Up date time.

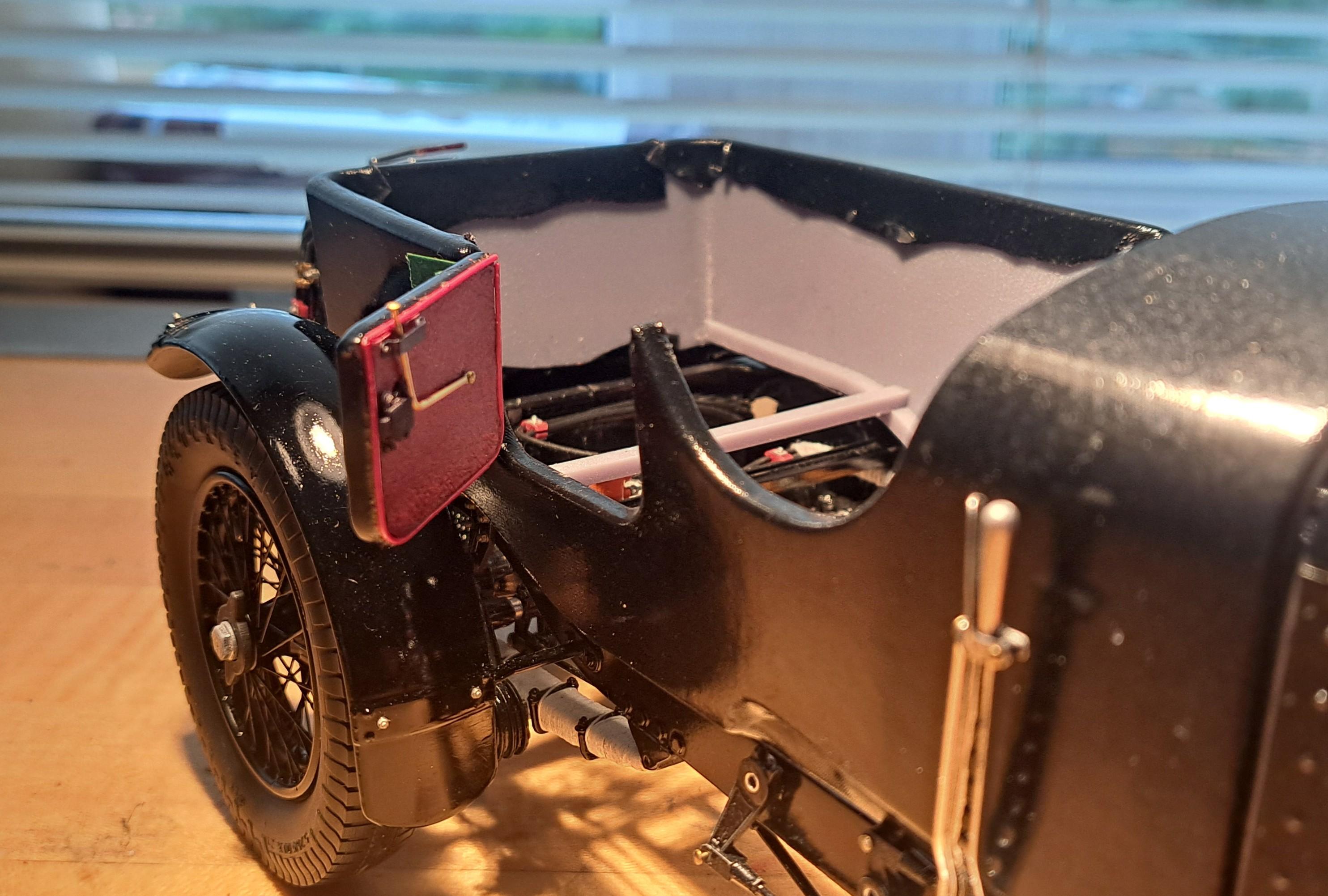

I'm slowly advancing the body. I made a full wrapping test using a 4 way stretch fabric. The result was pretty good but installation was very difficult. First, it needs to be glued using a spray on contact ciment. So once on, that is pretty much it. The edges once wrapped around don't hold very well since the material is so stretchy and contrary to leather, it doesn't react to well to ca glue.

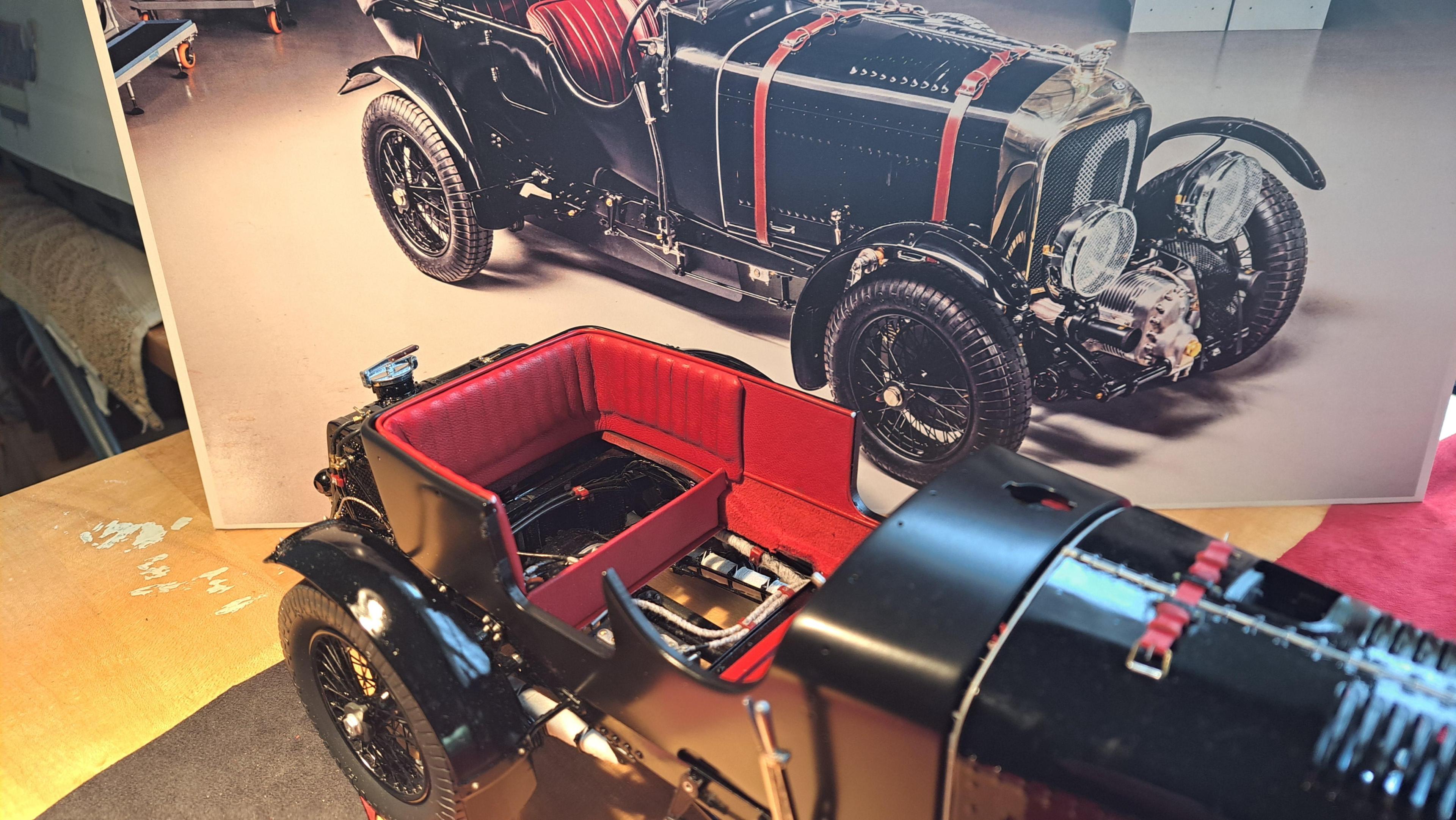

Here's what it looks like.

So I went back on the web to search some more and stumpled on a material called a vinyl car wrap which is basically a vinyl menbrane used to wrap over a car when you want to change color. And it just so happens that a big player in the car wrapping business is about 25 min from my house. There are many positive features to this product. First, it very cheap. 15$ for a 12in x 60in piece, big enough for at least 7 to 8 tries. Second, at only .005in (1/16in scaled up) , it's half the thickness of the 4 way fabric I tried and much more to scale. Third, it has heat activated glue on the back so I can reposition it as much as l like and once satisfied, apply heat to bond. And fourth, it's heat shrinking so once wrapped over the edges, you apply heat and it hucks the edge. I found a piece that is satin black that I think should look pretty good.

