Thank you for the prompt response, glad everything you need arrived fast. Way to go @Dave Stevens (Lumberyard) thank you for providing our members with quality timber.That is ebony, may end up needing to order some thicker pieces depending on the method I choose for planking the Wales.

This, like all my wood for projects is from Dave at Lumberyard. Very nice order put together, took about two weeks to arrive.

-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

-

PRE-ORDER SHIPS IN SCALE TODAY!

The beloved Ships in Scale Magazine is back and charting a new course for 2026!

Discover new skills, new techniques, and new inspirations in every issue.

NOTE THAT OUR FIRST ISSUE WILL BE JAN/FEB 2026

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The boards for the frames have been milled down to between 5.3 - 5.35 mm.

The final frames are measured at about 10.6 mm. Likely to be 10.5mm once completely sanded. For now they fit together very well happy with the outcome.

We'll see if these are enough boards, I'm thinking probably not. There's 148 frames to make but I only have 15 2" x 24x boards. We'll find out!

Next up is getting all the plans copied so I can cut them up and paste them to the boards. I have a large scanner but for those of you in the US do you have any suggestions where to get these plans copied? They're huge and the best I can figure is taking them to a FedEx and having them copied.

The final frames are measured at about 10.6 mm. Likely to be 10.5mm once completely sanded. For now they fit together very well happy with the outcome.

We'll see if these are enough boards, I'm thinking probably not. There's 148 frames to make but I only have 15 2" x 24x boards. We'll find out!

Next up is getting all the plans copied so I can cut them up and paste them to the boards. I have a large scanner but for those of you in the US do you have any suggestions where to get these plans copied? They're huge and the best I can figure is taking them to a FedEx and having them copied.

Thats very nice looking timber. The Lumberyard has great wood.

We'll see if these are enough boards, I'm thinking probably not. There's 148 frames to make but I only have 15 2" x 24x boards. We'll find out!

I im pretty sure, that you will need more boards - just checked, and counted, that each frame has 16 / 17 parts like floor timber, futtocks or top timbers.

This frigate is really a big ship and will get a really big model, especially in this scale of 1:48

Imagine, that you have 148 frames with 16 parts are all together appr. 2.400 parts. You have now 24 boards, so on each board you have to cut out somehow 100 parts......

- Joined

- Dec 3, 2018

- Messages

- 2,450

- Points

- 538

@ Gventura, I scan all the drawings of Rattlesnake in a place called Staples, which I think is an international group, they also save the drawings on a memory stick, PDF.

I know that it is possible to cut out relevant parts of the PDF drawing with Adobe and print on your own printer in actual size.

I have tried this but have not been able to, so far.

Regards Knut-

I know that it is possible to cut out relevant parts of the PDF drawing with Adobe and print on your own printer in actual size.

I have tried this but have not been able to, so far.

Regards Knut-

Next up is getting all the plans copied so I can cut them up and paste them to the boards.

Delacroix prepared all together 4 plansheets with frames, and each shown frame is overlapping the next one - so to get a copy of each frame you have to make two copies of each plan

I would not make big size copies, but you can take the drawings to every copyshop and make "normal" copies. we here in Europe have DIN A3 size

so you will need 4 times a copy for the individual parts, maybe more because of the butt joints which you have to cut very accurate - better you make 8 copies so you do not have to cut directly at the joint.

and 2 additional copies for the overall template when you glue the parts together to fix the complete frame - so If I count correctly you will need 10 copies showing two frames (like above) ......

I am pretty sure the handling will be much easier with such "small" copies than cutting out of big copied plansheets

I agree. Its expensive to make copies that size. I want to do as you suggest have them copied and made a digital copy, then I can cut out the ones I need and print at home. I was thinking 4 copies of each but 8 copies of each sounds possible based on how you describe it.Delacroix prepared all together 4 plansheets with frames, and each shown frame is overlapping the next one - so to get a copy of each frame you have to make two copies of each plan

View attachment 307743

I would not make big size copies, but you can take the drawings to every copyshop and make "normal" copies. we here in Europe have DIN A3 size

View attachment 307744

so you will need 4 times a copy for the individual parts, maybe more because of the butt joints which you have to cut very accurate - better you make 8 copies so you do not have to cut directly at the joint.

and 2 additional copies for the overall template when you glue the parts together to fix the complete frame - so If I count correctly you will need 10 copies showing two frames (like above) ......

