Hmm. We'll see. Technically that's rigging so it will have to wait. Do you think 's' twist or 'z' twist would be more comfortable?Hi Paul,

Great work as always. Oh no sorry there is room for improvement

You can add the "allemanseindje" to your seat of not so ease.

It is just a little piece of rope with untwisted end tight to the railing and hang down through the toilet into the water. See below how it is done on Batavia.

View attachment 264694

-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

-

SUBSCRIBE TO SHIPS IN SCALE TODAY!

The beloved Ships in Scale Magazine is back and charting a new course for 2026!

Discover new skills, new techniques, and new inspirations in every issue.

NOTE THAT OUR NEXT ISSUE WILL BE MARCH/APRIL 2026

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vasa - 1:65 DeAgostini [COMPLETED BUILD]

- Thread starter dockattner

- Start date

- Watchers 148

I think that depends on the SB or PS toilet.Hmm. We'll see. Technically that's rigging so it will have to wait. Do you think 's' twist or 'z' twist would be more comfortable?

I can tell you, I have made numerous mistakes and miscalculations on my current project. Some I could correct; some I could alter to seem as though they were part of the design; some were too far into the build to reckon with. Most observers will never pick them out. I, of course know where they are, but that was all part of the journey. There’s no such thing as a perfect model.

I will say, though, that I have rarely seen as nicely constructed a head, even on some of the best historical models. It is sometimes comforting to look closely at some of the more famous dockyard models; they are all works of art, but the effort varies, throughout the models. I often think that the models being made today, often far exceed the standards from centuries ago.

I will say, though, that I have rarely seen as nicely constructed a head, even on some of the best historical models. It is sometimes comforting to look closely at some of the more famous dockyard models; they are all works of art, but the effort varies, throughout the models. I often think that the models being made today, often far exceed the standards from centuries ago.

- Joined

- Oct 9, 2020

- Messages

- 2,266

- Points

- 488

Most rope is right hand twist. In fact I don't even know if you can buy left hand twist, which is why I purchased a rope making machine. I am still trying to figure out what ropes where right hand twist and which were left hand twist. So far I read that standing rigging is left hand twist.Hmm. We'll see. Technically that's rigging so it will have to wait. Do you think 's' twist or 'z' twist would be more comfortable?

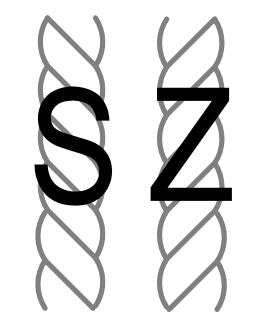

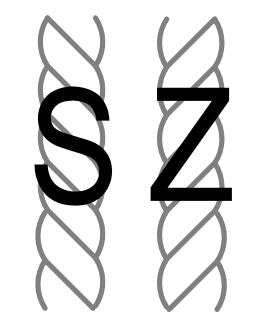

I found this sketch somewhere, I don't remember the source, just to make it clear what S and Z twist are. So when I say left I mean S and when I say right I mean Z.

Beautiful work!No worries guys; I am not offended in any way. I have been laughing right alongside you (and sometimes AT you)...

And also working on my ship...

This morning I wrapped up the beakhead for the time being. There are all sorts of painted castings that need to be attached but I don't think they're all painted yet and I'm not in the mood for painting right now. I'll probably save that for a winter activity.

I added some tiny angle brackets to the transverse pin rails and reworked the comfort stations...

View attachment 264658

View attachment 264657

And oiled her down for a night on the town:

View attachment 264653

View attachment 264654

I also painted the outboard surface of the bulwark:

View attachment 264656

That may look a bit wonky right now but there will be a parade of Roman emperors and other adornments installed later on...

Here is the big picture as of today:

View attachment 264660

Looking back I see I spent nearly a month on this scratch-built beakhead. It was a really fun and challenging project that I'm glad I took on. I think the kit supplied parts could have been put together in an afternoon so I'm not sure I passed the test of common sense - but I learned a lot and picked up some scroll saw skills along the way.

I think I'm going to figure out chain wales (channels?) and chain plates next. Or maybe not.

As always I am delighted you stop by to visit on occasion.

- Joined

- Oct 9, 2020

- Messages

- 2,266

- Points

- 488

Again another tidbit of information that I have in my information repository. Sorry I don't know the source:

All lines for sail handling - sheets, tacks, halyards, downhauls, braces are 'z' all shrouds and larger stays are 's' as they are made from 'z' line.

All lines for sail handling - sheets, tacks, halyards, downhauls, braces are 'z' all shrouds and larger stays are 's' as they are made from 'z' line.

- Joined

- Oct 9, 2020

- Messages

- 2,266

- Points

- 488

Wikipedia...Most rope is right hand twist. In fact I don't even know if you can buy left hand twist, which is why I purchased a rope making machine. I am still trying to figure out what ropes where right hand twist and which were left hand twist. So far I read that standing rigging is left hand twist.