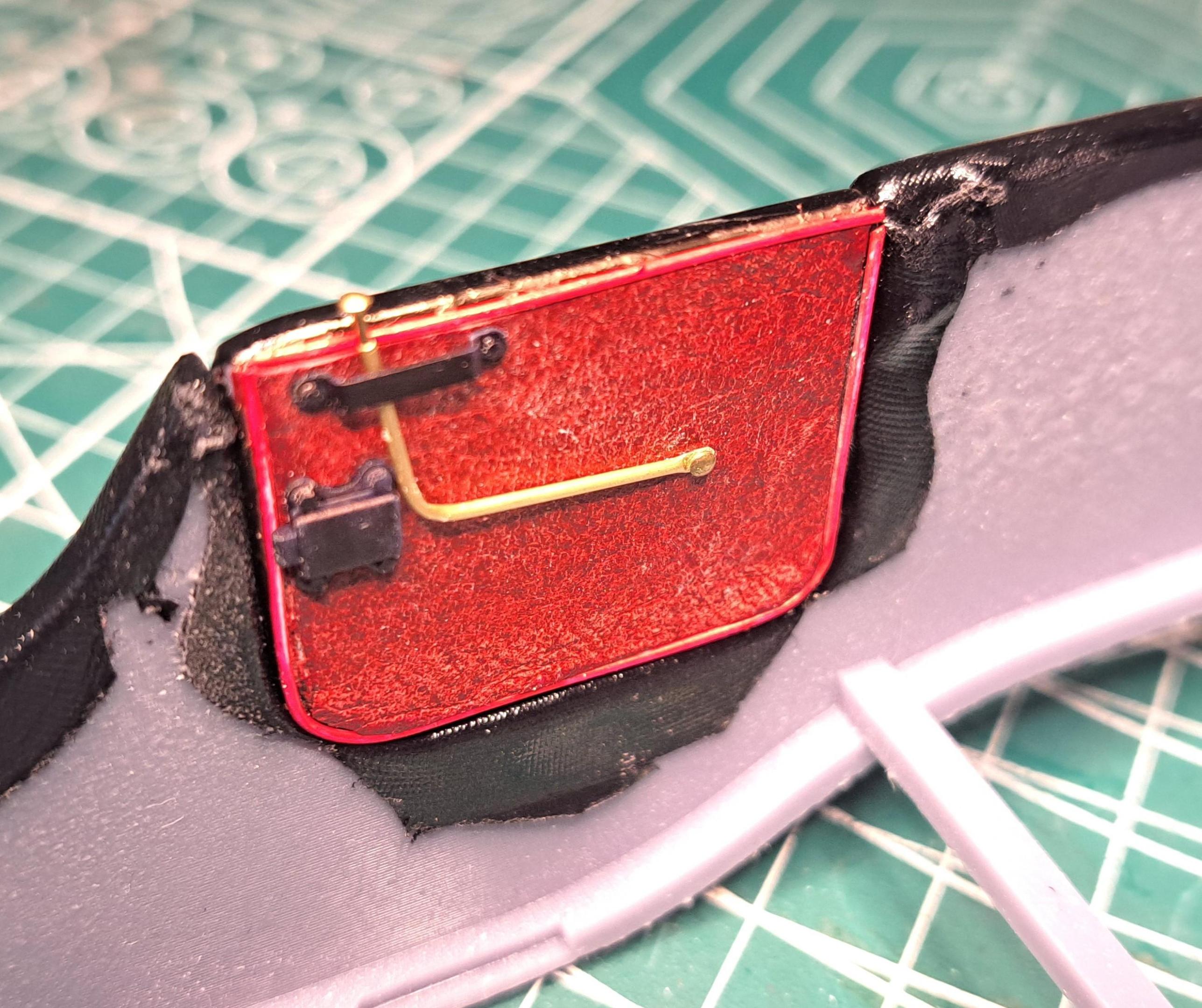

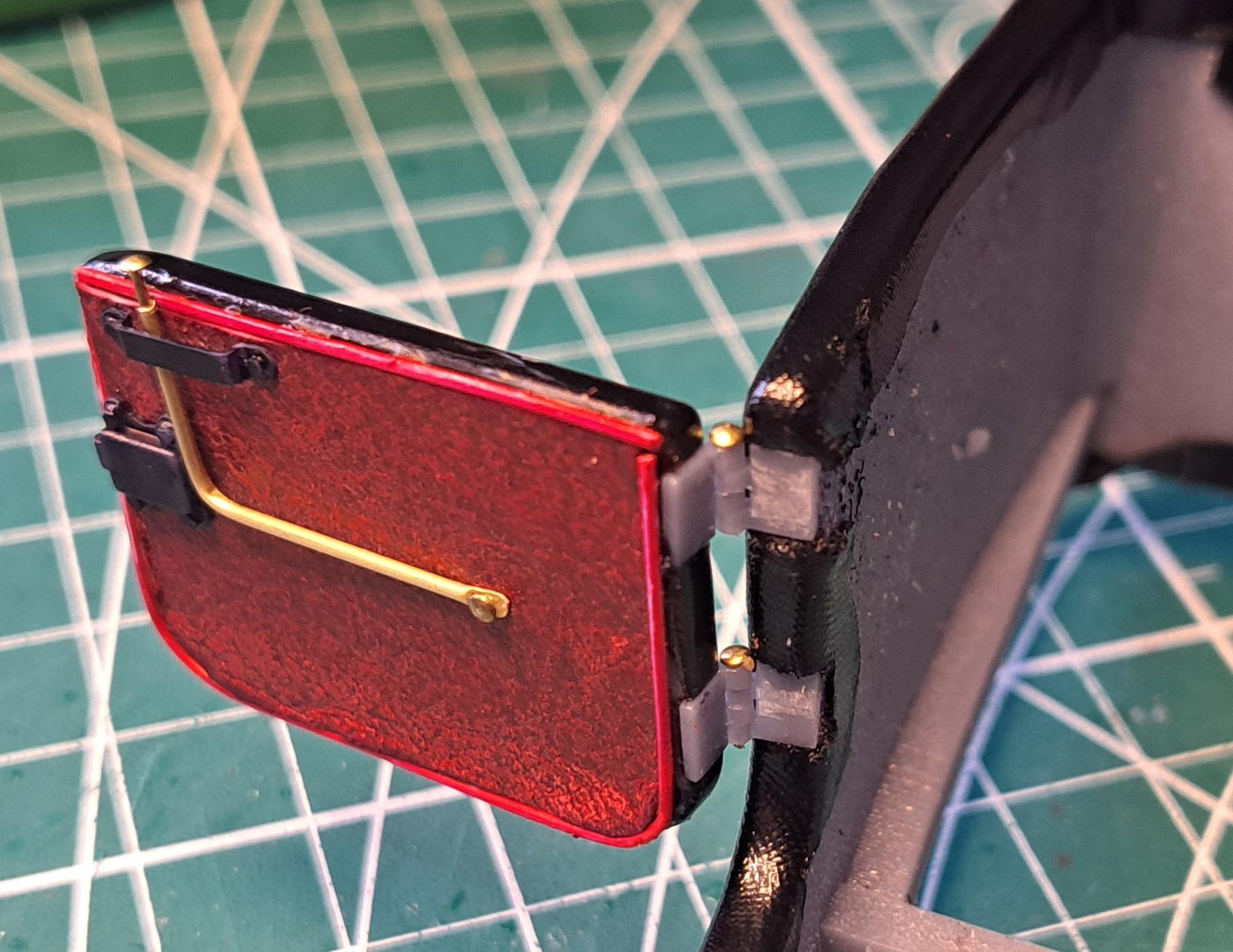

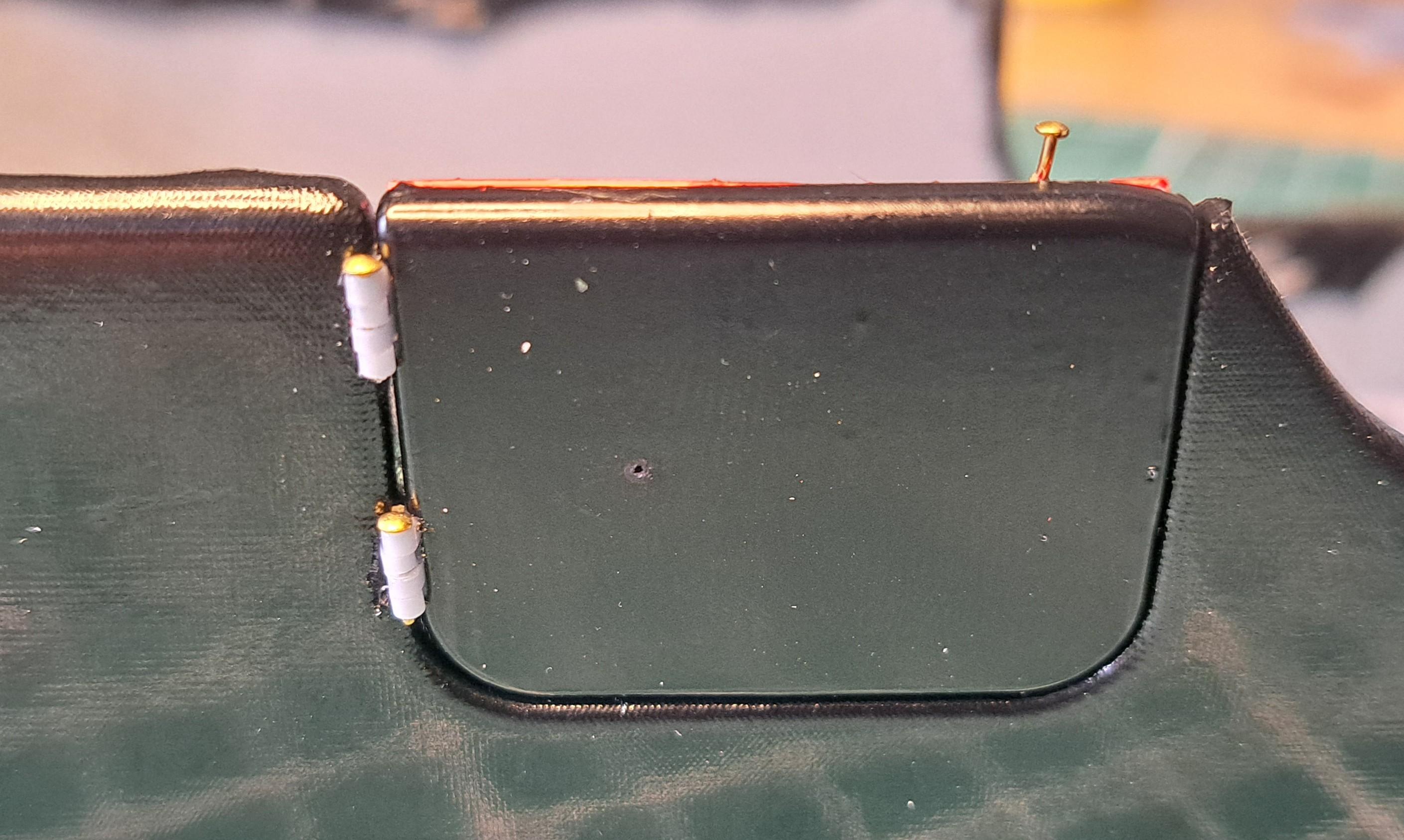

Here's a test I did on a door

I should be wrapping soon.