I am pretty sure the handling will be much easier with such "small" copies than cutting out of big copied plansheets

Agreed, I think 100 is too many per board lol, but I won't know until I get the copies. My guess is maybe 40-50 per board. Once I do the first one I can order more boards. And I have wood for other things so while I wait I can work on things like the keel.I im pretty sure, that you will need more boards - just checked, and counted, that each frame has 16 / 17 parts like floor timber, futtocks or top timbers.

This frigate is really a big ship and will get a really big model, especially in this scale of 1:48

View attachment 307740

Imagine, that you have 148 frames with 16 parts are all together appr. 2.400 parts. You have now 24 boards, so on each board you have to cut out somehow 100 parts......

Or even put together the jig once I have a copy of the plate I need to make that. Lots of moving parts!

- Joined

- Oct 15, 2017

- Messages

- 1,191

- Points

- 443

I also use Staples in my town. Framing plans certainly amount for the largest cost as pointed out by Uwe. As a precaution, I have Staples scan certain plates, save as PDFs and load electronic copies onto a thumb drive, flash drive, etc. I've not yet run into any plan sizes that Staples was not able to manage.

Would you share what large format scanner you are using? If I understand correctly, it can scan large formats, but not print them?

Cheers,

Ken

Would you share what large format scanner you are using? If I understand correctly, it can scan large formats, but not print them?

Cheers,

Ken

I also use Staples in my town. Framing plans certainly amount for the largest cost as pointed out by Uwe. As a precaution, I have Staples scan certain plates, save as PDFs and load electronic copies onto a thumb drive, flash drive, etc. I've not yet run into any plan sizes that Staples was not able to manage.

Would you share what large format scanner you are using? If I understand correctly, it can scan large formats, but not print them?

Cheers,

Ken

Oddly I don't have a Staples near by, but I'll see about doing that. When I built the Hannah the plans were obviously significantly smaller so I was able to scan them myself. I have a DocuMate 4700 that can scan a 12" x 18" paper, but these framing plans are at least twice that and while I could try and scan them in sections at a time I'd be concerned that would distort the image.

I USE FED-X FOR COPIES THEY ARE GREAT AND VERY, VERY ACCURATE TO THE ORIGINAL YES THE ANCRE PLANS ARE EXPENSIVE TO COPY BUT WELL WORTH THE MONEY JUST ME. GOD BLESS STAY SAFE ALL DON

Let me share this process because it was going to be very expensive and now it's going to be very cheap.

I took the 6 plates I needed copies of to FedEx as suggested (found out OfficeMax and Staples offer similar services). Scanning is super easy, it's about $3 to scan each plate, scanned them all at the highest DPI as possible which is 600. They need to be scanned as PDF not JPG, otherwise the sizing will not be accurate. Now here is the difference, as noted above you'll need at least 4-5 copies of each individual frame, because they overlap that would mean 8-10 copies of each plate. As I found out it cost about $10 per copy of each plate because it's about 4.5' long, so we're talking $400 or so just for framing copies! That's crazy.

Now I have a printer that can print A3 or 11"x17" pages. If you don't have one then this doesn't work, but if you do this often it may be worth investing. So I spent $60 on the cheapest ream of 1500 pages of A3 I could find. I opened the scanned copies and cropped the image as close to each frame as possible. Here is what they look like:

Taking all these PDFs you print them on Actual Size and auto-orientation.

I now have each frame on its own sheet. I'm about 40 copies short of the complete set, since I decided to start with 4 copies of each of the 76 frame.

Point being, if you're going to be doing this more than once you can invest a few hundred dollars in a large format printer (about $200-300), and $60 in 11"x17" paper for roughly the same cost as having a service scan and print. That's also assuming that you're only making copies of the frames. It becomes even more useful if you need copies of other plates, which is likely.