I found this sketch somewhere, I don't remember the source, just to make it clear what S and Z twist are. So when I say left I mean S and when I say right I mean Z.

Tremendous insight - this is something I was wondering, myself, recently. This makes perfect logical sense. Thanks for posting!Again another tidbit of information that I have in my information repository. Sorry I don't know the source:

All lines for sail handling - sheets, tacks, halyards, downhauls, braces are 'z' all shrouds and larger stays are 's' as they are made from 'z' line.

'Cuz I'm just that kind of Jerk, Paul, I was macro-ing your macros on my desktop, and the work STILL holds up under extreme magnification. You pay very close attention to the tiny details.

Thank you, all, for you positive reviews of my work and all the likes.

Last edited:

And since I'm feeling nostalgic: there was a time in my younger life when I was free to walk out on Batavia's sprit-mast to the top, in the hours before the museum opened to the public. For the three months I worked on the Werf, in 2003, every morning we went through the ship and cleared away all the webs from the Lelystad spiders that populated the ship. The spiders, themselves, were a decent size, but completely harmless. From a work perspective, these were some of the best times of my life! I replaced a fair amount of wood on that ship, some of which I'm sure has already been replaced all over again.

I never "used" the head, though. No one wants to be the "ugly American".

I don't know if Paul has enough 6" hawser left for that after making the anchor lines...Hmm. We'll see. Technically that's rigging so it will have to wait. Do you think 's' twist or 'z' twist would be more comfortable?

Now that's truly funny Marc (that kind of a jerk...). I believe you and I would be friends in real life.'Cuz I'm just that kind of Jerk, Paul, I was macro-ing your macros on my desktop, and the work STILL holds up under extreme magnification. You pay very close attention to the tiny details.

I sometimes think macros create glue residue that doesn't actually exist. I believe it is the work of Satan.

I will add that the beakhead on the Wasa is a magnificent piece of architectural eye-candy. It would be hard to do her wrong. I have even been considering taking a glamour shot and making it my avatar.I can tell you, I have made numerous mistakes and miscalculations on my current project. Some I could correct; some I could alter to seem as though they were part of the design; some were too far into the build to reckon with. Most observers will never pick them out. I, of course know where they are, but that was all part of the journey. There’s no such thing as a perfect model.

I will say, though, that I have rarely seen as nicely constructed a head, even on some of the best historical models. It is sometimes comforting to look closely at some of the more famous dockyard models; they are all works of art, but the effort varies, throughout the models. I often think that the models being made today, often far exceed the standards from centuries ago.

I love this story. Thanks for sharing it.And since I'm feeling nostalgic: there was a time in my younger life when I was free to walk out on Batavia's sprit-mast to the top, in the hours before the museum opened to the public. For the three months I worked on the Werf, in 2003, every morning we went through the ship and cleared away all the webs from the Lelystad spiders that populated the ship. The spiders, themselves, were a decent size, but completely harmless. From a work perspective, these were some of the best times of my life! I replaced a fair amount of wood on that ship, some of which I'm sure has already been replaced all over again.

Actual question (anyone can answer): are the channels (chain wale) perpendicular to the hull or parallel to the waterline? (I'm thinking the former.)

I believe you and I would be friends in real life too Kurt! I would love to share a workshop with a bunch of people on this forum. It would be a BLAST!I don't know if Paul has enough 6" hawser left for that after making the anchor lines...

Well, if you plan to visit Minnesota, let me know. We'll do shop talk until we pass out.I believe you and I would be friends in real life too Kurt! I would love to share a workshop with a bunch of people on this forum. It would be a BLAST!

- Joined

- Oct 9, 2020

- Messages

- 2,266

- Points

- 488

Can of worms now opened, or open mouth insert foot. Not sure which one is more appropriate:Again another tidbit of information that I have in my information repository. Sorry I don't know the source:

All lines for sail handling - sheets, tacks, halyards, downhauls, braces are 'z' all shrouds and larger stays are 's' as they are made from 'z' line.

Thus far I have been using a caliper to measure the thickness of the final rope, but it is very difficult. If anyone has a better suggestion, your help would be appreciated.

Also, is there a way to determine the final rope thickness based on the size of the initial threads?

One suggested wrapping it tightly around a mast or dowel 10 times and measuring with a caliper. Then divide what you measured by 10. That way, you don't compress the line with your caliper.Can of worms now opened, or open mouth insert foot. Not sure which one is more appropriate:

Thus far I have been using a caliper to measure the thickness of the final rope, but it is very difficult. If anyone has a better suggestion, your help would be appreciated.

Also, is there a way to determine the final rope thickness based on the size of the initial threads?

- Joined

- Oct 9, 2020

- Messages

- 2,266

- Points

- 488

thanks

I have found these two charts to be a great help in my rope making efforts.Can of worms now opened, or open mouth insert foot. Not sure which one is more appropriate:

Thus far I have been using a caliper to measure the thickness of the final rope, but it is very difficult. If anyone has a better suggestion, your help would be appreciated.

Also, is there a way to determine the final rope thickness based on the size of the initial threads?