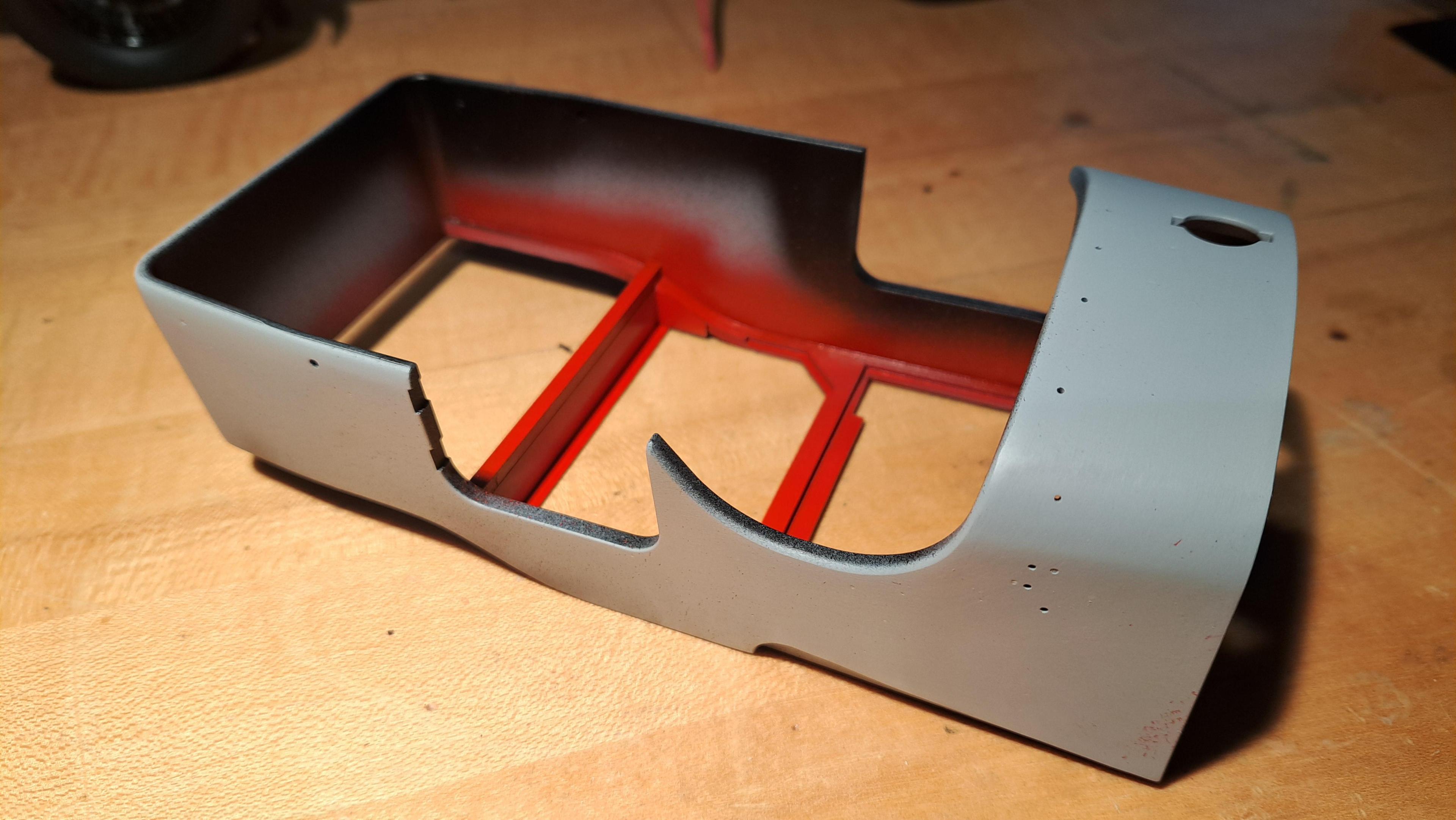

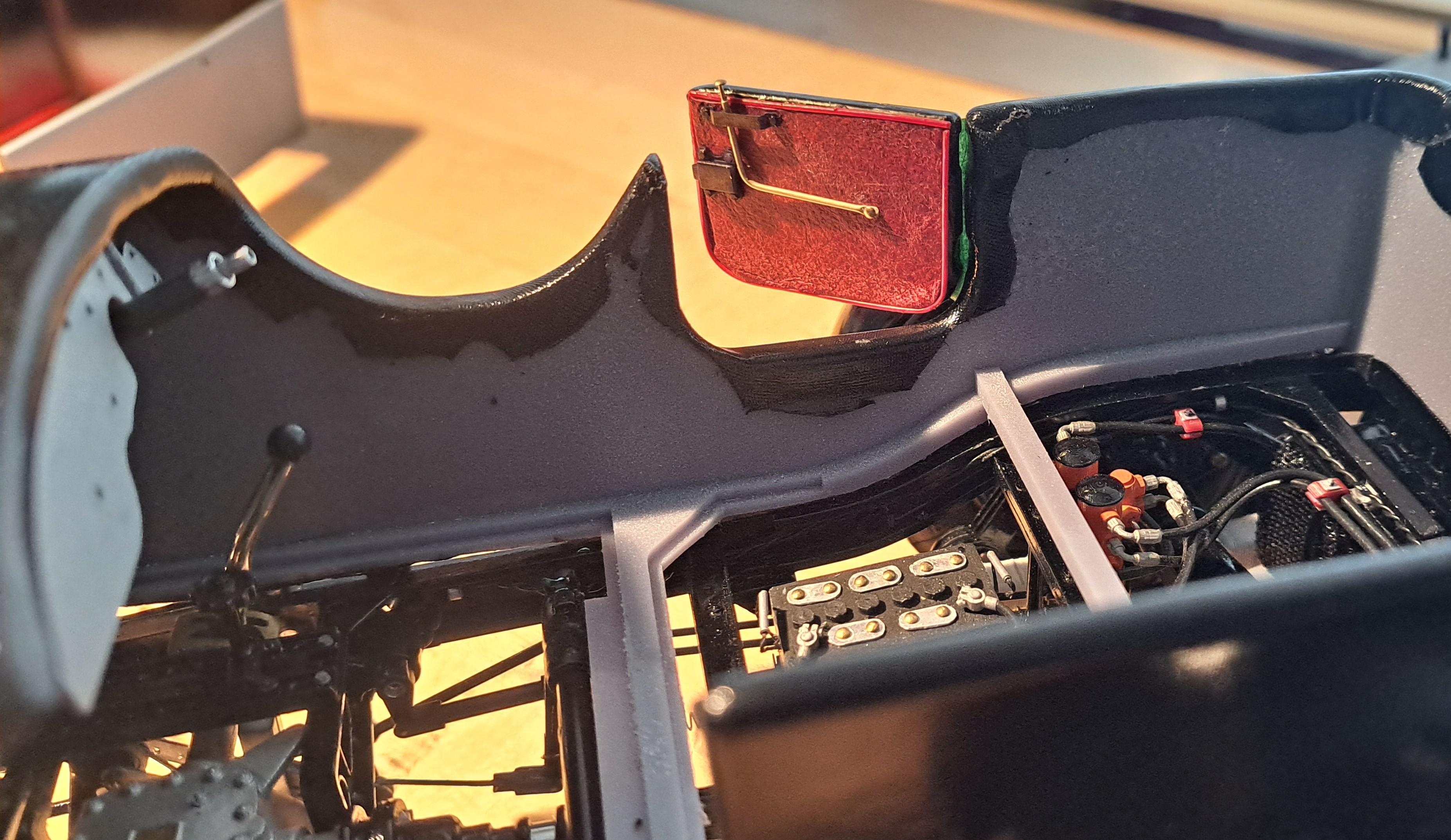

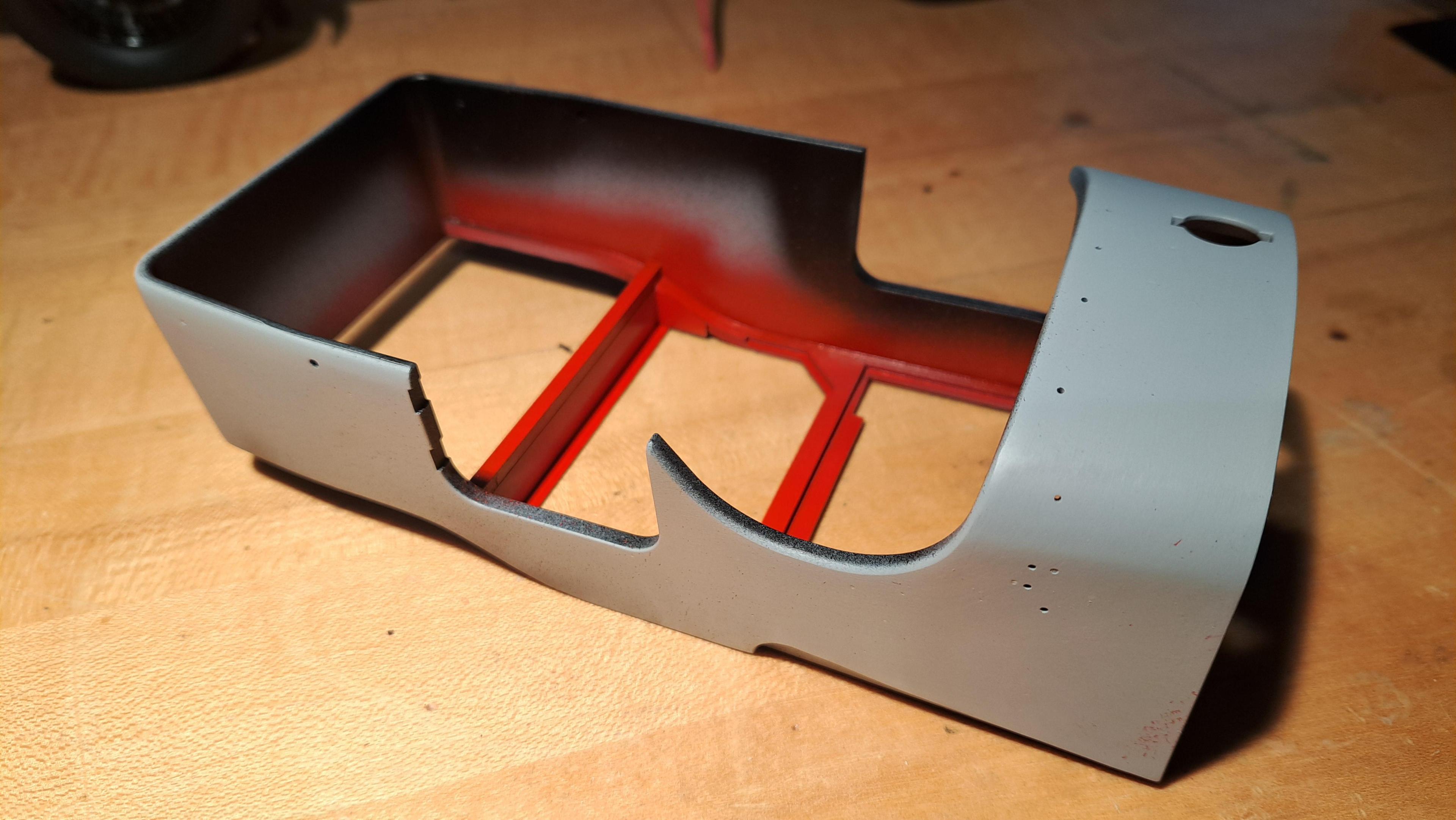

I reprinted a body with all mounting holes in it. It's now primed and ready for wrapping. Since the interior will be upholstered in red leather, I painted certain areas red in case the leather doesn't cover everything. I even incorporated hex nuts to screw in the foldable top frame.

here's my body collection so far

I found a nice piece of red leather for 5$. It's a bit thicker than l like but I should be able to skive it.