Anyway, just wanted to share my process, because I already had the printer it cost me $60 in paper and $15 in scanning fees. Opposed to $200 - 400 to have it all printer for me. Granted it's taking me probably a day or so to edit and print all of this myself opposed to the 2 hrs it would have taken for someone to print for me. Hopefully this is helpful for someone in the future.

I took the 6 plates I needed copies of to FedEx as suggested (found out OfficeMax and Staples offer similar services). Scanning is super easy, it's about $3 to scan each plate, scanned them all at the highest DPI as possible which is 600. They need to be scanned as PDF not JPG, otherwise the sizing will not be accurate. Now here is the difference, as noted above you'll need at least 4-5 copies of each individual frame, because they overlap that would mean 8-10 copies of each plate. As I found out it cost about $10 per copy of each plate because it's about 4.5' long, so we're talking $400 or so just for framing copies! That's crazy.

Now I have a printer that can print A3 or 11"x17" pages. If you don't have one then this doesn't work, but if you do this often it may be worth investing. So I spent $60 on the cheapest ream of 1500 pages of A3 I could find. I opened the scanned copies and cropped the image as close to each frame as possible. Here is what they look like:

Taking all these PDFs you print them on Actual Size and auto-orientation.

I now have each frame on its own sheet. I'm about 40 copies short of the complete set, since I decided to start with 4 copies of each of the 76 frame.

Point being, if you're going to be doing this more than once you can invest a few hundred dollars in a large format printer (about $200-300), and $60 in 11"x17" paper for roughly the same cost as having a service scan and print. That's also assuming that you're only making copies of the frames. It becomes even more useful if you need copies of other plates, which is likely.

Anyway, just wanted to share my process, because I already had the printer it cost me $60 in paper and $15 in scanning fees. Opposed to $200 - 400 to have it all printer for me. Granted it's taking me probably a day or so to edit and print all of this myself opposed to the 2 hrs it would have taken for someone to print for me. Hopefully this is helpful for someone in the future.

Hello there, I had the same issue about how much wood to get , I started the Sussex navy board model 6 months ago ,my first scratch build, all i can say is I got enough to complete all the frames and keel with some extra, and I've been pretty busy with that , I also have the Bynes saw & thickness sander & they are awesome machines, I'll be following your build, good luck with everythingHello again everyone!

I'm in the process of gathering all the necessary materials and setting up the workshop, in the next couple weeks I hope to start on L'Egyptienne. I'll be working from the Ancre monograph plans for the 24 pound Frigate L'Egyptienne, review you can find here:

Planset review - L'EGYPTIENNE - french 24-prd frigate - 1799" in scale 1:48 by Gerard Delacroix

Planset Review: L'EGYPTIENNE 24-prd French frigate - 1799 in scale 1:48 by Gerard Delacroix alias our member @G. DELACROIX Brand new release, just some days ago published and already on my desk - many thanks to Gerard for the fast and safe postage. This very comprehensive and detailed...shipsofscale.com

The plan is to build her in pearwood, with basswood carvings, planking, and siding, and basswood carvings/accessories.

A little background on where I've been. I had taken a short break from my Hannah when we had a burglary, they took all of the tools and supplies because they were boxed nicely while I was moving things around. Luckily lots of the other things that were stolen were recovered; however, they threw away everything from the shipyard. So I've decided to call the Hannah complete and move onto a more ambitious project. The positive that came from all of this was that everything was insured, so I've outfitted an entirely new workshop and am very excited.

Many of the tools I was using previously have just been replaced with the same, except for a few important pieces.

I replaced my table saw, disc sander, and added a thickness sander from Byrnes Model Machines that I'm very excited to get started with.

The rest of the new tools I'll point out along the way. I spent a lot of time researching replacements and I'm really excited to get started.

The last thing I have to do is determine how much wood I'll need. I can't seem to find a way to calculate how much wood I should order. I'm trying to avoid making over a bunch of orders of the months just because the time it takes to arrive. So if anyone has any suggestions on how to make those calculations let me know! I did get a bandsaw so I plan on ordering billets and resaw the pieces myself to have more control over quality. Something I learned the hard way with the Hannah.

