So, now let's talk about the wooden materials from the set in more detail.

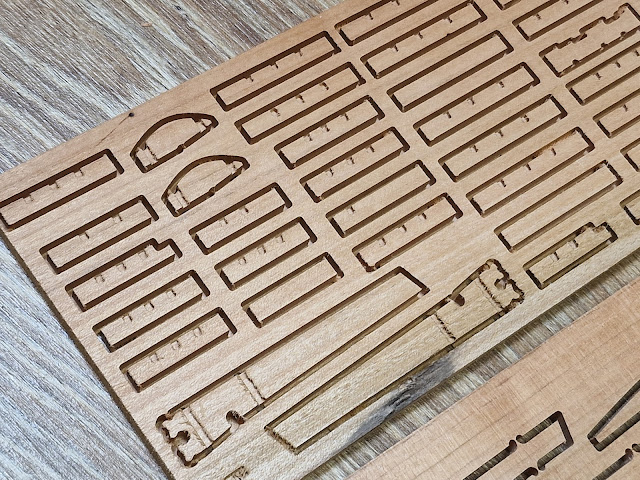

Let's start with the details of the frame. All of them are placed on 4 large (M7, M8, M9, M10) and one small plate (the last one below in the photo, M11).

From all these parts a slipway is assembled, in which almost the entire hull of the ship is assembled.

Previously, there was nothing like this in the kits and everything had to be assembled on the knee and the result was corresponding. I am very glad that progress does not stand still and manufacturers make life easier for modelers.

_______________________________________

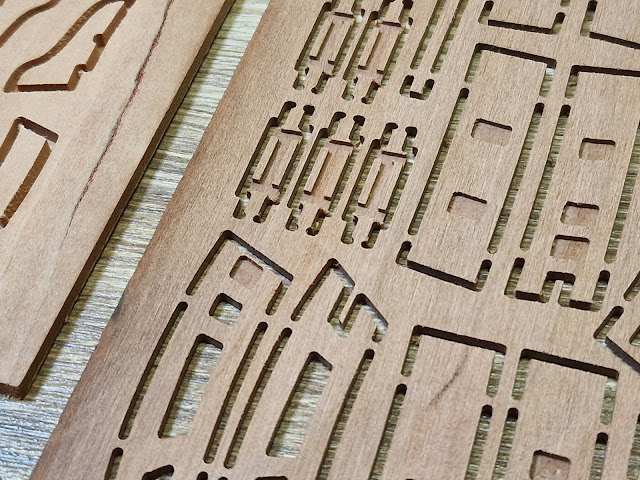

Next are the plates with conductors.

These plates, as details of the slipway, are not made of solid wood, but of pressed wood chips (fiberboard), but quite strong. Below in the photo is a plate (M11) from the slipway kit, M12 is a conductor for assembling the keel and the rest are conductors for assembling the frames.

In general, nothing complicated. M12 is a veneer in which the contours of the keel parts are cut out. By the way, in the first sets this jig was not made of veneer.

When assembling the original parts, they must be adjusted and inserted into the appropriate places of this jig. Very convenient and practical!

With plates M1, M2, M3, the situation is similar. They are needed for the correct assembly of frames and giving them the correct profile.

_______________________________________

The situation is completely similar with plates M4, M5, M6.

Some still have fragments of the slipway.

On others there are retaining clamps.

And on the M13 plate there are conductors, along which the frames are cut and the line of the barhouts, etc. is drawn. It, like the M12, is made of veneer.

The manufacturers have really gone to great lengths with all these devices and this greatly simplifies the assembly of the model! Not only does it simplify, but all these "Jigs" allow you to do everything clearly and accurately, which reduces the chance of errors accumulating that appear at the very beginning.

I briefly ran through the wooden parts that will not be on the ship, but without which it is impossible to assemble it... And below I will tell you in more detail about those that the model will consist of. This is what "The Ship. The Beginning" looks like )))

...