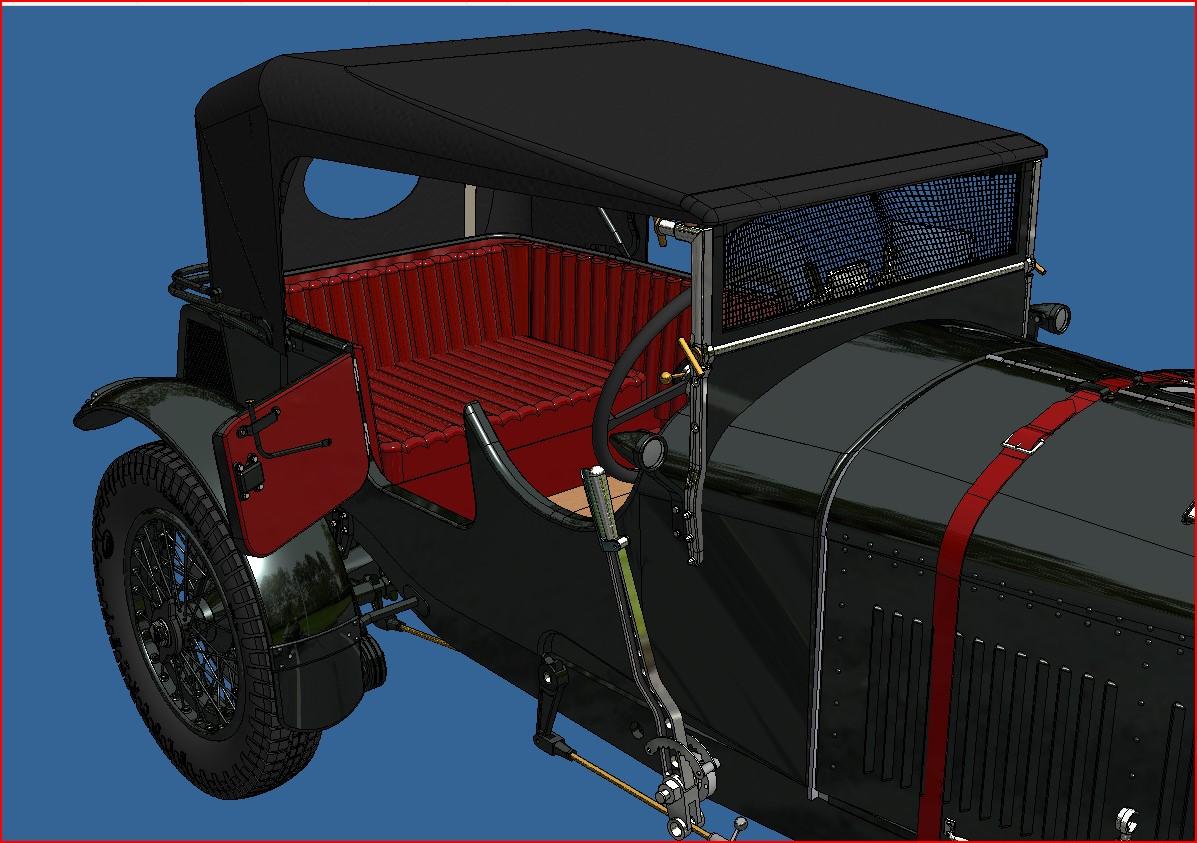

I started 3d modeling the interior finishes. I modeled the door latch based on the few pictures I could find.