I am also going to try and do more videos instead of photos this time around, so we'll see how that goes!

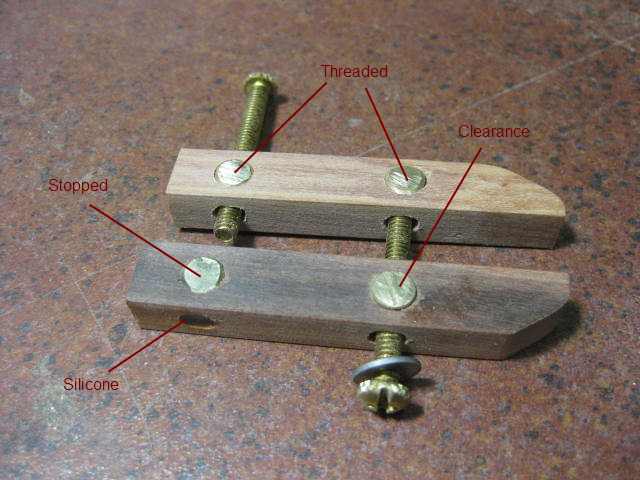

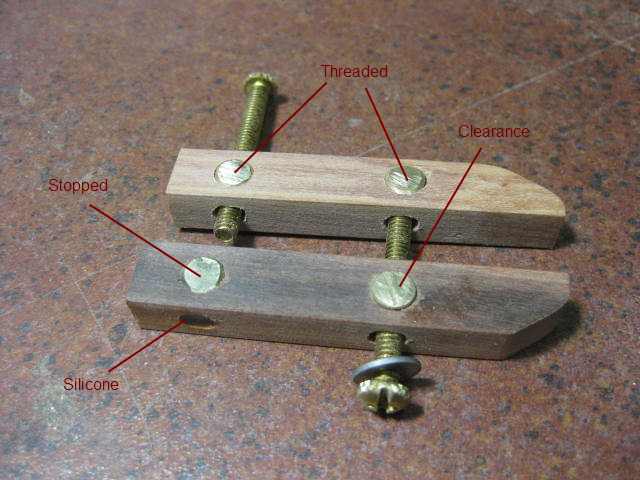

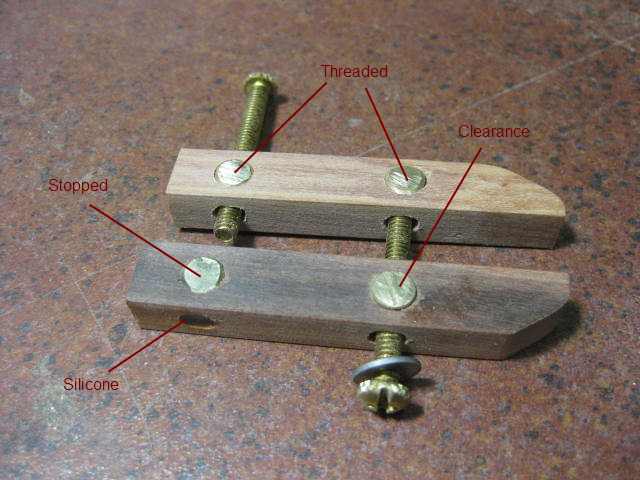

Has anyone built these? Particularly the Parallel Clamps. I'm trying to find the materials necessary in the US but having trouble. Anyone with any experience building them?

modelshipworld.com

modelshipworld.com

Useful Clamps for Fully Framed Models (and other models) by Dan Vadas

Hi all, I've had several requests to show how I built some special clamps that come in particularly useful if you are building a Fully Framed hull. They could also come in handy for other more "conventional" builds. There are three types of Clamp : 1. The first goes between Frames to hold interna...

modelshipworld.com

modelshipworld.com

I'm about to buy some myself online, toolmaker parallel clamps, usually made from steel come in several different sizes..Has anyone built these? Particularly the Parallel Clamps. I'm trying to find the materials necessary in the US but having trouble. Anyone with any experience building them?

