I am not completely understanding the point where you think, that I changed my mind.I have a question Uwe: When I questioned if the nails should really be in one straight row from gunwale to keel you said, if I'm not mistaken, that it would be redundant to have 2 rows of nails for the futtock overlaps. Obviously you have at a later stage changed your mind. Why?

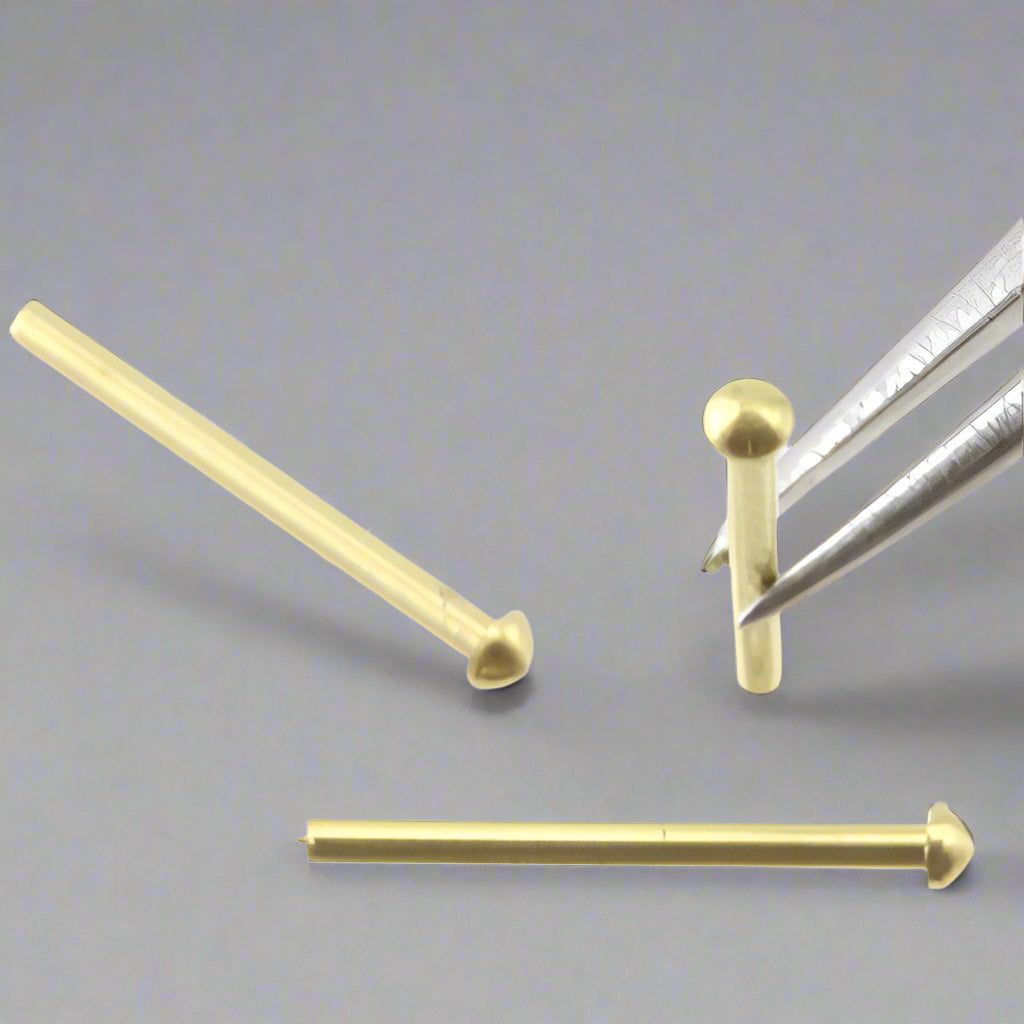

View attachment 216552

In the following I am using your markings (turned photo by 180°) to compare and overlay with my sketch afterwards

butt joints are green - planks are blue - nails are red

With this I think you can understand my thinking, where a nail should be following "my" pattern

Alternativ, but I did not follow, could be also this pattern

Maybe based on this sketch you could once more try to explain your point?