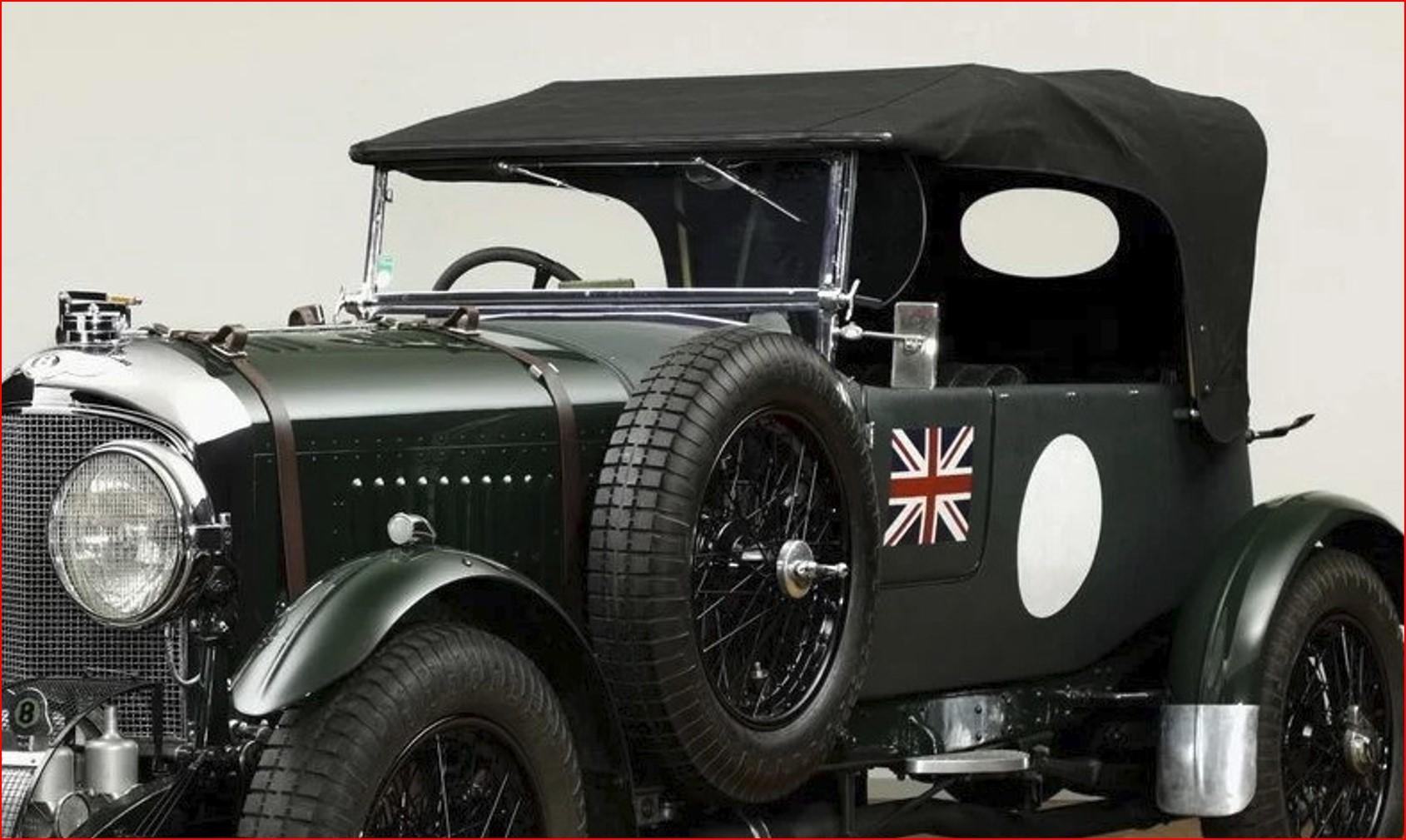

The latch inspiration

My 3d model

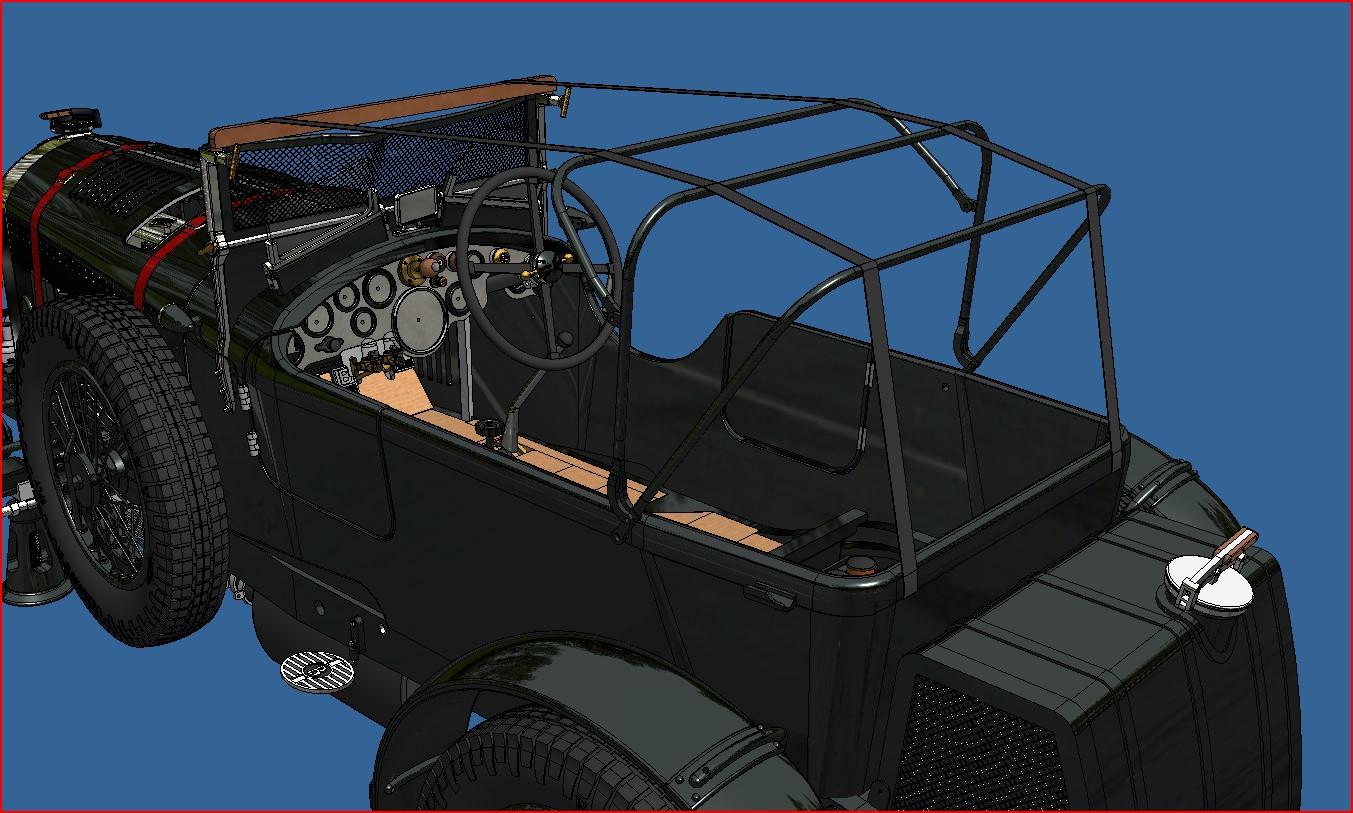

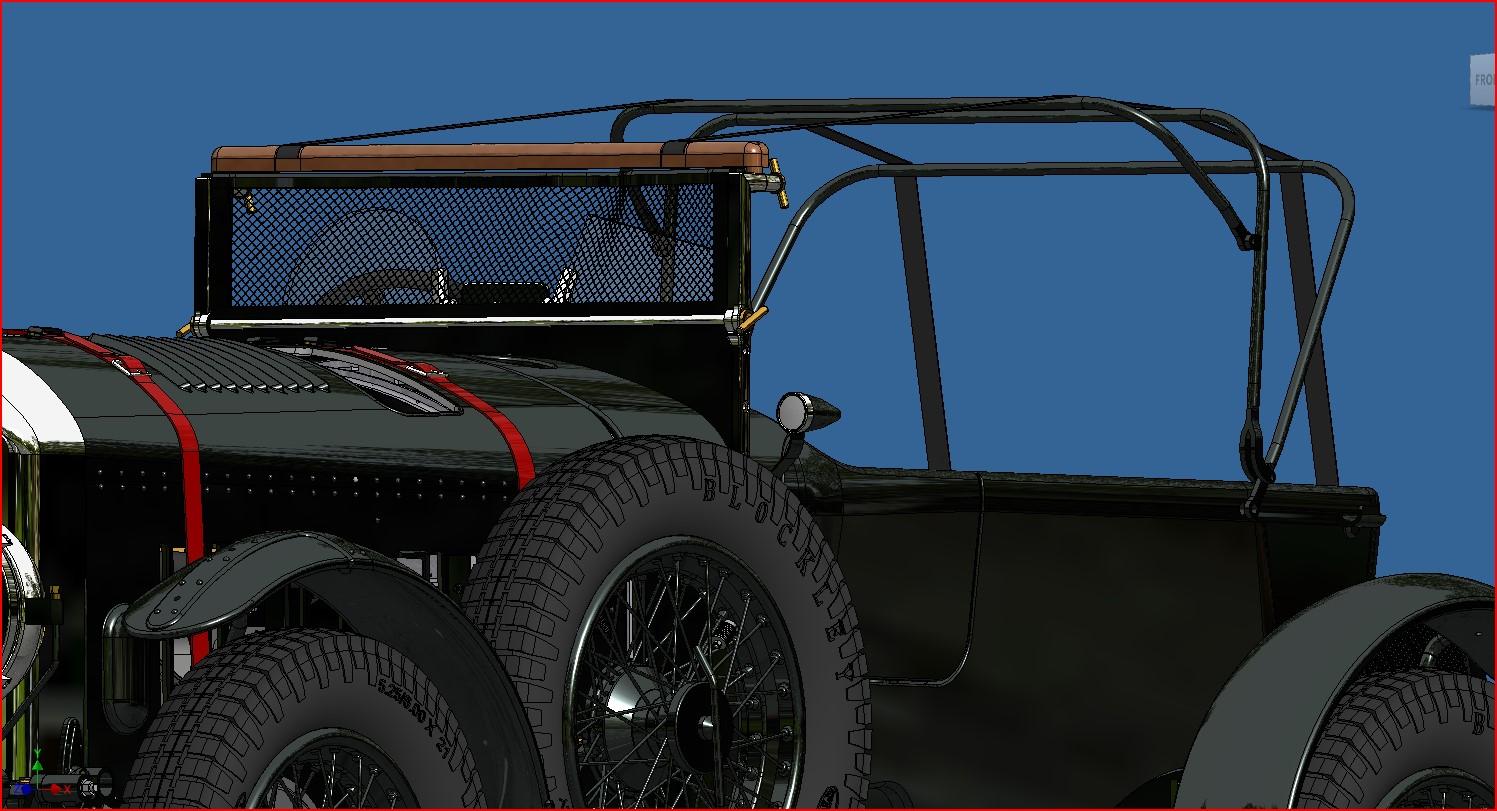