Useful Clamps for Fully Framed Models (and other models) by Dan Vadas

Hi all, I've had several requests to show how I built some special clamps that come in particularly useful if you are building a Fully Framed hull. They could also come in handy for other more "conventional" builds. There are three types of Clamp : 1. The first goes between Frames to hold interna...modelshipworld.com

I'm about to buy some myself online, toolmaker parallel clamps, usually made from steel come in several different sizes..

Oh yeah? Link to a store?

- Joined

- Apr 20, 2020

- Messages

- 6,259

- Points

- 738

Taytools Toolmakers Machinist Parallel Clamps | Taylor Tools

Taytools Toolmakers Machinist Parallel Clamps

Grizzly T10079 - Machinist / Toolmakers Parallel Clamps, 2-Pk. - Grizzly Industrial, Inc.

These Blued Steel Parallel Clamps are ideal for hobby, gunsmithing and intricate assembly work. Jaws measure 3/8" wide and maximum jaw opening is 1-1/2". Sold per pair.

Steel Machinist Parallel Clamps | Toolmakers Clamps

Steel Machinist Parallel Clamps | Toolmakers Clamps

www.victornet.com

Amazon.com: 4 Piece Set Taytools 772195 2 Inch Parallel Toolmakers Machinist Clamps, Overall Jaw Length 2 Inches, Usable Jaw Depth 1-3/4 Inches, Usable Jaw Opening 1-1/2 Inches : Tools & Home Improvement

Buy 4 Piece Set Taytools 772195 2 Inch Parallel Toolmakers Machinist Clamps, Overall Jaw Length 2 Inches, Usable Jaw Depth 1-3/4 Inches, Usable Jaw Opening 1-1/2 Inches: Bench Vises - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

- Joined

- Oct 15, 2017

- Messages

- 1,191

- Points

- 443

Thanks for sharing this. It seems like a very cost effective solution for those who plan on scratch building PoF models.Let me share this process because it was going to be very expensive and now it's going to be very cheap.

I took the 6 plates I needed copies of to FedEx as suggested (found out OfficeMax and Staples offer similar services). Scanning is super easy, it's about $3 to scan each plate, scanned them all at the highest DPI as possible which is 600. They need to be scanned as PDF not JPG, otherwise the sizing will not be accurate. Now here is the difference, as noted above you'll need at least 4-5 copies of each individual frame, because they overlap that would mean 8-10 copies of each plate. As I found out it cost about $10 per copy of each plate because it's about 4.5' long, so we're talking $400 or so just for framing copies! That's crazy.

Now I have a printer that can print A3 or 11"x17" pages. If you don't have one then this doesn't work, but if you do this often it may be worth investing. So I spent $60 on the cheapest ream of 1500 pages of A3 I could find. I opened the scanned copies and cropped the image as close to each frame as possible. Here is what they look like:

View attachment 308479

Taking all these PDFs you print them on Actual Size and auto-orientation.

View attachment 308478

I now have each frame on its own sheet. I'm about 40 copies short of the complete set, since I decided to start with 4 copies of each of the 76 frame.

View attachment 308477

Point being, if you're going to be doing this more than once you can invest a few hundred dollars in a large format printer (about $200-300), and $60 in 11"x17" paper for roughly the same cost as having a service scan and print. That's also assuming that you're only making copies of the frames. It becomes even more useful if you need copies of other plates, which is likely..

Anyway, just wanted to share my process, because I already had the printer it cost me $60 in paper and $15 in scanning fees. Opposed to $200 - 400 to have it all printer for me. Granted it's taking me probably a day or so to edit and print all of this myself opposed to the 2 hrs it would have taken for someone to print for me. Hopefully this is helpful for someone in the future.

not so muchThanks for sharing this. It seems like a very cost effective solution for those who plan on scratch building PoF models.

keep in mind, that the

1) Egyptienne is really a very big and looooong vessel, so much more frames than usual

2) I guess only for the frames and cantframes etc a modeler will need 1 year or more for building, maybe 200 to 400 working hours only for the keel with frames

so in total costs per modeling hour scratch building is a very very cheap hobby

This I am telling everytime my wife, when a new box with new tools are arriving

Drinking beer in a bar is much more expensive