Hello Uwe, I like the plain toothpick as well, bear in mind, if you will decide to oil the deck, it will actually emphasize the caulking effect (it will darken the around the hole).

-

Win a Free Custom Engraved Brass Coin!!!

As a way to introduce our brass coins to the community, we will raffle off a free coin during the month of August. Follow link ABOVE for instructions for entering.

-

PRE-ORDER SHIPS IN SCALE TODAY!

The beloved Ships in Scale Magazine is back and charting a new course for 2026!

Discover new skills, new techniques, and new inspirations in every issue.

NOTE THAT OUR FIRST ISSUE WILL BE JAN/FEB 2026

- Home

- Forums

- Ships of Scale Group Builds and Projects

- Le Coureur 1776 1:48 PoF Group Build

- Le Coureur 1776 1:48 Group Build Logs

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LE COUREUR - french Lugger 1776 - POF kit from CAF in 1:48 by Uwe

This I checked also already but did not make a photo right now.Hello Uwe, I like the plain toothpick as well, bear in mind, if you will decide to oil the deck, it will actually emphasize the caulking effect (it will darken the around the hole).

The treenails are getting slightly darker with oiling, but not because of the oiling effect.

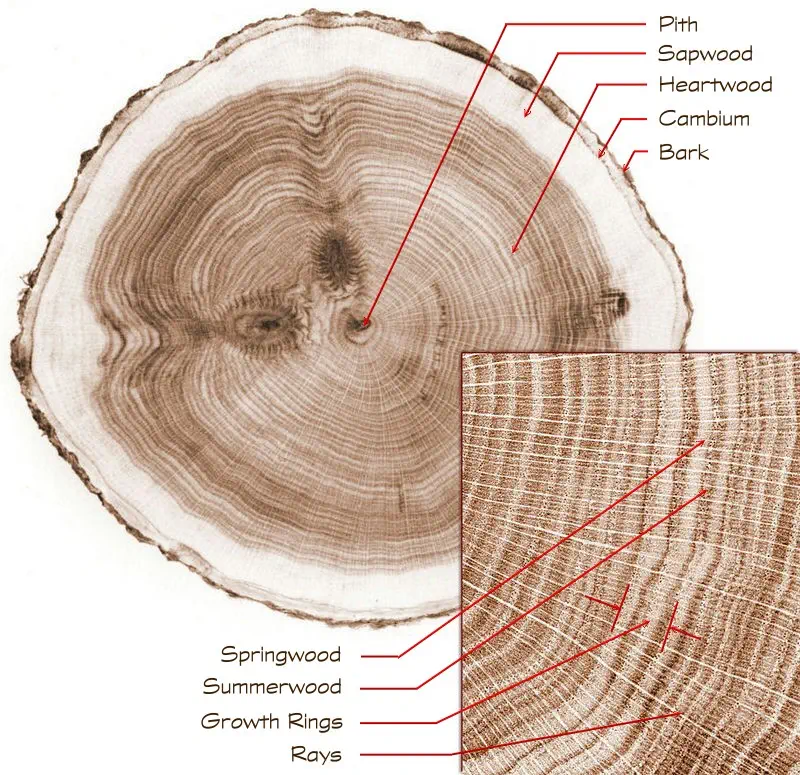

The grain of the toothpicks are in 90° compared to the grain of the planks - so we see the face side or front end of the timber (of the toothpicks).

Timber is loosing f.e. the humidity mainly via this area, so it is also soaking all fluids much more towards the face sides.

Therefore the the treenails are getting slightly darker than the planking, although it is the same wood.

On real ships the treenails were made like this sketch is showing

Some of the still existing ships have such treenails

Than the neails are realy darker than the deck, although it is the same timber

Often they made on top of the treenail an additional plug with a bigger diameter, but the grain of the plug visible on the surface followed the grain of the deck planking

visible on this photo very good -> with this you can hardly recognize the treenail

Interesting is the fact, that when a deck was wet and getting dry - than the treenails are also more visible, because of humidety staying longer inside the contact areas between treenail, plug and plank

Realy - I think at the end it is a pure question of taste of the modeler - they should have only the correct size and not being outscale

When they are too dark compared to the planking, the modeler can every time say, that just before it stopped raining

The end grain of wood always soaks up any finish, and requires more coats, and thus is naturally darker. But there are variables that would factor into that, such as the type of wood, and the direction the treenail was turned verses the direction of the wood grain. I am probably being rhetorical, but thought I would point out that they would most likely be somewhat darker if out of the same wood.This I checked also already but did not make a photo right now.