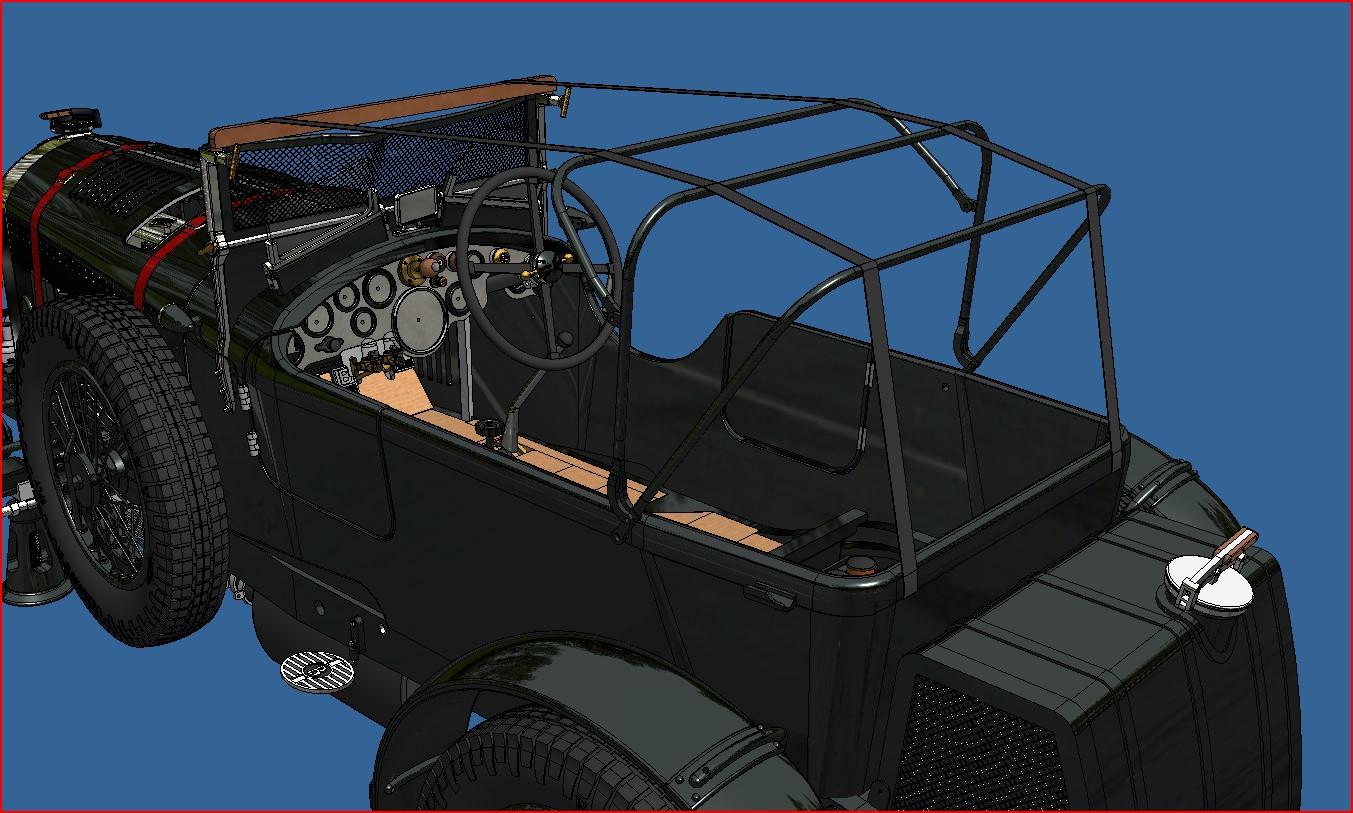

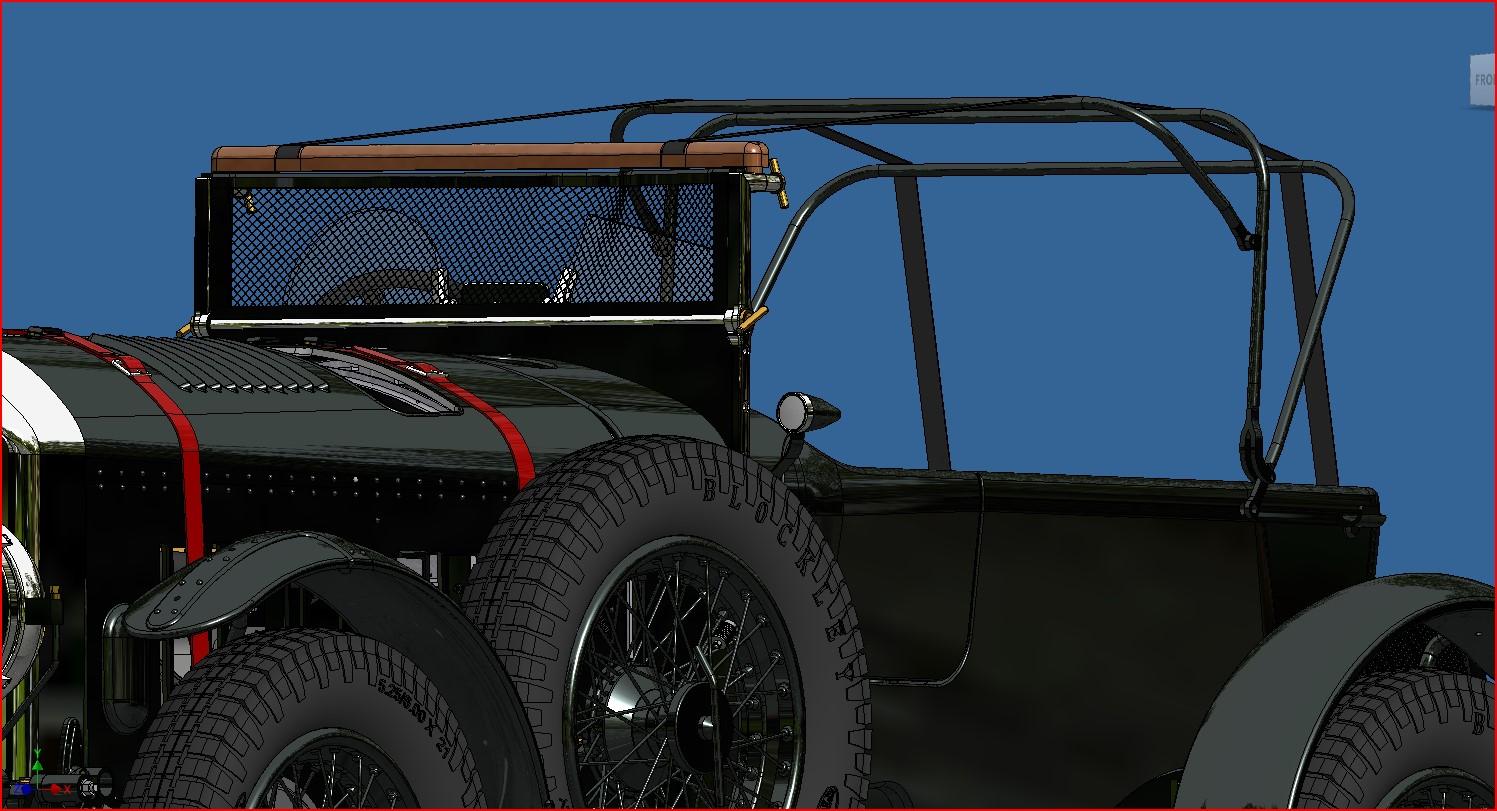

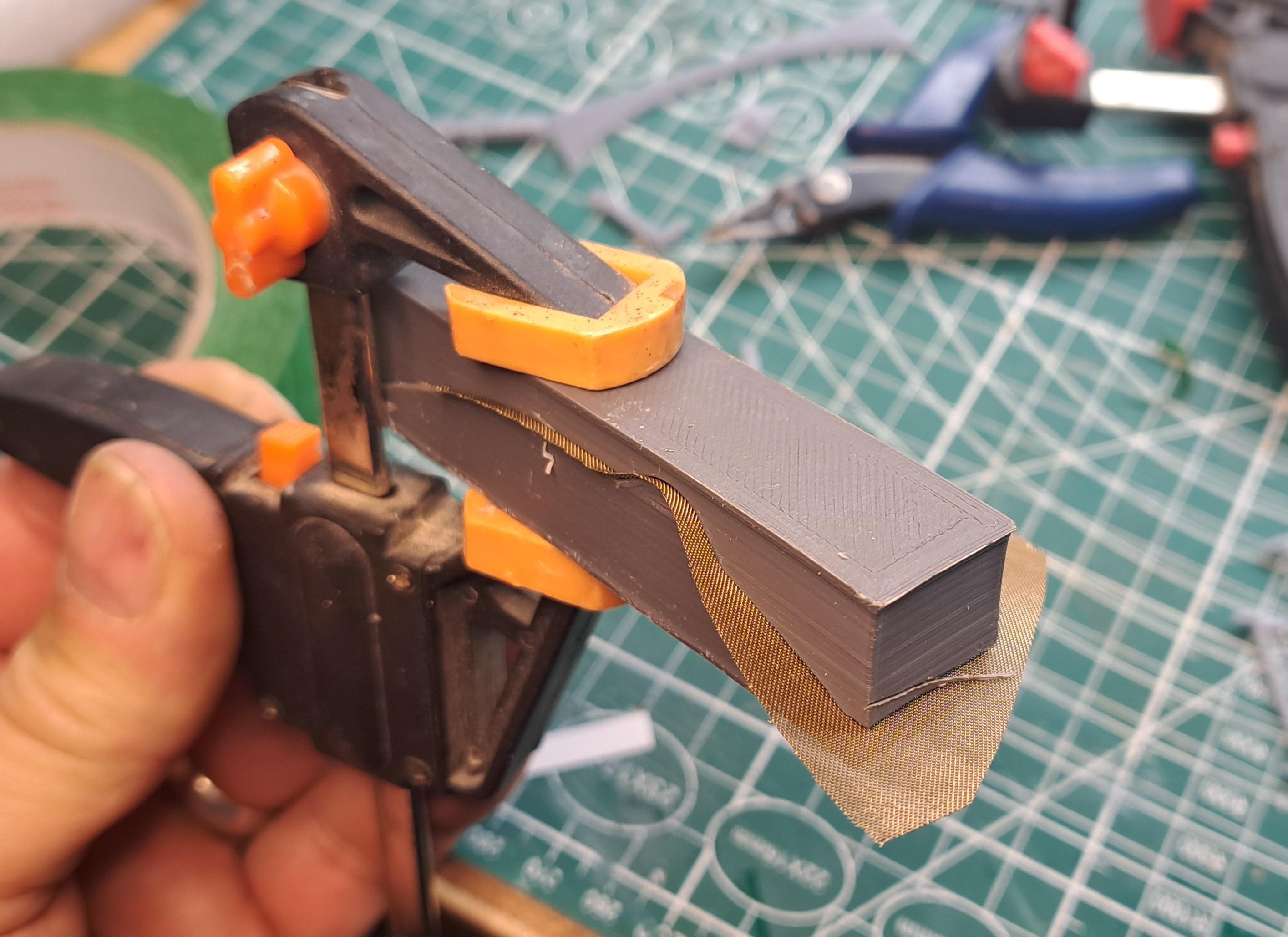

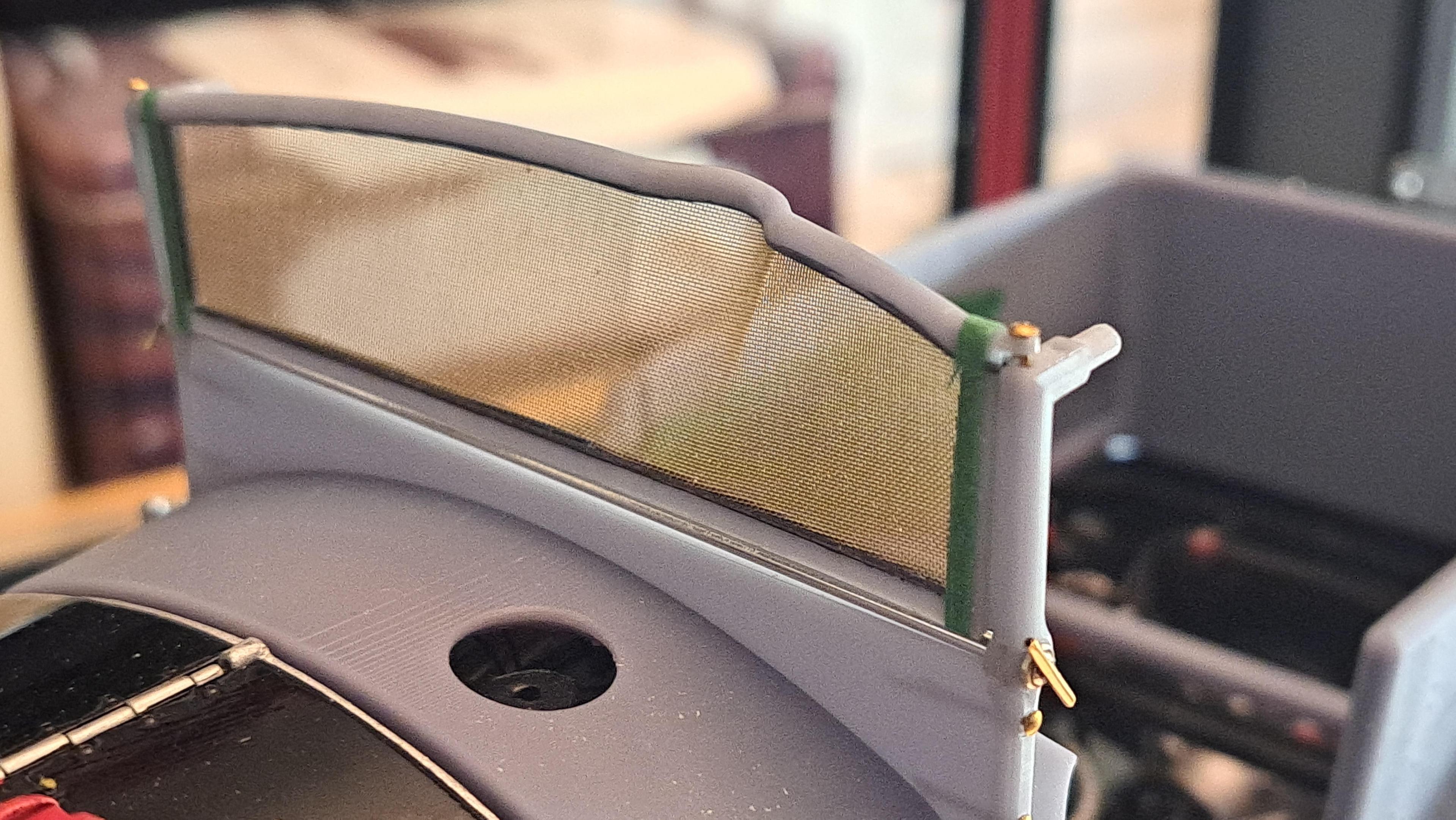

