want to encourage people burning out motors and otherwise breaking their Unimats by overloading them. I have no factual evidence of this, though. It's just a theory to explain why there's no tailstock riser in the catalog.

Kurt has raised the profile of UNIMAT and laudably got favourable responses.

When I got my lathes and tried to encourage interest around 10 years ago, all I got was derision from folk telling me the UNIMAT was obsolete and way inferior to admittedly superior modern equivalents.

Indeed he has!

The fact is, I don't think a lot of people know enough about machine tools to recognize the quality, nor the versatility, of the Unimat. Its main drawback is that it's no longer made, and parts are hard to come by. The Sherline products don't have that limitation, for the time being, but they cost a lot more money for really no greater accuracy or capacity and, if you want both turning and milling ability, you get both with a Unimat, but you have to buy both a lathe and a milling machine for twice the price of a Unimat which does both.

There's no question that Byrnes Model Machines produces a far better table saw and disk sander, or that a jig or scroll saw of better quality than Unimat's are available today, but I think anybody would be hard put to find fault with the Unimats for modeling work and the models of all the major modelers of the last sixty years or so seems to confirm that.

Kurt Konrath

Kurt Konrath

Thanks for the info on the alignment bar. I have seen one video on a similar pin for this purpose and how it was used, they said about 95% accuracy with this method, which is good enough for general work.I've never seen an EMCO-made alignment bar, either. I have one from Little Machine Shop. It's quite handy if you are 1. going to be moving the headstock a lot or 2. want as accurate a cut as possible. The headstock locating pin (which is an item quite frequently lost) is probably just roughly aligned, due to wear or slippage, although I've never clocked mine. If you want as close to perfect alignment as possible, it's best to use an alignment bar, although the old razor blade held between two dead centers trick will yield a very close equivalent. $31 online. See: https://www.amazon.com/UNIMAT-lathe-alignment-bar-LatheCity/dp/B017FSXKI8

View attachment 534700

Kurt Konrath

Kurt Konrath

I have seen some 3D printable files for a tailstock riser block, and even one for tool rest as well.

they said about 95% accuracy with this method, which is good enough for general work.

I expect you'll want better than 95% accuracy at some point. The headstock alignment pin is really only for "quick and dirty" centering of the headstock when using attachments like the table saw, etc. It's not intended for precision work. "95% accuracy" is plus or minus five hundredths of an inch. The machine is easily capable of working to tolerances of plus or minus two thousandths of an inch. Big difference when you are making small things that need to fit.

Precision depends upon the alignment of the head and tailstock, as is true of every lathe. The convenience of an alignment bar is that it is precisely machined to be perfectly round in section and to fit precisely into the headstock and tailstock holes. When the bar is held in the holes, by inserting it and sliding the tailstock towards the headstock to hold it, your headstock and tailstock are perfectly aligned. It just takes seconds to do.

Another, more fiddly way to align the headstock and tailstock is to put dead centers in each and run the points of the dead centers together until the fetch up against a razor blade held between the points. Using a small machinist's square for a reference, the headstock is adjusted on its axis until the points hold the razor blade vertically. If the points are out of alignment, the razor blade will tilt one way or the other.