The treenails are getting slightly darker with oiling, but not because of the oiling effect.

The grain of the toothpicks are in 90° compared to the grain of the planks - so we see the face side or front end of the timber (of the toothpicks).

Timber is loosing f.e. the humidity mainly via this area, so it is also soaking all fluids much more towards the face sides.

Therefore the the treenails are getting slightly darker than the planking, although it is the same wood.

On real ships the treenails were made like this sketch is showing

View attachment 237934

Some of the still existing ships have such treenails

View attachment 237931

Than the neails are realy darker than the deck, although it is the same timber

Often they made on top of the treenail an additional plug with a bigger diameter, but the grain of the plug visible on the surface followed the grain of the deck planking

View attachment 237936

visible on this photo very good -> with this you can hardly recognize the treenail

View attachment 237930

Interesting is the fact, that when a deck was wet and getting dry - than the treenails are also more visible, because of humidety staying longer inside the contact areas between treenail, plug and plank

View attachment 237932

Realy - I think at the end it is a pure question of taste of the modeler - they should have only the correct size and not being outscale

When they are too dark compared to the planking, the modeler can every time say, that just before it stopped raining

However wood plugs, used on schooners are cut to match the deck, and therefore do not have end grain exposed.

Last edited:

I fully agree with your words.The end grain of wood always soaks up any finish, and requires more coats, and thus is naturally darker. But there are variables that would factor into that, such as the type of wood, and the direction the treenail was turned verses the direction of the wood grain. I am probably being rhetorical, but thought I would point out that they would most likely be somewhat darker if out of the same wood.

However wood plugs, used on schooners are cut to match the deck, and therefore do not have end grain exposed.

Interesting and good to know is also the fact, that the end grain (now I know the correct term) is often darker than the surface grain

Very interesting page explaining the grain structure, different wood cells and growing of wood in detail

Workshop Companion - Woodworking Tips by Nick Engler

Explore woodworking tips, tools, and techniques. Learn about wood grain, structure, and patterns with Nick Engler's expert insights.

Wood Botany - Understanding Hardwoods and Softwoods

A detailed exploration of the botanical traits of hardwoods and softwoods, including angiosperms, gymnosperms, cell structures, grain patterns, and extractives.

Last edited:

Looking good! I share your taste

Thanxs Uwe, for showing your skills and techniques. The Ecoline-caulking looks very usefull. I kept it in mind for my BN.

Regards, Peter

Regards, Peter

Your model is advancing quite fast I must say and with an astonishining accuracy. Always something interesting to read besides the model building itself.

To bad You are "covering up" all the hard work on the deck below. Maybe I missed or forgot, but do You plan opening a section in the frames on one side to be able to view the inside of the hold?

To bad You are "covering up" all the hard work on the deck below. Maybe I missed or forgot, but do You plan opening a section in the frames on one side to be able to view the inside of the hold?

The hull planking was already done, which is shown in the posts beginning this year (i know there are a lot of posts in my log in the meantime)Your model is advancing quite fast I must say and with an astonishining accuracy. Always something interesting to read besides the model building itself.

To bad You are "covering up" all the hard work on the deck below. Maybe I missed or forgot, but do You plan opening a section in the frames on one side to be able to view the inside of the hold?