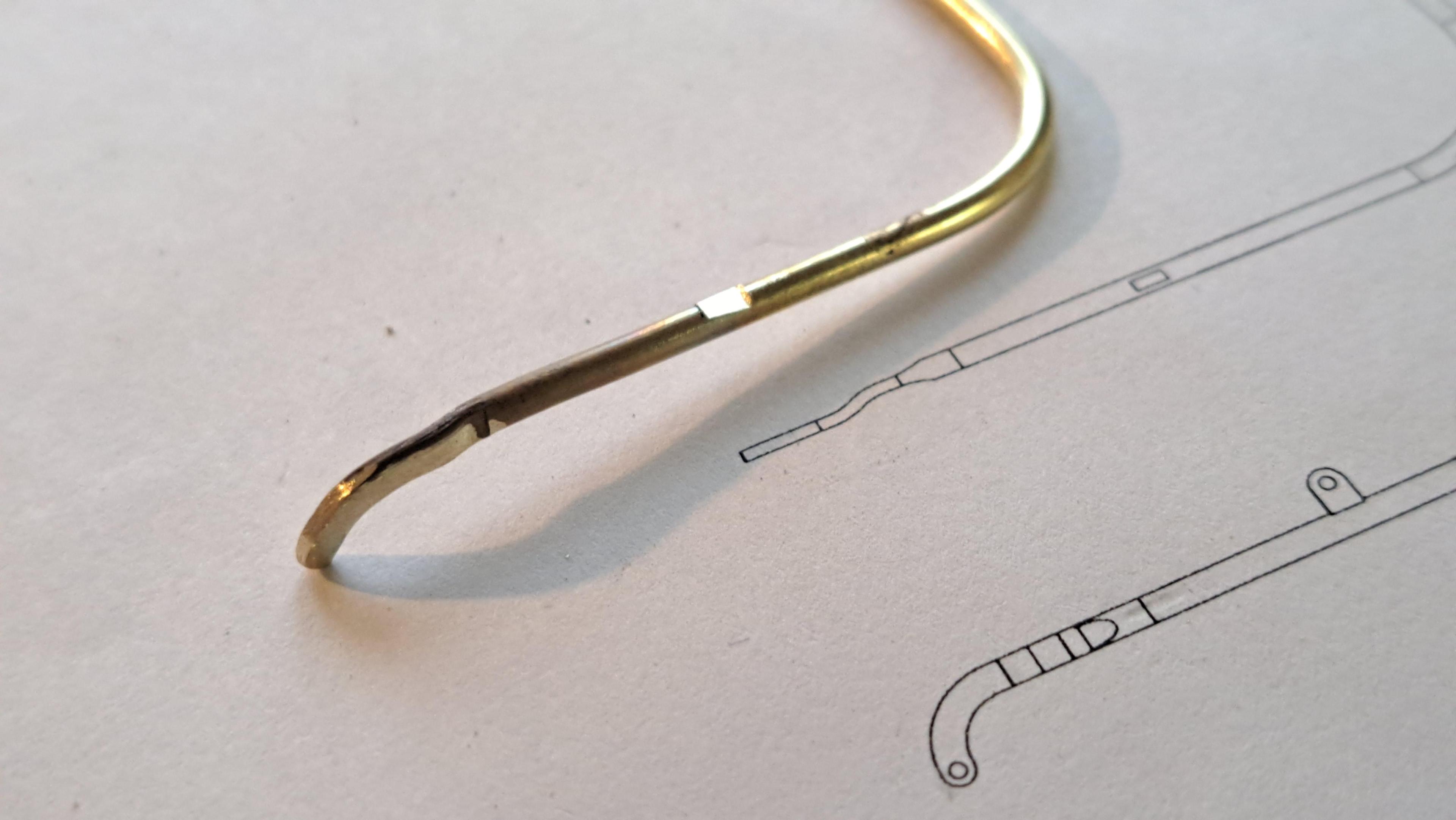

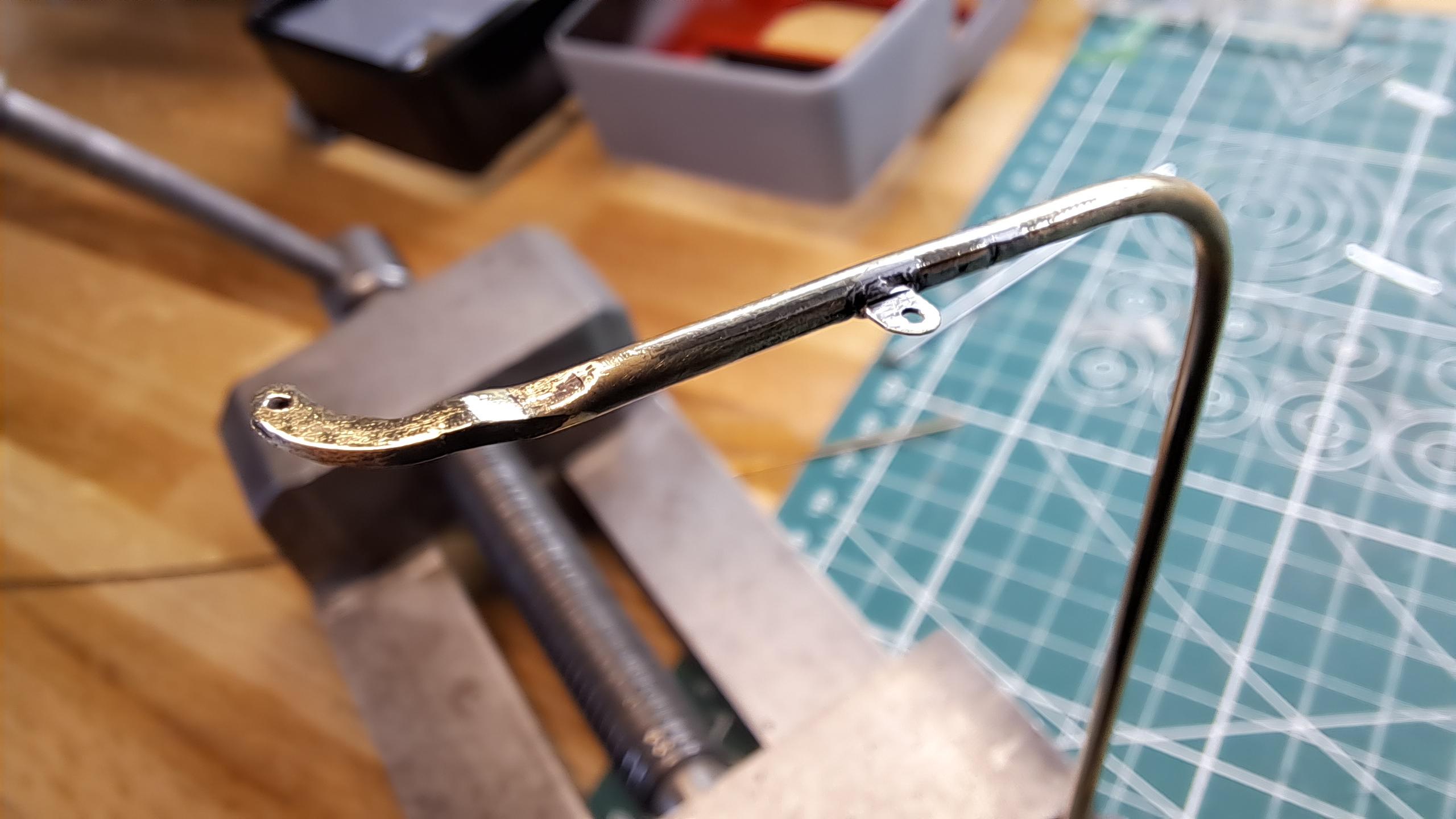

And finally, I made some bending test for the foldable top frame.

