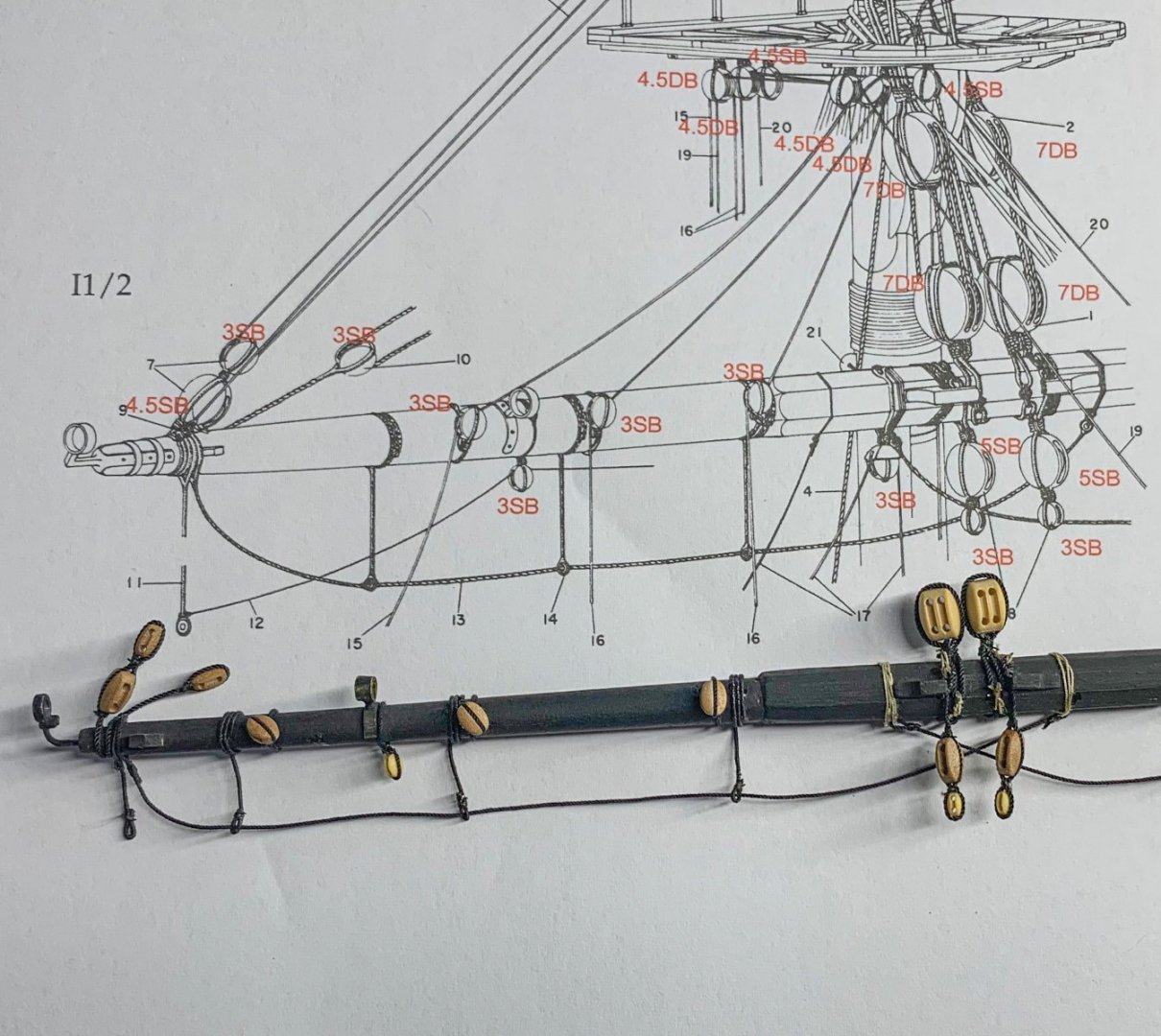

Hi Peter, how did you make the mice at the fore stays? I am at the point where I will be attaching these lines and would be interested to learn how you made them.

Your model is looking very good.

Trevor

Your model is looking very good.

Trevor