The best overview you can get at this post after finishing the nailing of the hull planks

LE COUREUR - french Lugger 1776 - POF kit from CAF in 1:48 by Uwe

I have a question Uwe: When I questioned if the nails should really be in one straight row from gunwale to keel you said, if I'm not mistaken, that it would be redundant to have 2 rows of nails for the futtock overlaps. Obviously you have at a later stage changed your mind. Why? I am not...

shipsofscale.com

Hallo friends, I find the finishes in term of treenails highly interesting, especially with toothpicks. I also opted for the toothpicks on my sloop. Only, not only the deck planking, but also the wall paneling should be provided with treenails. I drilled 0,5mm holes in the finished walls and deck planks after marking them in advance with a pencil and pressed the pre-prepared toothpicks into the holes, cut them off and sanded them.

The planks with treenails were treated with teak light wood stain and wall paneling wih oak. The result is amazing. The nails appear darker with teak and lighter with oak.

The planks with treenails were treated with teak light wood stain and wall paneling wih oak. The result is amazing. The nails appear darker with teak and lighter with oak.

Last edited:

@pianoforte

your treenailing work on the shown model is looking very good - which model is it? Would be interesting to see more, maybe you could show some more views here?

your treenailing work on the shown model is looking very good - which model is it? Would be interesting to see more, maybe you could show some more views here?

Submit Images of Completed Models Here

This forum is for those that would like to upload their completed ships for the Showcase.

shipsofscale.com

Hallo Uwe, this is my gaff sloop Marghareta, which I showed at the beginnig of my entry into this forum. It also appears in a post here about making sails from silkspan.

After the "positiv" testphase and the final decision I started the deck treenailing work on the aft

It is the work of 3 evening sessions, especially because I am drilling all the holes by hand and not with my Proxxon

- you know already my nickname "KILL DRILL"

everything is prepared for pushing the toothpicks into the 0,5mm drilled holes

due to missing space (for all my fingers plus picks) I am making usually 50%, so every second treenail. When the glue is dry, I cut the toothpick with a side cutter and have enough space for the other 50%.....

I find it very helpful to prepare the deckplanking (caulking plus treenails) segments on the table and install them when they are more or less finished later on on top of the beams

50% of the treenails prepared

one close up photo of the nailing (not oiled)

afterwards it was possible to glue and fix the deck segments on top of the beams - here also the structures on top, to mark the correct size of the openings in the deck in order to sand them to the correct size (the timber is still not treated with oil)

and now the finsihed deck - fixed, openings in correct size (I hope), oiled and the endings (near the pumps) cut to the correct length

The top view - I will install in future one or two additional planks between the segments - but in moment it is not clear for me which one - so let us see

It is the work of 3 evening sessions, especially because I am drilling all the holes by hand and not with my Proxxon

- you know already my nickname "KILL DRILL"

everything is prepared for pushing the toothpicks into the 0,5mm drilled holes

due to missing space (for all my fingers plus picks) I am making usually 50%, so every second treenail. When the glue is dry, I cut the toothpick with a side cutter and have enough space for the other 50%.....

I find it very helpful to prepare the deckplanking (caulking plus treenails) segments on the table and install them when they are more or less finished later on on top of the beams

50% of the treenails prepared

one close up photo of the nailing (not oiled)

afterwards it was possible to glue and fix the deck segments on top of the beams - here also the structures on top, to mark the correct size of the openings in the deck in order to sand them to the correct size (the timber is still not treated with oil)

and now the finsihed deck - fixed, openings in correct size (I hope), oiled and the endings (near the pumps) cut to the correct length

The top view - I will install in future one or two additional planks between the segments - but in moment it is not clear for me which one - so let us see

- Joined

- Apr 20, 2020

- Messages

- 6,257

- Points

- 738

great progress looks amazing, well doneAfter the "positiv" testphase and the final decision I started the deck treenailing work on the aft

It is the work of 3 evening sessions, especially because I am drilling all the holes by hand and not with my Proxxon

- you know already my nickname "KILL DRILL"

everything is prepared for pushing the toothpicks into the 0,5mm drilled holes

View attachment 238170

due to missing space (for all my fingers plus picks) I am making usually 50%, so every second treenail. When the glue is dry, I cut the toothpick with a side cutter and have enough space for the other 50%.....