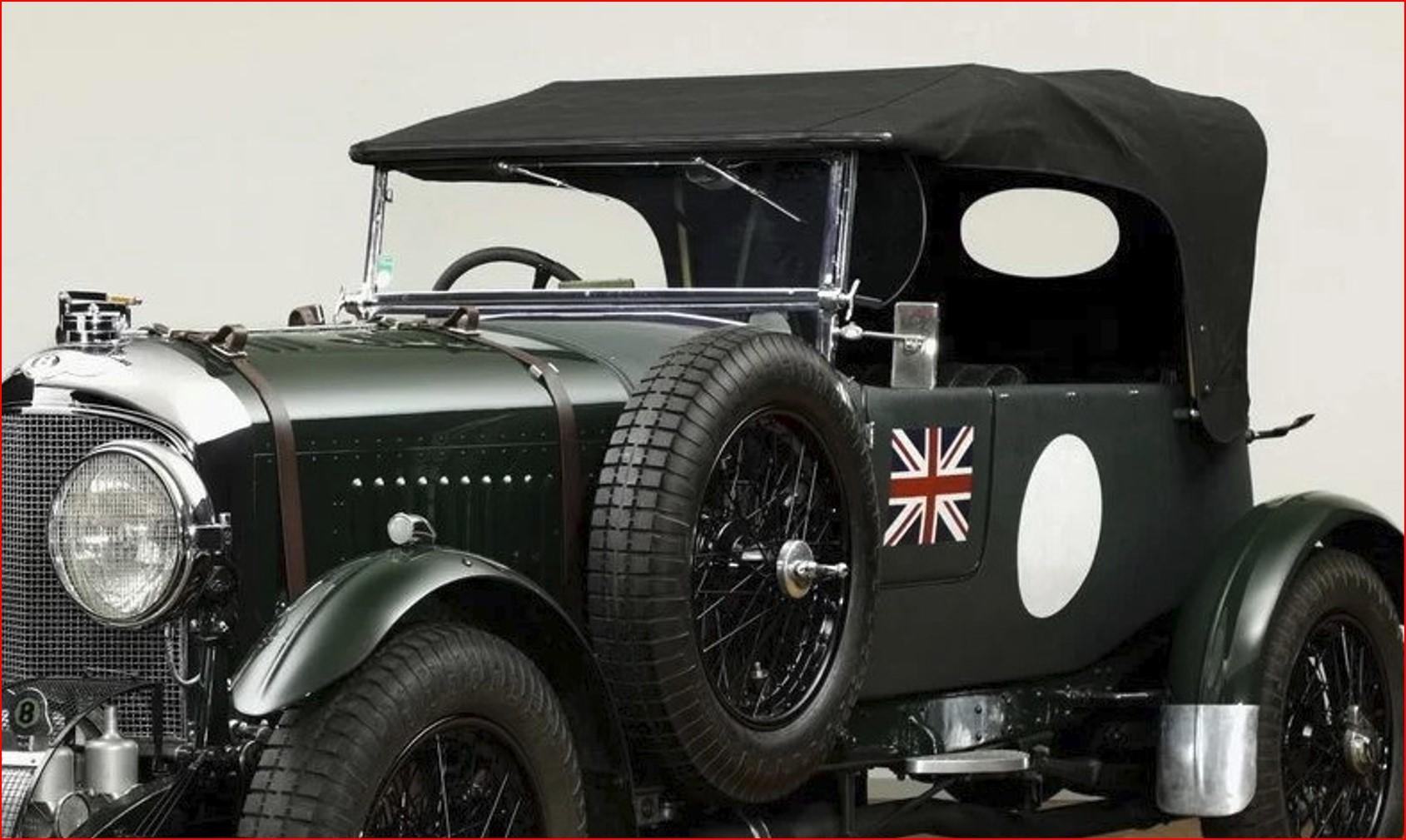

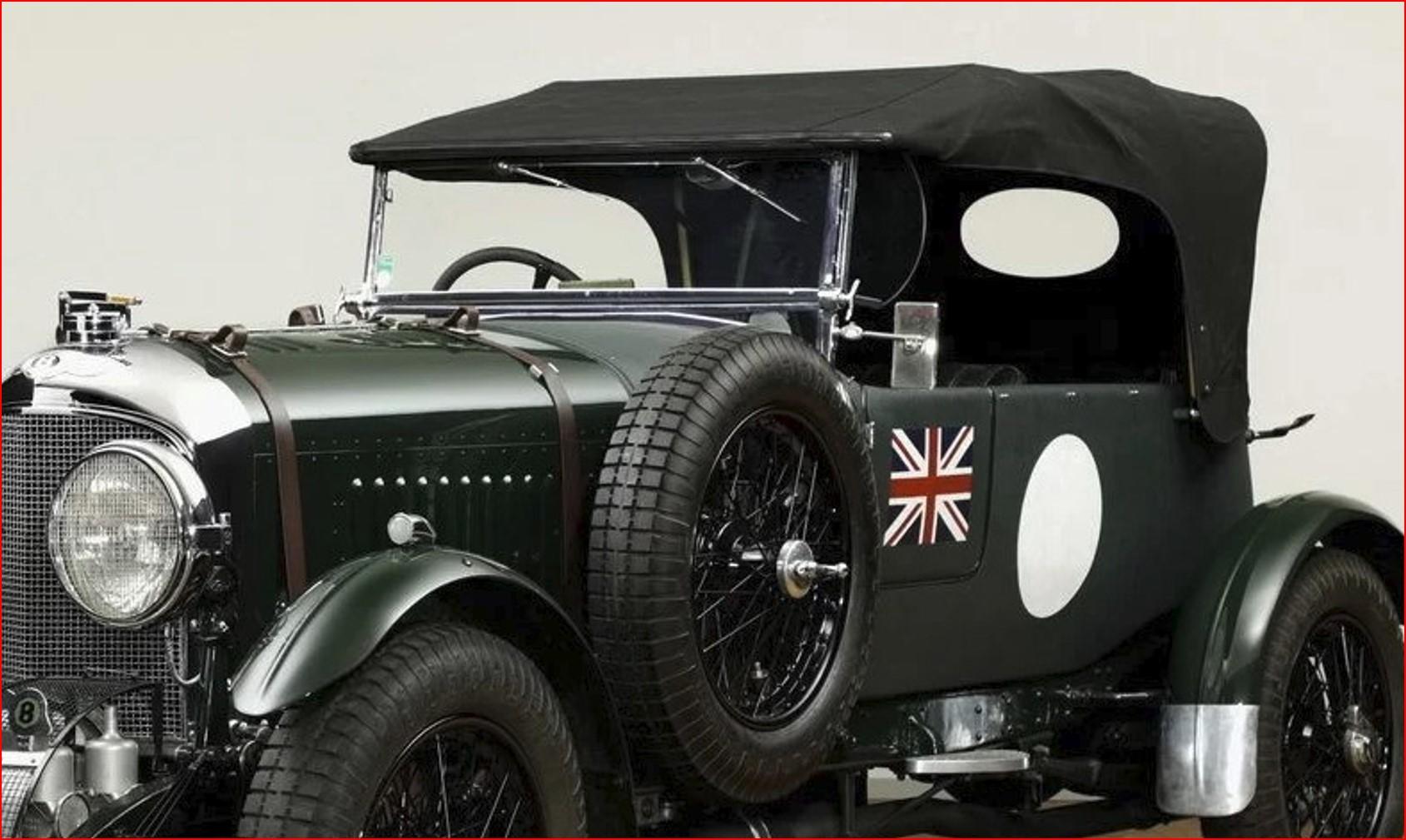

Here's another comparison shot of my model and the ref car

And another video of the running engine because it's just fun to watch.

View attachment 20240425_120412.mp4

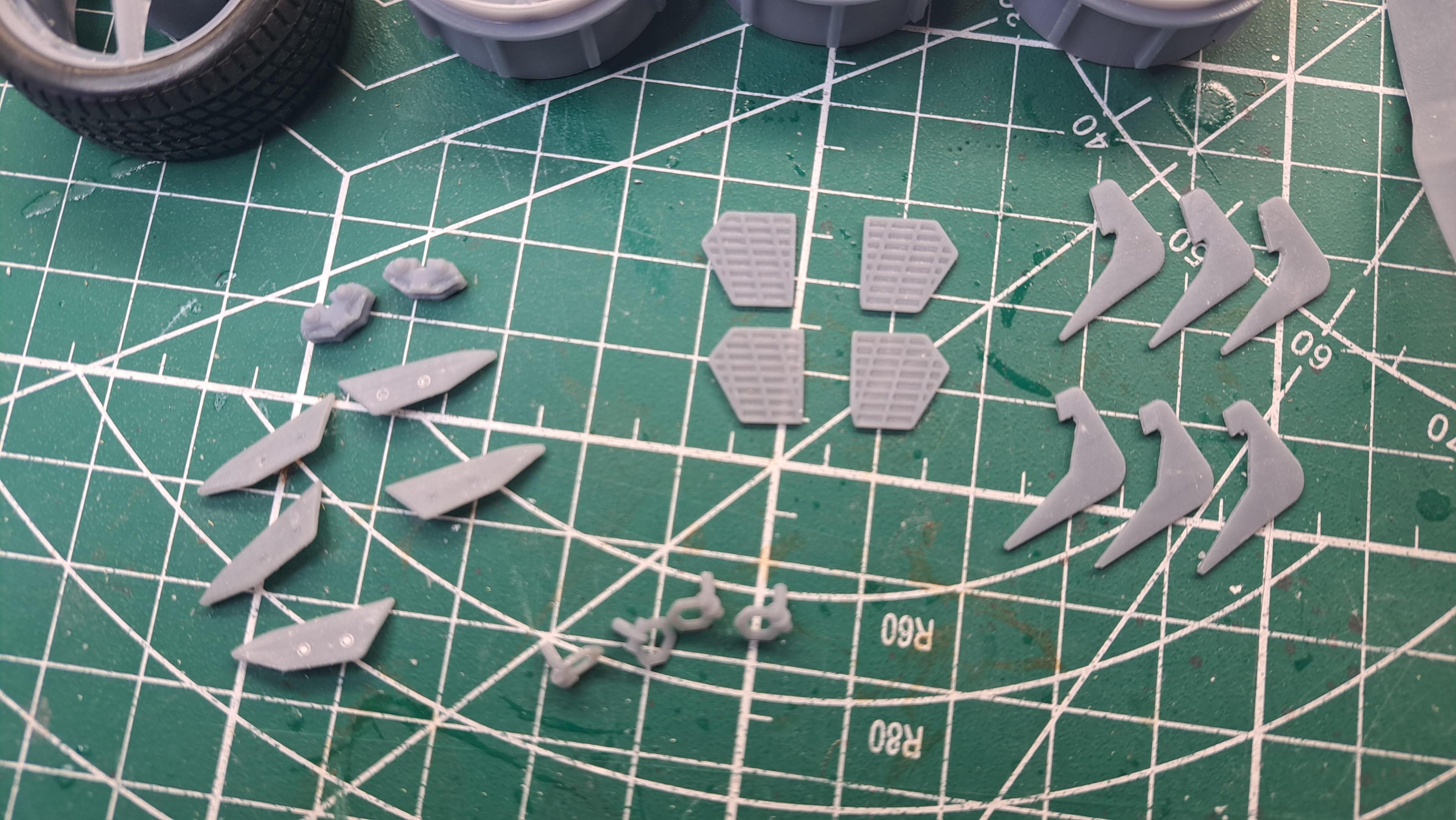

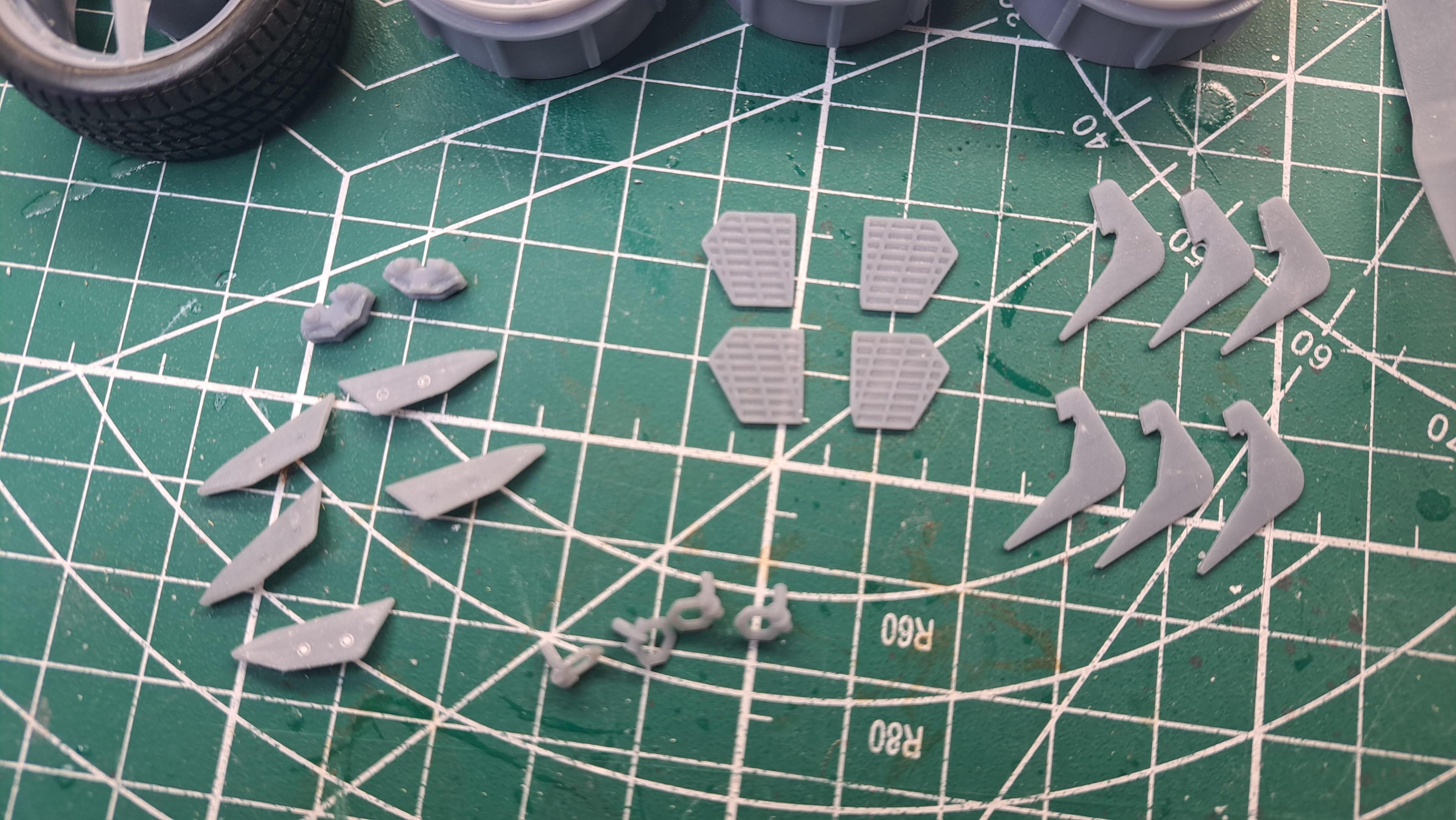

As a side note, I was asked to design and print some parts for a 1/18 scale diecast C8 Corvette. The guy has the real one but his diecast model didn't have the correct wheels, rear spoiler and was missing a few other parts.

Here's the real car

the wheels I printed

And all the parts