View attachment 238171

I find it very helpful to prepare the deckplanking (caulking plus treenails) segments on the table and install them when they are more or less finished later on on top of the beams

View attachment 238172

50% of the treenails prepared

View attachment 238173

one close up photo of the nailing (not oiled)

View attachment 238175

afterwards it was possible to glue and fix the deck segments on top of the beams - here also the structures on top, to mark the correct size of the openings in the deck in order to sand them to the correct size (the timber is still not treated with oil)

View attachment 238174

and now the finsihed deck - fixed, openings in correct size (I hope), oiled and the endings (near the pumps) cut to the correct length

View attachment 238177

View attachment 238176

View attachment 238178

The top view - I will install in future one or two additional planks between the segments - but in moment it is not clear for me which one - so let us see

View attachment 238179

View attachment 238181

Sieht saugut aus. Absolutely overwhelmimg, really encouraging.

Looks very fine. It´s more efficient than use the drawplate. The benefit of the drawplate is that you can use the same wood like the planks, like original. But who cares this detal ?

I never used the machine on my La Belle. My 2000 holes i did all with hand. I´m drillkilla too .

I never used the machine on my La Belle. My 2000 holes i did all with hand. I´m drillkilla too .

Uwe,

wonderful !!

please respond. What tool did you use to cut off the toothpicks (Plier Cutters, knife, chisel?) When I used the toothpicks (after they are dry), I used a flush plier cutter, and unfortunately, it squeezes the toothpick and distorts it. It is good for your procedure as you have nice ROUND treenails.

wonderful !!

please respond. What tool did you use to cut off the toothpicks (Plier Cutters, knife, chisel?) When I used the toothpicks (after they are dry), I used a flush plier cutter, and unfortunately, it squeezes the toothpick and distorts it. It is good for your procedure as you have nice ROUND treenails.

Hallo Donnie,Uwe,

wonderful !!

please respond. What tool did you use to cut off the toothpicks (Plier Cutters, knife, chisel?) When I used the toothpicks (after they are dry), I used a flush plier cutter, and unfortunately, it squeezes the toothpick and distorts it. It is good for your procedure as you have nice ROUND treenails.

I made yesterday evening some photos to explain - Yes I am using plier cutter for this.

There are two types of plier cutter, one is flash cutting and the right one not

here the flash and the cutting result at one toothpick - btw my daughter had it once in use and cut some nails, therefore the damages

and the result made by the other one (this one I use!)

Due to the fact, that the toothpicks are very hard wood and not splintering, the pliers are pressing first the stick together and only when the preassure is getting to high cut the center with a short "clack" (sound when it finaly cut the pick)

Here you can see the result at the pick - the dark horizontal center is the "cut" area

and this is the result after treenailing - you can see also here the dark center

I am using wood glue, so therefore every time I have a small hill of glue on top - so you can see that I am cutting the toothpick on top of the glue hill, therefore the "pressed area is also outside of the plank

an element of planks after cutting the toothpicks

after ct I am using sandpaper to get it treenail more or less flash with the plank, here I am also removing the glue during sanding

and afterwards I scratch once more in both direction gentle with the scrapper

BTW: When I push the toothpicks into the holes (0,5mm), the peak with a little bit glue, and a small hammer, the nail is going trough the complete plank of 1,5mm - you can see, that the peaks will be visible on the undersight of the planks

BTW2; The used wood of the planks is extremely good and also very hard -I am using the hammer and the toothpick is producing strong pressure against the holes during forcing the pick into the hole - but there is no deformation visible, or shivering or cracking of the planks, even nothing at the small ends of the planks - So I think that a very good quality of toothsticks wood and also the wood of the planks is important

Attachments

Before the final adjustments of the deck planking can start the waterway has to be finished and installed,

so here you can see the last part of the waterway directly at the bow - please remember, that I changed here the kit waterway construction, I made it from scratch

The very small difference in height has still to be corrected

Many Thanks for your interest .... to be continued ......

so here you can see the last part of the waterway directly at the bow - please remember, that I changed here the kit waterway construction, I made it from scratch

The very small difference in height has still to be corrected

Many Thanks for your interest .... to be continued ......